Professional Documents

Culture Documents

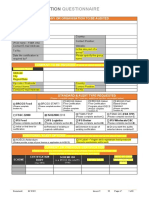

GP 4100 Food Questionnaire

Uploaded by

Julius MuhimboCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GP 4100 Food Questionnaire

Uploaded by

Julius MuhimboCopyright:

Available Formats

QUESTIONNAIRE – FOOD CERTIFICATION

Section 1: Company/Organisation Details

Name of Company or Organization Prime Meat Packers (U) Limited

( please enter the wording of your Company name EXACTLY as you wish it to

appear on the certificate)

Address Old Portbell Road.

Postcode

ADDRESS FOR INVOICE: if above, enter “same”

If company is part of a group, please specify group

Management Representative (Contact) 0751700348

Position Quality Analyst

Food safety Manager Julius Muhimbo

E-mail address juliusmuhimbo@gmail.com

Tel No: Fax No:

Section 2: Certification (s) Required (please tick)

ISO 22000:2005 BRC Global Food HACCP Others (please

indicate)

FSSC 22000 SQF Code ISO 9001:2008

Type of request

Certification Renewal of existing Extension ,

certification modification

Certification audit For integrated please identify your existing

integrated with existing certified standard you wish to combine with

std. the above certification.

> Does your company already have third party certification ?.. if yes, please indicate below.

Section 3: Scope/Processes

Standard (s) : ISO 9001:2008 CB (Certification Body)

ISO 14001:2004 CB

OHSAS 18001:2007 CB

ISO 22000 CB

HACCP/GMP CB

SQF Code CB

BRC CB

IFS CB

GAP / Global GAP CB

Others Please indicate

Please define the scope of registration e.g. product produced (please complete this question in detail or attach/send supporting information)

Processing of Beef

Processing of Goat Meat

Exclusions: Are there any local activities that are not included within the scope of the certification?. If so, please describe None

the exclusions (if any)

Q FOOD – GP 4100 Issue 6 Page 1

Give details if any specialist operations or services carried out by a sub contractor?

None

Product/Process Information

Please list below each product family(ies) and product types

(A product family shown common process or technology)

Exp. of product family: production of canned fruit juices and frozen fruit juices (2 product families)

Exp. of product types: canned mango juice, canned pineapple juice, canned guava juice and canned strawberry juice. (4 product types)

Product Type

Product Family

> Total number of production lines: * 1

> Number and type of HACCP study(ies) * : 2

* A HACCP study corresponds to a hazard analysis for a family of products/services with similar hazards and similar production technology and, where

relevant, similar storage technology. E.g. Production of ice-cream and cheese = 2 HACCP studies

> Please check off any of the following that apply to your business:

Labor intensive environment. Repetitive Tasks Simple process &/or Process automation

Important

List any legal requirements ,Licences and authorisations applicable, i.e. Process Authorisation, Consents etc and other

relevant info on production lines:

________________________________________________________________________

Please indicate if you have a timescale(s) for the following

Implementation date of the system 25th April 2021 Audit language English

Pre-audit(if applicable) Certification audit 25th June 2021

Section 4: > Number of employees = 15

Total # of shifts, along w/ employees per shift 15

Total number of employees that are non shift (i.e. management 5

,Admin, etc) Include temporary.

Total number of employees in shift (i.e. production workers) Include 10

temporary.

In case of seasonal product(s), please indicate the period(s) of production for each category of product including number of

employees (permanent & temporary ) included in the scope.

If additional sites, provide details;site/company name and address. Products or activities # of staff Documentation at this

site same as the main

office? .same system ?

1 Site One Receving 1

2. Same Site Processing 10

3. Same Site Storage 2

4. Same Site Dispatch 2

5. Same Site admin 5

Q FOOD – GP 4100 Issue 6 Page 2

Section 5 Background Information

Has previous contact been made with SGS Personnel i.e. via telephone etc.? YES

If you have used or intend to use consultancy services for the activities to be certified please give the name of the consultancy

organisation and/or the name of the individual consultant(s)

Where did you hear about SGS?

Internet

Main reason for certification competitive advantage improve food safety system Corporate Policy

Customer request: others:

Appendix 1

ISO/FSSC 22000/HACCP/GMP BUSINESS CATEGORIES AND FOOD SECTORS

Please indicate with a tick the category your products are produced under

(Internal use only_if indicate in proposal worksheet no need to submit this part )

For FSSC 22000, only categories C,D,I are applicable

Food Chain Food Mark

Category Food Chain Categories Sector Food Product Sector List Applicable

Codes Category

AI Farming (Animals) A1a Animal

A1b Raw Milk Production

A1c Egg production

A1d Beekeeping

AII Farming (Fish and A2 Aquaculture

Seafood)

BI Farming (Plants) B1 Fruits

Vegetables

Spices

Nuts

Horticulture products

BII Farming (Grains and B2 Grains

Pulses) Pulses

C1a Red and white meat/Poultry /Game/Meat product and preparation

CI Processing (Animal Red meat slaughtering plants

perishable product) Raw poultry/raw prepared poultry products

Inc. FSSC including all activities Lamb

22000 after farming e.g. Venison

slaughtering Offal

Other meat

FSSC 22000

Reconstituted raw meat/poultry product e.g. nuggets, fresh

cut meat, steak, sausage, frozen meat, meat etc.

C1b Charcuterie/Smallgoods

Cured/Smoked Meats - Bacon, Ham

Salami – cooked/cured

Dried Meats - Prosciutto/Jerky/Biltong/Pastrami

Pate

Cooked meats Devon /Fleishwurst /Strassburg / Mortadella

Cooked Continental Sausages –Chorizo/Kabana

/Cabanossi/Kransky

Slicing & packing of RTE Meats

C1c Fish and fish product

Wet fish (Raw/ready to eat)

Molluscs (Raw / Ready to eat)

Crustacean (Raw /Ready to eat)

Communited fish products - raw (chilled / frozen)

Smoked fish – raw (chilled / frozen)

Fish pate (chilled)

Kitchen ready fish products (chilled / raw ingredients)

C1d Egg

Shell egg

Liquid Egg

Q FOOD – GP 4100 Issue 6 Page 3

C1e Dairy

Liquid milks

Liquid milk fractions

Liquid cream (chilled)

Liquid milk drinks

Liquid tea and coffee creamers

Yogurt and fermented milk-based product (chilled)

Fromage frais / crème fraiche

Dried milk / milk formulation

Cream (frozen)

Yogurt and fermented milk (frozen)

Dairy-based desserts (chilled)

Dairy-based desserts (frozen)

Hard cheese

Semi hard cheese

Soft cheese

Mould ripened cheese

Processed cheese / cheese food

Raw milk products

Butter

CII Processing Fresh and Processed fruit C2 Fruit (fresh / chilled)

(perishable and vegetables (inc. RTE Juice( fresh/chilled)

plant product) Salads, juices, nut is Vegetables (fresh / chilled)

shell) Preserved fruits/vegetable

Inc. FSSC Herbs (fresh / chilled/ frozen)

22000 Nuts (in shell)

Fruit / fruit mixed (frozen)

Vegetables / vegetables mixed (frozen)

Raw Prepared Ready to C3a Fresh and frozen pies and pizzas

cook, chilled and frozen Fresh and frozen cooked dishes

Frozen desserts (pie)

Quiches / flans (chilled / frozen)

Pizza (chilled / frozen)

Sauces (chilled / frozen)

CIII Processing

Pasta/Lasagne (chilled)

of perishable

animal and

plant

Ready to Eat prepared C3b Sandwiches

foods, chilled and frozen Hot pie

products(mixed

products) Soup

Sauces (chilled / frozen)

Inc. FSSC Pasta (chilled)

22000 Ethnic foods (chilled / frozen)

Ready to eat meals

Baby food

Fresh convenient salads

Fresh pastas

Vegetable pate / spreads (chilled / frozen)

Salad dressings (chilled)

Myco protein / tofu

Pastries (fresh / frozen)

Cake (fresh / frozen)

Fruit pies / tarts (fresh / frozen)

Ambient C4a Low acid foods (canned)

CIV stable hermetically sealed High acid foods (canned)

-Processing of packs Low acid foods (in glass)

ambient stable High acid foods (in glass)

products Low acid foods (aseptic / UHT)

High acid foods (aseptic / UHT)

Inc. FSSC

Low acid foods (pouch / tray)

22000

High acid foods (pouch / tray)

Honey [if thermal process apply]

Beverages C4b Alcoholic drinks (distilled)

[Ready to Drink] Alcoholic drinks (fermented)

Alcoholic drinks (fortified wine)

Alcoholic drinks (brewed)

Alcopops

Soft drinks including flavoured water / Isotonics

Concentrates / squashes / cordials

Drinking /Minerals /Carbonated waters, ice

Tea/Herbal drinks/Coffee

Q FOOD – GP 4100 Issue 6 Page 4

Cereal beverages (food drinks)

Grain C4c Rice / rice-based food

products/cereals/biscuit/ Pasta / noodles

flour/confectionery/snack Nut preparations

Sugar confections (all variations)

Chocolate

Breakfast Cereals/ Muesli

Processed cereals / Oats

Biscuits

Crisps

Wheat/Corn snacks

Nuts (Processed)

Poppadum’s

Bread (fresh / par bake / frozen)

Ice cream accessories

Wheat/Corn Flour

Oil and fats C4d Cooking oils

Specialty oils

Vinaigrettes

Margarine

Low fat spreads

Analogues / ghee

Suet

Dried goods C4e Dried Soups

Dried Sauces / gravies

Spices/ Herbs

Food grade Salt

Stock cubes

Seasonings/Stuffings

Tea, instant coffee, coffee creamers

Beverage mixes

Food ingredients C4f Dried egg powder

Dried whey powder

Dietary supplement

Salt

Sugar

Gelatin

Vinegar

Candies fruits

Flour improvers

Home baking ingredients

Sugar/icing

Mill products (flours etc.)

Cake decorations

Cake mixes

Syrups (flavoured / unflavored)

Pectin

Compositional or C4g Pickles

heat preserved Jams

foods (excluding canning Fermented products

and dried foods) Sauces

Food Gases like carbon C4h Food Gases like carbon dioxide, nitrogen

dioxide, nitrogen

D– Production of Compound D1 Compound Animal feed, fish feed

Animal Feed Animal feed, fish feed

production Production of Domestic pet D2 Dried foods

Inc. FSSC Food (Canned/ Dried) Canned/pouches

22000

E– E1 Hotels, restaurants, catering

Catering Catering

F1 Retails/ wholesales/shop

F- Distribution Distribution

F2 Food Broker/Trading

Provision of Transport and G1 Provision of Transport and Storage Services for Perishable

Storage Services for Food and Feed

G - Transport Perishable Food and Feed

and storage Provision of Transport and G2 Provision of Transport and Storage Services for Ambient

Storage Services for Stable Food and Feed

Ambient Stable Food and

Feed

Water supply H1 Water supply(e.g. Town Water/De-Salination plant0

Q FOOD – GP 4100 Issue 6 Page 5

H– Cleaning/pest H2 Cleaning /disinfection

Services control/laundry Pest control

Industrial laundry

Services H3 Waste disposal

Transport and storage

Equipment and facilities

I Packaging Plastic I1 PET Bottles

material Film for onward conversion/conversion

manufacture Plastic Food storage containers

‘Food only’ Pouches

Inc. FSSC Paper and Board I2 Wooden Crates (direct contact with food e.g. apples)

22000 Cardboard boxes (secondary food packaging)

Bags for food storage

Metal I3 Cans

Foil trays

Glass I4 Jars

Bottles

J– Equipment J1 Equipment manufacture

Equipment and

facilities Facilities J2 Facility construction and maintenances

(Bio)Chemical K1 Additives e.g. emulsifier, stabilizer, food flavor, food color,

manufacturer preservatives, food conditioner , food acids

vitamins , minerals

FSSC 2200 Bio cultures

K– Drugs (no medical authority approval required only) (Not FSSC

(Bio) Chemical 22000)

Manufacturer

Inc. FSSC Pesticides/ Fertilizers K2 Pesticides/ Fertilizers

22000

Cleaning agents K3 Cleaning/processed reagents

Appendix 3

Primary Sector

Q FOOD – GP 4100 Issue 6 Page 6

In case of primary sector, please indicate the following information:

Cattle Breeding:

Type of cattle Nº of producers Activity Number of animals

Poultry:

No of house Activity

Vegetables producers:

Type of vegetable Nº of producers Activity Surface

Appendix 3

BRC Food

Q FOOD – GP 4100 Issue 6 Page 7

(Part 1)

Section 1

Disclosure Agreements (please tick the retailers with whom you have signed agreements to pass on

reports and/or certificates)

Asda KwikSave Somerfield

Boots Littlewoods Spar

Bookers Cash & Carry Marks & Spencer Tesco

Burger King Morrisons Wal Mart

CoOp Wholesale (CWS) Netto Other

Iceland Sainsburys

Section 2

WAREHOUSING AND DISTRIBUTION

Please give a brief outline of your own warehousing and distribution activities.

Do you subcontract any warehousing and distribution? If YES, please tick and give details.

BRC Food Addendum

(Part 2)

Q FOOD – GP 4100 Issue 6 Page 8

Section 3

PRODUCT RANGE – FOOD

Please indicate with tick products produced

Egg Packs Ambient Stable

Shell Egg Heat preserved

Raw Meat & Fish Hermetically sealed

Red Meat Slaughter & cutting Other

Raw Meat products & preparations

Beverages

Chill / Frozen Alcoholic

Beef / Veal Soft drinks

Pork / Lamb Fruit juices

Venison Coffee / Tea / Herbal

Offal / Other meat

Poultry Meat, Slaughter & cutting Bakery products – ambient

Chicken / Turkey Bread / Pastries

Duck / Goose Biscuits / Cake

Farmed & Wild Game

Fish – Wet / Chilled Dried Goods

Fish – Frozen Soup/Sauce/Gravy/Stock

Molluscs/ Crustacean – Raw Herbs / Seasoning / Stuffing

Molluscs / Crustacean – Cooked Nut preparations

Raw Fish products and preparations Pet food

Fruit Oils & Fats

Vegetables

Salads

Prepared/ Semi Processed

To eat or heat Food Ingredients

Chilled Egg – Liquid / dried

Frozen Dried Whey powder

Cooked meat Vitamins

Cooked fish Salt / Vinegar

Ready meals Home Baking ingredients

Sandwiches Cake decorations

Soups / Sauces Pectin

Pasta Confectionery

Quiches / Flans Snacks

Veg. Pates/ Spreads Breakfast cereals

Dairy Other

Chilled

Frozen

Q FOOD – GP 4100 Issue 6 Page 9

You might also like

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailFrom EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailRating: 5 out of 5 stars5/5 (3)

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- GP 4100 Food QuestionnaireDocument10 pagesGP 4100 Food Questionnairehunain zafarNo ratings yet

- Questionnaire - Food Certification: Section 1: Company/Organisation Details Name of Company or OrganizationDocument11 pagesQuestionnaire - Food Certification: Section 1: Company/Organisation Details Name of Company or OrganizationAliNo ratings yet

- Halal Application FormDocument8 pagesHalal Application FormKamrul HasanNo ratings yet

- GF0101 Generic Food Certification QuestionnaireDocument8 pagesGF0101 Generic Food Certification QuestionnaireLiliana Cobos ZambranoNo ratings yet

- Formato de Aplcacion BRCDocument9 pagesFormato de Aplcacion BRCmERCYNo ratings yet

- GF0101 Generic Food Certification QuestionnaireDocument6 pagesGF0101 Generic Food Certification QuestionnaireItatiana B. HerreraNo ratings yet

- Food Certification Questionnaire SEODocument6 pagesFood Certification Questionnaire SEODaniela JimenezNo ratings yet

- GF0101 Generic Food Certification QuestionnaireDocument7 pagesGF0101 Generic Food Certification QuestionnaireRasadi MohamadNo ratings yet

- 0100 - ENG - FORM - 010 - Basic data-FSSC V6Document5 pages0100 - ENG - FORM - 010 - Basic data-FSSC V6azizatheoneNo ratings yet

- SF01 Food Application Form SummaryDocument8 pagesSF01 Food Application Form SummaryAsif MerajNo ratings yet

- SF01 Food Application Form With All AnnexesDocument11 pagesSF01 Food Application Form With All AnnexesJulius MuhimboNo ratings yet

- TUV NORD-9001 2015 QuestionnaireQF 01 Rev17 09.10.2019 QuestionnaireDocument5 pagesTUV NORD-9001 2015 QuestionnaireQF 01 Rev17 09.10.2019 QuestionnaireRavi RathodNo ratings yet

- CERTIFICATION APPLICATIONDocument1 pageCERTIFICATION APPLICATIONkarupukamalNo ratings yet

- SummaryAuditReport v4 August2019Document12 pagesSummaryAuditReport v4 August2019RaihanNo ratings yet

- TÜV India Certification ApplicationDocument14 pagesTÜV India Certification ApplicationnisbabaNo ratings yet

- Questionnaire 637027722257034154Document13 pagesQuestionnaire 637027722257034154Santosh Kumar KurellaNo ratings yet

- GF0101 Generic Food Certification Questionnaire IFSDocument7 pagesGF0101 Generic Food Certification Questionnaire IFSerikaNo ratings yet

- Audit Report Template SummaryDocument4 pagesAudit Report Template Summaryivonastrid552No ratings yet

- TÜV India Certification Application for ISO StandardsDocument12 pagesTÜV India Certification Application for ISO StandardsCharanjeetSinghKhanujaNo ratings yet

- DNV Quote Request FormDocument5 pagesDNV Quote Request FormChris OpubaNo ratings yet

- 54.2017新版ISO IEC17025對實驗室管理系統之應用Document192 pages54.2017新版ISO IEC17025對實驗室管理系統之應用Chi Jui HanNo ratings yet

- AUD-F-02-Request For Proposal Cum Application FormDocument3 pagesAUD-F-02-Request For Proposal Cum Application FormPardeep100% (1)

- Global HACCP Certification for Meat Processing PlantDocument6 pagesGlobal HACCP Certification for Meat Processing Plantburgeees kamranNo ratings yet

- FSSC 22000 Version Comparison v1.0Document7 pagesFSSC 22000 Version Comparison v1.0Nuñez EdwardNo ratings yet

- B001 Company Profile Questionnaire R11Document5 pagesB001 Company Profile Questionnaire R11Neha UkaleNo ratings yet

- Iso Iec 17065 OverviewDocument78 pagesIso Iec 17065 OverviewJulio Gomez100% (3)

- GF0101 Generic Food Certification QuestionnaireDocument6 pagesGF0101 Generic Food Certification QuestionnaireKaren RNo ratings yet

- ISO Certification Needs AssessmentDocument3 pagesISO Certification Needs AssessmentAlex MaugoNo ratings yet

- TUV NORD Questionnaire - QFDocument6 pagesTUV NORD Questionnaire - QFArun VivekNo ratings yet

- Aar Certification Enquiry FormDocument6 pagesAar Certification Enquiry Formdhir.ankurNo ratings yet

- Accreditation of Food Safety Certification BodiesDocument38 pagesAccreditation of Food Safety Certification BodiesabeesNo ratings yet

- Application Halal CertificationDocument5 pagesApplication Halal CertificationFarazAkhtarMalikNo ratings yet

- AC 2.1 V.8.2 Application Form and Accreditation AgreementDocument9 pagesAC 2.1 V.8.2 Application Form and Accreditation AgreementAnonymous cP2LRltNo ratings yet

- Questionnaire For Offer Preparation: General InformationDocument2 pagesQuestionnaire For Offer Preparation: General InformationMichael FadjarNo ratings yet

- 1 PPT ISO 17025 2017 Emp TrainingDocument52 pages1 PPT ISO 17025 2017 Emp Trainingamit100% (5)

- Capwtoworkshop eDocument17 pagesCapwtoworkshop eHimanshu joonNo ratings yet

- Inquiry Form for Certification ServicesDocument1 pageInquiry Form for Certification ServicesKM YOUSUFNo ratings yet

- SGS Audit of PT. SMART Tbk. Belawan RefineryDocument4 pagesSGS Audit of PT. SMART Tbk. Belawan RefineryfransiskaNo ratings yet

- ISO 9001 2015 & 22000 2018 Internal Audit REV 01 Audit 09 UPDATED - Docx Hanif BhaiDocument23 pagesISO 9001 2015 & 22000 2018 Internal Audit REV 01 Audit 09 UPDATED - Docx Hanif BhaiShabarish SubramanyamNo ratings yet

- FR-212 Iso 9001-2015 Stage 2-Surveillance Audit ReportDocument5 pagesFR-212 Iso 9001-2015 Stage 2-Surveillance Audit ReporttriveshNo ratings yet

- Price List Cloud and On Premise - Ewebacc - 2019 Pt. Linuxindo Total SolusiDocument1 pagePrice List Cloud and On Premise - Ewebacc - 2019 Pt. Linuxindo Total SolusiRuddy KalaloNo ratings yet

- EBMT - Audit - Report - MGMT - Sys - V10 - July - 2016 - Oriental Fastech 2016 PDFDocument10 pagesEBMT - Audit - Report - MGMT - Sys - V10 - July - 2016 - Oriental Fastech 2016 PDFkhai ruleNo ratings yet

- Supplier Evaluation For It SMSDocument4 pagesSupplier Evaluation For It SMSAnkurNo ratings yet

- TUV NORD QuestionnaireDocument4 pagesTUV NORD QuestionnaireRajkumar RajendranNo ratings yet

- Calibration of BalanceDocument3 pagesCalibration of BalancesagorNo ratings yet

- SF01 - Application Form - Social Audit SMETA & AIM PROGRESSDocument6 pagesSF01 - Application Form - Social Audit SMETA & AIM PROGRESSsisseg.operacionesNo ratings yet

- TÜV NORD Indonesia Safety Certification ServicesDocument26 pagesTÜV NORD Indonesia Safety Certification ServicesIndra AffandiNo ratings yet

- IFS GMP Check Guidance V1 EN FINALDocument8 pagesIFS GMP Check Guidance V1 EN FINALCristina Caetano de MatosNo ratings yet

- Organic System Plan Marketer-Trader-Broker-Distributor/HandlerDocument8 pagesOrganic System Plan Marketer-Trader-Broker-Distributor/HandlerRika Rahma PutriNo ratings yet

- HACCP QuestionnaireDocument3 pagesHACCP Questionnairefyd100% (1)

- BSTI Product Certification AccreditationDocument45 pagesBSTI Product Certification Accreditationmohamed elsayedNo ratings yet

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Sirveen NQA Audit Request Form Jul20Document19 pagesSirveen NQA Audit Request Form Jul20MallikarjunaraoNo ratings yet

- ISO Certification Application SummaryDocument10 pagesISO Certification Application SummaryTao AbadiNo ratings yet

- Food Safety Certification GuideDocument2 pagesFood Safety Certification GuideAvinash MaheshwariNo ratings yet

- TNV F 001 Inquiry FormDocument3 pagesTNV F 001 Inquiry FormAMIT SHARMANo ratings yet

- AC 2.1 Application Form and Accreditation Agreement V9.1Document11 pagesAC 2.1 Application Form and Accreditation Agreement V9.1Ahmad ENo ratings yet

- Corrigendum Change in TechnicalDocument7 pagesCorrigendum Change in TechnicalAkash SinghNo ratings yet

- Ntungamo District Service Commission: External Advert No. 1 of 2020Document1 pageNtungamo District Service Commission: External Advert No. 1 of 2020Stephen Odongo100% (1)

- fs-18-322uDocument4 pagesfs-18-322uJulius MuhimboNo ratings yet

- SPD Solar Flood Lights SpecificationsDocument1 pageSPD Solar Flood Lights SpecificationsJulius MuhimboNo ratings yet

- Procurement Advert 1 22-23 (1)Document1 pageProcurement Advert 1 22-23 (1)Julius MuhimboNo ratings yet

- Form - CAR FormDocument6 pagesForm - CAR FormJulius MuhimboNo ratings yet

- 71bd00 Betopan Brosur TRDocument2 pages71bd00 Betopan Brosur TRJulius MuhimboNo ratings yet

- MTC Fabrication SystemDocument1 pageMTC Fabrication SystemJulius MuhimboNo ratings yet

- TDS - Technical Data SheetsDocument1 pageTDS - Technical Data SheetsJulius MuhimboNo ratings yet

- Fair Enough PDFDocument6 pagesFair Enough PDFJulius MuhimboNo ratings yet

- Newterra Quality Plan - Uganda WWTP - PWTPDocument1 pageNewterra Quality Plan - Uganda WWTP - PWTPJulius MuhimboNo ratings yet

- Comformity Certificate NewDocument4 pagesComformity Certificate NewJulius MuhimboNo ratings yet

- Ims Policy - Integrated Management System: Ergy For The WDocument4 pagesIms Policy - Integrated Management System: Ergy For The WJulius MuhimboNo ratings yet

- LED emergency bulkhead technical specDocument1 pageLED emergency bulkhead technical specJulius MuhimboNo ratings yet

- Solcourse Polythene DPM V005 TDSDocument3 pagesSolcourse Polythene DPM V005 TDSJulius MuhimboNo ratings yet

- Portability Water Testing For Construction PRNDocument1 pagePortability Water Testing For Construction PRNJulius MuhimboNo ratings yet

- Non-Conformances in Medical LabsDocument33 pagesNon-Conformances in Medical LabsJulius MuhimboNo ratings yet

- Anchor Bolt Detail 1Document1 pageAnchor Bolt Detail 1Julius MuhimboNo ratings yet

- ImranDocument6 pagesImranJulius MuhimboNo ratings yet

- GWC24AGDXE-K3DNA1A - Spec SheetDocument5 pagesGWC24AGDXE-K3DNA1A - Spec SheetJulius MuhimboNo ratings yet

- This Certificate of Compliance Validates The FollowingDocument6 pagesThis Certificate of Compliance Validates The FollowingJulius MuhimboNo ratings yet

- MSDS - Smoke Detector Test SprayDocument15 pagesMSDS - Smoke Detector Test SprayJulius MuhimboNo ratings yet

- Tusher Center Working Paper 7Document46 pagesTusher Center Working Paper 7Julius MuhimboNo ratings yet

- Wet Chemical Dry Charge MSDSDocument6 pagesWet Chemical Dry Charge MSDSJulius MuhimboNo ratings yet

- AppointmentDocument1 pageAppointmentJulius MuhimboNo ratings yet

- Sika Monotop 610 MsdsDocument14 pagesSika Monotop 610 MsdsJulius MuhimboNo ratings yet

- ToolBox MeetingDocument1 pageToolBox MeetingJulius MuhimboNo ratings yet

- Food Gap AnalysisDocument14 pagesFood Gap AnalysisJulius MuhimboNo ratings yet

- Tusher Center Working Paper 7Document46 pagesTusher Center Working Paper 7Julius MuhimboNo ratings yet

- PNW rn2Document7 pagesPNW rn2Julius MuhimboNo ratings yet

- SF01 Food Application Form With All AnnexesDocument11 pagesSF01 Food Application Form With All AnnexesJulius MuhimboNo ratings yet

- SKM - Product Brochure 20210805Document2 pagesSKM - Product Brochure 20210805Agung NugrohoNo ratings yet

- Technologies of Millet Value Added Products-1Document51 pagesTechnologies of Millet Value Added Products-1KeertNo ratings yet

- All Brands Bartender Learner Guide 1.2Document32 pagesAll Brands Bartender Learner Guide 1.2Ritchel Babor-limbagaNo ratings yet

- Cold N Brew MenuDocument3 pagesCold N Brew MenuRizki FitriaNo ratings yet

- Toor Dal (Split Yeldlow Pigeon Peas) Recipe - NYT CookingDocument1 pageToor Dal (Split Yeldlow Pigeon Peas) Recipe - NYT CookingBerta VicenteNo ratings yet

- L4_B1PLUS_U8_Grammar_BasicsDocument1 pageL4_B1PLUS_U8_Grammar_BasicsEva Lozano MelladoNo ratings yet

- TIB, Case Study Sweet AmsterdamDocument13 pagesTIB, Case Study Sweet AmsterdamhapposieniNo ratings yet

- KONFITERIADocument10 pagesKONFITERIAAlexA LugoNo ratings yet

- Squash Moringa Polvoron Chap1Document7 pagesSquash Moringa Polvoron Chap1Antonio Miguel DizonNo ratings yet

- اختبار استماع انجليزي ثاني متوسط ف2 موقع منهجيDocument3 pagesاختبار استماع انجليزي ثاني متوسط ف2 موقع منهجيyahia222000No ratings yet

- Donna Hay - RecipesDocument1 pageDonna Hay - RecipesNela Djokic TankosicNo ratings yet

- Where When What Why: 3. Make Questions Using The Past Continuous. Use, ,, or and The Words in ParenthesesDocument14 pagesWhere When What Why: 3. Make Questions Using The Past Continuous. Use, ,, or and The Words in Parenthesesmarcela padillaNo ratings yet

- E6 Unit 11 Bai Tap Ly Thuyet HayDocument2 pagesE6 Unit 11 Bai Tap Ly Thuyet HayNhung PhamNo ratings yet

- SIT30821 Certificate III Commercial Cookery: SITHCCC035 Prepare Poultry DishesDocument56 pagesSIT30821 Certificate III Commercial Cookery: SITHCCC035 Prepare Poultry Dishesrayzaoliveira.ausNo ratings yet

- Fortuna Automat Semi Automat 2010Document8 pagesFortuna Automat Semi Automat 2010faraonce2007No ratings yet

- MATH 10 Periodical Test - Key AnswerDocument3 pagesMATH 10 Periodical Test - Key AnswerWerty Gigz Durendez73% (11)

- Making Yoghurt at Home PDFDocument1 pageMaking Yoghurt at Home PDFAbe AkinolaNo ratings yet

- CadburyDocument20 pagesCadburySujeet GhagareNo ratings yet

- Diets Modified in ConsistencyDocument8 pagesDiets Modified in ConsistencyMartin Mitchelle Capistrano Monsod100% (1)

- The Beltsander S Cookbook Volume 1Document69 pagesThe Beltsander S Cookbook Volume 1Роман АсаевNo ratings yet

- Flora and Fauna MenuDocument2 pagesFlora and Fauna MenuDaniel GerzinaNo ratings yet

- TLE 7 Bread & Pastry Q1 Mod3Document31 pagesTLE 7 Bread & Pastry Q1 Mod3Jane Gomez PausanosNo ratings yet

- Instructions: Matcha PowderDocument11 pagesInstructions: Matcha PowderJenny TorredaNo ratings yet

- Variety of Ingredients in Preparing SandwichesDocument4 pagesVariety of Ingredients in Preparing SandwichesMARY JOY VILLARUELNo ratings yet

- UntitledDocument6 pagesUntitledDavid MartinsNo ratings yet

- English Exam Tips and InstructionsDocument8 pagesEnglish Exam Tips and InstructionsAyu Rhizky EamailiaNo ratings yet

- Rencana Anggaran Belanja Alat Pendidikan Tata BogaDocument7 pagesRencana Anggaran Belanja Alat Pendidikan Tata BogaAris SuryadiNo ratings yet

- Business Plan-SampleDocument32 pagesBusiness Plan-Samplekenji salongaNo ratings yet

- Parts of Speech (Part 2)Document52 pagesParts of Speech (Part 2)Polly NolisaNo ratings yet

- Unfinished Marketing PlanDocument5 pagesUnfinished Marketing PlanPatricia Gliane CatapangNo ratings yet