Professional Documents

Culture Documents

Parts of Lathe Machine:: Take Protecting It Seriously

Parts of Lathe Machine:: Take Protecting It Seriously

Uploaded by

Klucifer Xin0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

Lathe Machine

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageParts of Lathe Machine:: Take Protecting It Seriously

Parts of Lathe Machine:: Take Protecting It Seriously

Uploaded by

Klucifer XinCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

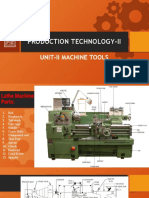

Lathe machine: Main Parts,

Operation and Working

take protecting it seriously

Parts of Lathe Machine:

The lathe consist following parts.

1. Bed

It is the main body of the machine. All main components are bolted on it. It is usually made by cast iron due to

its high compressive strength and high lubrication quality. It is made by casting process and bolted on floor

space.

2. Tool post

It is bolted on the carriage. It is used to hold the tool at correct position. Tool holder mounted on it.

3. Chuck

Chuck is used to hold the workspace. It is bolted on the spindle which rotates the chuck and work piece. It is

four jaw and three jaw according to the requirement of machine.

4. Head stock

Head stock is the main body parts which are placed at left side of bed. It is serve as holding device for the gear

chain, spindle, driving pulley etc. It is also made by cast iron.

5. Tail stock

Tail stock situated on bed. It is placed at right hand side of the bed. The main function of tail stock to support

the job when required. It is also used to perform drilling operation.

6. Lead screw

Lead screw is situated at the bottom side of bed which is used to move the carriage automatically during

thread cutting.

7. Legs

Legs are used to carry all the loads of the machine. They are bolted on the floor which prevents vibration.

8. Carriage

It is situated between the head stock and tail stock. It is used to hold and move the tool post on the bed

vertically and horizontally. It slides on the guide ways. Carriage is made by cast iron.

9. Apron

It is situated on the carriage. It consists all controlling and moving mechanism of carriage.

10. Chips pan

Chips pan is placed lower side of bed. The main function of it to carries all chips removed by the work piece.

11. Guide ways

Guide ways take care of movement of tail stock and carriage on bed.

12. Speed controller

Speed controller switch is situated on head stock which controls the speed of spindle.

13. Spindle

It is the main part of lathe which holds and rotates the chuck.

Lathe Machine Operation &

Working:

1. A cylindrical work piece _xed to the chuck. A chuck may have three jaw or for jaw according to the

requirement. The work piece is at the center or some eccentric according to the process perform.

2. The spindle starts to rotate and set it at desire speed. The spindle speed plays a huge role during cutting.

The spindle rotates the chuck and work piece.

3. Now check the work piece is turning properly. If it not set the work piece using dial gauge.

4. Now set the tool at desire feed by moving the tool post and carriage. The feed also play main role during

cutting. Large feed may cause unwanted temperature increase.

5. After it tool is introduce between moving work piece at desire feed rate. It cut the metal from work piece. The

feed rate is set at the cutting condition.

6. Now all unwanted metal is removed by moving the carriage form horizontally and vertically as desire

according to the job requirement. After complete all process we got a well finished job.

7. Lathe can perform turning, boring, chamfering, shaping, facing, drilling

knurling, grooving as shown in figure.

You might also like

- Thermodynamics Chapter 4 Solution Manual.Document11 pagesThermodynamics Chapter 4 Solution Manual.Nash Fernandez86% (100)

- ZINCALUME® G550 SteelDocument2 pagesZINCALUME® G550 SteelGeni SamudraNo ratings yet

- Lathe Machine: Description and Function of Lathe PartsDocument16 pagesLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (2)

- Machine Lab - ReportDocument11 pagesMachine Lab - Reportsaiq kamranNo ratings yet

- 6-Comparing AlternativesDocument7 pages6-Comparing AlternativesKlucifer XinNo ratings yet

- Dynaflo DP 60hz CatalogDocument44 pagesDynaflo DP 60hz Catalognpclap67% (3)

- F879MDocument6 pagesF879MmsbarretosNo ratings yet

- Inspection Manual For PipingDocument183 pagesInspection Manual For PipingMartin Zaballa100% (3)

- 2011 CatalogDocument29 pages2011 CatalogchainleighNo ratings yet

- Lathe MachineDocument8 pagesLathe MachineVipin TitariyaNo ratings yet

- Chapter 3 Lathe MachineDocument28 pagesChapter 3 Lathe MachineMohd HapisNo ratings yet

- Manufacturing Technology - Short NotesDocument5 pagesManufacturing Technology - Short NotesdevaNo ratings yet

- LATHE - WriteupDocument21 pagesLATHE - WriteupMERISH GURU100% (1)

- Lathe Machine: Parts and Fucntions 1. HeadstockDocument4 pagesLathe Machine: Parts and Fucntions 1. HeadstockNowellNo ratings yet

- Manufacturing ProcessDocument11 pagesManufacturing ProcessRimti BhowmikNo ratings yet

- Machine Tool Introduction - Types of MachineDocument19 pagesMachine Tool Introduction - Types of MachineAbdul AhadNo ratings yet

- Department of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokDocument21 pagesDepartment of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokWalid AdnanNo ratings yet

- Lathe PresentationDocument11 pagesLathe PresentationChandresh KulshresthaNo ratings yet

- Lathe MachineDocument3 pagesLathe MachineChristian VicenteNo ratings yet

- Assignment 1Document25 pagesAssignment 1quincygwapaNo ratings yet

- Unit 2 Machine ToolsDocument11 pagesUnit 2 Machine ToolsMemes TechnicalNo ratings yet

- Machine ToolsDocument22 pagesMachine ToolsSankalpRaiNo ratings yet

- What Are The Parts of Lathe Machine and Their Functions?Document15 pagesWhat Are The Parts of Lathe Machine and Their Functions?Redson BandaNo ratings yet

- Lathe MachineDocument36 pagesLathe MachinePrem100% (4)

- Lab 7 Workshop Teacher VersionDocument4 pagesLab 7 Workshop Teacher Versionumar272No ratings yet

- Layout of Mechanical Work ShopkkkkDocument7 pagesLayout of Mechanical Work ShopkkkkChaudhary Rizwan MeoNo ratings yet

- Unit-4 Machine ToolsDocument77 pagesUnit-4 Machine ToolsSOURABH GANGWARNo ratings yet

- Lathe Machine Definition Introduction Parts Operation Specification PDFDocument19 pagesLathe Machine Definition Introduction Parts Operation Specification PDFahsan aliNo ratings yet

- Turret & Capstan LathesDocument10 pagesTurret & Capstan LathesRenjith Rajendraprasad100% (3)

- Machine Shop Theory and Practi Ce: Mechanical EngineeringDocument17 pagesMachine Shop Theory and Practi Ce: Mechanical EngineeringJohn Borja100% (1)

- Lathe, Milling Machine, Computer Numerical Control (CNC) and RobotsDocument25 pagesLathe, Milling Machine, Computer Numerical Control (CNC) and RobotsLAKSH RAMASWAMYNo ratings yet

- Lathe Machine Definition Introduction Parts Operation Specification PDFDocument19 pagesLathe Machine Definition Introduction Parts Operation Specification PDFRitchie Carillo DaugdaugNo ratings yet

- IME (BESCK204D) Module-2Document16 pagesIME (BESCK204D) Module-2SusheelabaiNo ratings yet

- Lathe Machine (Mechanical Engineering)Document26 pagesLathe Machine (Mechanical Engineering)tahir100% (2)

- Lathe MachineDocument11 pagesLathe Machinesean cutshawNo ratings yet

- Lathe MachineDocument13 pagesLathe Machinemboniface763No ratings yet

- Title:: To Make A Slot by Shaper MachineDocument4 pagesTitle:: To Make A Slot by Shaper MachineMD Mahmudul Hasan MasudNo ratings yet

- Experiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineDocument5 pagesExperiment No. 1: Study of Universal 3 Jaw Chuck Lathe MachineHasnain AshrafNo ratings yet

- Lathe Machine Ex. No. 4Document3 pagesLathe Machine Ex. No. 4Rodgie Christian CruzNo ratings yet

- WorkshopDocument4 pagesWorkshopusama shehrozNo ratings yet

- LatheDocument16 pagesLathepokalNo ratings yet

- Workshop Practice II (MEng4191)Document35 pagesWorkshop Practice II (MEng4191)Tesema TeshomeNo ratings yet

- Lab Session No: 2: Introduction of Lathe Machine & Centering of The JobDocument6 pagesLab Session No: 2: Introduction of Lathe Machine & Centering of The JobsharjeelNo ratings yet

- Elijah Swatt - Metal Lathes 2Document6 pagesElijah Swatt - Metal Lathes 2api-626529107No ratings yet

- Lathe MachineDocument6 pagesLathe MachineJuno Eron TalamayanNo ratings yet

- Advance Manufacturing Process (Amp) Project FinalDocument12 pagesAdvance Manufacturing Process (Amp) Project FinalAyyan Gaonkhadkar100% (3)

- Parts of Lathe-WPS OfficeDocument2 pagesParts of Lathe-WPS OfficeJayvee FamisaranNo ratings yet

- Module 5 PDFDocument28 pagesModule 5 PDFkaushal shivaprakashNo ratings yet

- Lathe and Drilling MachineDocument99 pagesLathe and Drilling Machinesagar0% (1)

- BMEDocument23 pagesBMELawanbha LyngdohNo ratings yet

- LatheDocument4 pagesLatheAnees Calicut100% (1)

- Department of Mechanical Engineering: Machine Tool (ME-6004) Year / Semester: - III/VI Experiment No. 07Document10 pagesDepartment of Mechanical Engineering: Machine Tool (ME-6004) Year / Semester: - III/VI Experiment No. 07Ritik SisodiyaNo ratings yet

- MFT CH 3Document41 pagesMFT CH 3babulsethi1567No ratings yet

- Up Workshop Manual 2020Document62 pagesUp Workshop Manual 2020Yash MittalNo ratings yet

- Workshop AssignmentDocument23 pagesWorkshop AssignmentMr. NasrullahNo ratings yet

- Mahine LabDocument9 pagesMahine LabArun kumar rouniyarNo ratings yet

- Project PresentationDocument26 pagesProject PresentationRishav RakeshNo ratings yet

- ME3382-MT Lab Manual Part-1Document112 pagesME3382-MT Lab Manual Part-1KIRTHIVASAN K V D 905250% (2)

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDocument23 pagesLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFNeeraj JithuNo ratings yet

- Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFDocument27 pagesLathe Machine Definition Parts Types Operation Specification Advantages Application Notes PDFSky 6794No ratings yet

- Machine Tools Lab Manual (13-14)Document39 pagesMachine Tools Lab Manual (13-14)Krishna Murthy100% (1)

- Lathe: Lathe Is A Machine On Which The Machining Operations Can Be Done To Work Piece Get TheDocument7 pagesLathe: Lathe Is A Machine On Which The Machining Operations Can Be Done To Work Piece Get Theashoku2No ratings yet

- Unit IIDocument26 pagesUnit IISourasish TalukderNo ratings yet

- Machining Process - I: Lathe MachineDocument48 pagesMachining Process - I: Lathe MachineNajshhsNo ratings yet

- Lathe MachineDocument8 pagesLathe MachineAtrayee Das ME, 2026No ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- F DP DT DP FDTDocument3 pagesF DP DT DP FDTKlucifer XinNo ratings yet

- Introduction To Accounting: Caec 1 & 2: Financial Accounting and ReportingDocument6 pagesIntroduction To Accounting: Caec 1 & 2: Financial Accounting and ReportingKlucifer XinNo ratings yet

- Objectives Objective 1: Improve The Value Proposition of Enterprise Information Systems by Decreasing TheDocument8 pagesObjectives Objective 1: Improve The Value Proposition of Enterprise Information Systems by Decreasing TheKlucifer XinNo ratings yet

- Do Rocks Last Forever?: What You Need?Document2 pagesDo Rocks Last Forever?: What You Need?Klucifer XinNo ratings yet

- DynamicsDocument3 pagesDynamicsKlucifer XinNo ratings yet

- Formula - Regeratice Rankine CycleDocument1 pageFormula - Regeratice Rankine CycleKlucifer XinNo ratings yet

- Module 1-C1 Heat TransferDocument10 pagesModule 1-C1 Heat TransferKlucifer XinNo ratings yet

- How Can The Present Technological and Biological Changes Affect Human EvolutionDocument1 pageHow Can The Present Technological and Biological Changes Affect Human EvolutionKlucifer XinNo ratings yet

- Options Thinking and Platform Investments InvestinDocument21 pagesOptions Thinking and Platform Investments InvestinKlucifer XinNo ratings yet

- Acceleration Analysis MethodDocument12 pagesAcceleration Analysis MethodKlucifer XinNo ratings yet

- Module 1 - Chapter 1 Fluid MechanicsDocument24 pagesModule 1 - Chapter 1 Fluid MechanicsKlucifer Xin100% (4)

- Cam and Follower PDFDocument17 pagesCam and Follower PDFKlucifer XinNo ratings yet

- AckmntDocument1 pageAckmntKlucifer XinNo ratings yet

- Transformer Construction and Transformer Core DesignDocument14 pagesTransformer Construction and Transformer Core DesignKlucifer XinNo ratings yet

- Education, Opportunity and The Prospects For Social MobilityDocument25 pagesEducation, Opportunity and The Prospects For Social MobilityKlucifer XinNo ratings yet

- Difference Between Core Type and Shell Type Transformer (With Comparison Chart) - Circuit GlobeDocument9 pagesDifference Between Core Type and Shell Type Transformer (With Comparison Chart) - Circuit GlobeKlucifer XinNo ratings yet

- Acceleration Analysis MethodDocument12 pagesAcceleration Analysis MethodKlucifer XinNo ratings yet

- What Is A Transformer - Definition and Meaning - Circuit GlobeDocument8 pagesWhat Is A Transformer - Definition and Meaning - Circuit GlobeKlucifer XinNo ratings yet

- Transformer Basics and Transformer PrinciplesDocument21 pagesTransformer Basics and Transformer PrinciplesKlucifer XinNo ratings yet

- Working Tools IN WORKSHOPDocument11 pagesWorking Tools IN WORKSHOPKlucifer XinNo ratings yet

- Problem SetDocument11 pagesProblem SetKlucifer XinNo ratings yet

- Reactivity of IronDocument3 pagesReactivity of IronqamhNo ratings yet

- Maraging Steel: 1. Introduction and General CharacteristicsDocument12 pagesMaraging Steel: 1. Introduction and General CharacteristicsMubash Abd100% (1)

- Brochure - Ex TENDDocument4 pagesBrochure - Ex TENDBilly ZununNo ratings yet

- Retropod (Deep Water) : Technical DatasheetDocument1 pageRetropod (Deep Water) : Technical DatasheetReza AbadiNo ratings yet

- RocMaster Roc en PDFDocument24 pagesRocMaster Roc en PDFKKien VuNo ratings yet

- SliversDocument5 pagesSliversVarun MishraNo ratings yet

- Wikus Precision Band SawDocument52 pagesWikus Precision Band SawEnrique Murgia100% (1)

- Glass Ionomer CementDocument54 pagesGlass Ionomer CementNasecaNo ratings yet

- Metal Materials Commonly Used Brand of TableDocument7 pagesMetal Materials Commonly Used Brand of TablemtdflameNo ratings yet

- HDG DefectDocument45 pagesHDG DefectjasminneeNo ratings yet

- A 705 - A705m - 95 R00 Qtcwns9bnza1tqDocument7 pagesA 705 - A705m - 95 R00 Qtcwns9bnza1tqRuiz D. AntonioNo ratings yet

- Chapter 5 Gastrointestinal Agents Reviewer PDFDocument6 pagesChapter 5 Gastrointestinal Agents Reviewer PDFdavenNo ratings yet

- A.M.C. Akola Street Light 4 RoadsDocument24 pagesA.M.C. Akola Street Light 4 RoadsBharat Namdeo AmbhoreNo ratings yet

- Ukqa 2032Document9 pagesUkqa 2032Mohamad IkhwanNo ratings yet

- Malaysia Standart IncomingDocument21 pagesMalaysia Standart Incomingpanji akbarNo ratings yet

- Slitting CuttersDocument1 pageSlitting CuttersMartinianoArrietaNo ratings yet

- Boq Print - 03-SepDocument2 pagesBoq Print - 03-SepRoshan KejariwalNo ratings yet

- Maraging SteelDocument2 pagesMaraging SteelRachan PancheNo ratings yet

- Explosives-Whistles - Pyrotechnica XIDocument6 pagesExplosives-Whistles - Pyrotechnica XIhwelch5792No ratings yet

- Mil STD 193LDocument47 pagesMil STD 193LSon NguyenNo ratings yet

- Metallic BondingDocument10 pagesMetallic BondingArmando Alberto MassingueNo ratings yet

- Materials FerrousDocument3 pagesMaterials Ferrousjohnson_regoNo ratings yet

- Ohe IDocument41 pagesOhe IAnonymous sENwj8nwq100% (11)

- DIY Soldering For A Whiskey StillDocument2 pagesDIY Soldering For A Whiskey Stilldannyjan5080No ratings yet