Professional Documents

Culture Documents

Stem-1 MPF342 - 18-Feb

Uploaded by

Mohamed El-SawahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stem-1 MPF342 - 18-Feb

Uploaded by

Mohamed El-SawahCopyright:

Available Formats

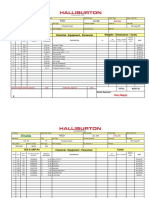

STEM-I: CPF Cement Pump Float

DISTRICT / LOCATION: HWYH-1147 / HWYH HUB ODOMETER READING: 83364 m/km STEM-I REPORT No.: Day Shift

UNIT DESCRIPTION: MPF-342 ENGINE HOURS - MIX PUMP: 2508 hrs INSPECTION DATE: 02-18-2020

UNIT No.: MPF34216Y0348 ENGINE HOURS - D/H PUMP: 2510 hrs OPERATOR NAME(S): Mohamed Ismail

Date Last STEM-II: 01-Nov-2019 Read the previous 2-3 STEM-I Reports DOT Papers Ok? Yes / No ASK IF IN DOUBT

Check Comments / Work Done / Outstanding Work

System / Component Guidelines on what to check Wear correct PPE Needs **Record operating oil pressures & temperatures and volumes of

Okay

Work fluid(s) added

Unit is CLEAN with correct labeling. Wash with fresh water

Appearance & Unit is PAINTED (SLB blue) - no corroded or partially painted areas Ok

1 Toolboxes/baskets - clean and free of trash

Cleanliness

Walkaround unit - check for leaks/damage: repair/report as required

Fire Extinguisher, Eye-Wash Bottle, First Aid Kit, Warning signs / Placarding, Wheel

chocks - check all available & in good condition Ok

2 Safety Equipment Walkways, Ladders & Grating - check for damage, secure & clean

Loads secured, no loose items, blinds & caps secure

Trailer Brake Systems - check work okay when hooked up to tractor

Trailer Lights - confirm all working

Tires, lugs, clamps - check for flats & damage and loose lugs or clamps

Coupling Devices - check 5th-wheel, pin & latch mechanism okay Ok

3 CPF - Trailer Air/Electric Hoses - connected to/from tractor/trailer, secure, no damage

Landing Gear & Legs -work okay, good condition, pins secured with chain

Suspension - check for sag/lean, cracked parts or deflated/ leaking air bags

Doors, Engine Compartment - no damage & do they close okay?

Check oil level 2 times, fill with engine oil as specified

Ok **

4 Engine Oils Oil appearance (note if milky/black). No leaks from hoses, connections, filters

Diesel tank 90% full, filler cap back on tight.

No leaks from fuel lines, connections, filters or fuel pump # Diesel tank 80% full.

5 Fuel Systems Drain water from diesel tank until clean diesel flows Ok

Check for water contamination in fuel filter sight bowls where fitted.

Antifreeze level 2" below filler neck (engine cold) - 50/50 Premixed) **

Radiators Radiator Cores (both sides) - clean, no leaks & no damage Ok

6 Hoses & Connections - clean, no leaks & no damage

Cooling Systems

Fan Belts - check tension (1/2" to 3/4" yield) & condition (no cracks)

Remove cover - check element for soot or water (clean as required)

7 Air Cleaners Check service indicator (replace if in RED or 20")

Ok

Exhaust blankets/wrap - in place and in good condition Ok

8 Exhaust Systems Pipework okay, no leaks, connections sound. Rain cap in place

Batteries - check electrolyte levels, clean terminals, tiedowns & surface. Voltage ≥ 12.4V (engine off) and w/engine running = 13.8-14.5V for a 12V system,

Check voltages: engine off (battery) and running (alternator) or 27.8-28.4 for a 24V system

9 Electrical System Ok

Work Lights - working and clean # Batteries Voltage: 12 V.

Cables/Connectors - no loose or broken wires. Isolation switch off after job

Air up system (90-110 psi) - check gauges okay & check for audible leaks

10 Air System

Drain all air reservoirs/tanks until clean, close drain valve

Ok # Air system: 110 psi.

Air Valves & Actuators - check all working & no leaks from air lines.

PRV/Tank Certifications - check test date and tag

Emergency Kill - test with engine stopped & reset latch

Throttle working okay (up/down)

Gauges (pressure & temperature) - all working, not broken and clean

Controls & Activate "lamp test" - check and note status of codes

Ok

11

Instrumentation Check normal kill operation and test OPSD's working (and reset)

Drain/clean air trap and/or add oil to lubricator as required

Control Area Roof - raises okay, no damage

Automatic - check oil level with engine idle, warm and in neutral **

12 Transmissions Condition of hoses and connections - clean, no leaks and no damage

Ok

Hyd. Oil - check level in reservoir (2" - 4" from top when cold) **

13 Hydraulic System Hyd. Hoses, Connections & Valves - undamaged, clean, no leaks, no cracks Ok

Check filter bypass indicator where fitted

PTO Operation - working, no air leaks & no unusual noises

14 PTO & Drivelines Bearings & U-Joints - check grease points, check guards secure & in place

Ok

Chain Cases / Check oil level (1/2 way up sight glass) and condition Ok

15

Gear Reducers No leaks, hoses in good condition. No unusual noises when unit running

Power End - check gear oil level & appearance, check pressure gauge Ok **

16 Power Ends Condition of hoses - no leaks and no damage

Working pressure - stencilled on fluid end. Tighten packing as required

Packing Lube Oil - check oil reservoir is full & system operates okay Ok

17 Fluid Ends Plungers - tight to pony rods (cross heads) & surface condition

Pony Rod Seals - no leaks & slinger rings not loose

Check & record circulating pressures and rates of C-Pumps

C-Pump Lubrication system

4x5 C-Pump - run to check operation & shut-in pressure > 45 psi

5x6 C-Pump - run to check operation & shut-in pressure > 60 psi

C-Pumps & BFV's

Ok

18

Process Piping Details on how to check the above are covered in Job Ready Mixing System

Maintenance SWI (InTouch content ID#6650863) and Post Washup Mixing system

Maintenance SWI (InTouch Content ID#6650882).

Suction Lines - remove suction caps, clean with no cement or sand

Cables/Connectors: condition, clean, tightness of connections, dust caps Circulate fresh water - check densitometer reads 8.34ppg

Electronic, Enclosures: Weather proof, all bolts in place, cables enter via proper glands

Recording & Sensors: Rate, Pressure & Density - check all working & calibrated okay

19 HMI Devices: Rate, Pressure & Density - check all working okay Ok

Monitoring

Devices DCU (HMI) - check all DCU's in diagnostic screen are online

DCU (Acquisition) - check communication with CAT software/hardware

See Bulk System STEM-I for Surge Tank (if fitted to CPF Trailer)

Knifegate/mixing jets; Hyd., Mix & Wash-Up Hoses & Connections; DCS

Details on how to check the above are covered in Job Ready Mixing System

Maintenance SWI (InTouch content ID#6650863) and Post Washup Mixing system

20 Mixing System Maintenance SWI (InTouch Content ID#6650882) .

Ok

HMI Devices: Rate, Pressure & Density - check all working okayDisplacement Tanks

& Slurry Tub(s) - clean and empty

Diesel/Wax Spray/Antifoam Tanks - check fluid levels & operation

Standard 23 Certifications - up-to-date with ID bands in place Pressure test 2" HP manifold & valves.

Grease plug valves and chicksan swivels, check 2" seal rings

Treating MD Gauge Protector Diaphragms - check for condition of diaphragm

21

Equipment

Ok

No burrs on wing nut lugs, valve indicators painted

Ensure all treating equipment mounted on the unit is tight prior to treatment

Fluid levels (Oil, Diesel, Antifreeze) - check & top up as required Note Compressor Engine Hours and volume of oil added

Starter / Shutdown - starts/stops without problem (electric, air or manual)

Air Compressor - No leaks (air, oil or diesel fuel), hoses & connections in good condition

22

(Bulk System) N/A

Controls & Gauges - all working okay and clean, linkages okay

Certification - air reservoir and relief valves okay & tagged

OPERATOR SIGNATURE: JOB SUPERVISOR SIGNATURE: FSM / MSV SIGNATURE:

Mohamed Ismail

18-Feb-2020 Date:

Date: Date:

Operator confirms that required STEM-I maintenance checks were performed & corrected & noted, & the unit is ready for the next job. FSM/MSV confirms reported defects are repaired & documented in CMMS, & that unit is green tagged & ready for the next job.

Controlled document. Do not modify or change without permission. Ref No.: WS-STEM1-WCS-003 V3.3 11-May-15_JRB

You might also like

- I10 Workshop Manual - ADocument292 pagesI10 Workshop Manual - ANorthstartechnology Company82% (11)

- Catalogue ACDelco Steering PDFDocument32 pagesCatalogue ACDelco Steering PDFSelvin GalindoNo ratings yet

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- BRM FRM 065 Light Vehicle Inspection ChecklistDocument2 pagesBRM FRM 065 Light Vehicle Inspection ChecklistSamuel YekoNo ratings yet

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistFyan SaputraNo ratings yet

- Form A: Preventive Maintenance Service & InspectionDocument1 pageForm A: Preventive Maintenance Service & InspectionMarco Arias Martinez100% (2)

- Procedure of Maintenance of DG SETDocument8 pagesProcedure of Maintenance of DG SETVatsavai Appala Narasimha RajuNo ratings yet

- Cryogenic Insulation TechnologyDocument61 pagesCryogenic Insulation Technologyeduard.turon100% (1)

- VK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualDocument76 pagesVK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualhaileNo ratings yet

- Job 3395-Emsco FB1600 PumpDocument123 pagesJob 3395-Emsco FB1600 PumpCristian BoselliNo ratings yet

- German Din Vde Standards CompressDocument3 pagesGerman Din Vde Standards CompressYurii SlipchenkoNo ratings yet

- PC78US-8 General Information On TroubleshootingDocument50 pagesPC78US-8 General Information On TroubleshootingHai Van60% (5)

- Spread of Hinduism To South East Asia by Land and Maritime RoutesDocument36 pagesSpread of Hinduism To South East Asia by Land and Maritime RoutesUday DokrasNo ratings yet

- Msds EthanolDocument7 pagesMsds EthanolHeru HarnadiNo ratings yet

- HVAC Maintenance PDFDocument13 pagesHVAC Maintenance PDFКирилл СоколовNo ratings yet

- Scissor Lift Pre Delivery Inspection Report PDFDocument1 pageScissor Lift Pre Delivery Inspection Report PDFlanza206No ratings yet

- Nitrogen Pump SM1 Checklist - Controlled Document PDFDocument4 pagesNitrogen Pump SM1 Checklist - Controlled Document PDFMaxim KanibetovNo ratings yet

- UGM Maint and Inspec Check List LHDsDocument2 pagesUGM Maint and Inspec Check List LHDsvictor toroNo ratings yet

- Omm DP50N CT28CDocument48 pagesOmm DP50N CT28Casri novhandi100% (2)

- Pre Mob Flatbed Truck Daily Inspection Checklist FormDocument3 pagesPre Mob Flatbed Truck Daily Inspection Checklist Formagusbudianto.dk168No ratings yet

- Nitrogen Tank SM1 Checklist - Controlled PDFDocument3 pagesNitrogen Tank SM1 Checklist - Controlled PDFMaxim Kanibetov0% (1)

- Testing & CommissioningDocument46 pagesTesting & CommissioningVuong Viet Cuong100% (1)

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- (Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)Document12 pages(Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)pdrichNo ratings yet

- Aerody Design of BladeDocument90 pagesAerody Design of BladeB Bala Venkata GaneshNo ratings yet

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- STEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Document1 pageSTEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Mohamed El-SawahNo ratings yet

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Document1 pageStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- Stem-1 - Frac TankDocument1 pageStem-1 - Frac TankMohamed El-SawahNo ratings yet

- Weekly Standard InspectionDocument3 pagesWeekly Standard InspectionFrancis Salonga100% (1)

- Major VisitDocument5 pagesMajor Visityoussef akrkawNo ratings yet

- Classic E.O.S. From SN #BE7Document4 pagesClassic E.O.S. From SN #BE7Foued MbarkiNo ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- 47.mewp Check List Unisco (F) - 47Document1 page47.mewp Check List Unisco (F) - 47ibrahimNo ratings yet

- Maintenance Checklist Shekar AugerDocument1 pageMaintenance Checklist Shekar Augershamsheer ikramNo ratings yet

- Formulario de Mantenimiento 1Document2 pagesFormulario de Mantenimiento 1Marco Arias MartinezNo ratings yet

- Document Title: SWT Wilden Pump Maintenance Sheets: Equipment InformationDocument5 pagesDocument Title: SWT Wilden Pump Maintenance Sheets: Equipment InformationAbdulqahar M.SabirNo ratings yet

- Cartilla Mantenimiento Brazo ArtDocument9 pagesCartilla Mantenimiento Brazo ArtFabian Jara RodriguezNo ratings yet

- Electronic Service Information System (IN10026C - DPKCXNT)Document2 pagesElectronic Service Information System (IN10026C - DPKCXNT)Abhijay MotorsNo ratings yet

- Snorkel Maintenimiento TB80 TB 86JDocument22 pagesSnorkel Maintenimiento TB80 TB 86Jcesar alejandro scavoNo ratings yet

- Impac Vehicle Maintenance Sheet - C, D, EDocument6 pagesImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroeNo ratings yet

- Maintenance Checklist Feed AugerDocument2 pagesMaintenance Checklist Feed Augershamsheer ikramNo ratings yet

- 2000H Service 16M GraderDocument3 pages2000H Service 16M GraderMohamedNo ratings yet

- Bendi - B3-30 - AC - Maintenance - Check Lists PDFDocument9 pagesBendi - B3-30 - AC - Maintenance - Check Lists PDFChristian BedoyaNo ratings yet

- Pre-Use Inspection Checklist: Forklift - Perform Inspection Before Each Shift. Document at Least Once Per WeekDocument4 pagesPre-Use Inspection Checklist: Forklift - Perform Inspection Before Each Shift. Document at Least Once Per WeekDaniel PradityaNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Service Report: Screw / ACDocument2 pagesService Report: Screw / ACDurgaNo ratings yet

- Breathing Apparatus ChecklistDocument6 pagesBreathing Apparatus ChecklistJhun AquinoNo ratings yet

- DAF Dealernet: Perform A ServiceDocument8 pagesDAF Dealernet: Perform A Serviceruman214No ratings yet

- Davie Xdcii 530 Eng DafDocument8 pagesDavie Xdcii 530 Eng Dafjose breno vieira silvaNo ratings yet

- Regular Safety & Mechanical Inspection CompactorDocument4 pagesRegular Safety & Mechanical Inspection CompactorRie ReiNo ratings yet

- Brass Plating Line - PencDocument2 pagesBrass Plating Line - PencPiyush VyasNo ratings yet

- Maintenance Interval Schedule Bulldozer D6RDocument2 pagesMaintenance Interval Schedule Bulldozer D6RRegi HermawanNo ratings yet

- Maintenance Interval Schedule GENSET 250KVADocument2 pagesMaintenance Interval Schedule GENSET 250KVARegi HermawanNo ratings yet

- Dust CollectorDocument1 pageDust Collectorkashifurrahaman8No ratings yet

- Detailed Failure Analysis (DFA)Document11 pagesDetailed Failure Analysis (DFA)Hari Hara SuthanNo ratings yet

- Cat Safety & Maintenance Checklist - SYKES PUMPSDocument1 pageCat Safety & Maintenance Checklist - SYKES PUMPSAlberto KelsoNo ratings yet

- PM Check SheetDocument7 pagesPM Check Sheetcharul2298No ratings yet

- VP MSP MP Annual Inspection Report PDFDocument1 pageVP MSP MP Annual Inspection Report PDFlanza206No ratings yet

- Grass Trimmer/Brush Cutter: Operator's ManualDocument36 pagesGrass Trimmer/Brush Cutter: Operator's ManualGonzalo AlvarezNo ratings yet

- Telehandler ChecklistDocument1 pageTelehandler ChecklistSteinol SolutionsNo ratings yet

- Service 38559Document2 pagesService 38559Sumeet SawlaniNo ratings yet

- (Air Compressor In-Service Inspection Checklist) D00-KOMD002-01Document1 page(Air Compressor In-Service Inspection Checklist) D00-KOMD002-01Noman AliNo ratings yet

- Final Iocl Udaipur Checklist For Reliable-18-5-2019 PDFDocument32 pagesFinal Iocl Udaipur Checklist For Reliable-18-5-2019 PDFMd Asif KhanNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 5'' Liner - 2009Document4 pages5'' Liner - 2009Mohamed El-SawahNo ratings yet

- Stem-1 MPF342 - 18-FebDocument1 pageStem-1 MPF342 - 18-FebMohamed El-SawahNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- QAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEDocument1 pageQAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEMohamed El-SawahNo ratings yet

- QAF5174 Rev 0 Crane Forklift Ops JSADocument90 pagesQAF5174 Rev 0 Crane Forklift Ops JSAMohamed El-SawahNo ratings yet

- QAF5175 Rev 0 Crane - Inspection - ChecklistDocument2 pagesQAF5175 Rev 0 Crane - Inspection - ChecklistMohamed El-SawahNo ratings yet

- Self-Assessment Exposure Checklist For Quest Exemption Jan 2020Document1 pageSelf-Assessment Exposure Checklist For Quest Exemption Jan 2020Mohamed El-SawahNo ratings yet

- Z BS ChecklistDocument1 pageZ BS ChecklistMohamed El-SawahNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- Air Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaDocument8 pagesAir Tunnels: Submitted By: Priyanka Sinha SK MD Sibli Akram Ananya Sreyansri NandaPriyanka SinhaNo ratings yet

- Biology F4 Review Summary NoteDocument117 pagesBiology F4 Review Summary NoteSocdal AbdiNo ratings yet

- NEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andDocument90 pagesNEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andliyanderNo ratings yet

- Heil 4000 FeaturesDocument1 pageHeil 4000 FeaturesBogdan NgrNo ratings yet

- Markov Interest Rate Models - Hagan and WoodwardDocument28 pagesMarkov Interest Rate Models - Hagan and WoodwardlucaliberaceNo ratings yet

- Mechanical Components SectionDocument428 pagesMechanical Components Sectionxristo xristovNo ratings yet

- BMC IV - Module 02 Finishes 200912Document56 pagesBMC IV - Module 02 Finishes 200912Fidha SulfiNo ratings yet

- A Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFDocument2 pagesA Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFPutra GagahNo ratings yet

- Animal Whisperer PDFDocument4 pagesAnimal Whisperer PDFKevinPriestmanNo ratings yet

- ABB Photovoltaic DisconnectorsDocument6 pagesABB Photovoltaic DisconnectorsBog PenNo ratings yet

- Preventive Pump SetDocument67 pagesPreventive Pump Setwtpstp sardNo ratings yet

- Material of OFFERING HELPDocument7 pagesMaterial of OFFERING HELPShorn x NyteNo ratings yet

- 2015 Nissan 370Z 3.7L Eng VIN A BaseDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A BaseData TécnicaNo ratings yet

- 100 Câu Viết Lại Câu Ôn Thi Vào Lóp 6Document10 pages100 Câu Viết Lại Câu Ôn Thi Vào Lóp 6Nguyễn Thanh PhươngNo ratings yet

- E2870-13 Standard Test Method For Evaluating RelativDocument6 pagesE2870-13 Standard Test Method For Evaluating RelativA MusaverNo ratings yet

- Hardie Reveal Panel Installation Instructions 1597005Document29 pagesHardie Reveal Panel Installation Instructions 1597005David TorskeNo ratings yet

- IBH Link UA Manual PDFDocument302 pagesIBH Link UA Manual PDFjavixl1No ratings yet

- IBRO News 2004Document8 pagesIBRO News 2004International Brain Research Organization100% (1)

- IoT & WSN - Module 5 - 2018 by Prof - SVDocument43 pagesIoT & WSN - Module 5 - 2018 by Prof - SVVignesh MJ83% (6)

- Electrical Inspections: Infrared ThermographyDocument28 pagesElectrical Inspections: Infrared ThermographyManish RajNo ratings yet

- Compound Wall Toilet Revised (4) - ModelDocument1 pageCompound Wall Toilet Revised (4) - ModelInfra SupportNo ratings yet

- Astm D3078-02Document3 pagesAstm D3078-02Geoff EricksonNo ratings yet

- MPDFDocument5 pagesMPDFRoyalAryansNo ratings yet