Professional Documents

Culture Documents

Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)

Uploaded by

Mohamed El-SawahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)

Uploaded by

Mohamed El-SawahCopyright:

Available Formats

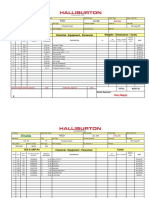

STEM-I: SUS - CENTRIFUGAL PUMP UNIT (Diesel Driven)

DISTRICT / LOCATION: SDGM-1095 / Site-26 Date Last STEM-II: 02-May-2019 REPORT No.: Night Shift

UNIT DESCRIPTION: C-Pump ENGINE HOURS: 1180 DATE: 22-Nov-2019

UNIT NUMBER: SUS23516Y0113 Check previous 2 - 3 STEM-I Reports OPERATOR NAME: Mohamed Ismail

Check P

Comments / Work Done / Outstanding Work

System / Component Guidelines on what to check Wear correct PPE Needs

Okay **Record work performed and parts used. ASK if in doubt

Work

Unit is CLEAN with correct labeling & Unit Number. Wash with fresh water

Appearance & Unit is PAINTED - no corroded or partially painted areas

1

Cleanliness Walk around unit - check for leaks/damage: repair/report as req'd Ok

No loose objects - do not use unit to transport fluids, sacks or drums

Skid & Crash Frame - No damage, corrosion, cracks or distortion Unit Weight & Dimensions - visible on units

Shackles, slings, pad-eyes, lugs - check visual & certifications

Fork Lift Pockets - check for damage

Ok

2 Skid / Crash Frame

Drip Pans - drain plugs fitted and pan clean before transportation

Earth/Ground Cable - in place & connected to stake in ground

Manifolds - no leaks from valves, end caps, flanged connections. Note: Ensure all pipe and suction hose connections are clean and tight

Mounting brackets - visually check brackets for damage & cracks to prevent air ingress.

BFV's - check valves open/close smoothly - grease as required.

Suction, Discharge BFV Handles - check in place & lock in place, open = open

3

Inserts & Discs - visually inspect for corrosion & wear where possible

Ok

Lines & Manifolds

Blind caps (2-piece) - in place as required: secured with chain

Unions - no burrs on wing nuts

Sample Points - check valves in good condition, no leaks

Volute - check for damage, no wear holes

Test - circulate H20 thru pump: verify rotation & discharge pressures

4 Centrifugal Pump Pressure Gauges - verify not damaged and working okay Ok

Mountings - check support brackets are secure with no damage/cracks

Drain plug - confirm volute drain plug in place, is not plugged & valve closes

Air-over-Oil Reservoir - verify lube oil level in lube-oil reservoir (to be full) **

Oil Seals - check oiler cycles as pump is running, no visible leaks

C-Pump

5 Lubrication

Braided/Rope Packing - check condition & tighten to allow small-to-no leak Ok

Grease - grease seals as required & confirm packing is not leaking

(Packing & Seals) Bearing Housing - check oil level or grease [depending on lube system]

Breather, Bearing Housing - check breather in place, undamaged & clean

Gearbox - check oil level, to be clean, no leaks. Oil fill/drain plug in place **

PTO Operation - working, no air leaks & no unusual noises

Engage/Disengage - verify C-pump starts, rotates in right direction & stops

Clutch, PTO & Ok

6 Lubrication - grease all points as required. Check grease zerks

Driveline Bearings & U-Joints - check lubrication, alignment and for abnormal noises

Coupling - visually inspect for damage & alignment.

Safety Guards - verify in place, mountings secure & in good condition

Check oil level 2 times, fill with engine oil as specified **

7 Engine Oil Oil appearance (not milky or black) Ok

No leaks in hoses, connections, filters

Diesel tank 90% full, filler cap back on tight. **

No leaks from fuel lines, connections, filters or fuel pump

8 Fuel System Drain water from diesel tank

Ok

Check for water contamination in fuel filter sight bowls where fitted.

Antifreeze level 2" below filler neck (engine cold) - 50/50 Premixed **

Radiator Radiator Core (both sides) - clean, no leaks & no damage

9 N/A

Cooling System Hoses & Connections - clean, no leaks & no damage

Fan Belts - check tension (1/2" to 3/4" yield) & condition (no cracks)

Remove cover - check element for soot or water (clean as required) Ok

10 Air Cleaner/Filter Check service indicator (replace if in RED or 20")

Exhaust blankets/wrap - in place and in good condition

11 Exhaust System Ok

Pipework okay, no leaks, connections sound. Rain cap in place

Batteries - electrolyte levels, terminals, tiedowns & surfaces clean Voltage ≥ 12.4V (engine off) and w/engine running = 13.8-14.5V for a

Check voltages: engine off (battery) and running (alternator) 12V system.

Alternator - check belts ok (1/2" to 3/4" yield) & wiring (if applicable) Ok

12 Electrical System Starter - check wiring & condition of starter (if applicable)

Work Lights - working and clean

Cables & Connectors - to be clean with no loose or broken wires

Air up system - check gauges okay & check for audible leaks

Drain all air reservoirs/tanks until clean, close drain valve

Air hoses, connections, piping, valves & actuators - no damage or leaks.

13 Air System Air hoses/connections - secure with safety cable / pins N/A

Air Reservoir Certification - check test date and tag

Air Starter (if fitted) - check no leaks & no unusual noises

Start engine - no problems. Check normal kill operation

Hydrostarter (if fitted) - check operation & oil level

Controls & Controls & Linkages - all working and in good condition Ok

14

Instrumentation Emergency Kill - test with engine stopped & reset latch

Gauges (pressure & temperature) - all working, not broken and clean

Drain/clean air trap and/or add oil to lubricator as required

COMMENTS: Describe any additional checks performed, parts used or other corrective maintenance performed. Use STEM-I Continuation/Repair Report if necessary.

# Last stem-2 >> 24/Nov/2019

# Next stem-2 >> 24/May/2019

# Next stem-3 >> 02/May/2020

OPERATOR SIGNATURE: JOB SUPERVISOR SIGNATURE: FSM / MSV SIGNATURE:

Mohamed Ismail

Date: 22-Nov-2019 Date: Date:

Operator confirms that required STEM-I maintenance checks were performed & corrected & noted, & the unit is ready for the next job. FSM/MSV confirms reported defects are repaired & documented in Fleet Assistant, unit is green tagged & ready for the next job.

Controlled document. Do not modify or change without permission. Ref No.: WS-STEM1-AUX-002-SUS V1.0 30-Mar-2010_RL

You might also like

- STEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Document1 pageSTEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Mohamed El-SawahNo ratings yet

- Stem-1 - Frac TankDocument1 pageStem-1 - Frac TankMohamed El-SawahNo ratings yet

- CPF Cement Pump Float STEM-I Inspection ReportDocument4 pagesCPF Cement Pump Float STEM-I Inspection ReportMohamed El-SawahNo ratings yet

- HD 2250Document47 pagesHD 2250- Emslie100% (1)

- MSI Triplex 600 HP Module 2015Document47 pagesMSI Triplex 600 HP Module 2015علي سعيد سعود100% (3)

- Lavadora Secadora LG WD15EGS6 PDFDocument100 pagesLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- 5 Amot 1672 Product DocumentDocument7 pages5 Amot 1672 Product DocumentThéodore NlendNo ratings yet

- Carpeta Tecnica Equipamiento Flush byDocument655 pagesCarpeta Tecnica Equipamiento Flush byFederico MoranNo ratings yet

- Wichita PH D e 0616 PDFDocument92 pagesWichita PH D e 0616 PDFsahidNo ratings yet

- BOPC Parts Catalog Rev 090809Document113 pagesBOPC Parts Catalog Rev 090809Tito RodriguezNo ratings yet

- H 276Document46 pagesH 276gustavofx21No ratings yet

- Troubleshooting. Compressor PDFDocument3 pagesTroubleshooting. Compressor PDFHasib KhanNo ratings yet

- User Manual: GeneratorDocument60 pagesUser Manual: GeneratorgebremichaelNo ratings yet

- G-Tech Rotary Lobe Pump OIM Manual PDFDocument23 pagesG-Tech Rotary Lobe Pump OIM Manual PDFGiorgiana Rosu100% (1)

- 48 PumpDrive SelectionGuide 1Document52 pages48 PumpDrive SelectionGuide 1rgopikrishna313No ratings yet

- Coiled Tubing Services Manual: DowellDocument7 pagesCoiled Tubing Services Manual: Dowellanthony lakpahNo ratings yet

- 8 Injector-W11058Document53 pages8 Injector-W11058MARIO FABRISNo ratings yet

- Altronic V Installation Manual (FORM AV II)Document12 pagesAltronic V Installation Manual (FORM AV II)francis_mouille_iiNo ratings yet

- Power Slips - General Edition - 5Document26 pagesPower Slips - General Edition - 5brasgNo ratings yet

- N5SC Swivel 1Document12 pagesN5SC Swivel 1Winda FaleviNo ratings yet

- 81W12186 (P12136) Operation and Maintenance Manual For LGT360 - English VersionDocument289 pages81W12186 (P12136) Operation and Maintenance Manual For LGT360 - English VersionMARIO FABRISNo ratings yet

- N2 Triplex Pump - 1Document6 pagesN2 Triplex Pump - 1Ibrahim AhmedNo ratings yet

- Model pl5 Service Manual PDFDocument31 pagesModel pl5 Service Manual PDFingcalderonNo ratings yet

- 30T-2 Parts ListDocument24 pages30T-2 Parts ListOrlando RojasNo ratings yet

- 230L2M551 - Cement Mixing EquipmentDocument43 pages230L2M551 - Cement Mixing Equipmentyao nestorNo ratings yet

- Accelerated Multiplex Plunger Pumps PDFDocument20 pagesAccelerated Multiplex Plunger Pumps PDFJessica montesNo ratings yet

- Well-Vac v.2 2-18Document133 pagesWell-Vac v.2 2-18Nerymar Coromoto Parra BustamanteNo ratings yet

- Graco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Document24 pagesGraco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Maulana Mufti MuhammadNo ratings yet

- JobMaster Data Acquisition Software SLSH - 0 PDFDocument2 pagesJobMaster Data Acquisition Software SLSH - 0 PDFMario FabrisNo ratings yet

- Hose Hanger Installation Operating Procedures Rev.1Document9 pagesHose Hanger Installation Operating Procedures Rev.1HSE PULAI ANo ratings yet

- Skidding SystemDocument6 pagesSkidding Systemjesus alfonso fragozo calderonNo ratings yet

- Walker1 PDFDocument2 pagesWalker1 PDFDian SikumbangNo ratings yet

- Sonceboz Chart Recorder Motor Spec SheetDocument2 pagesSonceboz Chart Recorder Motor Spec Sheetjesdcp7No ratings yet

- Group Annexures 2017-18Document45 pagesGroup Annexures 2017-18rajesh_rathNo ratings yet

- HH 102 SemitrailerDocument6 pagesHH 102 SemitrailerleoNo ratings yet

- A Pilotair ValvesDocument33 pagesA Pilotair ValvesZMCONTROL100% (1)

- 4216 Mud Balance ManualDocument2 pages4216 Mud Balance ManualAli AliievNo ratings yet

- 35-8-5 Cement Diesel Powered Offshore Skid ECS BJDocument4 pages35-8-5 Cement Diesel Powered Offshore Skid ECS BJSaid100% (1)

- 2013 Us Shop Tech BrochureDocument16 pages2013 Us Shop Tech Brochurefollowjesus100% (1)

- Pressure Sequence ValvesDocument3 pagesPressure Sequence ValvesJegan SJ100% (1)

- Chapter 15 BennetDocument91 pagesChapter 15 BennetpapipapiiNo ratings yet

- Twin Pumping Unit 600 HP Press PDFDocument2 pagesTwin Pumping Unit 600 HP Press PDFDidin Delgado100% (1)

- Technical Description MPPUDocument10 pagesTechnical Description MPPUNinaNo ratings yet

- Surface Cementing EquipmentDocument14 pagesSurface Cementing EquipmentDjohan Pranata KabanNo ratings yet

- NitrogenoDocument139 pagesNitrogenoEmanuelLopezNo ratings yet

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Xq114-6yx Manual PDFDocument55 pagesXq114-6yx Manual PDFFredy NavasNo ratings yet

- Multi Purpose Pumping Unit: Pump and Heating UnitDocument2 pagesMulti Purpose Pumping Unit: Pump and Heating UnitNinaNo ratings yet

- Keystone CatalogDocument8 pagesKeystone CatalogTalpes Alexandru100% (1)

- GD 3000 SGWS Stainless Steel FE Parts List 306TLS997 - ADocument14 pagesGD 3000 SGWS Stainless Steel FE Parts List 306TLS997 - AYeins Edson OrdoñezNo ratings yet

- Triplex Pump: TPH 400 Main SpecificationsDocument2 pagesTriplex Pump: TPH 400 Main SpecificationsAttou Housseyn100% (1)

- Original Manual: Type MF3iw - DVDocument37 pagesOriginal Manual: Type MF3iw - DVSuellen Fonseca100% (1)

- Cold and .N2Document24 pagesCold and .N2IVAN ARNULFO BUITRAGO LOZANO100% (3)

- Wa0004.Document90 pagesWa0004.Alfonso ReyesNo ratings yet

- 30-100 High-Torque Casing Tong: ApplicationsDocument1 page30-100 High-Torque Casing Tong: ApplicationsLuis Arreaza BelisarioNo ratings yet

- Maintenance Interval Schedule c15 MCW PDFDocument3 pagesMaintenance Interval Schedule c15 MCW PDFVictor NunezNo ratings yet

- API Adaptor ManualDocument2 pagesAPI Adaptor Manualesham2100% (1)

- Fracturing EquipmentDocument15 pagesFracturing EquipmentJesus Ponce G100% (1)

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- CPF Cement Pump Float Inspection ReportDocument1 pageCPF Cement Pump Float Inspection ReportMohamed El-SawahNo ratings yet

- # Barite >> To Increse the weight # Halad 413 >> Fluid loss reducer # HR-4 >> Halliburton Retarder # D.AIR >> Defoamer ةوغرلا ليزمDocument1 page# Barite >> To Increse the weight # Halad 413 >> Fluid loss reducer # HR-4 >> Halliburton Retarder # D.AIR >> Defoamer ةوغرلا ليزمMohamed El-SawahNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- 5'' Liner - 2009Document4 pages5'' Liner - 2009Mohamed El-SawahNo ratings yet

- Z BS ChecklistDocument1 pageZ BS ChecklistMohamed El-SawahNo ratings yet

- Time Rate Pressure Messages: 1001 SDGM Ahmed - Sami Saudi SLBDocument1 pageTime Rate Pressure Messages: 1001 SDGM Ahmed - Sami Saudi SLBMohamed El-SawahNo ratings yet

- Time Rate Pressure Messages: 1001 SDGM Ahmed - Sami Saudi SLBDocument1 pageTime Rate Pressure Messages: 1001 SDGM Ahmed - Sami Saudi SLBMohamed El-SawahNo ratings yet

- CPF Cement Pump Float Inspection ReportDocument1 pageCPF Cement Pump Float Inspection ReportMohamed El-SawahNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- CPF Cement Pump Float Inspection ReportDocument1 pageCPF Cement Pump Float Inspection ReportMohamed El-SawahNo ratings yet

- Z BS ChecklistDocument1 pageZ BS ChecklistMohamed El-SawahNo ratings yet

- QAF5174 Rev 0 Crane Forklift Ops JSADocument90 pagesQAF5174 Rev 0 Crane Forklift Ops JSAMohamed El-SawahNo ratings yet

- QAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEDocument1 pageQAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEMohamed El-SawahNo ratings yet

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Document1 pageStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- Z BS ChecklistDocument1 pageZ BS ChecklistMohamed El-SawahNo ratings yet

- Mobile Crane Inspection ChecklistDocument2 pagesMobile Crane Inspection ChecklistMohamed El-SawahNo ratings yet

- Self-Assessment Exposure Checklist For Quest Exemption Jan 2020Document1 pageSelf-Assessment Exposure Checklist For Quest Exemption Jan 2020Mohamed El-SawahNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- DRM Act 2015Document52 pagesDRM Act 2015Gail HoadNo ratings yet

- Tle9agricropproduction q1 m5 ProvidingworksupportinaccordancewithOHSforhorticulturalproductionwork v3Document26 pagesTle9agricropproduction q1 m5 ProvidingworksupportinaccordancewithOHSforhorticulturalproductionwork v3Marycon Lao NacitoNo ratings yet

- Inflammatory Bowel DiseaseDocument27 pagesInflammatory Bowel DiseaseMihai VladescuNo ratings yet

- Psychology IB Biology Approach To BehaviorDocument25 pagesPsychology IB Biology Approach To Behaviorana kiranaNo ratings yet

- 03-Security of Tenure PDFDocument2 pages03-Security of Tenure PDFSarabeth Silver MacapagaoNo ratings yet

- 3.14 Doxy PleurodesisDocument2 pages3.14 Doxy PleurodesisRheinald Joel BiscaroNo ratings yet

- Maritime Business Environment AssignmentDocument4 pagesMaritime Business Environment AssignmentsivaNo ratings yet

- Benefits of HobbiesDocument6 pagesBenefits of HobbiesAdam YapNo ratings yet

- Reviewer Ansc 111Document6 pagesReviewer Ansc 111Jeric MadroñoNo ratings yet

- From Paragraph to Essay: Structure and ComparisonDocument21 pagesFrom Paragraph to Essay: Structure and ComparisonDiego EscobarNo ratings yet

- Trophy Winners 2019Document10 pagesTrophy Winners 2019blackguard999No ratings yet

- 7e Lesson PlanDocument6 pages7e Lesson PlanDave Matthew LibiranNo ratings yet

- Electrometallurgy NptelDocument23 pagesElectrometallurgy NptelChayon MondalNo ratings yet

- Diabetes PDFDocument5 pagesDiabetes PDFErica MailigNo ratings yet

- Nust Hostel Rules H-12 Campus IslamabadDocument10 pagesNust Hostel Rules H-12 Campus IslamabadNeha KhanNo ratings yet

- Human Heredity Principles and Issues 10th Edition Michael Cummings Solutions Manual 1Document10 pagesHuman Heredity Principles and Issues 10th Edition Michael Cummings Solutions Manual 1yvette100% (39)

- Operating Instructions for SUMI Lift TruckDocument27 pagesOperating Instructions for SUMI Lift TruckXe Nâng Hàng YaleNo ratings yet

- Muskuloskeletal Disorder Menggunakan: Analisa Dan Penilaian Risiko Metode Manual Tasks Risk Assessment (Mantra)Document8 pagesMuskuloskeletal Disorder Menggunakan: Analisa Dan Penilaian Risiko Metode Manual Tasks Risk Assessment (Mantra)Dirgntra AlanNo ratings yet

- Soal UN SMP BH InggrisDocument5 pagesSoal UN SMP BH InggrisSammie GirsangNo ratings yet

- Production of Non Ferrous MetalsDocument68 pagesProduction of Non Ferrous MetalsDrTrinath TalapaneniNo ratings yet

- StressDocument128 pagesStressJulie Rose CastanedaNo ratings yet

- Listado de Precios HADocument6 pagesListado de Precios HAgloria c.fernandezNo ratings yet

- Technical Bulletin: Ptfe, 25% Glass Filled Slide PlatesDocument5 pagesTechnical Bulletin: Ptfe, 25% Glass Filled Slide PlatesDavid Luna MolinaNo ratings yet

- M7025cat Milpower Ysmetronics M7025-10aDocument5 pagesM7025cat Milpower Ysmetronics M7025-10abhutaniseNo ratings yet

- Environmental engineering guide for small boat basinsDocument40 pagesEnvironmental engineering guide for small boat basinsmote34No ratings yet

- Hardees ReviewDocument17 pagesHardees ReviewFarhan KamalNo ratings yet

- Easy Tom Micro and NanoDocument2 pagesEasy Tom Micro and NanoMURALINo ratings yet

- INDUSTRIAL TRAINING FOR UPSTREAM DOWNSTREAM PROCESS AND SERVICESDocument14 pagesINDUSTRIAL TRAINING FOR UPSTREAM DOWNSTREAM PROCESS AND SERVICESMshamil ShaamryNo ratings yet

- Checklist of Construction SiteDocument7 pagesChecklist of Construction SiteSurya PNo ratings yet

- Intelli Trac X1Document2 pagesIntelli Trac X1nadjibnetNo ratings yet