Professional Documents

Culture Documents

HAZOP Example

Uploaded by

N KannanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZOP Example

Uploaded by

N KannanCopyright:

Available Formats

HAZOP Example

HAZOP Example

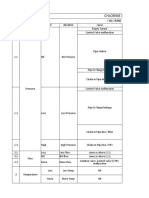

Here is an example of how a HAZOP can be used by an expert team to assess the procedure involved in

chemical production:

Setting: Chemical Mixing Plant

Objective: To produce a batch of 10% concentration HCl (Hydrochloric acid)

Steps:

1. Reverse Osmosis (RO) water is added to the batch mixer via centrifugal pump

2. Additives are mixed with the RO water

3. A 33% solution of HCl is added to the mixture of RO water and additives, resulting in 10%

concentration HCl

Guide word/Scenario: No RO water added.

Possible cause(s): Centrifugal pump loses priming or valve closed totally.

Consequence(s): Solution will be highly concentrated.

Safeguard(s): Proper monitoring of the centrifugal pump (hydraulic pressure).

Comments: Hydraulic pressure gauge should be reviewed and maintained on a regular basis.

Recommendation(s): Review and do maintenance work on the hydraulic pressure gauge of the centrifugal

pump.

HAZOP Guide Words

After identifying the objective and steps involved in the procedure, the team will then explore different

scenarios where the procedure could deviate from its intended function.

A HAZOP study encourages the use of “guide words” to help explore all potential deviations. Here is an

example of how the team could use common guide words to explore deviations involving the input and

mixture of RO water:

No or not (Design intent negated completely) – No RO water added

More (Quantitative increase) – RO water added is more than intended

Less (Quantitative decrease) – RO water added is less than intended

As well as (Qualitative modification/increase) – RO water mixed with UV water is added

Part of (Qualitative modification/decrease) – Tap water is added instead of RO water

Reverse (Logical opposite of design intent) – RO water is omitted from the mixture

Other than (Complete substitution) – UF water is used instead of RO water

Early (Relative to the clock time) – RO water is added too early

Late (Relative to the clock time) – RO water is added too late

Before (Relating to order or sequence) – RO water is added before the additives and 33% HCl are

ready

After (Relating to order or sequence) – RO water is added after the additives and 33% HCl

In the first scenario where “No RO water is added” the team will deliberate and identify the possible causes,

consequences, safeguards and ultimately provide a recommendation.

HAZOP Software

Use iAuditor by SafetyCulture to streamline data gathering and reporting. With iAuditor, you can:

Complete and document your HAZOP study using your smartphone/ tablet while on-site with your

expert team without returning to the office.

Take unlimited photo evidence and annotations of design systems and deviations.

Use voice dictation to save time and record detailed notes.

Securely save all your reports in the cloud and easily access them online.

To help you get started, we have created a free HAZOP template that you can download and customize for

your purpose.

Featured HAZOP Template

HAZOP Template

A HAZOP template is used to identify risks in a plant design, procedure, or operation. Use this template to

conduct a HAZOP study where you can:

list multiple scenarios for a variety of deviations to study

identify critical safety and improvement points for your design, system or process

capture photo evidence for risk hazards and opportunities for improvement

provide current safeguards that prevent risk and operational failure

assign actions and notify personnel in real-time

You might also like

- 2 4 HazopDocument14 pages2 4 HazopIMPG077080No ratings yet

- ChE 534 - Module 3Document34 pagesChE 534 - Module 3Precious JamesNo ratings yet

- Chapter 5 - Hazard IdentificationDocument53 pagesChapter 5 - Hazard IdentificationChieng Tiew Hing100% (1)

- 2 4 Hazop 1Document14 pages2 4 Hazop 1barbarojNo ratings yet

- Hazard and Operability Studies (HAZOP)Document28 pagesHazard and Operability Studies (HAZOP)anpuselvi125100% (1)

- Hazard evaluation techniques overviewDocument14 pagesHazard evaluation techniques overviewabdulmarNo ratings yet

- 5.7 Hazop V1.0Document14 pages5.7 Hazop V1.0Soda PopNo ratings yet

- HazopDocument66 pagesHazopBlack WidowNo ratings yet

- Introduction To HAZOPDocument39 pagesIntroduction To HAZOPapi-19846338100% (1)

- 2 4 HazopDocument14 pages2 4 HazopwarlindaekaNo ratings yet

- Hazard and Operability StudyDocument21 pagesHazard and Operability StudyBubbleNo ratings yet

- 5.7 Hazop V1.1Document14 pages5.7 Hazop V1.1scrbdgharaviNo ratings yet

- Hazop CH 13Document7 pagesHazop CH 13Asma Fayyaz67% (3)

- HAZOPSDocument21 pagesHAZOPSMalak HindiNo ratings yet

- HAZOP ExerciseDocument8 pagesHAZOP Exercisekefeinzel0% (1)

- HazOP Report SummaryDocument13 pagesHazOP Report Summarymir shifayatNo ratings yet

- Hazard and Operability StudiesDocument8 pagesHazard and Operability Studiesangry_granNo ratings yet

- HAZOPDocument11 pagesHAZOPNathan Naelz Sandy100% (1)

- Hyd RO Dose User ManualDocument114 pagesHyd RO Dose User ManualMohammed HassanNo ratings yet

- Chemical HAZOP Analysis and Risk IdentificationDocument13 pagesChemical HAZOP Analysis and Risk IdentificationTakreem SindhuNo ratings yet

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- CHAPTER 8 Hazop StudyDocument7 pagesCHAPTER 8 Hazop StudyNethiyaa50% (2)

- HAZOP (Hazard and Operability) Study: Home About Consulting Training Software Technical Blog ContactDocument5 pagesHAZOP (Hazard and Operability) Study: Home About Consulting Training Software Technical Blog ContactAlbertoNo ratings yet

- Hazop Hazard & Operability StudiesDocument30 pagesHazop Hazard & Operability StudiesKaitoNo ratings yet

- HAZOP Study GuideDocument30 pagesHAZOP Study Guidegandalalake2002No ratings yet

- Here is a concise, SEO-optimized title for the document:HAZOP Introduction to Process Safety and Hazard Identification TechniquesDocument37 pagesHere is a concise, SEO-optimized title for the document:HAZOP Introduction to Process Safety and Hazard Identification TechniquesSyed SamsamuddinNo ratings yet

- Human Factors in Process Plant Operation by David A. StrobharDocument66 pagesHuman Factors in Process Plant Operation by David A. StrobharAbdelsalam MahmoudNo ratings yet

- HazopDocument75 pagesHazopSaima Saima89% (9)

- La Técnica Del HazOpDocument13 pagesLa Técnica Del HazOpEugenio DuranNo ratings yet

- Hazard and Operability Study (Hazop)Document22 pagesHazard and Operability Study (Hazop)Aun AbbasNo ratings yet

- Hazard & Operability Study (HAZOP)Document14 pagesHazard & Operability Study (HAZOP)iFluids EngineeringNo ratings yet

- Chapter No. 13: Hazop StudyDocument9 pagesChapter No. 13: Hazop StudyMudassir HashmiNo ratings yet

- 5.7 Hazop V1.0Document14 pages5.7 Hazop V1.0Ricardo CorreaNo ratings yet

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 pagesHazard and Operability (HAZOP) & Hazard Analysis TrainingShainu Govindankutty100% (8)

- Tentative Schedule For Environment and Safety: Week 11-12Document39 pagesTentative Schedule For Environment and Safety: Week 11-12EMILY BLANDFORDNo ratings yet

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 pagesHazard and Operability (HAZOP) & Hazard Analysis TrainingBeste Ardıç Arslan100% (4)

- Hazard and Operability Study Guide (HAZOPDocument75 pagesHazard and Operability Study Guide (HAZOPVikas GaikwadNo ratings yet

- Hazop Day 2Document44 pagesHazop Day 2vermond.lainezNo ratings yet

- Application of HAZOP Study in Key SOP of Oil and Gas PipelinesDocument7 pagesApplication of HAZOP Study in Key SOP of Oil and Gas PipelineshanselozgumusNo ratings yet

- 2008 NPRA Q&A and Technology ForumDocument90 pages2008 NPRA Q&A and Technology ForumTuan YusoffNo ratings yet

- 01 02 04 22 (Hazop)Document5 pages01 02 04 22 (Hazop)David MacatangayNo ratings yet

- Hazard Identification and HAZOP StudyDocument53 pagesHazard Identification and HAZOP StudyNur Rofium100% (2)

- 3.2 HazopDocument66 pages3.2 Hazops sanjai100% (1)

- Chapter# 07 Hazop StudyDocument3 pagesChapter# 07 Hazop StudyShaan Salah Ud DinNo ratings yet

- HAZOPDocument7 pagesHAZOPfairusNo ratings yet

- HazopDocument8 pagesHazopferrari.indiaNo ratings yet

- HAZOP TrainingDocument21 pagesHAZOP TrainingEdmund MaletzkyNo ratings yet

- Basics of HAZOPDocument26 pagesBasics of HAZOPNg JoshuaNo ratings yet

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Scrum: Ultimate Guide to Scrum Agile Essential Practices!From EverandScrum: Ultimate Guide to Scrum Agile Essential Practices!Rating: 4 out of 5 stars4/5 (23)

- Root Cause Analysis Handbook: A Guide to Efficient and Effective Incident InvestigationFrom EverandRoot Cause Analysis Handbook: A Guide to Efficient and Effective Incident InvestigationNo ratings yet

- Scrum – Ultimate Guide to Scrum Agile Essential Practices!: The Blokehead Success SeriesFrom EverandScrum – Ultimate Guide to Scrum Agile Essential Practices!: The Blokehead Success SeriesNo ratings yet

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsFrom EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsRating: 2 out of 5 stars2/5 (1)

- Ultra-High Performance Liquid Chromatography and Its ApplicationsFrom EverandUltra-High Performance Liquid Chromatography and Its ApplicationsNo ratings yet

- How to Optimize Fluid Bed Processing Technology: Part of the Expertise in Pharmaceutical Process Technology SeriesFrom EverandHow to Optimize Fluid Bed Processing Technology: Part of the Expertise in Pharmaceutical Process Technology SeriesNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Titan: Nfpa 1981, 2013 Edition Compliant Self-Contained Breathing Apparatus (Scba) Operation ManualDocument40 pagesTitan: Nfpa 1981, 2013 Edition Compliant Self-Contained Breathing Apparatus (Scba) Operation ManualN KannanNo ratings yet

- Safety Periodical Check SheetsDocument1 pageSafety Periodical Check SheetsN KannanNo ratings yet

- Environmental Risk AssessmentDocument8 pagesEnvironmental Risk AssessmentN KannanNo ratings yet

- Fire DrillDocument2 pagesFire DrillN KannanNo ratings yet

- Maintenance and Thorough Examination of Mobile CranesDocument106 pagesMaintenance and Thorough Examination of Mobile CranesKate Poole100% (2)

- Chlorine Dosing System: Chlorine Tonner To PRVDocument4 pagesChlorine Dosing System: Chlorine Tonner To PRVN KannanNo ratings yet

- Steam Cycle: Boiler Drum To Steam TurbineDocument3 pagesSteam Cycle: Boiler Drum To Steam TurbineN KannanNo ratings yet

- LPG (Liquefied Petroleum Gas) - MsdsDocument3 pagesLPG (Liquefied Petroleum Gas) - MsdsN KannanNo ratings yet

- HAZOP ProcedureDocument4 pagesHAZOP ProcedureN KannanNo ratings yet

- Fire Extinguisher Checklist for Suntram FastenersDocument3 pagesFire Extinguisher Checklist for Suntram FastenersN KannanNo ratings yet

- Fire Extinguisher Checklist for Suntram FastenersDocument3 pagesFire Extinguisher Checklist for Suntram FastenersN KannanNo ratings yet

- LPG (Liquefied Petroleum Gas) - MsdsDocument3 pagesLPG (Liquefied Petroleum Gas) - MsdsN KannanNo ratings yet

- Fire Extinguisher Audit ListDocument2 pagesFire Extinguisher Audit ListN KannanNo ratings yet

- Unit 4 Question BankDocument2 pagesUnit 4 Question Bankwin proxyNo ratings yet

- FAULT CODE 415 - Engine Oil Rifle Pressure - Data Valid But Below Normal Operating Range - Most Severe LevelDocument3 pagesFAULT CODE 415 - Engine Oil Rifle Pressure - Data Valid But Below Normal Operating Range - Most Severe Levelkhaled kamelNo ratings yet

- Operation Manual - 67410699 - Engine - Control - Unit - MS - 6.3 PDFDocument76 pagesOperation Manual - 67410699 - Engine - Control - Unit - MS - 6.3 PDFcesar gaiborNo ratings yet

- Computer SystemDocument19 pagesComputer Systemkookie bunnyNo ratings yet

- Get Copy of Walmart ReceiptDocument17 pagesGet Copy of Walmart ReceiptMmNo ratings yet

- RCR3273R / RCR3373R: Universal Remote Control Owner's ManualDocument2 pagesRCR3273R / RCR3373R: Universal Remote Control Owner's ManualVictor PerezNo ratings yet

- BS-420 - Operation Card - V1.1 - ENDocument2 pagesBS-420 - Operation Card - V1.1 - ENEmilioPerezBallesterosNo ratings yet

- Useful ScriptsDocument3 pagesUseful ScriptsAjay KumarNo ratings yet

- Fxpro mt4 Backtesting - GuideDocument9 pagesFxpro mt4 Backtesting - GuideNizar RamadhanNo ratings yet

- Actividades económicas en Bolivia y el mundoDocument11 pagesActividades económicas en Bolivia y el mundoCl MarNo ratings yet

- Blip 1.1 User DocumentationDocument15 pagesBlip 1.1 User DocumentationglaburNo ratings yet

- 1 Intro To Stat & Data PresentationDocument21 pages1 Intro To Stat & Data PresentationKWANG QING XUANNo ratings yet

- Cyberpunk 2077 - The Lore, Story, SettingDocument16 pagesCyberpunk 2077 - The Lore, Story, SettingMorkizga100% (1)

- Cashtech WPDocument19 pagesCashtech WPZicoNo ratings yet

- applied-epic-en-usDocument2 pagesapplied-epic-en-uspraseedvinayakaNo ratings yet

- Software Requirements Specification Document Week 13: by Dr. Muhammad Ali MemonDocument49 pagesSoftware Requirements Specification Document Week 13: by Dr. Muhammad Ali MemonZahid AliNo ratings yet

- Test Automation Using Unified Functional Testing PreviewDocument38 pagesTest Automation Using Unified Functional Testing PreviewAnil KumarNo ratings yet

- Degree of Freedom PDFDocument17 pagesDegree of Freedom PDFdhanusiya balamuruganNo ratings yet

- 05 HammerDocument59 pages05 HammerrazuNo ratings yet

- Resume - Rushikesh YadavDocument3 pagesResume - Rushikesh YadavhanmantNo ratings yet

- SN e Reference PDFDocument1,269 pagesSN e Reference PDFPMNo ratings yet

- Canva - Step by Step GuideDocument10 pagesCanva - Step by Step GuideBoe DekweneNo ratings yet

- Catalogo PeaveyDocument140 pagesCatalogo PeaveyJhonny Alcivar MendozaNo ratings yet

- Project 1 RevisedDocument8 pagesProject 1 Revisedapi-547139290No ratings yet

- Students Guide To UG5E1001Document16 pagesStudents Guide To UG5E1001Snoo Nle CaesarNo ratings yet

- Casual Gaming Apps Report 2021 - enDocument28 pagesCasual Gaming Apps Report 2021 - enStepan FrolovNo ratings yet

- DLMS Ondemand InfosDocument12 pagesDLMS Ondemand InfosMohamed Yassine GaraliNo ratings yet

- SRN/ SEN15/ SEN25: General Electric HornsDocument2 pagesSRN/ SEN15/ SEN25: General Electric HornsRigoberto GomezNo ratings yet

- Laporan Kerja PraktikDocument46 pagesLaporan Kerja PraktikAmelNo ratings yet

- Designing With AR and VRDocument30 pagesDesigning With AR and VRPigmy LeeNo ratings yet