Professional Documents

Culture Documents

Vulcan Titan Roanoke Casestudy

Uploaded by

asu meongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vulcan Titan Roanoke Casestudy

Uploaded by

asu meongCopyright:

Available Formats

case study

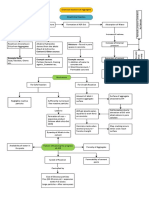

Vulcan block models optimise blending

Maptek™ Vulcan™ helped Titan Roanoke produce low alkali cement,

reducing waste while complying with stringent new emissions regulations.

The Titan America Roanoke Cement Low alkali cement is also recommended Solution

Company in Troutville, Virginia operates when reactive aggregates are used to Geological block models ensure the

an open pit quarry specialising in reduce the effect of alkali-silica reaction chemical composition for each block is

limestone and shale production. Cement which can result in expansion leading to well known before mining.

products are distributed to regional cracking.

construction industries. By blending material from different blocks

Challenge mined, Titan Roanoke was able to reduce

Since 2011, Titan Roanoke has focused the alkali in the raw materials to 0.6%,

Recently proposed EPA regulations in the

on reducing waste from stripping, and and significantly reduce SO2 emissions

USA will require cement companies to

at the same time producing low alkali when the raw materials are burned in the

drastically reduce sulphur emissions.

cement for customers. cement kiln.

Seeking a way to better control these

Low alkali cements are Portland cements

emissions, Titan Roanoke began using Results

with a total content of alkalis not above

Maptek™ Vulcan™ to generate block In 2014, for the first time, Titan Roanoke

0.6%. This is particularly beneficial

models to identify concentrations of SO3 was able to provide low alkali cement to

where concrete is at risk of deterioration,

gas in the host rocks. meet customer requirements.

for example when in contact with soil,

groundwater or seawater. Vulcan block models allowed Titan Thanks to

Roanoke to pinpoint seams of rock with Stan Cosoreanu, Quarry Manager

different chemical compositions which Roanoke Cement Company

Titan America LLC

could be mixed to achieve the target

chemistry of raw material stack

for cement kilns.

Vulcan block model defining geology in the quarry

(above) and blocks by chemical characteristics guide

mining to achieve optimum low alkali product (right)

© 2014 Maptek - 0914-TR www.maptek.com >

You might also like

- Final Invoice Storage Tank MagdyDocument6 pagesFinal Invoice Storage Tank MagdyAhmed KhalifaNo ratings yet

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- Question and Answer Samples and TechniquesDocument61 pagesQuestion and Answer Samples and TechniquesSigue Ramel HinayasNo ratings yet

- Chimestry Mechanical Engineering: Group No # 2 REG NO # 16 To 36 Lets StartDocument44 pagesChimestry Mechanical Engineering: Group No # 2 REG NO # 16 To 36 Lets StartarslanNo ratings yet

- Waterproofing BrochureDocument12 pagesWaterproofing Brochureroofingsolutions100% (3)

- Method Statement For Casting of Cement Based Screed-Checked by Const - TeamDocument8 pagesMethod Statement For Casting of Cement Based Screed-Checked by Const - Teammd_rehan_2100% (1)

- Cement, Gypsum Product, Quartz SandDocument14 pagesCement, Gypsum Product, Quartz SandHuda FauziNo ratings yet

- CY6251: Engineering Chemistry IIDocument26 pagesCY6251: Engineering Chemistry IIAnkur GuptaNo ratings yet

- Cement MaterialsDocument53 pagesCement MaterialsNagesh Poola100% (1)

- Portland Pozzolona CementDocument35 pagesPortland Pozzolona CementAustin RodriguesNo ratings yet

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocument4 pagesTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- LC3 For Cem Tech Oct 2020Document62 pagesLC3 For Cem Tech Oct 2020Subhan MuhammadNo ratings yet

- Type & Grades of CementDocument12 pagesType & Grades of CementAmit Agarwal93% (14)

- Ceramic Raw Materials: Institute of Ceramics Textbook SeriesFrom EverandCeramic Raw Materials: Institute of Ceramics Textbook SeriesRating: 3.5 out of 5 stars3.5/5 (3)

- Castable Refractory ConcreteDocument23 pagesCastable Refractory Concretemnaziria6612100% (3)

- Unit Weight of Building Materials CompleteDocument3 pagesUnit Weight of Building Materials Completehncc ghazni100% (1)

- Under Water ConcretingDocument104 pagesUnder Water ConcretingTarun PatelNo ratings yet

- Concreto Con Desechos Conchas Metacaolin y EscombrosDocument14 pagesConcreto Con Desechos Conchas Metacaolin y EscombrosCiro Arnold Gonzales PauccarNo ratings yet

- Concrete Technology Assignment # (10) : Submitted By: Honey I.D #: 119661 Date:31-10-2017Document2 pagesConcrete Technology Assignment # (10) : Submitted By: Honey I.D #: 119661 Date:31-10-2017Lavender HoneyNo ratings yet

- Building Technology - ConcreteDocument93 pagesBuilding Technology - ConcreteacmoradaNo ratings yet

- Parameters of Alumina Cement and Portland Cement WDocument7 pagesParameters of Alumina Cement and Portland Cement WmojmaildotelefonuNo ratings yet

- PLC After 10 Years in The FieldDocument7 pagesPLC After 10 Years in The FieldHimerozNo ratings yet

- Sulfate Resistance of Filler Cement MortarDocument4 pagesSulfate Resistance of Filler Cement MortarAbd El Nour KahlochNo ratings yet

- Techspec Lime and ClayDocument6 pagesTechspec Lime and ClayTrina CandelariaNo ratings yet

- Topic 2.2 CementDocument68 pagesTopic 2.2 Cement2022449652No ratings yet

- Topic 2.2 CementDocument68 pagesTopic 2.2 CementDEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNo ratings yet

- DAC 11503: CIVIL Engineering Materials: Class Leader Edmodo/Telegram Modul Test Quiz ProjectDocument21 pagesDAC 11503: CIVIL Engineering Materials: Class Leader Edmodo/Telegram Modul Test Quiz ProjectNur HazimahNo ratings yet

- Sulfateresistanceofhigh PerformanceconcreteDocument10 pagesSulfateresistanceofhigh PerformanceconcreteMaroof imadNo ratings yet

- Building Materials and Construction 4Document59 pagesBuilding Materials and Construction 4IswaryaNo ratings yet

- Sulfate Resistance of High-Performance Concrete: M.J. Shannag, Hussein A. ShaiaDocument7 pagesSulfate Resistance of High-Performance Concrete: M.J. Shannag, Hussein A. ShaiaeliNo ratings yet

- High Purity Calcium Aluminate Cements Production and PropertiesDocument6 pagesHigh Purity Calcium Aluminate Cements Production and Propertiesvimalp_20No ratings yet

- 19 DevelopmentOfAnAcid PDFDocument6 pages19 DevelopmentOfAnAcid PDFRogerio CannoniNo ratings yet

- Advanced Concrete Technology Unit 1: CementDocument18 pagesAdvanced Concrete Technology Unit 1: CementSwathiKurnalNo ratings yet

- Alkali Aggregate Reaction in Concrete - Types, Causes, and EffectsDocument7 pagesAlkali Aggregate Reaction in Concrete - Types, Causes, and EffectsPritha DasNo ratings yet

- Adobe Scan Aug 21, 2023Document15 pagesAdobe Scan Aug 21, 2023m9966822No ratings yet

- Share Your Knowledge: What Is Cement & How It Is ProducedDocument21 pagesShare Your Knowledge: What Is Cement & How It Is ProducedSujal SamarthNo ratings yet

- Engineering MaterialsDocument61 pagesEngineering MaterialsAlvee AyonNo ratings yet

- CementDocument82 pagesCementzohaib ul hassanNo ratings yet

- Lightweight Aggregates (L.W.A.)Document22 pagesLightweight Aggregates (L.W.A.)Ali IsmaelNo ratings yet

- CementDocument15 pagesCementSuTtA OPNo ratings yet

- Khftxs BHGFFDocument72 pagesKhftxs BHGFFfarhan sdNo ratings yet

- Effects of Groundnut Husk Ash-Blended Cement On Chemical Resistance of Concrete Adole, M. A., Dzasu, W. E., Umar, A., and Oraegbune, O.MDocument10 pagesEffects of Groundnut Husk Ash-Blended Cement On Chemical Resistance of Concrete Adole, M. A., Dzasu, W. E., Umar, A., and Oraegbune, O.MNiell Anakeen dela CruzNo ratings yet

- C51 PDFDocument3 pagesC51 PDFINARQ1979No ratings yet

- Lecture 4 Shallow Foundations in Aggressive Conditions 4Document19 pagesLecture 4 Shallow Foundations in Aggressive Conditions 4Ionuț Cosmin BaloghNo ratings yet

- Act Mod 1Document23 pagesAct Mod 1mehrinisha197No ratings yet

- E7-M22 - 2016.03 - POV - G.V.Ramana - Print (Y)Document13 pagesE7-M22 - 2016.03 - POV - G.V.Ramana - Print (Y)NorhazerahYussopNo ratings yet

- KMasthanvali DThrimurthiNaik 59Document10 pagesKMasthanvali DThrimurthiNaik 59DivyaNo ratings yet

- Characteristics of Portland Blast-Furnace Slag Cement Containing Cement Kiln Dust and Active SilicaDocument6 pagesCharacteristics of Portland Blast-Furnace Slag Cement Containing Cement Kiln Dust and Active SilicaAMIT GAURAVNo ratings yet

- (Asce) 0899-1561 (2007) 19 12 (1070)Document9 pages(Asce) 0899-1561 (2007) 19 12 (1070)Sandesh SharmaNo ratings yet

- Process For Manufacturing Low Alkali CementsDocument2 pagesProcess For Manufacturing Low Alkali CementsfaheemqcNo ratings yet

- Arcilla Calcinada-MetakaolinDocument9 pagesArcilla Calcinada-MetakaolinREAL20No ratings yet

- Lecture 3 CIS 401 (Lecture Notes)Document15 pagesLecture 3 CIS 401 (Lecture Notes)history.geek.911tsNo ratings yet

- Final Year Project Presentation ON: Portland CementDocument17 pagesFinal Year Project Presentation ON: Portland CementfarhanNo ratings yet

- ShortCourse Highway2Document58 pagesShortCourse Highway2Ruwan ThilankaNo ratings yet

- SumitDocument42 pagesSumitMrunmayee ManjariNo ratings yet

- Jorgen Skibsted 2019, Reactivity of Supplementary Cementitious Materials (SCMs0 in Cement BlendsDocument16 pagesJorgen Skibsted 2019, Reactivity of Supplementary Cementitious Materials (SCMs0 in Cement BlendsSatya ChaitanyaNo ratings yet

- Alkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackDocument3 pagesAlkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackVasanthapragash NadarajhaNo ratings yet

- Construction and Building Materials: Lei Jiang, Ditao NiuDocument11 pagesConstruction and Building Materials: Lei Jiang, Ditao NiuXtem AlbNo ratings yet

- Concrete and Other Cementitious MaterialsDocument11 pagesConcrete and Other Cementitious MaterialsRodel ElicotNo ratings yet

- RBL Final Report PDFDocument6 pagesRBL Final Report PDFJaison SelvarajNo ratings yet

- VCAS Data SheetDocument2 pagesVCAS Data SheetSeoudi AbdelhafidNo ratings yet

- Jeenith CT UNIT - 1Document4 pagesJeenith CT UNIT - 1Revanth ChintuNo ratings yet

- Out 6Document10 pagesOut 6VienRiveraNo ratings yet

- Preparation of Green ConcreteDocument5 pagesPreparation of Green ConcreteDinesh GuptaNo ratings yet

- 6 - CementDocument43 pages6 - CementMANJUNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Expoband H45Document3 pagesExpoband H45Balasubramanian AnanthNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet

- Haas - Et - Al-2015-Journal - of - Industrial - Ecology How Circular Is The Global EconomyDocument13 pagesHaas - Et - Al-2015-Journal - of - Industrial - Ecology How Circular Is The Global EconomyCPSNo ratings yet

- 86841Document98 pages86841fandhiejavanov2009No ratings yet

- Recycled Aggregate ConcreteDocument12 pagesRecycled Aggregate ConcreteHarsh ChordiyaNo ratings yet

- 2018 05 Cese Notfn PDFDocument26 pages2018 05 Cese Notfn PDFshanmugamNo ratings yet

- Stabilisation of Pavement Subgrade Soil Using Lime and Cement: ReviewDocument4 pagesStabilisation of Pavement Subgrade Soil Using Lime and Cement: ReviewzahraaNo ratings yet

- Chapter - 5 Fresh Properties of Self Compacting Mortar and Self Compacting ConcreteDocument34 pagesChapter - 5 Fresh Properties of Self Compacting Mortar and Self Compacting ConcreteMichael GelongNo ratings yet

- Astm c1090Document5 pagesAstm c1090ivanhermalNo ratings yet

- Welded Wiremesh: BRC West Indies Limited, Cane Garden, St. Thomas, BarbadosDocument29 pagesWelded Wiremesh: BRC West Indies Limited, Cane Garden, St. Thomas, BarbadosEngrDebashisMallickNo ratings yet

- 6 Tender Drawing (Structure)Document56 pages6 Tender Drawing (Structure)thandarwinNo ratings yet

- Maturity Method To Estimate Concrete StrengthDocument2 pagesMaturity Method To Estimate Concrete StrengthRV Vimal100% (1)

- 02 Bayset Sec2.WaterproofingmembrainsDocument39 pages02 Bayset Sec2.WaterproofingmembrainsKha PhucNo ratings yet

- AASHTO T121 Testing FormDocument4 pagesAASHTO T121 Testing Formdep_vinNo ratings yet

- High-Strength Concrete: Specifications: ACI 211.4R-7Document7 pagesHigh-Strength Concrete: Specifications: ACI 211.4R-7Manazir Hussain AnsariNo ratings yet

- Exposeal UWDocument2 pagesExposeal UWVenkata Raju KalidindiNo ratings yet

- Pidicrete 55EDocument1 pagePidicrete 55Enickdash09No ratings yet

- HvfacDocument18 pagesHvfacponchurrNo ratings yet

- Dekguard E2000 UAEDocument4 pagesDekguard E2000 UAEJanardhana ReddiNo ratings yet

- Comparison Shear Wall and Brick WallDocument15 pagesComparison Shear Wall and Brick Wallnawazkhan23No ratings yet

- Project ReportDocument55 pagesProject ReportAadil AhmadNo ratings yet

- An Experimental Study On Concrete by Using E - Waste As Partial Replacement For Course AggregateDocument7 pagesAn Experimental Study On Concrete by Using E - Waste As Partial Replacement For Course AggregateIJSTENo ratings yet