Professional Documents

Culture Documents

Reviewed by Reviewed by Prepared by Prepared by Approved by Approved by

Uploaded by

Mohan BabuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reviewed by Reviewed by Prepared by Prepared by Approved by Approved by

Uploaded by

Mohan BabuCopyright:

Available Formats

1 of 4

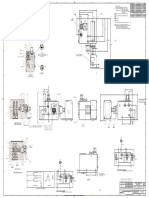

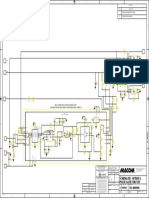

DEVELOPMENTCONSULTANTS

PRIVATE LIMITED

Reviewed for genera all conformance with Contra

act

ct

drawingsand specifications.

ACTION : 5

1 Approved 4 Disapproved.

Approved ex cept as

For information/reference

2 noted. Forward final 5 only.

drawing.

Approved ex cept as Information category with

3 noted. Resubmission 6 comments. Resubmission

BGR ENERGY SYSTEMS LIMITED required. required.

Approval of Contract documents by the Cons ultant shall

not relieve the Seller of his responsibility for any errors

and fulfilment of Contract requirements.

POWER PROJECTS DIVISION Digitally signed by Shouvik

Patari

DN: cn=Shouvik Patari,

PROJECT : 2 X 660 MW IB TPS, JHARSUGUDA o=DCPL, ou=DCPL,

FIELD INSPECTION AND TEST PLAN & CHECK LIST email=shouvikp@in.dclgroup.

com, c=IN

Date: 2015.01.28 12:06:04

FOR +05'30'

EARTHING SYSTEMS

PREPARED BY REVIEWED BY APPROVED BY

D.ARUN BHARATH K. SUBRAMANIAN K.KALYANARAMAN

P - Perform IR-Inspection Report GRN-Goods receipt note H-Hold

W - Witness S- Surveillance TR- Test Report LB-Log Book

V - Verification

Verification S R - Si tte

e re g

giis te

te r P .O

.O - Pu rrc

c ha

ha s

se

e O rd

rd e

err I MI

MI R - I n

nw

waarrd Ma te

te rrii al

al I n

ns

sppe

eccttion R ep

epo rrtt

R - Review S - Surveillance D .C - Delivery Challan IRN - Inspection Release Note

RW-Random Witness PR-Protocol TR-Test report FITP - Field Inspection And Test Plan DOCUMENT NO : BGR/PPD/208/EL/FQP/0553

BGR/PPD/208/EL/FQP/0553

A - An Activity checked & Cleared by Owner QA/QC / C - An Activity checked & Cleared by BGRESL Execution

Execution / Sub Contractor REVISION : 00

BGRESL QA/QC

B - An Activity checked & Cleared by Owner Executive Group

Group / BGRESL Execution DATE : 13.01.2015

2 of 4

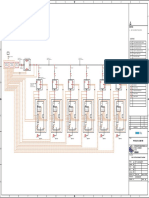

FIELD INSPECTION AND TEST PLAN & CHECK LIST

Package : EARTHING SYSTEM

PROJECT: 2X660 MW IB THERMAL POWER STATION

Doc No :BGR/PPD/208/EL/FQP/0553

Rev No : 00

CUSTOMER: ODISHA POWER GENERATION CORPORATION

Date : 13.01.2015 LIMITED

Inspecting Agency

Quantum/

Class of Ref documents & Format of

S. NO

NO Item /

/C

Component & O p

pe

eration Type of check Frequency Remarks

Check Acceptance std Record

of check SUB

BGRESL OPGCL

Contractor

1.0 Receipt

Verify MDCC issued by BGR/OPGC(If

PO,MDCC & LR/All the

applicable), BGR&OPGC verified test

1.1 C Visual 100% documents shall be IMIR P

reports,Dispatch documents (LR & packing List

…. ….

available

etc )

Veirfy the Dimesions of the Earthing

Random (3 PO,MDCC,IRN/ Material

1.2 Conductors & Down conductors (MS Rods, C Measurement IMIR P

samples /lot) shall confirm to IRN

…. ….

Galvanised MS Flats, Etc)

Verify the toatal Quantity in Kg/Mtons in

1.3 weighing Bridge with truck and tally with C Meaurement 100% MDCC,IRN IMIR … P ….

packing list

Veirfy the materials such as welding ele

ectrodes

ctrodes

1.4 C Visual 100% PO,MDCC/ IRN IMIR P

and anti corrossion paints

… ….

2.0 STORAGE

Ensure that Earthing Conductors are stored in

2.1 a covered space/outdoor in a well-drain

well-drained

ed & C Visual 100% FITP … ,,, P ….

raised area with firrm

m surface

Ensure that the storage area is free from

2.2 C Visual 100% FITP ,,, P

water logging.

… ….

Ensure that the material is stored seperately

2.3 as per the type and dimensions and not mixed C Visual 100% FITP … ,,, P ….

up

Consumables such as welding electrodes and

2.4 Anti corrosive painst shall be stored well C …. 100% FITP … ,,, P ….

ventilated dry indoor area

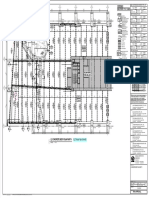

3 of 4

FIELD INSPECTION AND TEST PLAN & CHECK LIST

Package : EARTHING SYSTEM

PROJECT: 2X660 MW IB THERMAL POWER STATION

Doc No :BGR/PPD/208/EL/FQP/0553

Rev No : 00

CUSTOMER: ODISHA POWER GENERATION CORPORATION

Date : 12.01.2015 LIMITED

Quantum/ Inspecting Agency

Class of Ref documents & Format of

S. NO

NO Item /

/C

Component & O p

pe

eration Type of check Frequency SUB Remarks

Check Acceptance std Record BGRESL OPGCL

of check Contractor

3.0 ERECTION /INSTALLATION

Ensure the availability of approved Earthing

3.1 C Visual 100% Check L ist P ….

layouts of the respective area

….

Ensure that the approved materials(type and

3.2 C Visual Random Check Check L ist P ….

diemensions) are mobilized

….

Ensure the availability of "Work permit" for the

3.3 C Visual 100% Check L ist P P ….

respective area

Ensure that the ground grid of the respective

area is installed at a de

depth

pth of not less than

3.4 B Measurement 100% Check L ist P W RW

1000mm below finished grade during

installation

verify the installation of Earth

OPGC Witness is

3.5 Electrodes(auxiliary) during installation & pits B Visual 100% Check List P W RW

only for earth pits

after installation at specifed points

Appd Drg /Method

Ensure that the Ground conductors welded Statement

joints above and below ground(Before back

3.6 C Visual Random Check List P W

filling) are coated with 2 coats of anti

….

corrosive paintings

3.7 Ensure the availability of riser projecting 300 C Measurement 100% Check L ist P W

mm above ground at specified points

…

Ensure the availability of two risers for each

3.8 floor and two distinctive earth terminals for B Visual 100% Check List P W W

each equipments

Ensure the connection of internconnected

3.9 B Visual 100% Check List P W W

earth flats above ground with risers

Ensure the availabilty

lty of grid extension for

3.10 B Visual 100% Check List P W W

connecting to the main plant grid

4.0 TESTING OF INSTALLATION

Measurement of Earth pit resistance with and

4.1 A Testing 100% EF -02 P W W

without grid Appd Drg /Method

Statement

4.2 Verification of Earthing system continuity A Testing 100% EF -03 P W W

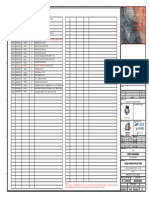

4 of 4

FIELD CHECK LIST FOR EARTHING SYSTEM

AREA DATE

ELEVATION REPORT NO

DRAWING NO

SL.No Description of Check OBSERVATION / NA Remarks

1 Verify the availability of approved Earthing layouts of the respective area

2 Check that the approved materials(type and diemensions) are mobilized

3 Verify the availability of "Work permit" for the respective area

Check that the ground grid of the respective area is installed at a depth of not less

4

than 1000mm below finished grade during installation

verify the installation of Earth Electrodes during installation & pits after installation at

5

specifed points

Verify that the Ground conductors welded joints above and below ground(Before back

6

filling) are coated with 2 coats of an

anti

ti corrosive paintings

7 Check the availability of riser projecting 300 mm above ground at specified points

Check the availability of two risers for each floor

floor and two distinctive earth terminals for each

8 equipments

9 Verify the connection of internconnected

internconnected earth flats above ground with risers

10 Verify the availabilty of grid extension for connecting to the main plant grid

Measurement of Earth pit resistance with and without grid (Test report shall be

11

enclosed)

12 Verification of Earthing system continuity (Test report shall be enclosed)

BGRESL OPGCL

You might also like

- Alaska Airlines 20-Minute Baggage Process ExcellenceDocument6 pagesAlaska Airlines 20-Minute Baggage Process ExcellenceLawrance Gan100% (1)

- Esquema Eletrico DYNAPAC CA250Document17 pagesEsquema Eletrico DYNAPAC CA250Fabiano Gomes0% (1)

- Boiler India 2020 Directory PDFDocument115 pagesBoiler India 2020 Directory PDFAvijitSinharoyNo ratings yet

- Nokia XL Dual SIM RM-1030 RM-1042 Service Schematics v1.0Document19 pagesNokia XL Dual SIM RM-1030 RM-1042 Service Schematics v1.0MarcinDryjaNo ratings yet

- XT2129-X - Moto g30 (Capri+) - SB - SchematicsDocument4 pagesXT2129-X - Moto g30 (Capri+) - SB - SchematicsFelipe de san anicetoNo ratings yet

- Astm PTC46 PDFDocument379 pagesAstm PTC46 PDFBryan Manalo100% (1)

- Computer Organization Unit Wise Important QuestionsDocument2 pagesComputer Organization Unit Wise Important QuestionsAishu50% (8)

- COS111u Tut 101 - 3 (2009)Document107 pagesCOS111u Tut 101 - 3 (2009)Willemien Du PlessisNo ratings yet

- C BRU160021 160428 Tsc/Va TD: J1939 D-SubDocument14 pagesC BRU160021 160428 Tsc/Va TD: J1939 D-SubMauro PerezNo ratings yet

- Ticket 20232212677-3Document1 pageTicket 20232212677-3Multani KanwarNo ratings yet

- J12530-01-C-910-P-3 Detail Layout Bulk EarthworksDocument1 pageJ12530-01-C-910-P-3 Detail Layout Bulk Earthworksvarity butheleziNo ratings yet

- SD Mount Rushmore 20150807 TM Geo PDFDocument1 pageSD Mount Rushmore 20150807 TM Geo PDFCAMDEN EDMONDSONNo ratings yet

- B05 DWG Anm SHD Ar Arc 0103 00Document1 pageB05 DWG Anm SHD Ar Arc 0103 00chumsak laoNo ratings yet

- LD PC CH.199+590Document4 pagesLD PC CH.199+590Aerotide InfrastructuresNo ratings yet

- Teresa Cubijies ModelDocument1 pageTeresa Cubijies ModelBaal BaalNo ratings yet

- GROUND BUILDING B-Layout2Document1 pageGROUND BUILDING B-Layout2Dan C. LabagnoyNo ratings yet

- Guard House: WarehouseDocument1 pageGuard House: WarehouseDan C. LabagnoyNo ratings yet

- WiseDocument1 pageWiseDan C. LabagnoyNo ratings yet

- LLC Multiple VoltageDocument2 pagesLLC Multiple VoltageDanut StanciuNo ratings yet

- ECU Pinout PDFDocument1 pageECU Pinout PDFJuan Fernando0% (1)

- Section B-B Shuttle Valve: Valve, Hydraulic, Self Sequencing RatchetDocument2 pagesSection B-B Shuttle Valve: Valve, Hydraulic, Self Sequencing Ratchetnikon reddyNo ratings yet

- A23006ab036 Id377381Document2 pagesA23006ab036 Id377381Mikro IndiaNo ratings yet

- QFD - FinalDocument1 pageQFD - FinalAngie Katherin MartínNo ratings yet

- World P Arking: Opportunity ParkingDocument1 pageWorld P Arking: Opportunity ParkingleilaNo ratings yet

- Termination Detail: 0.00 4.182 M ABU DHABI DATUMDocument1 pageTermination Detail: 0.00 4.182 M ABU DHABI DATUMAAMIR NISARNo ratings yet

- BC-6800 Fluidic DiagramDocument24 pagesBC-6800 Fluidic DiagramFENGNo ratings yet

- P1 SP7731G V3.0 SCHDocument9 pagesP1 SP7731G V3.0 SCHchanel kreasiNo ratings yet

- Mukemil Gemale G+2 PENSION Electrical Design FINALDocument2 pagesMukemil Gemale G+2 PENSION Electrical Design FINALzekeriya reshadNo ratings yet

- DocuSign Envelope ID: A6A70182-B5F1-4206-A70C-6C1DAA39ED23Document1 pageDocuSign Envelope ID: A6A70182-B5F1-4206-A70C-6C1DAA39ED23Leonel Perez RubioNo ratings yet

- Pim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Document1 pagePim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Alexsei BordaNo ratings yet

- List of Nozzles List of Nozzles: T T 1 T T 1Document1 pageList of Nozzles List of Nozzles: T T 1 T T 1גרבר פליקס100% (1)

- 2S6T 14a464 Ub PDFDocument3 pages2S6T 14a464 Ub PDFKemmerly ErazoNo ratings yet

- LBP A3 Example Office Case StudyDocument1 pageLBP A3 Example Office Case StudyOsvaldo ColinNo ratings yet

- Warriors TooManyZoozDocument1 pageWarriors TooManyZoozferrandNo ratings yet

- I WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NDocument1 pageI WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NAbid AyubNo ratings yet

- Вар№4Рокэн ролDocument9 pagesВар№4Рокэн ролЛінаNo ratings yet

- 115Kv Busbar & BF Protection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Document1 page115Kv Busbar & BF Protection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Anonymous BZQOJwWIh6No ratings yet

- Rev ADocument19 pagesRev Avan long BuiNo ratings yet

- 4cx Master Site Electrical DiagramDocument34 pages4cx Master Site Electrical DiagramDean mark rey luzonNo ratings yet

- Enq-439-Drainage R01Document6 pagesEnq-439-Drainage R01abdullah sahibNo ratings yet

- Peavey Electronics IncDocument3 pagesPeavey Electronics IncTrevor Washburn0% (1)

- NT1000 - Spindle 1Document1 pageNT1000 - Spindle 1Felipe SalesNo ratings yet

- Struktur Harvesting Per 18 Nov 2021 (Target Kiriman 10000 Ton)Document7 pagesStruktur Harvesting Per 18 Nov 2021 (Target Kiriman 10000 Ton)Eshika PrawitasariNo ratings yet

- Plans For Shop DrawingsDocument5 pagesPlans For Shop DrawingsApple CabreraNo ratings yet

- America BRDocument21 pagesAmerica BRVan VeigaNo ratings yet

- Building Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliDocument1 pageBuilding Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliRoyal JadhavNo ratings yet

- Fuel System Schematic DiagramDocument1 pageFuel System Schematic DiagramAbhilash100% (1)

- A101 Site PlanDocument1 pageA101 Site PlanWang TungChuNo ratings yet

- Farewell-Sergio AsaadDocument3 pagesFarewell-Sergio AsaadEdwardNo ratings yet

- HH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemDocument2 pagesHH45, HH55, HH65, and HH75 Harvester Heads Electrical SystemGilvan JuniorNo ratings yet

- 18 135100 0000100595 Acm STR DRG 102516 - ADocument1 page18 135100 0000100595 Acm STR DRG 102516 - Asaloman.vasuprada28No ratings yet

- Engineering analysis for neomDocument1 pageEngineering analysis for neomengineers.m.kazmiNo ratings yet

- Swage Optional Fase Wahlweise Optional Wahlweise: 04MAY2016 22SEP2016 21OCT2017 24SEP2018 3 4 5Document2 pagesSwage Optional Fase Wahlweise Optional Wahlweise: 04MAY2016 22SEP2016 21OCT2017 24SEP2018 3 4 5Usama TwabNo ratings yet

- 8003 Sonata No 1 For FL PN 3 XDocument4 pages8003 Sonata No 1 For FL PN 3 XCaitlyn VergaraNo ratings yet

- No.24 - Generator Hydrogen Control SysDocument1 pageNo.24 - Generator Hydrogen Control SysAdetunji Babatunde TaiwoNo ratings yet

- 2FDocument15 pages2FAbhie AlbukhariNo ratings yet

- Circuit-Diagram-MP5 PLAYERDocument1 pageCircuit-Diagram-MP5 PLAYERDevi HihuhNo ratings yet

- All designs are sole property of lentera architectureDocument1 pageAll designs are sole property of lentera architectureIznan KholisNo ratings yet

- Obj 27 D4 374 RV Park Site PlanDocument2 pagesObj 27 D4 374 RV Park Site PlanActionNewsJaxNo ratings yet

- 10 136033 4800000533 Sha Civ SHD 050851 BoxDocument1 page10 136033 4800000533 Sha Civ SHD 050851 BoxAfZaL MuHammeDNo ratings yet

- 12.7kV SWER 2Document1 page12.7kV SWER 2Mosa Elnaid ElnaidNo ratings yet

- C-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelDocument1 pageC-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelHUSSEIN FNEISHNo ratings yet

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Type Dial Size Pressure Gauge QTY SL - No Service Fluid: RIBO Industries PVT LTD Page: 1/10Document10 pagesType Dial Size Pressure Gauge QTY SL - No Service Fluid: RIBO Industries PVT LTD Page: 1/10Mohan BabuNo ratings yet

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuNo ratings yet

- Relay Setting Chart for 33kV Switchyard ProtectionDocument10 pagesRelay Setting Chart for 33kV Switchyard ProtectionMohan BabuNo ratings yet

- Ike Electric Pvt. LTD.: System Fault Level Calculation M/S TnebDocument5 pagesIke Electric Pvt. LTD.: System Fault Level Calculation M/S TnebMohan BabuNo ratings yet

- S.No Item - No Description Material Unit Rating Total QTY Total Qty With 10% MarginDocument1 pageS.No Item - No Description Material Unit Rating Total QTY Total Qty With 10% MarginMohan BabuNo ratings yet

- Sri Ganesh Engineers: No.74, Sri Shanthi Nagar, S.N Chavadi, Cuddalore-607001Document7 pagesSri Ganesh Engineers: No.74, Sri Shanthi Nagar, S.N Chavadi, Cuddalore-607001Mohan BabuNo ratings yet

- List Chemical IndustryDocument13 pagesList Chemical IndustryKRUNAL Parmar100% (1)

- WHRB FittingDocument2 pagesWHRB FittingMohan BabuNo ratings yet

- S.No Item.N O Description Material Unit Rating Total QTY Total Qty With 10% MarginDocument1 pageS.No Item.N O Description Material Unit Rating Total QTY Total Qty With 10% MarginMohan BabuNo ratings yet

- WHRB FittingDocument2 pagesWHRB FittingMohan BabuNo ratings yet

- List Chemical IndustryDocument13 pagesList Chemical IndustryKRUNAL Parmar100% (1)

- Instrument Price Theri PaperDocument10 pagesInstrument Price Theri PaperMohan BabuNo ratings yet

- List of Pharmaceutical Companies in PuneDocument5 pagesList of Pharmaceutical Companies in PuneMohan Babu100% (1)

- List Chemical PSUsDocument34 pagesList Chemical PSUsindusexposiumNo ratings yet

- Pharma IndiaDocument58 pagesPharma IndiaSaravana Kumar50% (4)

- EIL Vendors ListDocument12 pagesEIL Vendors ListMohan Babu0% (1)

- Disclosure To Promote The Right To InformationDocument37 pagesDisclosure To Promote The Right To InformationLaily Noor OkvitasariNo ratings yet

- Goa PharmaDocument10 pagesGoa PharmaTaher100% (1)

- Industrial Cable List Price - 17th August 2021Document6 pagesIndustrial Cable List Price - 17th August 2021Mohan BabuNo ratings yet

- I6s UPS Catalogue (Domestic)Document8 pagesI6s UPS Catalogue (Domestic)SagarNo ratings yet

- Is 1255Document87 pagesIs 1255Mala Rani50% (2)

- PDF Cable Tray Amp Accessories - CompressDocument11 pagesPDF Cable Tray Amp Accessories - CompressMohan BabuNo ratings yet

- LT Switchgear Construction Specifcations With Is CodesDocument99 pagesLT Switchgear Construction Specifcations With Is Codessuresh5254No ratings yet

- Vendor DetailsDocument2 pagesVendor DetailsMohan BabuNo ratings yet

- Is 7098 1 1988Document24 pagesIs 7098 1 1988Hriday AgarwalNo ratings yet

- PDF Cable Tray Amp Tray Support Drawingspdf - CompressDocument14 pagesPDF Cable Tray Amp Tray Support Drawingspdf - CompressMohan BabuNo ratings yet

- Type K ThermocoupleDocument4 pagesType K ThermocoupleMohan BabuNo ratings yet

- Procurement Vendor ListDocument40 pagesProcurement Vendor ListMohan BabuNo ratings yet

- MICROWAVE ENGINEERING QUESTION BANKDocument7 pagesMICROWAVE ENGINEERING QUESTION BANKRahul KoshtaNo ratings yet

- Axa China Bank ADA Enrollment Form PDFDocument1 pageAxa China Bank ADA Enrollment Form PDFAna A OverlyNo ratings yet

- Zone 13 PDFDocument54 pagesZone 13 PDFSobiya100% (1)

- PT 100 Za TemperaturaDocument21 pagesPT 100 Za Temperaturawarmaster81No ratings yet

- Suspended Solids and Turbidity Analysis: Model 7110-MTFDocument2 pagesSuspended Solids and Turbidity Analysis: Model 7110-MTFEfrain HerreraNo ratings yet

- Truss 0402Document35 pagesTruss 0402Cos_sensNo ratings yet

- Introduction To Cisco Unified Communication Manager InterfacesDocument76 pagesIntroduction To Cisco Unified Communication Manager InterfacesjeffgrantinctNo ratings yet

- CG 2015131 00 - 2016 Vert PrePiped Bladder TanksDocument4 pagesCG 2015131 00 - 2016 Vert PrePiped Bladder TanksRomner CordovaNo ratings yet

- नेपाल टेलीकम SwotDocument8 pagesनेपाल टेलीकम SwotVivas PyasiNo ratings yet

- VLSI Design REC702Document2 pagesVLSI Design REC702Abhimanyu YadavNo ratings yet

- R6P / SUM3 / AA Size: Product SpecificationsDocument1 pageR6P / SUM3 / AA Size: Product SpecificationsAdrian SatoNo ratings yet

- cRIO 9073Document28 pagescRIO 9073Emanuel GabrielNo ratings yet

- MUST Product Catalogue New PDFDocument31 pagesMUST Product Catalogue New PDFJoshua Immanuel GaniNo ratings yet

- Fatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiDocument15 pagesFatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiSamir KulkarniNo ratings yet

- Valvulas Velan bv6d Web PDFDocument36 pagesValvulas Velan bv6d Web PDFAndres CortezNo ratings yet

- Wavelet Feature Based Fault Detection and Classification Technique For Transmission Line ProtectionDocument7 pagesWavelet Feature Based Fault Detection and Classification Technique For Transmission Line ProtectionGRD JournalsNo ratings yet

- Assignment Sequential CircuitsDocument2 pagesAssignment Sequential CircuitsPavan SaiNo ratings yet

- (Nelson Newman) Raspberry Pi 4 Projects User Guide PDFDocument143 pages(Nelson Newman) Raspberry Pi 4 Projects User Guide PDFluigui20100% (3)

- Ship Structural StrengthDocument13 pagesShip Structural StrengthZhihao LiNo ratings yet

- SMB PRO MULTI BMS Supports LFP, LI Ion, LTO & LIPO CellsDocument6 pagesSMB PRO MULTI BMS Supports LFP, LI Ion, LTO & LIPO CellsGustavo R GorNo ratings yet

- DrainageDocument42 pagesDrainagekingjames90100% (3)

- Mary Wix Resume 2016Document2 pagesMary Wix Resume 2016api-302404484No ratings yet

- E-Link 1000EXR Datasheet v16 PDFDocument2 pagesE-Link 1000EXR Datasheet v16 PDFjorlugonNo ratings yet

- BIM GainingMomentumDocument13 pagesBIM GainingMomentumRenee Kilkn ONo ratings yet

- PresentationDocument28 pagesPresentationSoumya SukumarNo ratings yet

- A1500 Flyer E PDFDocument2 pagesA1500 Flyer E PDFMohamed TalebNo ratings yet