Professional Documents

Culture Documents

01 Pipe Reinf Comparision

Uploaded by

ajayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Pipe Reinf Comparision

Uploaded by

ajayCopyright:

Available Formats

Comparison of Pipe Reinforcement Arrangements

DESIGN AND BUILD OF BUHIMBA-NALWEYO-BULAMAGI AND BULAMAGI-IGAYAZA-

KAKUMIRO ROADS UPGRADING (93 Km.)

1. COMPARISION OF PRECAST PIPE REINFORCEMENT ARRANGEMENTS

1.1. INTRODUCTION

Generally pipe culverts are not desgined on case by case basis since they are numerous and do not have a

significant impact on the cost of the project. So, a generic design, considering a comfortable margin in

terms of strength and servicebility is followed for all pipe culverts with commonly used diameters of 0.9

and 1.2 m.

Since this project is under the “Design and Build” mode the consultant has carried out the design of pipe

culverts under various ranges of fill heights to find out the exact reinforcement and economise the steel

quantity in pipe culverts.

1.1.1. REINFORCEMENT ARRANGEMENT IN PIPE CULVERTS

In response to the Engineers concern regarding the change in the arrangement of pipe reinforcement for

precast pipes of 0.9 m, 1.2 m and 1.5 m diameter the consultant would like to explain the reason behind

the change and present pertinent arguments validating the proposed arrangement.

Initially, the contractor had proposed a triple cage arrangement as per AASHTO M170M-04, Fig 2. A

representative figure is shown below.

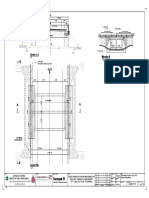

Figure 1-1 Triple Cage Reinforcement as per AASHTO M170M-04

This type of arrangement seeks to reinforce the most critical locations of the pipe wall using an extra

elliptical ring that is placed in such a way that it adds to tensile strength to the inner side of pipe wall at top

and bottom and the outer side of the wall at the sides, in accordance with most widely accepted moment

distribution diagrams for a typical pipe structure. An example of typical pipe loading is shown below.

CANADA | INDIA | AFRICA | MIDDLE EAST Page | 1-1

Structural Design Report (45+000 km to 60+000 km)

DESIGN AND BUILD OF BUHIMBA-NALWEYO-BULAMAGI AND BULAMAGI-IGAYAZA-

KAKUMIRO ROADS UPGRADING PROJECT (93 Km.)

Figure 1-2 General force distrbution duagram for pipe culvert

However, this arrangement of reinforcement requires special machinery to execute and construct the

same. As such machinery was not available with the contractor and procurement of the same would cause

critical delay in the construction operations it was decided to go back to the conventional double cage

reinforcement. The consultant thus had to refer to the quadrant reinforcement option given in AASHTO

M170M-04, Fig 1.

Figure 1-3 Quadrant reinf. arrangement as per AASHTO M170M-04

CANADA | INDIA | AFRICA | MIDDLE EAST Page | 1-2

Structural Design Report (45+000 km to 60+000 km)

DESIGN AND BUILD OF BUHIMBA-NALWEYO-BULAMAGI AND BULAMAGI-IGAYAZA-

KAKUMIRO ROADS UPGRADING PROJECT (93 Km.)

This type of arrangement divides the pipe reinforcement ring into 4 parts or quadrants which coincide with

the critical force diagram shown above. These quadrants are then reinforced with extra bars in specified

proportions so that they can act in the same manner as the elliptical ring. However, since adding small

pieces of reinforcement at the critical locations would entail giving sufficient bonding length on either side,

it would be efficient and easier to construct if the required steel is given as an additional cage. Hence

quadrant reinforcement was proposed which has in most cases, equivalent or extra steel quantity as

compared to the triple cage proposal.

A brief calculation showing the calculation of steel reinforcement for a single cell pipe culvert of 0.9m

diameter is attached in Appendix-1. The calculation has been done using the triple cage and quadrant

reinforcement options and aims to show that in both options there is no compromise on the structural

strength and integrity of the pipe wall.

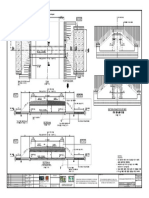

Figure 1-4 Typical reinforcement for Single Cell Pipe Culvet as per earlier proposal

Figure 1-5 Typical reinforcement for Single Cell Pipe Culvet as per latest proposal

CANADA | INDIA | AFRICA | MIDDLE EAST Page | 1-3

Structural Design Report (45+000 km to 60+000 km)

DESIGN AND BUILD OF BUHIMBA-NALWEYO-BULAMAGI AND BULAMAGI-IGAYAZA-

KAKUMIRO ROADS UPGRADING PROJECT (93 Km.)

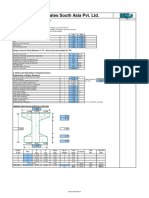

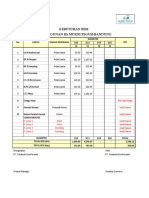

1.1.2. COMPARISION OF PIPE REINFORCEMENT

In accordance with the reinforcement calculation presented in Appendix 1, a summary of pipe

reinforcement provided earlier and as per the latest proposal is given below for reference.

DESIGN PIPE REINFORCEMENT - LATEST

TYPICAL REINFORCEMENT DETAIL FOR PRECAST PIPES

Pipe Longitudinal

Intern Circumferential Reinforcement

Design Class Concre Barrel Reinforcement

al

Classifi (AASHTO te Thickn For Outer For Inner Max Fill.

Diame

cation M170M- Grade ess Circular Circular Outer Inner

ter

04) Hoop Hoop

(N/m

- -

m2) d (mm) t (mm) L1 L2 C1 C2 H (m)

TYPE 1 CLASS III 30/20 900 100 8 Nos. Y8 8 Nos. Y8 Y8 @ 75 c/c Y10 @ 100 c/c H≤ 5

TYPE 2 CLASS IV 30/20 900 100 8 Nos. Y8 8 Nos. Y8 Y10 @ 75 c/c Y12 @ 90 c/c 5 < H ≤ 10

TYPE 4 CLASS III 30/20 1200 125 8 Nos. Y8 8 Nos. Y8 Y10 @ 90 c/c Y12 @ 100 c/c H≤ 5

Y12 @ 100 c/c

TYPE 5 CLASS IV 30/20 1200 125 8 Nos. Y8 8 Nos. Y8 Y12 @ 75 c/c + Y10 @ 100 5 < H ≤ 10

c/c*

TYPE 7 CLASS III 30/20 1500 150 8 Nos. Y8 8 Nos. Y8 Y12 @ 90 c/c Y12 @ 75 c/c H≤ 5

Y10 @ 75 c/c + Y12 @ 90 c/c +

TYPE 8 CLASS IV 35/20 1500 150 8 Nos. Y10 8 Nos. Y10 5 < H ≤ 10

Y10 @ 75 c/c* Y12 @ 90 c/c*

* Hoops of specified bar diameters shall be bundled using wires, at given spacing respectively

DESIGN PIPE REINFORCEMENT - SUPERCEDED

TYPICAL REINFORCEMENT DETAIL FOR PRECAST PIPES

Pipe Class Longitudinal reinf. Circumferential reinf.

Design Barrel

(AASHTO Concrete Internal For each For

Classifi Thickn Max Fill.

M170M- Grade Diameter Circular Elliptical Outer Inner Elliptical

cation ess

04) Hoop hoop

- - (N/mm2) d (mm) t (mm) L1 L2 C1 C2 C3 H (m)

Y8 @ 100

TYPE 1 CLASS III 30 900 100 12 Nos. Y8 8 Nos. Y8 Y8 @ 100 c/c Y8 @ 100 c/c H≥5

c/c

Y8 @ 100 Y10 @ 100

TYPE 2 CLASS IV 30 900 100 12 Nos. Y8 8 Nos. Y8 Y8 @ 100 c/c 5 < H ≤ 10

c/c c/c

Y8 @ 100 Y10 @ 100 Y10 @ 100

TYPE 4 CLASS III 30 1200 125 12 Nos. Y8 8 Nos. Y8 H≥5

c/c c/c c/c

Y8 @ 75

TYPE 5 CLASS IV 30 1200 125 12 Nos. Y8 8 Nos. Y8 Y12 @ 75 c/c Y10 @ 75 c/c 5 < H ≤ 10

c/c

Y8 @ 100 Y10 @ 100 Y12 @ 100

TYPE 7 CLASS III 30 1500 150 12 Nos. Y8 8 Nos. Y8 H≥5

c/c c/c c/c

Y10 @ 75

TYPE 8 CLASS IV 35 1500 150 12 Nos. Y8 8 Nos. Y8 Y12 @ 75 c/c Y12 @ 75 c/c 5 < H ≤ 10

c/c

CANADA | INDIA | AFRICA | MIDDLE EAST Page | 1-4

You might also like

- Mander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteDocument23 pagesMander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteSalvatore MirandaNo ratings yet

- 11 Malmaison 1600Document23 pages11 Malmaison 1600Bruno TudeiaNo ratings yet

- Erection of Transmission Tower and Design of ResidentialDocument40 pagesErection of Transmission Tower and Design of ResidentialBoopathi YoganathanNo ratings yet

- Summary Sheet (Annexure F1 & F2)Document5 pagesSummary Sheet (Annexure F1 & F2)Ajay Malik100% (1)

- Tokyo Gate BridgeDocument10 pagesTokyo Gate BridgeAnonymous NameNo ratings yet

- Technical Report FORMATDocument8 pagesTechnical Report FORMATmaneeshNo ratings yet

- Mander, Priestley & Park - Observed Stress-Strain Behavior of Confined ConcreteDocument23 pagesMander, Priestley & Park - Observed Stress-Strain Behavior of Confined ConcreteAndrés Esteban Garzón RamírezNo ratings yet

- PipeDocument30 pagesPipepudumai100% (1)

- Aerodynamic Investigation of Cable-Stayed Bridge With 2-Edge GirderDocument5 pagesAerodynamic Investigation of Cable-Stayed Bridge With 2-Edge GirderparamsandhuNo ratings yet

- Bridge ManagementDocument53 pagesBridge Managementsanusi69No ratings yet

- BE-Final Year Project Thapathali PDFDocument41 pagesBE-Final Year Project Thapathali PDFBigyan Upadhayay50% (2)

- Presentation For Mathura Site RCC - WorkDocument143 pagesPresentation For Mathura Site RCC - WorkAnbu100% (1)

- Analysis, Design and Estimation of Multi-Storey Building Using Build MasterDocument37 pagesAnalysis, Design and Estimation of Multi-Storey Building Using Build MasternaveenNo ratings yet

- 0pile Load Test - 1Document39 pages0pile Load Test - 1rushikeskNo ratings yet

- OHE Mast - Bridges - PDFDocument37 pagesOHE Mast - Bridges - PDFMadhurimaMitra70% (10)

- Duratray Steve HallDocument0 pagesDuratray Steve HallPrimitivo GonzálezNo ratings yet

- Jack-In Pile On Weathered GraniteDocument4 pagesJack-In Pile On Weathered GraniteShamsul Bahrin SulaimanNo ratings yet

- Bridge Construction MethodsDocument107 pagesBridge Construction MethodsHendra Ginting73% (11)

- Perhitungan Menara 52 NLS03Document41 pagesPerhitungan Menara 52 NLS03yuwonoNo ratings yet

- Honbun-5030 05 PDFDocument14 pagesHonbun-5030 05 PDFAsif MuhammadNo ratings yet

- Advanced Structural DesignDocument22 pagesAdvanced Structural DesignSarvag NarsudeNo ratings yet

- J3295-W-047 C Temporary Bollard DesignDocument19 pagesJ3295-W-047 C Temporary Bollard DesignKelvin TsoiNo ratings yet

- ZISCO Installs World LongestDocument11 pagesZISCO Installs World LongestJoshua GrahitaNo ratings yet

- The Cracking of StormwaterDocument8 pagesThe Cracking of StormwaterBen SinambelaNo ratings yet

- Development and Application of Lightweight CoringDocument7 pagesDevelopment and Application of Lightweight CoringKevin Kangwa MwilaNo ratings yet

- LEA Associates South Asia Pvt. LTDDocument2 pagesLEA Associates South Asia Pvt. LTDajayNo ratings yet

- Non-Linear Earthquake-Response Analysis of Long Span Cablestayed Bridge ApplicationDocument14 pagesNon-Linear Earthquake-Response Analysis of Long Span Cablestayed Bridge ApplicationTanjil MominNo ratings yet

- Attachment 3 Tender Design DrawingsDocument32 pagesAttachment 3 Tender Design DrawingsPoh T KhoNo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- IBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsDocument10 pagesIBP1081 - 19 Seamless Line Pipes For Challenging Offshore ApplicationsMarcelo Varejão CasarinNo ratings yet

- TRB 01 21 Rooftop Ductwork Round or RectangularDocument4 pagesTRB 01 21 Rooftop Ductwork Round or Rectangularagb71c2478No ratings yet

- Revision 3 Methodology & AP Design - Balaji - Ludhiana-MinDocument38 pagesRevision 3 Methodology & AP Design - Balaji - Ludhiana-MinHemant Yesaji100% (1)

- ROB - No-290 SUP-DESDocument120 pagesROB - No-290 SUP-DESmohana t100% (1)

- T-20-Mehdi Bakhshi-Design of Segmental Tunnel Linings For Serviceability Limit State PDFDocument48 pagesT-20-Mehdi Bakhshi-Design of Segmental Tunnel Linings For Serviceability Limit State PDFMarlonNo ratings yet

- HRC ReportDocument7 pagesHRC ReportswapnilNo ratings yet

- Codal Practices For RCC Design Part A General by VKMehtaDocument22 pagesCodal Practices For RCC Design Part A General by VKMehtavijaymehta3450% (1)

- Cer Alum Ladder Tray CatalogDocument37 pagesCer Alum Ladder Tray Catalogmashan98No ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Mining Solutions BrochureDocument4 pagesMining Solutions Brochuredjb300No ratings yet

- Kaptronics Private Limited PDFDocument9 pagesKaptronics Private Limited PDFkaptronicsNo ratings yet

- Azad 2015Document13 pagesAzad 2015pradeep kankeriNo ratings yet

- Super TitanDocument56 pagesSuper TitanJaime Alvarez LiraNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Kamewa Steel Series WaterjetsDocument2 pagesKamewa Steel Series WaterjetsAnkit singhNo ratings yet

- Design Report - Basement SlabDocument27 pagesDesign Report - Basement Slabsd.bushra91No ratings yet

- Underpinning For TBM To Under-Cross A Building in Thomson-East Coast Line (TEL) Contract T220Document11 pagesUnderpinning For TBM To Under-Cross A Building in Thomson-East Coast Line (TEL) Contract T220freezefreezeNo ratings yet

- 05.waterjet 2p-20.11.20Document2 pages05.waterjet 2p-20.11.20Nico LomibaoNo ratings yet

- The Pipeline-Steels X100 and X120Document24 pagesThe Pipeline-Steels X100 and X120thepleguyNo ratings yet

- Petroleum Production Engineering-I: Third Year Second TermDocument46 pagesPetroleum Production Engineering-I: Third Year Second Termsarfraz hussain100% (1)

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- All Type of Pile Load TestDocument120 pagesAll Type of Pile Load TestLindsey Smith100% (17)

- Rainer Wenty, Plasser & TheurerDocument8 pagesRainer Wenty, Plasser & Theurerbalaji817150No ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Sampling LectureDocument40 pagesSampling LectureajayNo ratings yet

- Beam Analysis by Stiffness MethodDocument5 pagesBeam Analysis by Stiffness MethodajayNo ratings yet

- National Highways Authority of IndiaDocument6 pagesNational Highways Authority of IndiaajayNo ratings yet

- QB103622 UnitIIDocument33 pagesQB103622 UnitIIdhavamanidossNo ratings yet

- Span 20 MDocument111 pagesSpan 20 MajayNo ratings yet

- Sampling Distributions LectureDocument51 pagesSampling Distributions LectureajayNo ratings yet

- 1.0 1.1 GeneralDocument6 pages1.0 1.1 GeneralajayNo ratings yet

- Properties of Matrix Addition, Subtraction, Multiplication, Examples-1-11Document11 pagesProperties of Matrix Addition, Subtraction, Multiplication, Examples-1-11ajayNo ratings yet

- 11,580 5,790 L/L 5,790 L/R 1,500 1,500: Guard Rail Ref. General Details - Guard RailDocument4 pages11,580 5,790 L/L 5,790 L/R 1,500 1,500: Guard Rail Ref. General Details - Guard RailajayNo ratings yet

- BC 15Document2 pagesBC 15ajayNo ratings yet

- IMWA TL 00441 Submission of Lateral Pile Load Test Report For Test Pile at MJB at CH 341+577 Dated 12.06.2021Document7 pagesIMWA TL 00441 Submission of Lateral Pile Load Test Report For Test Pile at MJB at CH 341+577 Dated 12.06.2021ajayNo ratings yet

- 07 Appendix 2eDocument4 pages07 Appendix 2eajayNo ratings yet

- New Reinforced Concrete Beam. Grouted Stone Pitching Erosion ProtectionDocument1 pageNew Reinforced Concrete Beam. Grouted Stone Pitching Erosion ProtectionajayNo ratings yet

- Design For 1x2x2m BoxDocument44 pagesDesign For 1x2x2m BoxajayNo ratings yet

- Street Light For Somalia DriveDocument5 pagesStreet Light For Somalia DriveajayNo ratings yet

- Box Culvert Design As Per AASHTO LRFDDocument18 pagesBox Culvert Design As Per AASHTO LRFDshish0iitr0% (1)

- LEA Associates South Asia Pvt. LTDDocument2 pagesLEA Associates South Asia Pvt. LTDajayNo ratings yet

- Design of Abutment-24+680Document27 pagesDesign of Abutment-24+680ajayNo ratings yet

- Staad Model Showing Node NumberDocument4 pagesStaad Model Showing Node NumberajayNo ratings yet

- Appendix - 1: Comparison of Pipe Reinforcement ArrangementsDocument1 pageAppendix - 1: Comparison of Pipe Reinforcement ArrangementsajayNo ratings yet

- Worked Examples Ec2 Def080723Document29 pagesWorked Examples Ec2 Def080723Paulius StasiulaitisNo ratings yet

- LEA Associates South Asia Pvt. LTDDocument2 pagesLEA Associates South Asia Pvt. LTDajayNo ratings yet

- Design of Abutment - 31+010Document26 pagesDesign of Abutment - 31+010ajayNo ratings yet

- Section B-B Details of Typical RC Pipe Joint: Table For Non Encased PipeDocument1 pageSection B-B Details of Typical RC Pipe Joint: Table For Non Encased PipeajayNo ratings yet

- General Notes... 2-ModelDocument1 pageGeneral Notes... 2-ModelajayNo ratings yet

- Section B-B: Table For Non Encased PipeDocument1 pageSection B-B: Table For Non Encased PipeajayNo ratings yet

- Design Philosophy of UDocument6 pagesDesign Philosophy of UajayNo ratings yet

- Lea Associates South Asia Pvt. LTDDocument41 pagesLea Associates South Asia Pvt. LTDajayNo ratings yet

- Inlet To Kazo: NotesDocument1 pageInlet To Kazo: NotesajayNo ratings yet

- A Seminar Report On Significance of Non-Destructive Testing of Concrete.Document21 pagesA Seminar Report On Significance of Non-Destructive Testing of Concrete.Nikhil50% (2)

- Kluber PresentationDocument79 pagesKluber PresentationZegera MgendiNo ratings yet

- Worcester 819 829Document8 pagesWorcester 819 829Văn Đình NhậtNo ratings yet

- HILTI CE - Ch.9 - Firestop PDFDocument30 pagesHILTI CE - Ch.9 - Firestop PDFValentin A.No ratings yet

- Compressor Technical Data: NJ6226Z 220-240 V 50 HZ 142HAO4 A - Application / Limit Working ConditionsDocument3 pagesCompressor Technical Data: NJ6226Z 220-240 V 50 HZ 142HAO4 A - Application / Limit Working ConditionsFernando GomezNo ratings yet

- Is-Code Books ListDocument51 pagesIs-Code Books ListMohan Kumar100% (3)

- Presentation1 6.10.15Document31 pagesPresentation1 6.10.15Paramasivam VeerappanNo ratings yet

- VRV Heat Recovery Hot Water System - PCVMT1536 PDFDocument12 pagesVRV Heat Recovery Hot Water System - PCVMT1536 PDFAhmed NabilNo ratings yet

- Bbs Pot. Besi RS MTDocument8 pagesBbs Pot. Besi RS MTAmudNo ratings yet

- Indomo BrochureDocument28 pagesIndomo BrochureShen YpNo ratings yet

- Hydraulics Reviewer For Civil Engineering StudentsDocument2 pagesHydraulics Reviewer For Civil Engineering StudentsKing BangngayNo ratings yet

- Abstract of Retaining Wall & Bathing Ghat To Protect Ramraja Temple From Flood Protection of Angori River at Bhagor VillageDocument4 pagesAbstract of Retaining Wall & Bathing Ghat To Protect Ramraja Temple From Flood Protection of Angori River at Bhagor VillageankitNo ratings yet

- Flupec - Catalog-Garnituri PDFDocument928 pagesFlupec - Catalog-Garnituri PDFRadu VasileNo ratings yet

- Polymer: P. Müller, J. Bere, E. Fekete, J. M Oczo, B. Nagy, M. K Allay, B. Gyarmati, B. Puk AnszkyDocument10 pagesPolymer: P. Müller, J. Bere, E. Fekete, J. M Oczo, B. Nagy, M. K Allay, B. Gyarmati, B. Puk AnszkyKeiidys MartinezNo ratings yet

- MSS-SP-97 (2006)Document15 pagesMSS-SP-97 (2006)Rahul MehtaNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument1 pageSpreadsheets To BS 8110: The Concrete CentreAung MayNo ratings yet

- Btech Project Report Template-1Document38 pagesBtech Project Report Template-1OMShivRajaBabuNo ratings yet

- Jeffamine D-205 Amine: Technical BulletinDocument3 pagesJeffamine D-205 Amine: Technical BulletinMichael WokurekNo ratings yet

- TDS - Mastertop 20Document2 pagesTDS - Mastertop 20Venkata RaoNo ratings yet

- Airfield Pavement Rehabilitation PDFDocument114 pagesAirfield Pavement Rehabilitation PDFTim LinNo ratings yet

- Application Bulletin - Paints and CoatingsDocument2 pagesApplication Bulletin - Paints and CoatingsjoseNo ratings yet

- Pre-Final Bill Supplimentary works-MVGR 02.07.2019Document112 pagesPre-Final Bill Supplimentary works-MVGR 02.07.2019Anonymous ImoZI0363No ratings yet

- Fire - X 1620 - ENDocument2 pagesFire - X 1620 - ENFrikkie Le GrangeNo ratings yet

- Advantages of ForgingDocument20 pagesAdvantages of ForgingPramod DhaigudeNo ratings yet

- RESULT Conclusion and Discussion LAB 7Document11 pagesRESULT Conclusion and Discussion LAB 7Fiena Azmi50% (2)

- Kitz Complete Ball Valve Catalog PDFDocument132 pagesKitz Complete Ball Valve Catalog PDFDinifaanNo ratings yet

- Thermo Exp Refrigeration Cycle ReportDocument11 pagesThermo Exp Refrigeration Cycle Reportbaemaejor100% (1)

- Solutions From Dow Automotive SystemsDocument8 pagesSolutions From Dow Automotive SystemsHuỳnh TGNo ratings yet

- Sama Wira Mulpha IndustiresDocument24 pagesSama Wira Mulpha Industireslbhock123No ratings yet