Professional Documents

Culture Documents

Angela - Crowell - NEW PDF

Uploaded by

KARTICK PRASAD0 ratings0% found this document useful (0 votes)

21 views2 pagesOriginal Title

Angela - Crowell_NEW.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesAngela - Crowell - NEW PDF

Uploaded by

KARTICK PRASADCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Angela Crowell

15415 Lakeside Village Dr. Apt 105 (810) 610-9053

Clinton Township, MI 48038 Crowell.Angela.A@gmail.com

Work Experience:

Production Modeling Corporation Auburn Hills, MI December 2019 to Present

Process Simulate Human Specialist contracted to FCA

* Use Process Simulate Human posture simulations to identify potential ergonomic, process and tooling issues for critical assemblies,

part fly-ins of component / assemblies to identify product / shingling issues.

* Human quick walk simulations for critical stations to validate station cycle times and optimize the operator workstations to reduce

operator walk times.

* Perform detailed moving simulations that require kinematics for process tooling to each work element provided in AMPS (Automated

Manufacturing Planning Systems) MA (Man Assignment).

* Provide technical support and prioritization of simulation requests by work in place team.

* Import product and tool data from Teamcenter.

* Support Virtual Reality reviews in the digital simulation lab.

* Coordinate simulation deliverables, tracking files, and glide paths following the Virtual assembly standards.

* Use of Microsoft suite tools and Google docs to communicate with team members and IEs.

* Document and identify major process, tooling and layout issues early in the launch process to create an optimized ergonomically safe

system with a higher cost benefit factor.

* Created 21 process improvements in 10 months with a cost savings of over $5,000,000.

* Work in the plant GA (General Assembly) area with the UAW

4D Systems Lake Orion, MI October 2010 to December 2019

Simulation/Robotic Engineer

* Performed robotic simulation studies using Process Simulate, Robcad, and Delmia to evaluate processes, cycle time, validation of

tooling, and plant layouts.

* Provided full running robotic line simulations for accurate cycle times and sequencing of events.

* Imported and updated MDM through Process Designer.

* Completed final checks of robotic simulations to ensure highest quality.

* Supported engineering on the plant floor with the UAW by proving field checks of robotic workcells, consisting of validation of layouts,

clearance conditions and other potential problems.

* Worked side by side with the customer at the build shops on a daily basis.

* Programmed robots for engine wash and deburring stations, CNC machine tending. Also programmed BIW (Body In White) robots at

GM, FCA and Ford.

* DCS (Dual Check Safety) final checks.

* Worked in the GM research department on robotic cell concepts.

* Robotic Software Used: ABB (Rapid), IRC5, Fanuc RJ3, and R-30iA

* Robotic Applications: Spot Welding, Material Handling, Dispense, Vision, Stud, Roller Hemming, Deburring and Rivet Guns

Weiss Advocacy Center (Volunteer) Flint, MI February 2010 to February 2013

Court Appointed Special Advocate

* Attended court hearings, reviews and meetings pertaining to child/children cases.

* Maintained documentation about the case.

* Submitted written recommendations to the court and maintained contact with all parties on a monthly basis.

Applied Manufacturing Technologies, Inc. Orion, MI January 2004 to November 2008

Simulation Engineer

* Performed robotic simulation studies using Delmia to evaluate processes, cycle time, validation of tooling, and plant layouts.

* Provided simulation support for the plant floor with the UAW during installations.

* Provided follow up documentation to ensure ISO compliance.

* Interfaced with customers and other supporting engineers daily.

* Core Value Award Recipient in 2006 for exemplifying the core values of the company.

* Programmed, calibrated, and dressed out ABB and Fanuc robots.

* Trained GM UAW employees in robot programming.

* Completed a first yield pass on the robot downloads.

* Ran the simulation for robot dress in the test cell.

* Updated the mass system which is the plant backup of all robot’s programs.

* Worked at various GM and Chrysler plants while on the plant floor with union employees.

* Robotic Software: ABB (Rapid), IRC5, S4Cplus, S4C, Fanuc RJ3, R-30iA

* Robotic Applications: Spot Welding, Material Handling, Dispense, Vision, Stud, Roller Hemming, Deburring and Rivet Guns

Pinnacle Foods Corporation/Vlasic Imlay City, MI January 2003 to January 2004

Warehouse Supervisor

* Supervised 10 to 15 union employees.

* Monitored computer data to insure proper warehouse inventory.

* Restructured daily warehouse routines to optimize daily output of product.

Option One/XO Communications Saginaw, MI September 2001 to March 2002

Customer Support Technician

* Provided customer, technical and billing support for the Internet.

* Used Cams (Communication Software Tracking) and Remedy.

Norrell Staffing/Morgan Splicing Saginaw, MI January 2001 to August 2001

Warehouse Supervisor

* Maintained and organized warehouse and inventory.

* Pulled stock, operated forklift, and followed up on purchase requests and purchase orders.

Benchmark National Corporation Saginaw, MI February 2000 to November 2000

Warehouse Manager

* Maintained and organized warehouse and inventory.

* Followed up on purchase requests and purchase orders.

* Material handler – pulled stock and operated forklift.

* Monitored computer data to maintain proper warehouse inventory

Education:

Mott Community College: Associate in Applied Science Applied Technology – Manufacturing

Ross Medical Education Center: Medical Assistant Program Certificate 2011

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Basics Guide: Autodesk Maya 2020Document40 pagesBasics Guide: Autodesk Maya 2020KARTICK PRASADNo ratings yet

- Skirmishes Graham Harman PDFDocument383 pagesSkirmishes Graham Harman PDFparaiaNo ratings yet

- Progressive Muscle Relaxation ExerciseDocument2 pagesProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

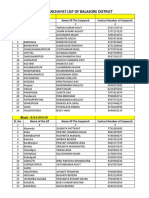

- Gram Panchayat List of Balasore District: Block: BahanagaDocument10 pagesGram Panchayat List of Balasore District: Block: BahanagaKARTICK PRASAD100% (2)

- Getting Startedwith Maya 8Document682 pagesGetting Startedwith Maya 8KARTICK PRASADNo ratings yet

- Simulation of Spot Welding Robot For Automotive Manufacturing ApplicationDocument14 pagesSimulation of Spot Welding Robot For Automotive Manufacturing ApplicationKARTICK PRASADNo ratings yet

- Resume Kartick PrasadDocument4 pagesResume Kartick PrasadKARTICK PRASADNo ratings yet

- Resume Kartick PrasadDocument4 pagesResume Kartick PrasadKARTICK PRASADNo ratings yet

- Resume: Kartick Prasad Satapathy MOBILE NO.-7909035104Document3 pagesResume: Kartick Prasad Satapathy MOBILE NO.-7909035104KARTICK PRASADNo ratings yet

- This Is A System-Generated Statement. Hence, It Does Not Require Any SignatureDocument15 pagesThis Is A System-Generated Statement. Hence, It Does Not Require Any SignatureKARTICK PRASADNo ratings yet

- Curriculum Vitae: Ronit Rajendra PatilDocument3 pagesCurriculum Vitae: Ronit Rajendra PatilKARTICK PRASADNo ratings yet

- Government of Odisha: Office of Special Relief CommissionerDocument11 pagesGovernment of Odisha: Office of Special Relief CommissionerKARTICK PRASADNo ratings yet

- Wibu Licensing Guide Cenit PDFDocument15 pagesWibu Licensing Guide Cenit PDFKARTICK PRASADNo ratings yet

- Shubham Jaiswal: Education CredentialsDocument3 pagesShubham Jaiswal: Education CredentialsKARTICK PRASADNo ratings yet

- GSTCredit Note DL2202112 AD81754Document1 pageGSTCredit Note DL2202112 AD81754KARTICK PRASADNo ratings yet

- Group Corporate HR - Training Calendar For JANUARY 2021Document1 pageGroup Corporate HR - Training Calendar For JANUARY 2021KARTICK PRASADNo ratings yet

- Kartick Prasad ResumeDocument4 pagesKartick Prasad ResumeKARTICK PRASADNo ratings yet

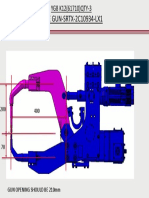

- Gun Modification For 61710 Yg8 K12Document1 pageGun Modification For 61710 Yg8 K12KARTICK PRASADNo ratings yet

- Yta Dash Process - Rev 3RD - 5 May 20Document28 pagesYta Dash Process - Rev 3RD - 5 May 20KARTICK PRASADNo ratings yet

- Managing Markets Strategically: Professor Noel CaponDocument49 pagesManaging Markets Strategically: Professor Noel CaponChristiandeuxNo ratings yet

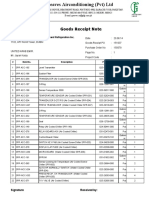

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNo ratings yet

- CTRLX Automation BrochureDocument60 pagesCTRLX Automation BrochureNinja do SofáNo ratings yet

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- Aicte Internship Approval Pending 1Document7 pagesAicte Internship Approval Pending 1Anisha KumariNo ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Why We Need A Flying Amphibious Car 1. CarsDocument20 pagesWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedNo ratings yet

- Matsusada DC-DC ConvertersDocument4 pagesMatsusada DC-DC ConvertersAP SinghNo ratings yet

- Analyst - Finance, John Lewis John Lewis PartnershipDocument2 pagesAnalyst - Finance, John Lewis John Lewis Partnershipsecret_1992No ratings yet

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocument10 pagesBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275No ratings yet

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Document6 pagesSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNo ratings yet

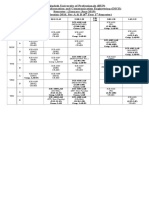

- Class Routine Final 13.12.18Document7 pagesClass Routine Final 13.12.18RakibNo ratings yet

- IES OBJ Civil Engineering 2000 Paper IDocument17 pagesIES OBJ Civil Engineering 2000 Paper Itom stuartNo ratings yet

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNo ratings yet

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaNo ratings yet

- Modular Heavy Duty Truck TransmissionDocument6 pagesModular Heavy Duty Truck Transmissionphucdc095041No ratings yet

- Angle ModulationDocument26 pagesAngle ModulationAtish RanjanNo ratings yet

- Problems: C D y XDocument7 pagesProblems: C D y XBanana QNo ratings yet

- Lab 3 Report Fins RedoDocument3 pagesLab 3 Report Fins RedoWestley GomezNo ratings yet

- I. Objectives Ii. Content Iii. Learning ResourcesDocument13 pagesI. Objectives Ii. Content Iii. Learning ResourcesZenia CapalacNo ratings yet

- تأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFDocument36 pagesتأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFSofiane DouifiNo ratings yet

- Measures of Indicator 1Document2 pagesMeasures of Indicator 1ROMMEL BALAN CELSONo ratings yet

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Document880 pages1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNo ratings yet

- Group 4 - When Technology and Humanity CrossDocument32 pagesGroup 4 - When Technology and Humanity CrossJaen NajarNo ratings yet

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocument3 pagesBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaNo ratings yet

- En DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence enDocument8 pagesEn DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence endieuwrignNo ratings yet

- Electro TechniquesDocument2 pagesElectro TechniquesPinkk DaisyfieldNo ratings yet