Professional Documents

Culture Documents

FIR No. JSL-KAN-OGC-92091-FIR-151 Insp. Date. 12.01.2021

Uploaded by

kbpatel123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIR No. JSL-KAN-OGC-92091-FIR-151 Insp. Date. 12.01.2021

Uploaded by

kbpatel123Copyright:

Available Formats

FIR No:

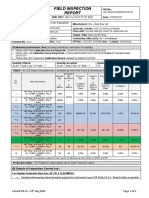

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/151

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 13/01/2021

Project: South Grid Debottlenecking Phase II Project Manufacturer: M/s. Jindal Saw Ltd.

Supply Intended For: OQ Gas Network (OGC) Order No/ LOA No: OGC-21-2019-LOA-92091

Inspection Ordered By: M/s. Jindal Saw Ltd. Place with: OQ Gas Network (OGC) to Jindal Saw Ltd.

Supplier: M/s. Jindal Saw Ltd. Supply / Item: Bare LSAW Pipes

Performing Office (PO): BV – Gandhidham Contracting Office (CO): BV – Ahmedabad

Drawing No: -N.A.- Rev.: -N.A.- ITP No. : Q-OGC-2020S Rev. : C Dated : 03/07/2020

A] Measuring Instruments Used (including satisfactory verification of suitability)

Please refer Plant Calibration Record Report No. JSLM/ICR/J1/21/0002 Rev.0 Dated 03.01.2021

Please refer Lab Calibration Record Report No. JSLM/LAB/CALIBRATION LIST/2021/02 Rev.0 Dated 08.01.2021

Quantity Offered: Quantity Accepted: Quantity Rejected:

As per “Today’s Qty” of Table – 1 As per “Today’s Qty” of Table – 1 Nil

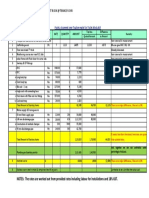

TABLE – 1: LOA Status (Cumulative Qty is accepted qty from Final Visual & Dimensional Inspection)

Ordered

Ordered Previous Today’s Cumulative Balance

Qty

Qty Qty Qty Qty Qty

combined

Sr. %

Item Description In

No. In Meters In Meters Completed

In In Meters

(No's of (No's of In Meters

Meters Meters (No's of

Pipe) Pipe)

Pipe)

PART 36" Pipe, 22.23mm WT, API 5L

24 24 0.000 24.860 24.860 NIL 100.00%*

A/014 Gr. X65MS / L450MS, PSL2, SAWL

PART 32" Pipe, 22.23mm WT, API 5L

48 48 0.000 0.000 0.000 48.000 0.00%

A/016 Gr. X65MS / L450MS, PSL2, SAWL

* - Completed % finalize after satisfactory test result of lab testing.

TABLE – 2: Production Status of Item mentioned in Table – 1 (32” OD X 19.05 MM WT)

Inspection Stage Previous Qty Today’s Qty Cumulative Qty

Plates Received at Plant 2732 0 2732

Plate Auto UT 2716 3 2719

Pipe Forming 2715 4 2719

Tack Welding 2715 4 2719

ID Welding 2715 4 2719

OD Welding 2715 4 2719

Cold Expansion 2715 4 2719

Hydro Test 2715 4 2719

Magnetic Particle Inspection 2714 4 2718

Final Auto Weld UT 2714 4 2718

End X-Ray 2713 0 2713

Repair Required 27 0 27

Repair Pipe Accepted 27 0 27

Pipes Accepted from Final Visual & Dimensional Inspection (No’s of Pipe) 2710 0 2710

Pipes Accepted from Final Visual & Dimensional Inspection (Meters) 33621.950 0.000 33621.950

Pipes Released (No’s of Pipe) 0 0 0

Pipes Released (Meters) 0.000 0.000 0.000

Pipe Rejected (No's of Pipe) 0 0 0

B] Details of Inspection Carried out :

For MPQT & Regular production of Pipes (Size: 36” OD X 22.23 MM WT). :-

Selected MPQT pipes L121A01935, L121A01936 and L121A01938.

Witnessed Weldability test as per ITP Sr.No.B.31 - Found satisfactory. (As per client e-mail on 6th Oct 2020

confirmation with proceed the Weldability for the size of 36’’ (914mm) mm OD X 22.23mm WT. (Welding under

progress).

Format FIR r5 – 19th Aug 2015 Page 1 of 2

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/151

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 13/01/2021

B] Details of Inspection Carried out :

For Regular Production of Pipe Size: 32” OD X 19.05 MM WT.:-

Monitoring Edge milling as per ITP Sr.No.3.1 - Found satisfactory.

Monitoring Crimping of plates as per ITP Sr.No.3.2 - Found satisfactory.

Monitoring JCO forming as per ITP Sr.No. 3.3 - Found Satisfactory.

Monitoring welding consumable of wire, Flux & Electrode as per approved WPS and as per ITP Sr.No.4.2 - Found Satisfactory.

Monitoring Automatic tack welding as per ITP Sr.No. 4.3- Found satisfactory.

Monitoring Tab welding for GMAW welding as per ITP Sr.No. 4.4- Found satisfactory.

Monitoring Automatic submerged arc welding as per ITP Sr.No. 4.5 - Found satisfactory.

Monitoring preliminary visual inspection as per ITP Sr.No.4.6 - No injurious surface observed.

Monitoring straightness of pipe as per ITP Sr.No.6.0 - Found within acceptable limit.

Random witnessed Cold expansion as per ITP Sr.No.7.0 - Found satisfactory.

Random witnessed weekly Pressure gauge calibration as per ITP Sr.No. 8.0 - Found satisfactory.

Random witnessed hydrostatic test as per ITP Sr.No.8.0 - Neither pressure drop nor leakage observed during holding time of 10

seconds minimum.

Random witnessed calibration of pipe for final automatic Ultrasonic testing as per ITP Sr.No. 9.1 - Found satisfactory.

Random witnessed Final Automatic Ultrasonic testing as per ITP Sr.No. 9.1 - No significant defect observes.

Random witnessed calibration of MUT as per ITP Sr.No. 9.2 - Found satisfactory.

Random witnessed MUT untested weld length of 250mm mini. and AUT indication by angle probe as per ITP Sr.No. 9.2 - No

significant defect observes.

Random witnessed MUT circumference direction for longitudinal defect detection 25 mm mini. angle probe as per ITP Sr.No. 9.2 -

No significant defect observes.

Random witnessed MUT circumference up to 110mm mini. by TR Probe as per ITP Sr.No. 9.2 - No significant defect observes.

Random witnessed magnetic particle inspection as per ITP Sr.No. 9.4 - No significant defect observes.

Random witnessed residual magnetism as per ITP Sr.No. 9.5 - Found within acceptable limit.

Identification: Nil

Remark: Photographs not attached due to USB access not permitted to JSL premises.

Note:-

1) RMTC review for 22.23mm WT – Inclusion report Thickness Wrong and Continuous cast method not specified

2) RMTC review for 19.05mm WT – Continuous cast method not specified

3) RMTC review for 14.27mm WT – Continuous cast method not specified, HIC Control sample Heat No. are wrong in Main MTC and

HIC report.

Attending Inspectors: Nimesh Patel, Kaushikkumar Patel - Day Shift & Mohit Solanki – Night Shift

Category: (1) Accepted, (2) Conditionally Accepted, (3) Re-Inspection Required, (4) Rejected, (5) Advice / Instruction from Client Required.

Inspection Date(s):

ANY NON Yes

12/01/2021

CONFORMITY

FOUND? No

Complete

Inspection Place(s):

ORDER

JCO – I, Jindal Saw Ltd, Kaushikkumar Patel

STATUS

Nanakapaya, Mundra Balance Supplier’s Signature & Date Date: 13.01.2021

Telephone No. Mobile No. +91-9687000073

`

Format FIR r5 – 19th Aug 2015 Page 2 of 2

You might also like

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- FIR No. JSL-KAN-OGC-92091-FIR-152 Insp. Date. 13.01.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-152 Insp. Date. 13.01.2021kbpatel123No ratings yet

- Field Inspection Report for Jindal Saw LtdDocument3 pagesField Inspection Report for Jindal Saw Ltdkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-179 Insp. Date. 09.02.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-179 Insp. Date. 09.02.2021kbpatel123No ratings yet

- Field Inspection Report for Jindal Saw LtdDocument2 pagesField Inspection Report for Jindal Saw Ltdkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- Monthly Progress Report For January 2019 Bridge ConstructionDocument11 pagesMonthly Progress Report For January 2019 Bridge Constructionghaghra bridge100% (1)

- FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021kbpatel123No ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020kbpatel123No ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- Piping & Mechanical BOQ - R1Document100 pagesPiping & Mechanical BOQ - R1yassh RaoNo ratings yet

- Project Status As at 26.08.20Document4 pagesProject Status As at 26.08.20Anilduth BaldanNo ratings yet

- Field Inspection Report for Jindal Saw LtdDocument4 pagesField Inspection Report for Jindal Saw Ltdkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- Mechanical Commissioning Testing ToolsDocument4 pagesMechanical Commissioning Testing ToolsGibbs PerNo ratings yet

- Q28743 - C1 CondenserDocument1 pageQ28743 - C1 CondenserMuneeb AkhtarNo ratings yet

- Heat Exchanger Specification Sheet HRS UnitsDocument1 pageHeat Exchanger Specification Sheet HRS UnitsMuneeb AkhtarNo ratings yet

- JSL/KAN/OGC/92091/FIR/014 Field Inspection ReportDocument2 pagesJSL/KAN/OGC/92091/FIR/014 Field Inspection Reportkbpatel123No ratings yet

- Daily Progress Report: SR No Activity Unit ProgressDocument1 pageDaily Progress Report: SR No Activity Unit ProgressLokabhiram DikshitNo ratings yet

- Weld Cost Calculation: Weld Detail: Weld TypeDocument18 pagesWeld Cost Calculation: Weld Detail: Weld TypeTunji AminuNo ratings yet

- Daily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Document3 pagesDaily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Manoranjan sharmaNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- PR Bolt-2Document3 pagesPR Bolt-2rupesh417No ratings yet

- Steam Drum CalulationDocument85 pagesSteam Drum Calulationsibi_s_rajNo ratings yet

- Installation Pipework: Distribution Main Ring Distribution Ring 1 Distribution Ring 2Document4 pagesInstallation Pipework: Distribution Main Ring Distribution Ring 1 Distribution Ring 2Rizwan AliNo ratings yet

- EN455-vinyl&nitrile Blend GlovesDocument8 pagesEN455-vinyl&nitrile Blend GlovesBenny Jaime Toshio ZhaoNo ratings yet

- CHECKLIST (Work Performed, Repaired & Replaced)Document2 pagesCHECKLIST (Work Performed, Repaired & Replaced)jabirNo ratings yet

- IS-REKA-59.1-KU001 Inspection Sheet of Ceilling Kereta UkurDocument21 pagesIS-REKA-59.1-KU001 Inspection Sheet of Ceilling Kereta UkurBhimantara Yudha PrawiraNo ratings yet

- New Pipe Plant Tentative Plan and Cost EstimationDocument8 pagesNew Pipe Plant Tentative Plan and Cost EstimationUtkarsh TiwariNo ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020kbpatel123No ratings yet

- Masoneilan Valves Spec Data Sheet for Steam and Nitrogen NEW VALVESDocument5 pagesMasoneilan Valves Spec Data Sheet for Steam and Nitrogen NEW VALVESRaulRodriguezNo ratings yet

- RAB - 2 Mahakal Const HDPE Pipe Laying WorkDocument13 pagesRAB - 2 Mahakal Const HDPE Pipe Laying WorkgautamNo ratings yet

- Agnice Fire Rate QuotationDocument10 pagesAgnice Fire Rate QuotationRathodNo ratings yet

- Guinea SOS Fluid Analysis Laboratory ReportDocument2 pagesGuinea SOS Fluid Analysis Laboratory ReportEddie RoetsNo ratings yet

- Hydraulic Cal - Tanks Vent To FlareDocument1 pageHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Vernier CalibDocument1 pageVernier CalibOmkar PrindavankarNo ratings yet

- 3.1digital Vernier Caliper Calibration CertificateDocument1 page3.1digital Vernier Caliper Calibration CertificateGolden RosesNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Name of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUDocument45 pagesName of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUTuara sangmaNo ratings yet

- SAUDI ARAMCO GOSP-4 B2 Heat Exchanger Tube Inspection ReportDocument7 pagesSAUDI ARAMCO GOSP-4 B2 Heat Exchanger Tube Inspection ReportDavoodNo ratings yet

- By Pass Valve BifurcationDocument5 pagesBy Pass Valve BifurcationSarthak EnterprisesNo ratings yet

- 2mva TR-2 For 2 PT MillDocument2 pages2mva TR-2 For 2 PT MillVishal Kumar SinghNo ratings yet

- RFI Submission Jaffna-Updated-AprilDocument4 pagesRFI Submission Jaffna-Updated-Aprillakshitha WithanageNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- Project Data: Project Name Soluble Evaporation Project Number 027 Author Rajesh Description Date 5/17/2021 Design Code ENDocument29 pagesProject Data: Project Name Soluble Evaporation Project Number 027 Author Rajesh Description Date 5/17/2021 Design Code ENAbdul basithNo ratings yet

- Gas Pressure DropDocument11 pagesGas Pressure DropamirejazNo ratings yet

- 16 - Gas Line SizingDocument11 pages16 - Gas Line SizingJunaid MateenNo ratings yet

- Review Over Topline ReplyDocument1 pageReview Over Topline ReplyMaha KalaiNo ratings yet

- JSL/KAN/OGC/92091/FIR/014 Field Inspection ReportDocument2 pagesJSL/KAN/OGC/92091/FIR/014 Field Inspection Reportkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-014 Date. 16.06.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-014 Date. 16.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- Field Inspection Report SummaryDocument3 pagesField Inspection Report Summarykbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- Industry & Facilities Inspection ReportDocument10 pagesIndustry & Facilities Inspection Reportkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- CV Ram Deo Yadav Quality EngineerDocument7 pagesCV Ram Deo Yadav Quality Engineerkbpatel123No ratings yet

- Release Note No: JSL/KAN/OGC/92091/SAWL/BARE/RN/003Document2 pagesRelease Note No: JSL/KAN/OGC/92091/SAWL/BARE/RN/003kbpatel123No ratings yet

- Tax Invoice: Product Description Qty Gross Discount Taxable Value Igst TotalDocument1 pageTax Invoice: Product Description Qty Gross Discount Taxable Value Igst Totalkbpatel123No ratings yet

- Inspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour ServiceDocument1 pageInspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour Servicekbpatel123No ratings yet

- Curriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting EquipmentDocument4 pagesCurriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting Equipmentkbpatel123No ratings yet

- Steelbird - Faceshield BillDocument1 pageSteelbird - Faceshield Billkbpatel123No ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- Check ListDocument1 pageCheck Listkbpatel123No ratings yet

- Inspection of CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 NON-SOUR SERVICE & API 5L Gr. L450Ms (X65Ms), Psl2 Sour ServiceDocument1 pageInspection of CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 NON-SOUR SERVICE & API 5L Gr. L450Ms (X65Ms), Psl2 Sour Servicekbpatel123No ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021kbpatel123No ratings yet

- Chandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979Document13 pagesChandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979kbpatel123No ratings yet

- Ts LSAW SpecificationDocument40 pagesTs LSAW Specificationkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- Inspection Certificate: IC No.: Date: Page 1 of 3Document3 pagesInspection Certificate: IC No.: Date: Page 1 of 3kbpatel123No ratings yet

- Inspection Certificate: IC No.: Date: Page 1 of 3Document3 pagesInspection Certificate: IC No.: Date: Page 1 of 3kbpatel123No ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Cucs 016 13 PDFDocument16 pagesCucs 016 13 PDFAnonymous SlyvspdBNo ratings yet

- Compare and Contrast History EssayDocument9 pagesCompare and Contrast History EssayGiselle PosadaNo ratings yet

- Leaders Eat Last - Book Summary - VWS - v2.0Document23 pagesLeaders Eat Last - Book Summary - VWS - v2.0REEM HAMDY100% (1)

- Bonny Norton Peirce - Social Identity and InvestmentDocument24 pagesBonny Norton Peirce - Social Identity and InvestmentAllie SANo ratings yet

- Coding deCoding class insightsDocument18 pagesCoding deCoding class insightsShalabh Vikram SahuNo ratings yet

- RRB NTPC Cut Off 2022 - CBT 2 Region Wise Cut Off Marks & Answer KeyDocument8 pagesRRB NTPC Cut Off 2022 - CBT 2 Region Wise Cut Off Marks & Answer KeyAkash guptaNo ratings yet

- Lauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Document66 pagesLauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Olga de Ramos100% (1)

- Slogan Goes Here: Local Store Importing CompanyDocument1 pageSlogan Goes Here: Local Store Importing Company5gt6kdfdqhNo ratings yet

- Carco h90vsDocument9 pagesCarco h90vsRoxana Elizabeth Valencia NavarrteNo ratings yet

- Bungsuan NHS Then and Now in PerspectiveDocument2 pagesBungsuan NHS Then and Now in Perspectivedanicafayetamagos02No ratings yet

- Energy Performance of Hot, DryDocument128 pagesEnergy Performance of Hot, DrySrinu ReddyNo ratings yet

- Chapter 12 1Document15 pagesChapter 12 1Brigitte ReyesNo ratings yet

- Summer Training Report at B H E L BhopalDocument66 pagesSummer Training Report at B H E L BhopalshantanuNo ratings yet

- ResearchDocument44 pagesResearchGwend MemoracionNo ratings yet

- JuliadatascienceDocument214 pagesJuliadatascienceFulvio JoséNo ratings yet

- 2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Document96 pages2Tafseer2019Sep4 17 24oc1 8 29nov5 262020jan7 21F11 18 25Aroob YaseenNo ratings yet

- Envi. Data AcquisitionDocument10 pagesEnvi. Data AcquisitionDexter John Gomez JomocNo ratings yet

- Macalloy Corporate Brochure September 2018 LR PDFDocument12 pagesMacalloy Corporate Brochure September 2018 LR PDFsampathkumarNo ratings yet

- DBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1Document282 pagesDBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1RaymondNo ratings yet

- Hypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHDocument6 pagesHypomorphic Mutations in PRF1, MUNC13-4, and STXBP2 Are Associated With Adult-Onset Familial HLHLeyla SaabNo ratings yet

- Treatment: Animated Text Onstage:: Topic: Learning Objective: WMS Packages Module Introduction Display 1Document8 pagesTreatment: Animated Text Onstage:: Topic: Learning Objective: WMS Packages Module Introduction Display 1hikikNo ratings yet

- Kendriya Vidyalaya Sangathan: Observation & ReportingDocument6 pagesKendriya Vidyalaya Sangathan: Observation & ReportingSravan KumarNo ratings yet

- Standard Top Up Vouchers: Prices:: Internet Blocked Internet BlockedDocument15 pagesStandard Top Up Vouchers: Prices:: Internet Blocked Internet BlockedJeet SinghNo ratings yet

- Farmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptDocument87 pagesFarmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptYemima MNo ratings yet

- 03 Agriculture GeofileDocument4 pages03 Agriculture GeofilejillysillyNo ratings yet

- Structural Knowledge LEEERRR PDFDocument22 pagesStructural Knowledge LEEERRR PDFMaría Paula BaqueroNo ratings yet

- Social Responsibility and Managerial Ethics (Principles of Management)Document35 pagesSocial Responsibility and Managerial Ethics (Principles of Management)Reader94% (16)

- Court Documents - Purdue Pharma CaseDocument236 pagesCourt Documents - Purdue Pharma CaseHung LeNo ratings yet

- PXI Express Chassis 14/18-Slot Rack Mount Kits: Installation GuideDocument4 pagesPXI Express Chassis 14/18-Slot Rack Mount Kits: Installation GuideDomenico DomyNo ratings yet

- Interconnection of Power SystemsDocument5 pagesInterconnection of Power SystemsRohan Sharma50% (2)