Professional Documents

Culture Documents

A20J120614 Valuable Customer 0

A20J120614 Valuable Customer 0

Uploaded by

Chandra Hermanto SinagaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A20J120614 Valuable Customer 0

A20J120614 Valuable Customer 0

Uploaded by

Chandra Hermanto SinagaCopyright:

Available Formats

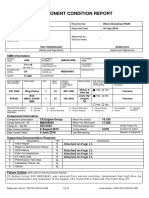

Scheduled Oil Sampling Report

PT. Trakindo Utama S•O•S Fluids Analysis Laboratory

JI. Cilandak KKO Raya No. 1, Jakarata 12560, PO Box 2282/JKT - Indonesia

Tel: (62-21) 7822373, Fax. (62-21) 7822357, 7822379

Customer Information Unit Information

SATRIA BAHANA SARANA PT. Category Oil Equip Make Komatsu Received Date: 10/12/2020 9:00:00AM

ATTN: Valuable Customer Lab No A20J120614 Equip Model GD825A-2 Reported Date: 10/12/2020 5:22:36PM

JURANG PARIGI DALAM NO. 05 RT 001 RW 004 Unit Number GD03-004 Location BANKO Sample Note

PASAR TANJUNG ENIM LAWANG KIDUL Equip Serial 13004 Jobsite 632574A - TANJUNG ENIM Evaluation Code B Monitor Compartment.

MUARA ENIM SUMATERA SELATAN, TANJUNG ENIM , Compartment Transmission-PS Job No

Sample Point Interpreted by: Interpreter / Danu Setiawan (A)

Label No 632574A

Phone

Element Reading (mg/kg = ppm) - ASTM D-5185

Lab No. Sample Date Eval CMU SMU HOO Oil Added Fluid Filter Oil Type Oil Grade

Wear Metal Contaminant Additives

Date Process Chg Chg

Cr Pb Fe Cu Al Sn Ni Si K Na B Ca P Zn Mg Mo

12/Oct/20 B 14513 513 0 N TRANSLIK HD SAE 30 0 0 7 2 2 0 0 4 0 4 3 3477 881 1026 12 20

A20J120614 29/Sep/20

20/Aug/20 B 14022 1022 0 Y TRANSLIK HD SAE 30 0 0 5 1 2 0 0 3 0 0 3 3356 646 758 12 32

A20H211117 10/Aug/20

04/Jul/20 B 13558 558 0 N TRANSLIK HD SAE 30 0 0 5 2 1 0 0 3 1 3 1 2823 962 1193 10 0

A20G060208 26/Jun/20

Element Reading (mg/kg = ppm) Oil Condition (JOAP) ASTM E2412 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464

Lab No Ba * Ti * Ag * V* ST OXI NIT SUL FP (P/N) DF (%) * V100 V40 VI * TBN TAN * W (P/N) * W(%) PQ * Visual * PC 04 * PC 06 PC 14 ISO 04* ISO 06 ISO 14

(cSt) * (cSt) * (idx)

A20J120614 11.4 N 4.0 - 29635 496 22 16

A20H211117 11.1 N 3.0 - 6735 51 20 13

A20G060208 11.0 N 5.0 - 6841 122 20 14

Lab No. Tendency (5' Tendency (5' Tendency (5' Stability (10' Stability (10' Stability (10' Milipore Sludge

aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * Test *

A20J120614

A20H211117

A20G060208

Recommendation ** Rekomendasi **

THE ISO CODE HIGHER THAN CLEAN LINES RANGE. (CLEANLINESS TARGETS = 18/15). OTHER READINGS ARE ACCEPTABLE. ISO CODE LEBIH TINGGI DARI TARGET TINGKAT KEBERSIHAN. (TARGET TINGKAT KEBERSIHAN = 18/15). ELEMEN LAINNYA DALAM

CHECK OIL LEVEL, BREATHER, SEALS/ GASKET FAILURE. TAKE OIL SAMPLES AT 250 HOUR INTERVALS TO MONITOR CONDITION. BATAS NORMAL. PERIKSA LEVEL OLI, BREATHERS, KERUSAKAN SEALS/GASKET. AMBIL SAMPEL OLI PADA INTERVAL 250 JAM UNTUK

MEMONITOR KONDISI.

This analysis provided is indicative of conditions based upon sample information received and the quality of sample supplied. Any decision relating to repair of components is entirely at the descretion of the customer.

A20J120614 Page 1 of 2

* Not Include on scope of Accreditation

** The evaluation / Recommendation made by Equipment Management PT. Trakindo Utama

Glossaries

Elements P=Phosphorus (LoD=0.74) Water Criteria ISO6=ISO Code 6 V100=Viscosity 100°C (WIN.MP.05)

Si-Silicon (LoD=0.26) B=Boron (LoD=0.40) W=Water - ASTM D 4928 / ASTM D 4377 ISO14=ISO Code 14 V40=Viscosity 40°C - ASTM D445

AI=Aluminum (LoD=0.12) Mo=Molybdenum (LoD=0.20) % =Percentage Oil Condition cSt=Centistokes

Cr=Chromium (LoD=0.12) Zn=Zinc (LoD=0.17) N=Negative ST=Soot DF(%) - ASTM D 3524

Fe=Iron (LoD=0.11) Ti=Titanium P=Positive (0.5 - 0.8%) OXI=Oxidation Visual

Pb=Lead (LoD=0.82) V=Vanadium T=Trace (Cloudy but < 0.5%) NIT=Nitration LQ = Low Quantity

Cu=Copper (LoD=0.01) Ag=Silver E=Excessive (> 0.8%) SUL=Sulfation MQ = Medium Quantity

Sn=Tin (LoD=0.25) Note: Results = 0 < LoD (Limit of Detection) Particle Count Physical / Chemical HQ = High Quantity

Ni=Nickel (LoD=0.38) ppm=Parts Per Million (ASTM D 4464 & ASTM D 7596) PQ=Particle Quantifier (Idx=Index) Met = Metallic

Mg=Magnesium (LoD=0.01) FP Criteria PC04=Particle Count at 4 micron TBN=Total Base Number - ASTM D 4739 Non Met = Non Metallic

Ca=Calcium (LoD=0.05) FP=Flash Point (ASTM D 3828 - Method A) PC06=Particle Count at 6 micron (mg KOH /g) F = Fine

K=Potassium (LoD=0.64) P=Positive PC14=Particle Count at 14 micron TAN=Total Acid Number - ASTM D 664 C = Coarse

Na=Sodium (LoD=0.42) N=Negative ISO4=ISO Code 4 (mg KOH /g) Granul = Granular

General Analysis Guide ***

Primary Element Secondary Element Potential Wear Problem area & causes Primary Element Secondary Element Potential Wear Problem area & causes

Si Al Piston, Rings, Liner Air induction, breathers, dirt. Cr Mo Piston ring Blow by, oil consumption

Liner, piston, valve, gear Dirt, abnormal temperature, lack of lubricant, Na Si, B Cooling system Water Pump, Cyl Head, Liner seal, Oil Cooler,

Fe - Anti Freeze

train, crankshaft storage (rust)

Al Cr Piston & Rings Blow-by

Pb, Sn Cu, Al Bearing Dirt contamination, lack of lubricant.

Fe Cr Piston ring Abnormal operating temperature

Al or Cu Sn, Pb Bearing Low or fluctuating oil pressure. Fe Al Liner Restricted air induction system

*** THIS CHARTS ARE FOR GENERAL USE ONLY, AND DO NOT INDICATE DEFINITE LIMITS OF WEAR METALS FOR ANY SPECIFIC MAKE OR MODEL.

TABEL INI HANYA DIGUNAKAN UNTUK ANALISIS SECARA UMUM DAN TIDAK MENGINDIKASIKAN SUATU BATASAN UNTUK MODEL DAN MEREK TERTENTU

KINDLY ADVISED YOU TO CONTACT US PRIOR 7 DAYS AFTER REPORT RELEASE SHOULD YOU NEED FURTHER DISCUSSION ABOUT THIS SAMPLE.

DISARANKAN AGAR DISKUSI LEBIH LANJUT MENGENAI SAMPLE INI HARUS DILAKUKAN SEBELUM 7 HARI DARI TANGGAL LAPORAN DI TERBITKAN

Wear Metal Contaminant Viscosity

7 4 12

3.5

6 10

3

5

8

2.5

4 Al

Cr K

Fe 2 Na 6 V100

Pb Si

3 PQ

1.5

4

2

1

2

1 0.5

0 0 0

9/29/2020 8/10/2020 6/26/2020 9/29/2020 8/10/2020 6/26/2020 9/29/2020 8/10/2020 6/26/2020 Approved by

Mukhlisin

Manager S•O•S Laboratory

A20J120614 Page 2 of 2

You might also like

- Bengt Broms - Foundation EngineeringDocument262 pagesBengt Broms - Foundation EngineeringAnonymous lMTMFfmPl80% (10)

- Pipe Material Pricing - ChrisDocument21 pagesPipe Material Pricing - ChrisMichael HaiseNo ratings yet

- B Sa-435Document2 pagesB Sa-435Antonio GutierrezNo ratings yet

- Type: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Document194 pagesType: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Víctor MatíasNo ratings yet

- School Building Analysis Report Final RebuildDocument51 pagesSchool Building Analysis Report Final RebuildNabin Acharya100% (1)

- Vegetable Stone - Tincture MethodDocument1 pageVegetable Stone - Tincture MethodMrMantura100% (1)

- Executive Order No. 002 Creating BeswmcDocument2 pagesExecutive Order No. 002 Creating Beswmc잔돈100% (2)

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Refining Crude OilDocument24 pagesRefining Crude OilalagurmNo ratings yet

- EB-Paper and Pulp ManualDocument108 pagesEB-Paper and Pulp Manualsanjeevvange100% (1)

- Aluminium's Corrosion Resistance - Aluminium DesignDocument7 pagesAluminium's Corrosion Resistance - Aluminium DesignCarlos LuNo ratings yet

- Compressor DataDocument2 pagesCompressor DataShirazUddinSiddiqueNo ratings yet

- Ms 522 Part 12003 Portland Cement (Ordinary and Rapid-Hardening) Part 1 Specification (Second Revision) - 709539Document26 pagesMs 522 Part 12003 Portland Cement (Ordinary and Rapid-Hardening) Part 1 Specification (Second Revision) - 709539Deraman Abdullah100% (5)

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaNo ratings yet

- A20J120618 Valuable Customer 0Document2 pagesA20J120618 Valuable Customer 0Chandra Hermanto SinagaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTONo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNo ratings yet

- B14A243506 - Hanurata Ahmad Zarkasi (A) - 0Document1 pageB14A243506 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Purchase Request: Qualitycontrol DepartmentDocument2 pagesPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNo ratings yet

- Welding Daily ReportDocument2 pagesWelding Daily ReporthseptpspNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- CCR JN 5646488-Sis-C9 Engine en Mbd09063-High BlowbyDocument15 pagesCCR JN 5646488-Sis-C9 Engine en Mbd09063-High Blowbyahmat ramadaniNo ratings yet

- CCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Document12 pagesCCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Sidik NopiansyahNo ratings yet

- Modified BitumensDocument6 pagesModified BitumensDonNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Purchase Request: Qualitycontrol DepartmentDocument2 pagesPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNo ratings yet

- 55.JSS GOH PC850-8R1 Ulimanitra 10 Desember 2022Document21 pages55.JSS GOH PC850-8R1 Ulimanitra 10 Desember 2022doni granadaNo ratings yet

- Al Muaser Petroleum Services PVT LTD Client/Consultant: Indian Oil Corporation Limited Kaspl Pipeline Project Incoming Material Inspection ReportDocument1 pageAl Muaser Petroleum Services PVT LTD Client/Consultant: Indian Oil Corporation Limited Kaspl Pipeline Project Incoming Material Inspection ReportsojeckNo ratings yet

- Hyderabad Investment - Machinery Valuation 05092018Document5 pagesHyderabad Investment - Machinery Valuation 05092018R SwethaNo ratings yet

- Preliminary 00122.00023 Pt. Semesta Alam BaritoDocument2 pagesPreliminary 00122.00023 Pt. Semesta Alam BaritoBayu Araruna NangasNo ratings yet

- Document Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. NumberDocument4 pagesDocument Title: Revision: Vendor Rev.: Facility Identifier: Discipline: Document Type: Project Doc. Number: Vendor Doc. Numberrajindo1No ratings yet

- Reference: Selection No# C25943: EP R 2EB 030A 10,2Y S100M1 F10e I75x550 B51Document5 pagesReference: Selection No# C25943: EP R 2EB 030A 10,2Y S100M1 F10e I75x550 B51Ян Харлакевич 5172мNo ratings yet

- 1714 MirDocument1 page1714 MirIftekhar AhmedNo ratings yet

- T7888 FR DPS So#41715258Document1 pageT7888 FR DPS So#41715258alwanbagasNo ratings yet

- Scheduled Oil Sampling Report: Eval CodeDocument1 pageScheduled Oil Sampling Report: Eval CodePutra JawaNo ratings yet

- Hook BlockDocument1 pageHook BlockAbinash NeupaneNo ratings yet

- 01 EngineCheckReport802Document5 pages01 EngineCheckReport802phutthawongdanchai041215No ratings yet

- A545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple TagsDocument3 pagesA545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple Tagsmahesh.easwaran3609No ratings yet

- Quotation / Proforma InvoiceDocument1 pageQuotation / Proforma InvoiceSubham DasNo ratings yet

- Les Codes D'erreur (SNCFT) Error Codes From Page 8Document58 pagesLes Codes D'erreur (SNCFT) Error Codes From Page 8youssefhs957No ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- 9562 109 Pve P 004 02Document71 pages9562 109 Pve P 004 02Hariprasath JayaprakashNo ratings yet

- Hoses - SRV - Air VesselDocument3 pagesHoses - SRV - Air VesselAjinkya PatilNo ratings yet

- Final - Pump - 5P0312ABCD - Antico - GAD - Code 1Document1 pageFinal - Pump - 5P0312ABCD - Antico - GAD - Code 1Rishabh Verma100% (1)

- Pulley IdlerDocument1 pagePulley IdlerLazzarus Az GunawanNo ratings yet

- Industrial: Severity UrgentDocument2 pagesIndustrial: Severity UrgentNasser AyoubNo ratings yet

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Document1 pageB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNo ratings yet

- Battery Manufacturers Print-5Document1 pageBattery Manufacturers Print-5nbhushan001No ratings yet

- 33Document2 pages33wwwsfssssrNo ratings yet

- Mpi Lube Tank 6000l 05Document3 pagesMpi Lube Tank 6000l 05Peter StanleyNo ratings yet

- D146010587 8998960721254007 SchedulescDocument2 pagesD146010587 8998960721254007 SchedulescShubham JoshiNo ratings yet

- Tools / Equipment Inventory List: Non Metallic Maintenance Works ScopeDocument1 pageTools / Equipment Inventory List: Non Metallic Maintenance Works ScopeJoseph PerezNo ratings yet

- Motor Data Sheet (32-Hal-201ab)Document5 pagesMotor Data Sheet (32-Hal-201ab)Ahmad FaujiNo ratings yet

- Final: Equipment Sectional Drawing With Part ListDocument23 pagesFinal: Equipment Sectional Drawing With Part ListInsertec LtdaNo ratings yet

- PT Petrolab Services: Grease Analysis ReportDocument1 pagePT Petrolab Services: Grease Analysis Reportvictor josuaNo ratings yet

- 7test Report of Petroleum Coke Dated 13.07.2020Document1 page7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalNo ratings yet

- KLJ Hdpe BK 9606 Arat AratDocument1 pageKLJ Hdpe BK 9606 Arat AratDinesh SinghNo ratings yet

- Plate - ADocument9 pagesPlate - ASumit SinghNo ratings yet

- Vessel's Info Form - BunkerDocument2 pagesVessel's Info Form - BunkerFilip NikolevskiNo ratings yet

- Inventory Akhir: Engine Model: Rr250-C20B Inventory DateDocument5 pagesInventory Akhir: Engine Model: Rr250-C20B Inventory DateMilhan InsaniNo ratings yet

- Createds PDFDocument1 pageCreateds PDFAkshay0% (1)

- PT. Tekenomiks IndonesiaDocument4 pagesPT. Tekenomiks IndonesiaAhmat RamadaniNo ratings yet

- Activated Sludge ProcessDocument48 pagesActivated Sludge Processrozma khanNo ratings yet

- Prof. Dr. Saeed AhmadDocument10 pagesProf. Dr. Saeed AhmadEngr.Hamid Ismail CheemaNo ratings yet

- DSMTS-0032.5 FeCr StainlessSteel WireDocument4 pagesDSMTS-0032.5 FeCr StainlessSteel WireJesus D. Gutierrez G.No ratings yet

- Air CasterDocument5 pagesAir CasterNitin Tembhurnikar0% (1)

- D-70 Cupronickel Rev 06Document3 pagesD-70 Cupronickel Rev 06Luis Gustavo AndradeNo ratings yet

- Name: Nur Huda Binti Hamzah Registration Number: 08Dkm19F1063 Class: Dkm5BDocument5 pagesName: Nur Huda Binti Hamzah Registration Number: 08Dkm19F1063 Class: Dkm5BSyahzlan IskandarNo ratings yet

- Earthen Pond Fish FarmingDocument9 pagesEarthen Pond Fish FarmingkatyNo ratings yet

- Denture Cleanser & Denture Adhesive: BY, R.VenkateshwaranDocument77 pagesDenture Cleanser & Denture Adhesive: BY, R.VenkateshwaranrayaimNo ratings yet

- Telecommunications Construction Guide Specification: Telecommunications Infrastructure Standards - Revision 3Document134 pagesTelecommunications Construction Guide Specification: Telecommunications Infrastructure Standards - Revision 3Girma teferaNo ratings yet

- JNE1N3Document236 pagesJNE1N3michaelstarr1969No ratings yet

- Cchemistry Practical Scribd Sux CoxDocument307 pagesCchemistry Practical Scribd Sux CoxTheSocializer WazzupNo ratings yet

- Kertas 1 Pat 2023Document15 pagesKertas 1 Pat 2023Nazirah binti HarunNo ratings yet

- Trans-Blot Turbo Quick Start GuideDocument2 pagesTrans-Blot Turbo Quick Start GuideDi XiaNo ratings yet

- Soft Chemical Routes For Synthesis of Nanomaterials: A. K. TyagiDocument51 pagesSoft Chemical Routes For Synthesis of Nanomaterials: A. K. Tyagibalachandar r kNo ratings yet

- 3.6 Leakage Current On Non Ceramic InsulatorsDocument5 pages3.6 Leakage Current On Non Ceramic Insulatorsyudd hiNo ratings yet

- Cyclic CO2 Chemisorption Desorption Behavior of Na2ZrO3, Structural, Microstructural and Kinetic Variations Produced As A Function of TemperatureDocument7 pagesCyclic CO2 Chemisorption Desorption Behavior of Na2ZrO3, Structural, Microstructural and Kinetic Variations Produced As A Function of TemperatureserchNo ratings yet

- Experiment 3 - Thermal ConductivityDocument9 pagesExperiment 3 - Thermal ConductivitySaniha Aysha AjithNo ratings yet

- Teclumos Light Glass SKD PDocument2 pagesTeclumos Light Glass SKD PKasraNo ratings yet

- Gas-Vapor Mixtures and Air-Conditioning Study Guide in PowerpointDocument37 pagesGas-Vapor Mixtures and Air-Conditioning Study Guide in PowerpointHoussein AmmarNo ratings yet

- Lyle 2022 J. Electrochem. Soc. 169 060527Document9 pagesLyle 2022 J. Electrochem. Soc. 169 060527Emre KAÇANERNo ratings yet