Professional Documents

Culture Documents

Rod Handler RH 714: Ranger, Scout

Uploaded by

cristianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rod Handler RH 714: Ranger, Scout

Uploaded by

cristianCopyright:

Available Formats

C 35700-- 6 en 0406 / PIR 1 (20)

ROD HANDLER RH 714

RANGER, SCOUT

ROD HANDLER RH 714

RANGER, SCOUT

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

2 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

CONTENTS

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1. Type identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.1. Using 1 1/4” MF rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.2. Using 1 1/4” extension rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.3. Using 2” extension rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. MAIN COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1. Taking rod to drilling centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2. Taking rod to cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. HYDRAULICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1. Hydraulic components RANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2. Hydraulic circuit diagram RANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3. Operation RANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.4. Hydraulic components SCOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5. Hydraulic circuit diagram SCOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.6. Operation SCOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7. MECHANICAL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1. Adjusting pito retainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2. Adjusting rod handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2. Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3. Grease nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 3 (20)

ROD HANDLER RH 714

RANGER, SCOUT

1. GENERAL

These instructions describe the structure, operating principle and adjustments of the RH

714 rod handler.

Tamrock Service is always ready to offer advice and help in all service problems.

2. SAFETY INSTRUCTIONS

Maintenance and adjustments are only allowed to persons who have

received specific training on the device in question. Read the system

adjustment instructions before starting adjustment work.

WARNING

OBSERVE ABSOLUTE CLEANLINESS WHEN DISASSEMBLING AND

ASSEMBLING HYDRAULIC EQUIPMENT.

Blow all parts clean with compressed air and wipe them using a CLEAN,

CAUTION

non-- fluffy cloth before assembling.

Pressurized hydraulic hoses must not be touched by hand. The hoses

may have unnoticeable needle holes that let out high-- pressure oil

sprays that may penetrate the skin.

WARNING

Beware of moving machine parts. Do the service and repair work only

with the rig stopped. Make also sure that the rig cannot be accidentally

started during maintenance or repair work.

WARNING

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

4 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

3. TECHNICAL DATA

3.1. Type identifier

RH 714

Rod

Handler

Rock drill serie

Rod length max 14’

3.2. Technical data

Number of rods . . . . . . . . . . . . . . . 6 pcs in cassette + 1 in rock drill

Rod length . . . . . . . . . . . . . . . . . . . 10, 12 or 14 feed

Rod size . . . . . . . . . . . . . . . . . . . . . 1 1/4”, 1 1/2”, 1 3/4” and 2’’ (*)

All cassette functions are electrically controlled.

The upper end rod handler has three alternative mounting positions:

-- The upper position is for 14’ extension rods, whereby the upper gripper jaw grips

the sleeve.

-- The middle position is for 14’ MF rods and 12’ extension rods.

-- The lower position is for 12’ MF rods and 10’ extension rods.

-- With 12’ and 14’ MF rods, the upper gripper grips the rod.

-- With extension rods, the upper jaw grips the sleeve.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 5 (20)

ROD HANDLER RH 714

RANGER, SCOUT

(*) The cassette can be used with 1 1/4”, 1 1/2“, 1 3/4” or 2” rods when the length of lifting

cylinder stroke is adjusted with adjusting screw (A).

The spare parts required by different rods are listed in the spare parts manual.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

6 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

3.2.1. Using 1 1/4” MF rods

-- replace the jaw (1) of both rod handlers

-- replace the jaw piece (2) of both rod handlers

-- adjust the rod space of both rod handlers with spacers (3) until suitable

3.2.2. Using 1 1/4” extension rods

-- replace the jaw (1) of the lower rod handler

-- replace the jaw piece (2) of the lower rod handler

-- adjust the rod space of the lower rod handler with spacers (3) until suitable

3.2.3. Using 2” extension rods

-- replace the jaw (1) of the upper rod handler

-- replace the jaw piece (2) of the upper rod handler

-- replace the latch (4) of the upper rod handler

2

4

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 7 (20)

ROD HANDLER RH 714

RANGER, SCOUT

4. MAIN COMPONENTS

1. Rod handler, upper end (The upper end rod handler has three alternative

mounting positions.) (1*)

2. Rod handler, lower end

D The rod handlers perform:

-- rod transfers to drilling centre or to cassette, and

-- gripping of rod with jaws and rod storing into cassette.

3. Lower support

D The rods rest against the lower support in the cassette.

4. Rod gripping cylinder

D The cylinder presses the gripper jaws around the rod.

5. Gripper transfer cylinder

D The cylinder moves the rods in gripper jaws to drilling centre or to cassette.

6. Top cover

D The top cover prevents the rods from falling out of the cassette during tramming

or transport.

7. Rod feed cylinder

D The cylinder keeps the rods in a position where rod handling can take place.

8. Slide gate

D Prevents rods from rolling out and falling from the cassette.

9. Valve block

D The valves control the rod handler, Pito retainer, and movable suction head.

10. Flow divider valve

D The valve divides the oil flow so that both grippers (upper and lower end) move

simultaneously to drilling centre or to cassette.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

8 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

6

8 5 4

1

1*

1*

7

9

9

10

2

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 9 (20)

ROD HANDLER RH 714

RANGER, SCOUT

5. OPERATING PRINCIPLE

5.1. Taking rod to drilling centre

When a rod is added, the gripper jaw (1) presses the slide gate (2) so that the rod can move

over the slide gate with the gripper to the drilling centre.

When the gripper is in the drilling centre, the rods in the cassette are retained behind the

slide gate (2) and under the surface (3), preventing the rods from falling out.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

10 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

5.2. Taking rod to cassette

When disassembling is started, the inclined edge (4) of the gripper body first presses the

rods downwards in the cassette, and then the slide gate under surface (3).

When a rod is taken from the drilling centre to the cassette, the gripper jaw and the rod

together push the slide gate (2) and the rods (5) in the cassette downwards, making room

for the rod coming from the drilling centre.

When the jaws open, the slide gate (2) closes, preventing the rods from escaping from

the cassette.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 11 (20)

ROD HANDLER RH 714

RANGER, SCOUT

6. HYDRAULICS

6.1. Hydraulic components RANGER

50. Variable displacement pump; output to rotation, rod handler, winch, boom and

oscillation.

173. Pressure relief valve of LS line for cassette and oscillation circuits

199. Double overcenter valve

200. Rod handler control valve block; the valve block is used for controlling the

movements of rod handler, Pito retainer and movable suction head.

201. Control valve for gripper transfer cylinders

202. Control valve for lower gripper jaw

203. Control valve for upper gripper jaw

204. Control valve for movable suction head

205. Pito control valve

206. LS--valve; the valve is activated every time any other valve in the valve block 200

is activated. The function of the valve is to direct the LS signal to pump 50. The

other port is used for directing oil to valve 209.

207. Cylinder lock--up valves, 6 pcs

208. Flow divider valve for the gripper transfer cylinders; keeps the speed of cylinder

movements equal by regulating the oil flow in and out.

209. Relief valve for warming up the oil

210. Rod feed cylinders

211. Pito cylinder

212. Movable suction head cylinder

213. Cylinder of the upper gripper jaw

214. Cylinder of the lower gripper jaw

215. Gripper transfer cylinder

216. Gripper transfer cylinder

217. Control valve for the rod feed cylinders; directs the oil from the feed cylinders into

the receiver when rods are taken into the cassette.

218. Shuttle valve; controls LS signal

219. Valve for releasing the lower gripper

236. Front centralizer cylinder

237. Front centralizer cylinder

243. Directional valve of rod centralizer

263. Pressure relief valve for rod lifting cylinders

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

12 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

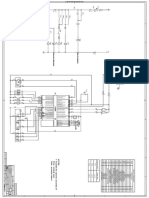

6.2. Hydraulic circuit diagram RANGER

173

80 50 1 90

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 13 (20)

ROD HANDLER RH 714

RANGER, SCOUT

6.3. Operation RANGER

The rod handler is controlled using levers located in the cabin. They control the directional

valves in the rod handler valve block (200) with the purpose of directing the output oil from

the variable displacement pump (50) to the cylinders. Rod handler valve block (200) is

mounted to the side of the feed.

The valve block (200) consists of eight on/off --type control valves (201--205, 217, 219,

243). In addition, the LS valve (206) is provided for pressurizing the pump (50). Valves

(201), (202), and (203) control rod handling functions. Control valve (201) directs oil flow

to the gripper transfer cylinders, moving the rod from cassette to drilling centre and from

drilling centre to cassette. Control valve (202) moves the jaw of the lower gripper

(open/closed). Control valve (203) moves the jaw of the upper gripper (open/closed).

When the upper jaw is opened, valve 219 releases pressure from the lower jaw cylinder

into the receiver thus releasing the grip in the rod; the lower jaw continues to guide the

rod during threading. Control valve (204) moves the suction head (up/down), and control

valve (205) moves the Pito jaws (open/closed).

The double overcenter valve (199) at the Pito directional valve (205) has the purpose of

preventing damage to the Pito arms when threads are being loosened in Pito. All other

cylinders controlled by directional valves have their own lock--up valve (207) that ensures

the remaining pressure in the cylinder while the valve spool is in the middle position. The

rod transfer cylinders (215, 216) are provided with an additional flow distribution valve

(208) whose purpose is to distribute an equal oil flow to both cylinders in both directions.

When the rod string is being disassembled and a rod is taken to cassette, the coil Y217

of the control valve (217) for the rod lifting cylinders (210) becomes activated and directs

the return oil flow from he cylinders into the tank. This decreases the force used for

pushing a rod into the cassette. When the rod is in the cassette and the control lever is

released, the coil Y217 becomes dead and pressure enters through the pressure

regulator (263) to the piston head side of cylinders (210) and tightens the rods in the

cassette. The set value of the pressure regulator (263) is 30--40 bar.

The directional valve (243) is used for controlling the rod centralizer cylinders (option).

Oil flows from variable displacement pump (50) to port P2 of rod changer valve block

(200). From there, oil flows to the desired cylinders as directed by the control valves.

The coil Y206a of the LS valve (206) is activated whenever any coil of the directional

valves (201--205, 217, 219, 243) in the valve block (200) is activated. The valve (206) is

used for directing the LS signal to the variable displacement pump (50) as long as any of

the directional valve coils is activated. The LS signal line also has a pressure relief valve

(173) that restricts the maximum pressure of the pump for cassette movements to 230 bar.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

14 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

6.4. Hydraulic components SCOUT

80. Gear pump; output for dust collector, cassette, and oscillation.

85. Pressure relief valve of pump 80

86. Pressurizing valve for pump 80

199. Double overcenter valve of Pito

200. Rod handler control valve block; the valve block is used for controlling the

movements of rod handler, Pito retainer and movable suction head.

201. Control valve for gripper transfer cylinders

202. Control valve for lower gripper jaw

203. Control valve for upper gripper jaw

204. Control valve for movable suction head

205. Pito control valve

207. Cylinder lock--up valves, 6 pcs

208. Flow divider valve for the gripper transfer cylinders; keeps the speed of cylinder

movements equal by regulating the oil flow in and out.

210. Rod feed cylinders

211. Pito cylinder

212. Movable suction head cylinder

213. Cylinder of the upper gripper jaw

214. Cylinder of the lower gripper jaw

215. Gripper transfer cylinder

216. Gripper transfer cylinder

217. Control valve for the rod feed cylinders; directs the oil from the feed cylinders into

the receiver when rods are taken into the cassette.

219. Valve for releasing the lower gripper

236. Front centralizer cylinder

237. Front centralizer cylinder

243. Directional valve of rod centralizer

263. Pressure reducing valve for rod lifting cylinders

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 15 (20)

ROD HANDLER RH 714

RANGER, SCOUT

6.5. Hydraulic circuit diagram SCOUT

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

16 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

6.6. Operation SCOUT

The rod handler is controlled using the levers on the control panel. They affect the

directional valves in the rod handler valve block (200) that have the purpose of directing

the output of the gear pump (80) to the cylinders. Rod handler valve block (200) is

mounted to the side of the feed.

The valve block (200) consists of eight on/off --type control valves (201--205, 217, 219,

243). Valves (201), (202), and (203) control rod handling functions. Control valve (201)

directs oil flow to the gripper transfer cylinders, moving the rod from cassette to drilling

centre and from drilling centre to cassette. Control valve (202) moves the jaw of the lower

gripper (open/closed). Control valve (203) moves the jaw of the upper gripper

(open/closed). When the upper jaw is opened, valve 219 releases pressure from the lower

jaw cylinder into the receiver thus releasing the grip in the rod; the lower jaw continues to

guide the rod during threading. Control valve (204) moves the suction head (up/down),

and control valve (205) moves the Pito jaws (open/closed).

The double overcenter valve (199) at the Pito directional valve (205) has the purpose of

preventing damage to the Pito arms when threads are being loosened in Pito. All other

cylinders controlled by directional valves have their own lock--up valve (207) that ensures

the remaining pressure in the cylinder while the valve spool is in the middle position. The

rod transfer cylinders (215, 216) are provided with an additional flow distribution valve

(208) whose purpose is to distribute an equal oil flow to both cylinders in both directions.

When the rod string is being disassembled and a rod is taken to cassette, the coil Y330

of the control valve (217) for the rod lifting cylinders (210) becomes activated and directs

the return oil flow from he cylinders into the tank. This decreases the force used for

pushing a rod into the cassette.

When the rod is in the cassette and the control lever is released, the coil Y330 becomes

dead and pressure enters through the pressure regulator (263) to the piston head side

of cylinders (210) and tightens the rods in the cassette. The set value of the pressure

regulator (263) is 30--40 bar.

The directional valve (243) is used for controlling the rod centralizer cylinders (option).

From the gear pump (80) oil flows to the port P1 of the rod handler valve block (200) and,

controlled by the directional valves, continues to the desired cylinders.

The coil Y124 of the pressurizing valve (86) of the pump (80) is unactivated whenever any

coil of the directional valves (201--205, 217, 219, 243) in the valve block is activated. The

valve (86) is used for directing the output of the pump (80) against the plug (A1), whereby

oil flow either to an actuator of the cassette or, if the actuator is at its extreme position,

through the pressure limit valve (85) to the tank.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 17 (20)

ROD HANDLER RH 714

RANGER, SCOUT

7. MECHANICAL FUNCTIONS

7.1. Adjusting pito retainer

D Loosen the bolts between the feed and the Pito retainer.

D Mount a shank to the rock drill and an extension sleeve to the Pito retainer jaws.

D Drive the shank into the sleeve by using the rock drill.

D Tighten the bolts, and run the rock drill to the upper position.

7.2. Adjusting rod handler

D Move a rod with the gripper transfer cylinders between the extension sleeve and

the rock drill shank.

D Loosen the bolts (1) between the rod handlers and the feed.

D Loosen the locking nuts of the adjusting screws (2, 3, 4).

D Centralize the rod to the drilling centre using the adjusting screws (2, 3). Lock the

adjustment.

D Move the rod back to the cassette, and adjust the screw (4) so that the rod is far

enough in the cassette (behind the slide gate) and that the gripper jaw pushes the

rod against the inclined surface of the gripper. Lock the adjustments.

D Test all the movements.

2 4

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

18 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

8. MAINTENANCE INSTRUCTIONS

8.1. Tools

No special tools required.

8.2. Periodic maintenance

Each shift:

-- Check possible oil leaks.

-- Tighten all loosened nuts and screws.

-- Lubricate the sliding body (4) grease nipples (2 pcs).

Once a week:

-- Wash the rod handler.

-- Lubricate all grease nipples.

-- Check the condition of the gripper and Pito jaws.

8.3. Grease nipples

In both rod handlers (upper and lower end):

1. Latch . . . . . . . . . . . . . . . . . . 2 pcs

2. Gripper jaw cylinder . . . . . 2 pcs

3. Gripper transfer cylinder . 1 pc

4. Sliding body . . . . . . . . . . . . 2 pcs

5. Sliding surface . . . . . . . . . 1 pc

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

C 35700-- 6 en 0406 / PIR 19 (20)

ROD HANDLER RH 714

RANGER, SCOUT

2

5

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

20 (20) C 35700-- 6 en 0406 / PIR

ROD HANDLER RH 714

RANGER, SCOUT

Notes:

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

You might also like

- CylinderDocument25 pagesCylinderthomazNo ratings yet

- SLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Document11 pagesSLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Gabo Luna MorenoNo ratings yet

- Dp1500i Maintenance ManualDocument62 pagesDp1500i Maintenance ManualLewis Nemananga100% (2)

- Pantera Dpi Compressor and Air Circuit: Original InstructionsDocument89 pagesPantera Dpi Compressor and Air Circuit: Original InstructionsLewis NemanangaNo ratings yet

- 04 Diagramas Pantera SandvikDocument59 pages04 Diagramas Pantera SandvikEnrique RojoNo ratings yet

- Document AnalysisDocument43 pagesDocument Analysishaimay118No ratings yet

- Overhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESDocument2 pagesOverhaul Kits Yamamoto Drifter YH-80 - 9851 2623 01 - LOWRESEsra Demir100% (1)

- LDocument5 pagesLAditi DasNo ratings yet

- DiagramsDocument54 pagesDiagramsHaianh ChauNo ratings yet

- Powerbit T45 and T51Document20 pagesPowerbit T45 and T51Nicolas BaquedanoNo ratings yet

- Training: HL 710 245 KGDocument72 pagesTraining: HL 710 245 KGEduardo MoreiraNo ratings yet

- Operating ST1000-SN 281Document102 pagesOperating ST1000-SN 281Rene Ramos MenesesNo ratings yet

- LH410 18Document3 pagesLH410 18JavierNo ratings yet

- Drill Rigs Safety PowerROC T50Document46 pagesDrill Rigs Safety PowerROC T50Seno AgusNo ratings yet

- Rammer 7013 Operator's ManualDocument70 pagesRammer 7013 Operator's ManualSerkanAl100% (1)

- Electric EquipmentDocument232 pagesElectric Equipmentangel alvarezNo ratings yet

- Instruções de Elevação para Perfurador de Rocha: HE 122 / HE 119 39 KG HE 300 89 KG HL 300 94 KG HL 300 S 92 KGDocument64 pagesInstruções de Elevação para Perfurador de Rocha: HE 122 / HE 119 39 KG HE 300 89 KG HL 300 94 KG HL 300 S 92 KGJoão Guardado100% (1)

- Operator's ManualDocument102 pagesOperator's ManualJulliana SilvaNo ratings yet

- ST7Document4 pagesST7marcelonieto761No ratings yet

- Feed LF1520: Original InstructionsDocument46 pagesFeed LF1520: Original InstructionsLewis NemanangaNo ratings yet

- Komatsu D375A-5 PDFDocument12 pagesKomatsu D375A-5 PDFtechnical trainer 011cNo ratings yet

- Manual de Ensamble 1200-6Document224 pagesManual de Ensamble 1200-6RonyRafaelAgamezMoreno100% (1)

- Operator's Manual: Original InstructionsDocument204 pagesOperator's Manual: Original InstructionsPercy R. Samaniego Valdez100% (1)

- Ecm585 Mcii Serial X011173ca Parts ManualDocument578 pagesEcm585 Mcii Serial X011173ca Parts ManualHassan ZAFFA CISNEROS100% (1)

- 9852 2730 01 Maintenance Schedules FlexiROC T35, T40 PDFDocument51 pages9852 2730 01 Maintenance Schedules FlexiROC T35, T40 PDFWilliams A. GomezNo ratings yet

- 8991 3488 00 Diagrams and Drawings PDFDocument56 pages8991 3488 00 Diagrams and Drawings PDFLuis GutierrezNo ratings yet

- 9852 1466 01h Safety Boomer 281 - 282 DC15Document47 pages9852 1466 01h Safety Boomer 281 - 282 DC15lidoNo ratings yet

- Model 53R Rigid Planetary AxleDocument2 pagesModel 53R Rigid Planetary AxleMarek WyszatyckiNo ratings yet

- Roc 442PCDocument5 pagesRoc 442PCluizpmrNo ratings yet

- Specifications PDFDocument4 pagesSpecifications PDFrisal doNo ratings yet

- Atlas Copco LM100 Drill ManualDocument239 pagesAtlas Copco LM100 Drill Manualnilesh asthana100% (2)

- Sunil Kumar: Current Employment Summary:::: Employment HistoryDocument2 pagesSunil Kumar: Current Employment Summary:::: Employment HistoryAnsh RajNo ratings yet

- Control PanelDocument40 pagesControl PanelHaianh ChauNo ratings yet

- 1 Eurostar EngineeringDocument13 pages1 Eurostar EngineeringriteshreplyNo ratings yet

- BoomDocument67 pagesBoomBruno Almeida Carvalho100% (1)

- Powerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentDocument5 pagesPowerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentElgi Alam PangestuNo ratings yet

- Guide To Ejc 417 Hydraulic SystemDocument50 pagesGuide To Ejc 417 Hydraulic SystemAnonymous VCvIxKNo ratings yet

- Electrical Instrument PDFDocument6 pagesElectrical Instrument PDFLonghuynh LêNo ratings yet

- 9852 3243 01 PowerROC T50 Tier 3 Maintenance SchedulesDocument54 pages9852 3243 01 PowerROC T50 Tier 3 Maintenance SchedulesrolandNo ratings yet

- Hydrive IOMDocument14 pagesHydrive IOMCristopher PatricioNo ratings yet

- Reverse Circulation Hammer-Rc45Document1 pageReverse Circulation Hammer-Rc45hamed ShNo ratings yet

- BoomDocument110 pagesBoomSantiago AriasNo ratings yet

- Electric EquipmentDocument302 pagesElectric Equipmentmahami lawalNo ratings yet

- Circuit DiagramsDocument143 pagesCircuit DiagramsRebeca Santos100% (1)

- Cop1640+spare PartsDocument7 pagesCop1640+spare PartsHugo EstradaNo ratings yet

- TSNB - SDE Installation CT20Document9 pagesTSNB - SDE Installation CT20Jose luis VargasNo ratings yet

- Atlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Document790 pagesAtlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Nasrul arul100% (1)

- Safety and Environmental InstructionsDocument86 pagesSafety and Environmental InstructionsrolandNo ratings yet

- Pit Viper 235 High Resolution US Tcm1241-3515574Document4 pagesPit Viper 235 High Resolution US Tcm1241-3515574Mackarena Isabel Santander Alegre100% (1)

- dx-800 TechDocument3 pagesdx-800 TechUgurNo ratings yet

- 9852 3346 01d Maintenance Instructions COP3060ME VerBDocument46 pages9852 3346 01d Maintenance Instructions COP3060ME VerBMiguel Angel Isla NarvaezNo ratings yet

- Pneumatic ComponentsDocument30 pagesPneumatic ComponentsatertemizNo ratings yet

- Pantera Dpi Hydraulic System: Original InstructionsDocument98 pagesPantera Dpi Hydraulic System: Original InstructionsLewis Nemananga100% (1)

- 3 RH 714 PDFDocument22 pages3 RH 714 PDFAGUSTINNo ratings yet

- Pantera1500 T 2Document45 pagesPantera1500 T 2Anonymous Z8Vr8JA100% (1)

- HC 150RP (Ep) MontabertDocument17 pagesHC 150RP (Ep) MontabertFacundo100% (1)

- DM45DM50Document456 pagesDM45DM50Barreno DrillingNo ratings yet

- Minetruck MT436LP: Underground Truck With 32.6-Tonne Load CapacityDocument8 pagesMinetruck MT436LP: Underground Truck With 32.6-Tonne Load CapacityPablito LopezNo ratings yet

- Rod Handler RH 714 CHADocument14 pagesRod Handler RH 714 CHAJoão GuardadoNo ratings yet

- Rod Changer-1Document21 pagesRod Changer-1Mitchelle GonouyaNo ratings yet

- Hydraulic Systems Components and FunctionsDocument2 pagesHydraulic Systems Components and FunctionscristianNo ratings yet

- Manual de Partes 220A PM 874072Document155 pagesManual de Partes 220A PM 874072cristianNo ratings yet

- PC450-8 en MSDocument1,078 pagesPC450-8 en MSRoger urbina100% (5)

- HDLinkedDocument33 pagesHDLinkedcristianNo ratings yet

- Sistema ElectricoDocument79 pagesSistema ElectricocristianNo ratings yet

- 313D)Document26 pages313D)cristian0% (1)

- 01Document1 page01cristianNo ratings yet

- 02Document1 page02cristianNo ratings yet

- 02 Plano de Ge - 17KG560B2 (Tamaño Carta)Document115 pages02 Plano de Ge - 17KG560B2 (Tamaño Carta)cristianNo ratings yet

- 3/380 V, 60Hz 3/440 V, 60Hz 3/400 V, 50Hz: Technical SpecificationDocument1 page3/380 V, 60Hz 3/440 V, 60Hz 3/400 V, 50Hz: Technical SpecificationcristianNo ratings yet

- Instruction Manual T500 - ENDocument88 pagesInstruction Manual T500 - ENcristian100% (1)

- Customer's Installation L1 L2 L3 PE: Table of Components Mark Description GridDocument1 pageCustomer's Installation L1 L2 L3 PE: Table of Components Mark Description GridcristianNo ratings yet

- 3176C DI TA Test Spec 7ZR23111Document3 pages3176C DI TA Test Spec 7ZR23111cristianNo ratings yet

- KA2 KA3 S1a: NotesDocument1 pageKA2 KA3 S1a: NotescristianNo ratings yet

- Hydraulics: Spare Part ManualDocument138 pagesHydraulics: Spare Part ManualcristianNo ratings yet

- Test Spec - 7ZR22379Document6 pagesTest Spec - 7ZR22379cristianNo ratings yet

- Dl3 Series: Mse Electric SystemDocument57 pagesDl3 Series: Mse Electric SystemcristianNo ratings yet

- Table of Components for Electrical InstallationDocument1 pageTable of Components for Electrical InstallationcristianNo ratings yet

- Equipamioento ElectricoDocument106 pagesEquipamioento ElectricocristianNo ratings yet

- J TL943 CAT PartsDocument356 pagesJ TL943 CAT PartscristianNo ratings yet

- DiagramasDocument121 pagesDiagramascristianNo ratings yet

- ZR 20 / 32 P Boom: C 44120 - 2 en 0507/LHDocument41 pagesZR 20 / 32 P Boom: C 44120 - 2 en 0507/LHcristianNo ratings yet

- Cable Reel ManualDocument27 pagesCable Reel ManualcristianNo ratings yet

- Maintenance and Adjusting: Cylinder Feed LF 700Document51 pagesMaintenance and Adjusting: Cylinder Feed LF 700cristianNo ratings yet

- Modulo de PerforacionDocument217 pagesModulo de Perforacioncristian100% (1)

- Dl3 and Dl4 Series: Water CircuitDocument98 pagesDl3 and Dl4 Series: Water CircuitcristianNo ratings yet

- Rock DrillDocument76 pagesRock Drillcristian100% (1)

- Maintenance and Lubrication Manual: Drill Carrier TC 5Document244 pagesMaintenance and Lubrication Manual: Drill Carrier TC 5cristianNo ratings yet

- HomeDocument1 pageHomecristianNo ratings yet

- FeedDocument45 pagesFeedcristianNo ratings yet

- ENGINEERING WORKSHOP SYLLABUSDocument115 pagesENGINEERING WORKSHOP SYLLABUSweak manNo ratings yet

- Great Star 2023KG01109 PO#GS20230220 Packing ListDocument6 pagesGreat Star 2023KG01109 PO#GS20230220 Packing Listcelemo7771No ratings yet

- Pindex System InstructionsDocument6 pagesPindex System InstructionsJASPREETKAUR0410No ratings yet

- Procedimiento de Relocacion PDFDocument99 pagesProcedimiento de Relocacion PDFGon LizaNo ratings yet

- Mounted reversible plough parts listDocument106 pagesMounted reversible plough parts listPuhača VeljkoNo ratings yet

- Murphy Bed InstDocument20 pagesMurphy Bed InstRobert ParkerNo ratings yet

- Installation Instructions: Parts List Driver's SideDocument6 pagesInstallation Instructions: Parts List Driver's SideEyoma EtimNo ratings yet

- Crosman 13xx Guys Read This Post - The Green Crosman ForumDocument10 pagesCrosman 13xx Guys Read This Post - The Green Crosman ForumM KNo ratings yet

- RAC Shark Type PRTDocument3 pagesRAC Shark Type PRTmido kassemNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesMuhammad ElbarbaryNo ratings yet

- Locking Systems PDFDocument6 pagesLocking Systems PDFTamer Hesham AhmedNo ratings yet

- Firearm Injuries578 PDFDocument26 pagesFirearm Injuries578 PDFRio LorraineNo ratings yet

- 40+ Construction Tools List With Images For Building ConstructionDocument31 pages40+ Construction Tools List With Images For Building ConstructionJohn NjunwaNo ratings yet

- Installation, Operation and Maintenance of Threaded and Wafer Style FlowmetersDocument8 pagesInstallation, Operation and Maintenance of Threaded and Wafer Style FlowmetersRoger GimenesNo ratings yet

- CNC Solitaire Game: A Fun Beginner Project for Learning CAD/CAMDocument7 pagesCNC Solitaire Game: A Fun Beginner Project for Learning CAD/CAMManuel TorresNo ratings yet

- ÜRÜN LİSTESİ - Gakgo Gayrimenkul 2020-2021Document9 pagesÜRÜN LİSTESİ - Gakgo Gayrimenkul 2020-2021sefa ünalNo ratings yet

- Piping Class - FS70Document2 pagesPiping Class - FS70Dmitriy RybakovNo ratings yet

- Forensic BallisticDocument53 pagesForensic BallisticLhairin Joy Boñon BontoNo ratings yet

- 5e D&D - Firearms of The Realms V 2.1Document6 pages5e D&D - Firearms of The Realms V 2.1Anonymous t0Y7z8m100% (5)

- Von Duprin 98 99 Series Rim Exit Device Installation Instructions 107600Document8 pagesVon Duprin 98 99 Series Rim Exit Device Installation Instructions 107600edielNo ratings yet

- KPC Tender Online 0516Document3 pagesKPC Tender Online 0516Rizky AntoNo ratings yet

- Company Profile Padma Soode Indonesia 2018Document23 pagesCompany Profile Padma Soode Indonesia 2018dickyNo ratings yet

- Commercial HVAC Maintenance PDF ReportDocument6 pagesCommercial HVAC Maintenance PDF ReportSoham PatilNo ratings yet

- Remove & Install Travel Motor & Final DrivesDocument49 pagesRemove & Install Travel Motor & Final DrivesAngelica VergaraNo ratings yet

- Workbench - Mob - ImperialDocument11 pagesWorkbench - Mob - ImperialGheorghe CiubotaruNo ratings yet

- Install Additional Hydraulic Circuit Manual PC300 ExcavatorsDocument140 pagesInstall Additional Hydraulic Circuit Manual PC300 ExcavatorsОлексій РумянцевNo ratings yet

- Traditional FurnitureDocument130 pagesTraditional Furniturearquivoslivros100% (2)

- Woodsmith Magazine 243 (June 2019) PDFDocument70 pagesWoodsmith Magazine 243 (June 2019) PDFJaime Montiel100% (1)

- SR05 Supplementary Requirements Calibration LabsDocument14 pagesSR05 Supplementary Requirements Calibration Labsarienta777No ratings yet

- Blondal M Series - Service Manual Version 1 8Document34 pagesBlondal M Series - Service Manual Version 1 8Firdaus YahyaNo ratings yet