Professional Documents

Culture Documents

Technical Specifications / Tender Text Wöhr Autoparksysteme GMBH Parklift 462-2,0 D / 462-2,6 D

Uploaded by

thanggimme.phanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specifications / Tender Text Wöhr Autoparksysteme GMBH Parklift 462-2,0 D / 462-2,6 D

Uploaded by

thanggimme.phanCopyright:

Available Formats

Technical specifications / Tender text

WÖHR Autoparksysteme GmbH

PARKLIFT 462-2,0 D / 462-2,6 D

Specification

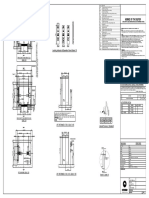

General: Car parking system for independent parking of 2 x 2 cars aside each other. For dimensions please see

data sheet PARKLIFT 462 with its dimensions for pit, height and width. This car parking system has three

horizontal double platforms. The lower platforms have one front wedge each per parking space for the

correct positioning of the car. Guided by the operating instruction the user has to adjust the front wedge

to his car.

Design and The Parklift consists of two pillars mounted on the floor in the middle on the left and right side of the system

description: and two hoisting slides moving the platforms along the pillars. Gear racks are mounted on the pillars to

ensure the mechanically synchron run by two pinions on each side and torsion bars hidden under the lower

platform. Two hydraulic cylinders are mounted upon the hoisting slides and four connection bars for additional

connection between the platforms.

Components: One upper platform, as a trough, 10 cm deep, consisting of:

Eight covering plates, nine cross bars, two side panels, screws, nuts.

Two lower platforms consisting of:

20 driving plates, one adjustable front wedge per parking space, two side panels, one middle panel,

three cross bars, screws, nuts etc.

Synchronizing device:

Four gear racks, two through torsion bars with two pinions each, fixing material etc.

Supporting structure consisting of:

Two pillars with hoisting slides, connecting parts in the pit, four bracings, four connection bars between

the platforms, dowels, screws etc.

Hydraulic components:

Two hydraulic cylinders, two magnetic valves, hydraulic pipes, screwings and fixing material.

Electric parts:

Operating device with Emergency Stop button, key interlock and two keys per parking space.

Standards: WÖHR Car Parking Systems are machines according to the Council Guideline governing machinery

2006/42/EC, Annex 1 and EN 14010.

Corrosion protection: For details please see enclosed information Surface protection 2017, No. 023-0028.

Hydraulic power pack: One hydraulic power pack can drive several Parklifts provided that they are arranged side by side

(e.g. underground car park). Each Parklift is controlled individually at its operating device.

The electric motor with pump is mounted rubber-bonded-to-metal. The hydraulic power pack consists

of an oil tank with appropriate filling for the entire system, two gear pumps, two electric motors (2 x 5.5 kW

230/400 V, 50 Hz), switch box with motor contactor and thermal relay already wired for connection,

pressure relief valve and hydraulic hoses reducing the noise transmission to hydraulic pipes.

Provided by customer: 1. Electric work according to enclosed data sheet PARKLIFT 462 (supply lines with lockable main switch to

hydraulic power packs).

2. Acceptance by authorised inspector, if required together with a fitter, if not included in offer.

3. Additional corrosion protection, if required by architect/customer.

4. If required to allow lifting a car on the upper parking space, railings or a carport have to be installed

on top.

5. Because of their weight pillars cannot be mounted by hand. The customer has to provide a crane free of

charge (hook clearance min. 6 m above entrance level, for a maximum weight of 1,400 kg).

6. At the pit edge drainage channel embedded in the concrete with connection to the sewerage system.

7. For high-precipitation areas extra drainage channel outside around the pit.

8. Marking at pit edge, 10 cm wide and yellow-black according to ISO 3864, if required.

9. Drainage of the pits provided by customer.

10. Maintenance shaft with covering, ladder and entrance to the pit.

11. We recommend to provide a ventilation system to reduce humidity and condensation.

12. The flooring of the upper platform provided by customer requires an additional border of the pit.

13. The flooring of the upper platform provided by customer requires a sealing analog flat roof.

14. Concrete quality according to the static requirements of the building, but for the dowel fastening we

require a concrete quality of min. C20/25.

Enclosure: Surface protection 2017, Nr. C023-0028.

The manufacturer reserves the right to modify or alter above specifications.

WÖHR Autoparksysteme GmbH

Article No. C026-0135

As in 10.2017

You might also like

- Technical Annex No. 1Document13 pagesTechnical Annex No. 1Ermiza11No ratings yet

- Dealcorp CanadaDocument12 pagesDealcorp CanadaJesus DugarteNo ratings yet

- Class VT 642 Diesel Multiple Unit DESIRO: For German RailDocument4 pagesClass VT 642 Diesel Multiple Unit DESIRO: For German RailAlexandra Idmt100% (1)

- Technical Specs of LiftDocument4 pagesTechnical Specs of Liftsumit11235100% (2)

- 14 20 00 Elevators and Lifts (Savaria)Document29 pages14 20 00 Elevators and Lifts (Savaria)Bahaa RaslanNo ratings yet

- Manual GISDocument36 pagesManual GISDanil Pangestu ChandraNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationRaisa AviannyNo ratings yet

- 20m3 Plant Mobile Mixer With Skip 2014Document8 pages20m3 Plant Mobile Mixer With Skip 2014Nguyen Trong NghiaNo ratings yet

- Asphalt PlantDocument6 pagesAsphalt Plantdesibaba_mamaNo ratings yet

- Levelling, Lining and Tamping MachinesDocument6 pagesLevelling, Lining and Tamping MachinesAnonymous Byopfd100% (2)

- C42 Specifications For Heavy Duty Self Propelled, 6000Tph Rotary Snow Blower ScopeDocument9 pagesC42 Specifications For Heavy Duty Self Propelled, 6000Tph Rotary Snow Blower Scopejony perzNo ratings yet

- Lost Foam Foundry SystemDocument28 pagesLost Foam Foundry SystemDeepak Khanna100% (1)

- Specification For 2000Hp Ac Draw Works, Drives and Controls: QTY Description 1 E-2000 DrawworksDocument22 pagesSpecification For 2000Hp Ac Draw Works, Drives and Controls: QTY Description 1 E-2000 DrawworksSunil GandhiNo ratings yet

- Carte Tehnica Masina de Spalat HM270-670 en NEWDocument53 pagesCarte Tehnica Masina de Spalat HM270-670 en NEWniki2530No ratings yet

- Eaton: New Reel Feeder VersionDocument4 pagesEaton: New Reel Feeder VersionRazvan PredaNo ratings yet

- Section 16600 - Emergency Generator Systems: Part 1 - General Related SectionsDocument4 pagesSection 16600 - Emergency Generator Systems: Part 1 - General Related SectionsDony RamdhaniNo ratings yet

- 15m TugboatDocument8 pages15m TugboatnavalarchmarineNo ratings yet

- Ukprod OverviewDocument8 pagesUkprod Overviewabuzer1981No ratings yet

- Mobile Crusher 900x600Document7 pagesMobile Crusher 900x600macross086100% (7)

- 16480Document5 pages16480Ahmed AliNo ratings yet

- Aplus CompactorDocument8 pagesAplus CompactorAlex ChewNo ratings yet

- Technical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Document11 pagesTechnical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Naushad WadiaNo ratings yet

- Shelter Quick Installation Guide For HuaweiDocument25 pagesShelter Quick Installation Guide For HuaweiFrancisco Salvador MondlaneNo ratings yet

- Technical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Document23 pagesTechnical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Naushad WadiaNo ratings yet

- LULA SpecsDocument2 pagesLULA Specsbena1No ratings yet

- Electric Submersible Sewage PumpsDocument8 pagesElectric Submersible Sewage PumpsMiroslavCrnogoracNo ratings yet

- Automatic Raising BollardsDocument26 pagesAutomatic Raising BollardsK SubramaniNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaNo ratings yet

- 48kl Tank Semi TrailerDocument7 pages48kl Tank Semi Trailerali hassanNo ratings yet

- The Requirements of The Contract, Division 1, and Division 16 Apply To Work in This SectionDocument11 pagesThe Requirements of The Contract, Division 1, and Division 16 Apply To Work in This SectionYousif_AbdalhalimNo ratings yet

- Als-F Iom 510 C - 07-02 e - enDocument48 pagesAls-F Iom 510 C - 07-02 e - enRomeo PunkerNo ratings yet

- ABG Titan 325 EPM 21 28 0199-30-xxxxDocument12 pagesABG Titan 325 EPM 21 28 0199-30-xxxxGabriel Cizmarita50% (2)

- Heli Rig-21Document14 pagesHeli Rig-21baanglore345100% (1)

- Dependent Parking For Permanent User Only! : Function Width DimensionsDocument2 pagesDependent Parking For Permanent User Only! : Function Width DimensionsEduardo PujolNo ratings yet

- TECHNICAL LITERATURE. Al Ain HospitalDocument12 pagesTECHNICAL LITERATURE. Al Ain HospitalManaging PartnerNo ratings yet

- Optima SecurityDocument28 pagesOptima SecurityNaveed Shaheen0% (1)

- Master Specifications Vehicle LiftsDocument14 pagesMaster Specifications Vehicle LiftskarliftsolutionNo ratings yet

- Sewer Lift StationDocument15 pagesSewer Lift StationFrancisco M. RamosNo ratings yet

- Platform M33Document25 pagesPlatform M33alex2gustavo2cuevas2No ratings yet

- Silo-Truck Technical Specifications For IsraelDocument4 pagesSilo-Truck Technical Specifications For IsraelDaniela AndronacheNo ratings yet

- Spraymec 8100 VC 100075480Document12 pagesSpraymec 8100 VC 100075480Hamid CRNo ratings yet

- Kessel 010 773 Ken23 - 2Document36 pagesKessel 010 773 Ken23 - 2sb_stefanNo ratings yet

- ALIMAK SC45-30 - Technical Description - Construction HoistDocument60 pagesALIMAK SC45-30 - Technical Description - Construction HoistErick Adrian Quintero Jaramillo67% (3)

- FinkbeinerDocument38 pagesFinkbeinermordidomiNo ratings yet

- Iso 5199Document21 pagesIso 5199pankajNo ratings yet

- Specification of Chilled Water PumpsDocument8 pagesSpecification of Chilled Water PumpsssarangNo ratings yet

- 16482Document21 pages16482Andy WijayaNo ratings yet

- Capacitor BANKDocument15 pagesCapacitor BANKalokedas11100% (1)

- QY50K Truck Crane Technical SpecificationDocument9 pagesQY50K Truck Crane Technical Specificationkim alfonsoNo ratings yet

- PANEADocument20 pagesPANEAAndrey TazNo ratings yet

- Trash Rack Cleaning MachineDocument9 pagesTrash Rack Cleaning Machinepradip panthaNo ratings yet

- Offer Technical SpecificationDocument5 pagesOffer Technical SpecificationErmiza11No ratings yet

- Daikim PDFDocument9 pagesDaikim PDFBvitalizeNo ratings yet

- Typ34-G enDocument67 pagesTyp34-G enprojetos_automacao_industrial2733No ratings yet

- Standard Erection Manual (Boiler Auxiliaries) PDFDocument222 pagesStandard Erection Manual (Boiler Auxiliaries) PDFharpreetresearchNo ratings yet

- At B SystemsDocument2 pagesAt B SystemsUmmes AhmedNo ratings yet

- t000002656 - Filename2 - FLNG Machin Specs - 30.8 PackDocument17 pagest000002656 - Filename2 - FLNG Machin Specs - 30.8 PackhadiNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Install Shematic 3300 APDocument4 pagesInstall Shematic 3300 APthanggimme.phanNo ratings yet

- Fujitec CP40Document43 pagesFujitec CP40thanggimme.phanNo ratings yet

- Cap Connect PC DB9 FDocument1 pageCap Connect PC DB9 Fthanggimme.phanNo ratings yet

- US5250765Document13 pagesUS5250765thanggimme.phanNo ratings yet

- Us 5063337Document7 pagesUs 5063337thanggimme.phanNo ratings yet

- Fuji Inverter ManualDocument103 pagesFuji Inverter Manualthanggimme.phanNo ratings yet

- US5274312Document11 pagesUS5274312thanggimme.phanNo ratings yet

- Ban Ve Dien Thang Huyndai WC VF (Old Type)Document22 pagesBan Ve Dien Thang Huyndai WC VF (Old Type)thanggimme.phanNo ratings yet

- US4832158Document24 pagesUS4832158thanggimme.phanNo ratings yet

- Compact Fans For AC and DC 2016 01 BENDocument272 pagesCompact Fans For AC and DC 2016 01 BENthanggimme.phanNo ratings yet

- Drako Lube enDocument11 pagesDrako Lube enthanggimme.phanNo ratings yet

- Description of Common Fault Codes For Fujitec CP28 Controller Elevator p2Document3 pagesDescription of Common Fault Codes For Fujitec CP28 Controller Elevator p2thanggimme.phanNo ratings yet

- Drako Fluid SF 10 enDocument11 pagesDrako Fluid SF 10 enthanggimme.phanNo ratings yet

- Lifts, Escalators and Moving Walks Part 5: Escalators and Moving WalksDocument8 pagesLifts, Escalators and Moving Walks Part 5: Escalators and Moving Walksthanggimme.phanNo ratings yet

- Câ U Hi'nh Thang Ma y MonarchDocument1 pageCâ U Hi'nh Thang Ma y Monarchthanggimme.phanNo ratings yet

- Door Gibs: Size and Number DescriptionDocument1 pageDoor Gibs: Size and Number Descriptionthanggimme.phanNo ratings yet

- Faxi120c Belt MachineDocument2 pagesFaxi120c Belt Machinethanggimme.phanNo ratings yet

- TAKO Troubleshooting and IO Board Diagnostic InstructionsDocument5 pagesTAKO Troubleshooting and IO Board Diagnostic Instructionsthanggimme.phanNo ratings yet

- Khe H An Toàn Cho ESC GB 16899-2011 (China) Trans EnglishDocument10 pagesKhe H An Toàn Cho ESC GB 16899-2011 (China) Trans Englishthanggimme.phanNo ratings yet

- Err Management 3VFMAC MP Có Phòng MáyDocument3 pagesErr Management 3VFMAC MP Có Phòng Máythanggimme.phanNo ratings yet

- OMRON FV Interflite OL ManualDocument33 pagesOMRON FV Interflite OL Manualthanggimme.phanNo ratings yet

- Dematron 60 70 Parlour Sheet 1.03Document1 pageDematron 60 70 Parlour Sheet 1.03Andrés HurtadoNo ratings yet

- Data Structures and Problem Solving Using JavaDocument20 pagesData Structures and Problem Solving Using JavaBrent Xavier AgnoNo ratings yet

- Factura/Invoice: Et 1, Cernavoda, ConstantaDocument1 pageFactura/Invoice: Et 1, Cernavoda, ConstantaMadalina TibaNo ratings yet

- Tariq Ali 1Document62 pagesTariq Ali 1Hafeezullah ShareefNo ratings yet

- Your Paragraph TextDocument11 pagesYour Paragraph TextTalha AamirNo ratings yet

- S. P. Rosenbaum (Auth.) - Edwardian Bloomsbury - The Early Literary History of The Bloomsbury Group Volume 2-Palgrave Macmillan UK (1994)Document573 pagesS. P. Rosenbaum (Auth.) - Edwardian Bloomsbury - The Early Literary History of The Bloomsbury Group Volume 2-Palgrave Macmillan UK (1994)HilmiNo ratings yet

- Energy Sector Capacity Building Diagnostic and Needs Assessment StudyDocument150 pagesEnergy Sector Capacity Building Diagnostic and Needs Assessment StudyAyoub EnergieNo ratings yet

- Holes by Louis Sachar: Guided Reading Questions, Vocabulary, and Task Sheets by Heather BlackburnDocument22 pagesHoles by Louis Sachar: Guided Reading Questions, Vocabulary, and Task Sheets by Heather BlackburnSonia ChowdhariNo ratings yet

- Teaching & Learning Activities: Biology (Sb015) - PelajarDocument2 pagesTeaching & Learning Activities: Biology (Sb015) - PelajarLeevandraaNo ratings yet

- Dzone Refcard 292 Advanced Kubernetes 2020 PDFDocument9 pagesDzone Refcard 292 Advanced Kubernetes 2020 PDFLeonardo Moreno ForeroNo ratings yet

- Tomato BankDocument67 pagesTomato Bankkmusatheek musatheekNo ratings yet

- Sheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNDocument4 pagesSheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNrowaida elsayedNo ratings yet

- MILLER Testable ConceptsDocument109 pagesMILLER Testable ConceptsMohammedGooda100% (1)

- Strategic Cost ManagementDocument12 pagesStrategic Cost ManagementvionysusgoghNo ratings yet

- RoE - T9 & T10 Research v.2Document1 pageRoE - T9 & T10 Research v.2Susa Na100% (1)

- NEB Syllabus For Class 12 Science PhysicsDocument4 pagesNEB Syllabus For Class 12 Science Physicskumar HarshNo ratings yet

- Essay 1 DraftDocument1 pageEssay 1 Draftgdx3100% (3)

- Arch MLCDocument471 pagesArch MLCJoseNo ratings yet

- Cot On Theoretical and Experimental ProbabilityDocument8 pagesCot On Theoretical and Experimental ProbabilityNoemie BautistaNo ratings yet

- 360 Peoplesoft Interview QuestionsDocument10 pages360 Peoplesoft Interview QuestionsRaghu Nandepu100% (1)

- Clarion CX Basics FundamentalsDocument15 pagesClarion CX Basics FundamentalsRajesh VenkatNo ratings yet

- PF2 S02-10 in Burning DawnDocument31 pagesPF2 S02-10 in Burning Dawnxajos85812No ratings yet

- How Fractions, Decimals and Percentages Work TogetherDocument9 pagesHow Fractions, Decimals and Percentages Work TogetherjohnteecubeNo ratings yet

- Seminar ReportDocument25 pagesSeminar ReportChethan kumar D NNo ratings yet

- Banasthali Vidyapith: Bachelor of Arts and Bachelor of LawsDocument172 pagesBanasthali Vidyapith: Bachelor of Arts and Bachelor of Lawssimranrai122002No ratings yet

- English Compulsory (1) PrintDocument15 pagesEnglish Compulsory (1) PrintZakir KhanNo ratings yet

- E Dies Astm d5963 CuttingdiesDocument1 pageE Dies Astm d5963 CuttingdiesNate MercerNo ratings yet

- Alessandro Albanese - All Season CollectionDocument29 pagesAlessandro Albanese - All Season CollectionWilliam BourneNo ratings yet

- EacdocDocument84 pagesEacdocJohanMonNo ratings yet

- ConclusionDocument1 pageConclusionArun GuptaNo ratings yet