Professional Documents

Culture Documents

List Learned - T.L.E. 10 2018-2019

List Learned - T.L.E. 10 2018-2019

Uploaded by

Ronel SuanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

List Learned - T.L.E. 10 2018-2019

List Learned - T.L.E. 10 2018-2019

Uploaded by

Ronel SuanCopyright:

Available Formats

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

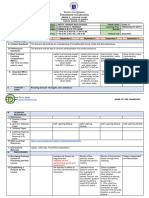

Learning Area: T.L.E.10-SMAW Grading Period: First Quarter SY: 2018 – 2019

Item % of Correct Test Item LC Tested

No. Responses

7 0% ________7. Some people trust in one’s ability. What PECs refers to___?

a. Self-confidence c. talented Personal

b. skillful d. committed Entrepreneurial

Competencies

43 17% ______43. This symbol is a supplementary symbol indicated by a circle at

the intersection of the arrow and reference line, which specifies that the Personal

weld extends completely around the joint. Entrepreneurial

a. Weld-all-around b. fillet weld c. intermittent fillet weld Competencies

d. Staggered intermittent fillet weld

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

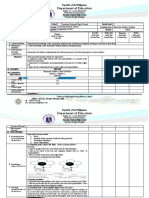

Learning Area: SMAW GRADE-10 Grading Period: Third Quarter SY: 2018 – 2019

Item % of Correct Test Item LC Tested

No. Responses

11. 37% ________11. Where the weld fractures or breaks apart. A

good example would be welding on cast iron. If it is not Identifying Weld Defects &

pre-heated and post-heated right, or if the wrong electrode Causes

is used.

a. Crack c. Convexity

b. Corner joint d. concavity

21. 49% _________21. This refers to the process in which welding time

and heat to the joint will increase. It can result in increased costs, Essentials of Welding

heat affected zone, cracking or distortion.

a. Larger electrode c. small electrode

b. current d. travel speed

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher I

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

Learning Area: SMAW GRADE-11 T.V.L. Grading Period: Second Quarter SY: 2017 – 2018

Item % of Correct Test Item LC Tested

No. Responses

30. 35% ______30. This is when the base metal transitions from solidus

to liquids as you heat it during the welding process. It's right at Welding Carbon Steel Plates

that point where it goes from being solid mass, to melting and in Horizontal Position

becoming liquid.

a. Crater

b. Critical temperature

c. Current

d. cylinder

49. 38% _________49. This is the only condition a welder may need to

change. Because of this, impurities and gases can become Essentials of Welding

entrapped, making the bead face narrow with pointing ripple.

Incomplete penetration due to loss of the keyhole in root pass is

possible.

a. Larger electrode

b. Current

c. Small electrode

d. Travel speed

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

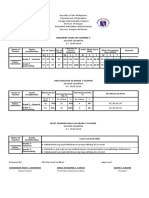

Learning Area: SMAW GRADE-11 T.V.L. Grading Period: Third Quarter SY: 2017 – 2018

Item % of Correct Test Item LC Tested

No. Responses

9. 36% _____9. This joint is used for heavy plate thickness up to

25.40mm. Welding is done from both sides of the plate. It is Different Types of Joints

used for severe loads. Good root penetration is necessary. Joint

preparation is expensive.

a. Single J tee joint

b. Single bevel tee joint

c. Plain tee joint

d. Double bevel tee

20. 43% _____20. It is the distance from the fusion face to the weld

interface. Parts of Fillet Weld

a. Weld interface

b. Depth of Fusion

c. Fusion face

d. Actual throat

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

Learning Area: SMAW GRADE-11 T.V.L. Grading Period: Fourth Quarter SY: 2017 – 2018

Item % of Correct Test Item LC Tested

No. Responses

1. 7% _____1. This refers to the process in which welding time and

heat to the joint will increase. It can result in increased costs, Essentials of Welding

heat affected zone, cracking or distortion.

a. Larger electrode

b. current

c. small electrode

d. travel speed

15. 21% ______15. When electrode coating absorbs moisture, what will

be the effect to the weld bead? Identifying weld defects &

a. poor penetration causes

b. porosities

c. excessive penetration

d. undercut

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

Learning Area: SMAW GRADE-12 T.V.L. Grading Period:First Quarter SY: 2017 – 2018

Item % of Correct Test Item LC Tested

No. Responses

12. 20% ________12. A Current that regularly reverses the direction of

its flow. It is best to use AC for SMAW when welding larger work Welding Set-up

pieces with larger electrodes. Current Set-up

a. Alloy

b. Alternating Current

c. Aluminum

d. Amperage

14. 30% ________14. The amount of current flowing in a circuit. SMAW

uses 10 to 500 amps. Welding Set-up

a. Alloy Current Setting

b. Alternating Current

c. Aluminum

d. Amperage

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Checked & Approved:

LUZ C. LONGOS

School Head

Head Teacher I

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

Learning Area: SMAW GRADE-12 T.V.L. Grading Period:Second Quarter SY: 2017 – 2018

Item % of Correct Test Item LC Tested

No. Responses

13. 40% ______13. This is the only condition a welder may need to

change. Because of this, impurities and gases can become Essentials of Welding

entrapped, making the bead face narrow with pointing ripple.

Incomplete penetration due to loss of the keyhole in root pass is

possible.

a. larger electrode

b. current

c. small electrode

d. travel speed

14. 20% ______14. This is a very important for weld puddle control that

this element will cause the deposit to be neat of even ripple and Essentials of Welding

of good penetration.

a. electrode size

b. current

c. work angle

d. arc length

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Checked & Approved:

LUZ C. LONGOS

School Head

Head Teacher I

Republic of the Philippines

Department of Education

Caraga Adminstrative Region

Division of Siargao

ROXAS NATIONAL HIGH SCHOOL

Roxas, San Isidro Surigao del Norte

LEAST LEARNED

Not Mastered 0-49%

Nearing Mastery 50-74%

Mastered 75-100%

Learning Area: SMAW GRADE-10. Grading Period: Fourth Quarter SY: 2018 – 2019

Item % of Correct Test Item LC Tested

No. Responses

11. 39% _______11. Where the weld fractures or breaks apart. A

good example would be welding on cast iron. If it is not Identifying Weld Defects

pre-heated and post-heated right, or if the wrong electrode

is used.

a. Crack b. Corner joint

c. Convexity d. concavity

13. 34% _________13. In which of the welding defects, which has

the causes of wrong speed, current improperly adjusted, Identifying weld defects &

faulty preparation, and improper electrode size? causes

a. Warping c. crack welds

b. undercutting d. poor fusion

Prepared by:

RONEL E. SUAN

Subject Teacher

Teacher III

Reviewed by: Noted:

RANDY A. RUDILA LUZ C. LONGOS

Master Teacher I School Head

Head Teacher

You might also like

- Oil and Gas AccountingDocument81 pagesOil and Gas Accountingmike8895100% (1)

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuNo ratings yet

- SMAW7 Mod1 Identify and Select Materials and Tools Version3Document33 pagesSMAW7 Mod1 Identify and Select Materials and Tools Version3Ronel Suan100% (1)

- Analytical Chem Notes For BST-1Document26 pagesAnalytical Chem Notes For BST-1Odongo TonnyNo ratings yet

- Visual Testing IN Asnt Level IiDocument49 pagesVisual Testing IN Asnt Level IiMAXX ENGINEERS100% (1)

- Wireline Logging IntroductionDocument83 pagesWireline Logging Introductionojrfgmrf100% (2)

- Asme Section II A Sa-193 Sa-193mDocument18 pagesAsme Section II A Sa-193 Sa-193mAnonymous GhPzn1xNo ratings yet

- Sulfonamides: AntibacterialsDocument21 pagesSulfonamides: AntibacterialsRiimsha AaymNo ratings yet

- 4a's Lesson Plan For Demo #1 2022-2023Document4 pages4a's Lesson Plan For Demo #1 2022-2023Ronel SuanNo ratings yet

- SMAW7 Q1 Mod8 Store-Tools V3Document21 pagesSMAW7 Q1 Mod8 Store-Tools V3Ronel Suan100% (3)

- Designerguide enDocument46 pagesDesignerguide endan20050505No ratings yet

- Chemistry ProjectDocument12 pagesChemistry ProjectAditya Kumar83% (12)

- SMAW7 Q1 Mod6 CheckFunct V3Document31 pagesSMAW7 Q1 Mod6 CheckFunct V3Ronel SuanNo ratings yet

- SMAW7 Mod2 Select Measuring Instruments Version3Document24 pagesSMAW7 Mod2 Select Measuring Instruments Version3Ronel SuanNo ratings yet

- TLEsmaw9 Q1 Mod2 Welding-Equipment v3Document39 pagesTLEsmaw9 Q1 Mod2 Welding-Equipment v3Ronel SuanNo ratings yet

- SMAW7 Mod1 Identify and Select Materials and Tools Version3Document35 pagesSMAW7 Mod1 Identify and Select Materials and Tools Version3Ronel Suan50% (2)

- Smaw7 q1 Mod9 Analyze Signs v3Document20 pagesSmaw7 q1 Mod9 Analyze Signs v3Ronel SuanNo ratings yet

- Investigatory Project Chapter 3Document8 pagesInvestigatory Project Chapter 3Ian Agatha AndresNo ratings yet

- SMAW7 Mod5 Control Hazards and Risks Version3Document29 pagesSMAW7 Mod5 Control Hazards and Risks Version3Ronel SuanNo ratings yet

- SMAW7 Mod3 CarryOut Measurements and Calculations Version3Document20 pagesSMAW7 Mod3 CarryOut Measurements and Calculations Version3Ronel SuanNo ratings yet

- Smaw7 q1 Mod7 Perform-Basic-Prev v3Document32 pagesSmaw7 q1 Mod7 Perform-Basic-Prev v3Ronel SuanNo ratings yet

- SMAW7 Mod4 Evaluate Hazards and Risks Version3Document30 pagesSMAW7 Mod4 Evaluate Hazards and Risks Version3Ronel Suan100% (2)

- List Learned - Copy 2015 2016Document15 pagesList Learned - Copy 2015 2016Ronel SuanNo ratings yet

- List Learned - T.L.E 8-2018-2019Document4 pagesList Learned - T.L.E 8-2018-2019Ronel SuanNo ratings yet

- List Learned - Esp 8 2018-2019Document4 pagesList Learned - Esp 8 2018-2019Ronel SuanNo ratings yet

- List Learned 2018-2019Document18 pagesList Learned 2018-2019Ronel SuanNo ratings yet

- Mplgrading Period Subject For SHSDocument23 pagesMplgrading Period Subject For SHSjeankayzelrodelasNo ratings yet

- Dll-Gen Math Q1Document10 pagesDll-Gen Math Q1Anjanette GuibijarNo ratings yet

- SF9 Updated BlankDocument6 pagesSF9 Updated BlankJoshua BarontoyNo ratings yet

- DLL Perdev q1 w1 Personal Development Quarter 1 Week 1Document6 pagesDLL Perdev q1 w1 Personal Development Quarter 1 Week 1maclarettejoy.pasionNo ratings yet

- 1st Quarter DLLDocument115 pages1st Quarter DLLAl Lhea Bandayanon MoralesNo ratings yet

- fORM 138 E For K 12 Curriculum School Report CardDocument5 pagesfORM 138 E For K 12 Curriculum School Report CardMark SalvadorNo ratings yet

- 3RsPlus - Learners Final AssessmentDocument4 pages3RsPlus - Learners Final AssessmentarrocantreNo ratings yet

- Mps in Elementary Mathematics: First QuarterDocument4 pagesMps in Elementary Mathematics: First QuarterNoel TorioNo ratings yet

- 3Rs Learners Weekly Progress ReportDocument3 pages3Rs Learners Weekly Progress ReportarrocantreNo ratings yet

- Homeroom Guidance 2022 Del PilarDocument2 pagesHomeroom Guidance 2022 Del PilarCristita Macaranas VigoNo ratings yet

- Division of Toledo City Division of Toledo CityDocument2 pagesDivision of Toledo City Division of Toledo CityJOHN RULF OMAYANNo ratings yet

- Work Immersion Evaluation ToolDocument1 pageWork Immersion Evaluation ToolWenelyn BautistaNo ratings yet

- DLL Perdev Q1 W1Document5 pagesDLL Perdev Q1 W1Nyco NoriegaNo ratings yet

- LRs INVENTORY REPORT (RBNHS)Document1 pageLRs INVENTORY REPORT (RBNHS)GelieNo ratings yet

- Mean Profile Diagnostic.Document78 pagesMean Profile Diagnostic.Riza Mae P. ChavezNo ratings yet

- MPS RejanoDocument1 pageMPS RejanoMARIANNE REJANONo ratings yet

- Sample of Weekly Plan For TeachersDocument53 pagesSample of Weekly Plan For TeachersleilaNo ratings yet

- Department of Education: Tumalim National High SchoolDocument5 pagesDepartment of Education: Tumalim National High SchoolSanta Esmeralda GuevaraNo ratings yet

- Report On Learner'S Observed Values Core Values Behavior Statements Quarters 1 2 3 4Document3 pagesReport On Learner'S Observed Values Core Values Behavior Statements Quarters 1 2 3 4Alojha Mae AbrenicaNo ratings yet

- Aral - Pan 8 MPSDocument4 pagesAral - Pan 8 MPSGenelyn GallardoNo ratings yet

- Department of Education: Shared ResponsibilitiesDocument4 pagesDepartment of Education: Shared ResponsibilitiesKrissia Lee Meneses BuñoNo ratings yet

- Grade Level Report Summary On The Results of The First Peridical Test.Document1 pageGrade Level Report Summary On The Results of The First Peridical Test.Danny LineNo ratings yet

- Report Card 1Document4 pagesReport Card 1Sheine Nasayao MatosNo ratings yet

- School Profile 2015Document24 pagesSchool Profile 2015Jan Jan HazeNo ratings yet

- Action Plan SampleDocument11 pagesAction Plan SampleKent Jeano AlboresNo ratings yet

- MPS Least LearnedDocument16 pagesMPS Least LearnedJey Ann P. PajaNo ratings yet

- K To 12 FORM 138 - Grade 1-2Document3 pagesK To 12 FORM 138 - Grade 1-2Joyce Anne DominoNo ratings yet

- BERAGODocument2 pagesBERAGOJacqueline RosalemNo ratings yet

- Blank - CID Initiated Monitoring and Tracking ToolDocument3 pagesBlank - CID Initiated Monitoring and Tracking ToolSherelle Lou de LeonNo ratings yet

- Deped Form 138: Mabinay District Ii Bagtic National High SchoolDocument5 pagesDeped Form 138: Mabinay District Ii Bagtic National High SchoolNouiea Bernardelle AcabalNo ratings yet

- Aurora Pioneers Memorial College: Report On AttendanceDocument4 pagesAurora Pioneers Memorial College: Report On AttendanceEva DE Pio SandeNo ratings yet

- DLL Perdev q1 w3Document8 pagesDLL Perdev q1 w3maclarettejoy.pasionNo ratings yet

- Students Weekly Monitoring Tool NikkiDocument15 pagesStudents Weekly Monitoring Tool NikkiNikki John BruzonNo ratings yet

- Budget of Work - Science 10Document236 pagesBudget of Work - Science 10Mary Angelie GreciaNo ratings yet

- Department of Education: Region II - Cagayan Valley Division of Cauayan CityDocument2 pagesDepartment of Education: Region II - Cagayan Valley Division of Cauayan CityAirishAinneNo ratings yet

- WHLP TemplateDocument2 pagesWHLP TemplateDe Leon AileneNo ratings yet

- ATABAYDocument1 pageATABAYgerlie cerbaniaNo ratings yet

- WEEKLY INTERVENTION AND REMEDIATION PLAN Aug. Sept. 5 9Document2 pagesWEEKLY INTERVENTION AND REMEDIATION PLAN Aug. Sept. 5 9Mj FernandezNo ratings yet

- Action Plan - AbakadaDocument2 pagesAction Plan - AbakadaChyla BiscochoNo ratings yet

- Intro To Philo Quarter 2 November 14-18Document4 pagesIntro To Philo Quarter 2 November 14-18Marjolane BobadillaNo ratings yet

- Erf Form Long SizeDocument2 pagesErf Form Long SizeKarla Lyca Sequijor EscalaNo ratings yet

- WLP TemplateDocument4 pagesWLP TemplateJaena Perez AriolaNo ratings yet

- Template No.3 PRE CALCULUSDocument1 pageTemplate No.3 PRE CALCULUSChristian BernardNo ratings yet

- Homeroom GuidanceDocument1 pageHomeroom GuidanceMyden EslleraNo ratings yet

- Math 10 LP 2022 2023Document4 pagesMath 10 LP 2022 2023Francisco Jr. MadisNo ratings yet

- School Pl Report 2nd QuarterDocument3 pagesSchool Pl Report 2nd Quarterjuvilee marquitaNo ratings yet

- Sat Rpms 2019Document18 pagesSat Rpms 2019Susie CruzNo ratings yet

- Cadaloria High School: Schools Division Office of IsabelaDocument2 pagesCadaloria High School: Schools Division Office of IsabelaJessie MangaboNo ratings yet

- Shs Report Card FRONTDocument2 pagesShs Report Card FRONTTrishia Mae PacleNo ratings yet

- Comparative-Analysis in MAPEHDocument6 pagesComparative-Analysis in MAPEHwilsonNo ratings yet

- Jpmes - Grades1 3 - MTB First Quarterly Learning Assessment ReportDocument20 pagesJpmes - Grades1 3 - MTB First Quarterly Learning Assessment ReportLeni dela cruzNo ratings yet

- Department of Education: Template For Smea SY 2021-2022Document1 pageDepartment of Education: Template For Smea SY 2021-2022KarpioNo ratings yet

- Report On Attendance: Deped Form 138-ADocument8 pagesReport On Attendance: Deped Form 138-AWillie Montes Poblacion Jr.No ratings yet

- Table 1-c and 1-f YearlyDocument10 pagesTable 1-c and 1-f Yearlyjun del rosarioNo ratings yet

- Homeroom Guidance Grades 7 10Document2 pagesHomeroom Guidance Grades 7 10Christopher E. ZernaNo ratings yet

- Preventing Disruptive Behavior in Colleges: A Campus and Classroom Management Handbook for Higher EducationFrom EverandPreventing Disruptive Behavior in Colleges: A Campus and Classroom Management Handbook for Higher EducationNo ratings yet

- 4a's Lesson Plan For Demo # 2Document5 pages4a's Lesson Plan For Demo # 2Ronel SuanNo ratings yet

- A Study of Carbonized Lignin As An Alternative To Carbon BlackDocument7 pagesA Study of Carbonized Lignin As An Alternative To Carbon BlackMathilda PasaribuNo ratings yet

- Airborne Oil and Gas TCP Flowline Brochure 2017Document4 pagesAirborne Oil and Gas TCP Flowline Brochure 2017Aaron Vazquez MartinezNo ratings yet

- Lyphochek Assayed Chemistry Control Levels 1 and 2: Revision Date 2015-04-29 Indicates Revised InformationDocument20 pagesLyphochek Assayed Chemistry Control Levels 1 and 2: Revision Date 2015-04-29 Indicates Revised InformationvijayaNo ratings yet

- Atomic ResearchDocument21 pagesAtomic ResearchPrashant DoundNo ratings yet

- GAMMA-GT Carboxy GPNA: BiolaboDocument2 pagesGAMMA-GT Carboxy GPNA: BiolaboFariz KasyidiNo ratings yet

- Solubility and PermeabilityDocument3 pagesSolubility and PermeabilityGNCDWNo ratings yet

- True - False - The-WPS OfficeDocument4 pagesTrue - False - The-WPS OfficeAndyria amoreNo ratings yet

- TDS - DotpDocument2 pagesTDS - DotpHoussem Eddine LakhelNo ratings yet

- Section 14. Handling and Care of Aircraft RecoveredDocument2 pagesSection 14. Handling and Care of Aircraft RecoveredblackhawkNo ratings yet

- Science Revision Sheet - Term 1-Year 4: NameDocument18 pagesScience Revision Sheet - Term 1-Year 4: NameSaid HusseinNo ratings yet

- Reboilers & VaporisersDocument17 pagesReboilers & VaporisersKamran MalikNo ratings yet

- Nitrate Chromotropic Acid West1966Document8 pagesNitrate Chromotropic Acid West1966eveltoncNo ratings yet

- Basf Tds - Lupranate m20sDocument3 pagesBasf Tds - Lupranate m20sShivam NagarkarNo ratings yet

- Substitutes For Xylene in HistopathologyDocument13 pagesSubstitutes For Xylene in Histopathologyerick_khristianNo ratings yet

- Non Return Valve Nv100 200 UkDocument3 pagesNon Return Valve Nv100 200 UkThái Mai ĐìnhNo ratings yet

- Removal of Microplastics From Waters ThroughDocument15 pagesRemoval of Microplastics From Waters ThroughPhạm Thế VinhNo ratings yet

- Basics of Chromatographic Techniques Course 1: Kannan R., Ph. DDocument43 pagesBasics of Chromatographic Techniques Course 1: Kannan R., Ph. DNabilDouadiNo ratings yet

- Made by Drache. Casthouse Technology - Worldwide.: English VersionDocument28 pagesMade by Drache. Casthouse Technology - Worldwide.: English VersionСтанислав ПодольскийNo ratings yet