Professional Documents

Culture Documents

Assembly Management System-2 Machine Lasting: Men's

Uploaded by

Sachin SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assembly Management System-2 Machine Lasting: Men's

Uploaded by

Sachin SinghCopyright:

Available Formats

Presentation of PGFDP Student 2015-17 Batch-A :Sachin Singh

Assembly Management System-2

Machine Lasting

+ Neoprene

Sole Pressing [ Pressure3-6 bar] 14-16 sec

Roughing [ Wire Brush ] {Remove grain

Heat Setting 5-6 minutes[Full Grain]

Adhesive Application: PU Adhesive

Drying in Machine: 10 minutes

Tack Removal From Insole

Adhesive on Lasting margin

Dry time : 30-40 minutes

Scouring[ Emery Paper]

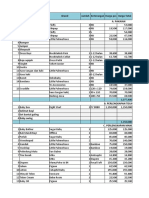

Material Consumption

Shoe Room & Packing

Lacing [ Lace

Shoe ] Toepuff Counter Toe Mulling

Heat Reactivator

Selection of Sole

Insole Attaching Molding [m/c]

Article No

Attachment Derby: 10 [M/c] [ M/c] [ Steam

structure}

[Tools used: Insertion of mm gap [0.8-1.5mm Heat]

Delasting

Cleaning

Marking

Ponding

Staples or hot Toepuff & thk Gents] Hot:1500C 1100C, 6-8 Toe Seat

Chiller

Selectio melt Stiffener into Oxford : 2-3 Time 6-8 Lining sec in case Lasting Lasting

Cost

Style of Shoe √ n of Last Size adhesive] Upper Leather √ Upper mm Gap sec 1100 C 0

Cold: ─5 C Pasting of Leather [M/c] [M/c]

Men's Aniline Finish √ × √ × √ √ √ √ √ √ √ √ √ √ √ √ √

Derby √ Semi Aniline Finish

Oxford Pigmented

C Hinge Last & Heel Plated Last

Brogue Nappa

Continental/ Blended Insole

Boat Oil Pull up

Moccasin Glazed Finish

Boot Burnish

7 √ √ √ √ √ √ √ √

Monk Embossed

Sneaker PU Film Coated

Slip on Brush off

Sandals Waxy Nubuck

Canvas Dye Nubuck

Bucks Split Suede

Mocs Reverse Suede

Skilled Labor

SemiSkilled Labor

Un Skilled Labor

Note: Cemented Construction

Direct Attachment: Soles are attached directly to the Lasted Upper.

FDDI NOIDA

You might also like

- Member List For Indonesia Mold & Die AssociationDocument14 pagesMember List For Indonesia Mold & Die AssociationDaniel Pandapotan MarpaungNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro calixtoNo ratings yet

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- ADawliah Saudi ArabiaDocument435 pagesADawliah Saudi ArabiaDataGroup Retailer AnalysisNo ratings yet

- Cross Stitch Collection - August 2016Document75 pagesCross Stitch Collection - August 2016mabelsepu4201100% (19)

- Volvo: Engine Type EngineDocument9 pagesVolvo: Engine Type EngineDávid VargaNo ratings yet

- Checkmate - Large 6mm Foam Parts - 2021-08-07Document1 pageCheckmate - Large 6mm Foam Parts - 2021-08-07Pan MietekNo ratings yet

- Alta Resolução Teia Bilionaria Industria Das SementesDocument1 pageAlta Resolução Teia Bilionaria Industria Das SementesMichele FreitasNo ratings yet

- 3M Quick Reference Guide Jun17Document10 pages3M Quick Reference Guide Jun17Faith_No_MoreNo ratings yet

- Zone Froide - 20°C 24 CAISSES (Une Palette)Document1 pageZone Froide - 20°C 24 CAISSES (Une Palette)Daniela DuşaNo ratings yet

- 4 CA4250P25K15T1NE5A80 DZ722R 哥伦比亚 维修手册 电气线路图 英文Document1 page4 CA4250P25K15T1NE5A80 DZ722R 哥伦比亚 维修手册 电气线路图 英文Jorge Elieser Sánchez RiosNo ratings yet

- MCB Toilet ElevationspdfDocument1 pageMCB Toilet Elevationspdfjuy rose cunananNo ratings yet

- Philippines Masinloc Power Plant: Project TileDocument1 pagePhilippines Masinloc Power Plant: Project TileLeo PascualNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- GN 300 002Document1 pageGN 300 002Xavier LeeNo ratings yet

- Guu 508: Site Planning of An Urban Area: EntryDocument1 pageGuu 508: Site Planning of An Urban Area: EntryvandniNo ratings yet

- XB2BD33 DATASHEET AU en-GB PDFDocument1 pageXB2BD33 DATASHEET AU en-GB PDFCaarlosNo ratings yet

- F3-500-CI-PLN-PPL-0001 - AD Overall Plot PlanDocument1 pageF3-500-CI-PLN-PPL-0001 - AD Overall Plot PlanErim EsenNo ratings yet

- Contact Block XEPA1081D64 PDFDocument1 pageContact Block XEPA1081D64 PDFzeljkoNo ratings yet

- Shell Asgard Basement 1 CCTVDocument1 pageShell Asgard Basement 1 CCTVbharathayyappa1806No ratings yet

- Tumkur Bangalore PlanDocument1 pageTumkur Bangalore PlanNarasimman NarayananNo ratings yet

- Mech Engine PowerShift Transm PDFDocument2 pagesMech Engine PowerShift Transm PDFFútbol y másNo ratings yet

- Panduan Tugas Pip PDFDocument72 pagesPanduan Tugas Pip PDFMuhammad RienaldyNo ratings yet

- 07A. Section-Sub-station Automation - System Architecture 1 - 2Document1 page07A. Section-Sub-station Automation - System Architecture 1 - 2Prashant SinghNo ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- PLU - WS - REVISED SHAKTI SPORT CLUB-ModelDocument1 pagePLU - WS - REVISED SHAKTI SPORT CLUB-ModelvishalNo ratings yet

- July 2021 Daily MeetingDocument4 pagesJuly 2021 Daily MeetingPegelou Jhon LagutinNo ratings yet

- Sample Cause & EffectDocument1 pageSample Cause & EffectNishant AroraNo ratings yet

- MCM - 120-Pin Connector: All Information Subject To Change Without NoticeDocument1 pageMCM - 120-Pin Connector: All Information Subject To Change Without NoticeLuis Eduardo Corzo EnriquezNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Interconnection Diagram XL-200 - 110V PDFDocument1 pageInterconnection Diagram XL-200 - 110V PDFOluas OlivNo ratings yet

- M81 CURVE KPI 100 Kontrak 18 Bulan SD Nov'23Document5 pagesM81 CURVE KPI 100 Kontrak 18 Bulan SD Nov'23Dimas TaufiqNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Benjamín Muñoz MuñozNo ratings yet

- Quotation Expandable Seal ProtoDocument8 pagesQuotation Expandable Seal ProtoRohitNo ratings yet

- GGP 92 000000 MP 4033 93801 0001 GG300HBN0251 03 ModelDocument1 pageGGP 92 000000 MP 4033 93801 0001 GG300HBN0251 03 Modelchandana kumarNo ratings yet

- SampleDocument1 pageSampleKYC BIM010No ratings yet

- Electric CAT375L-1JMDocument2 pagesElectric CAT375L-1JMTrần Tiến AnhNo ratings yet

- Ag Ug: 330 TH Ru GR Av El at El - +2 370 0Document1 pageAg Ug: 330 TH Ru GR Av El at El - +2 370 0John SmitNo ratings yet

- DRP001-OUF-GAL-940090-K-ERC-002-001-S1 - SignedDocument1 pageDRP001-OUF-GAL-940090-K-ERC-002-001-S1 - SignedpathanNo ratings yet

- SUB SOIL & SURFACE DRAINS FOR B-01,02&03-ModelDocument1 pageSUB SOIL & SURFACE DRAINS FOR B-01,02&03-ModelKaran KumarNo ratings yet

- TRD-XXXX-Assam - Guwahati - Lal Ganesh-1st-flr-Type-B-ML-Ver 0 0 - 07-07-2022-1st-FLDocument1 pageTRD-XXXX-Assam - Guwahati - Lal Ganesh-1st-flr-Type-B-ML-Ver 0 0 - 07-07-2022-1st-FLpalashkalita127No ratings yet

- Mag Stal Aerodrome Map 2021v1Document1 pageMag Stal Aerodrome Map 2021v1Nathaniel BradburyNo ratings yet

- Fpso OverviewDocument1 pageFpso OverviewSean ChoiNo ratings yet

- 24022024NS ObDocument1 page24022024NS Obpurnomosp.1000973No ratings yet

- T5 B2 LayoutDocument1 pageT5 B2 Layoutsatyam.pulkam7490No ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro sanchezNo ratings yet

- Sectorization Giang PDFDocument1 pageSectorization Giang PDFNguyen Xuan NhuNo ratings yet

- 23-0452-O Costes Rev02 - KUMARDocument162 pages23-0452-O Costes Rev02 - KUMARSHASHANK BHARATHI V ms22w040No ratings yet

- Mdcintegmatlawm DatasheetDocument1 pageMdcintegmatlawm DatasheetVasile CiupituNo ratings yet

- En PDFDocument1 pageEn PDFSamir SamuelNo ratings yet

- Morreu Por Mim PNDocument2 pagesMorreu Por Mim PNanacaumusicNo ratings yet

- Stair Case DetailsDocument1 pageStair Case DetailsSOUNDARYA CHOTHENo ratings yet

- Draft 2Document1 pageDraft 2K61 ĐOÀN HỒ GIA HUYNo ratings yet

- SE1718 - CSRD Pa RD D5Document1 pageSE1718 - CSRD Pa RD D5williamNo ratings yet

- Cont. On: FW FW BW FW FW FW FW BW FW FW BWDocument1 pageCont. On: FW FW BW FW FW FW FW BW FW FW BWrumahorbo1974No ratings yet

- Engine Harness P/N 0587299-00 Diagram Revision - A - : Component ListDocument1 pageEngine Harness P/N 0587299-00 Diagram Revision - A - : Component ListPabloAntonioCerdaSotoNo ratings yet

- BBQ Chicken Nustar KFSS A1Document1 pageBBQ Chicken Nustar KFSS A1agflamesengineering.salesNo ratings yet

- Pages From 023-GF-31017 - T01-C01A - 001Document1 pagePages From 023-GF-31017 - T01-C01A - 001Ajizul Rohim AkbarNo ratings yet

- Foundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)Document1 pageFoundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)GUNJAN KUMBHARNo ratings yet

- Cont. On: FW BW FW FW FW FW BW FW FW FW BWDocument1 pageCont. On: FW BW FW FW FW FW BW FW FW FW BWrumahorbo1974No ratings yet

- Desarea: L07I09: Cont. OnDocument1 pageDesarea: L07I09: Cont. Onrumahorbo1974No ratings yet

- Gad Aglr 06 12 17Document1 pageGad Aglr 06 12 17Hemant GaikwadNo ratings yet

- Jeanne Arthes Love Generation SexyDocument1 pageJeanne Arthes Love Generation SexyMarcela BremenkampNo ratings yet

- Hindustan Unilever LTDDocument12 pagesHindustan Unilever LTDKarishma Seth100% (3)

- Glutinous RiceDocument5 pagesGlutinous RicebigbangNo ratings yet

- CB&NM Pre Mid-Sem Assign..Document12 pagesCB&NM Pre Mid-Sem Assign..Amisha SinghNo ratings yet

- Boutique BusinessDocument19 pagesBoutique BusinessFaisal khan100% (3)

- Inventory: Financial Accounting Volume 1 6:30 - 7:30Document35 pagesInventory: Financial Accounting Volume 1 6:30 - 7:30Juliet Leron MediloNo ratings yet

- Midea MY-CS6002WP1 Electric Pressure Cooker User ManualDocument19 pagesMidea MY-CS6002WP1 Electric Pressure Cooker User ManualgufumNo ratings yet

- Perlengkapan Bayi Ellena and FamilyDocument6 pagesPerlengkapan Bayi Ellena and FamilyStefani VeraNo ratings yet

- Amigurumi UFO and Alien Crochet Pattern - v2Document6 pagesAmigurumi UFO and Alien Crochet Pattern - v2juraj gresner100% (2)

- Wayhan SCM Study Guide Exam 1Document6 pagesWayhan SCM Study Guide Exam 1adegroot13No ratings yet

- Adults Beginner Sewing Class - Course Syllabus - NEW YORK CITYDocument2 pagesAdults Beginner Sewing Class - Course Syllabus - NEW YORK CITYMichael Coleman100% (1)

- F&B Service Equipments - FamiliarizationDocument6 pagesF&B Service Equipments - FamiliarizationSIVA KRISHNA PRASAD ARJANo ratings yet

- Easy Baked Cheesecake: Prep Time Cook Time Total TimeDocument6 pagesEasy Baked Cheesecake: Prep Time Cook Time Total TimeAndreeaNo ratings yet

- 2013 Readers' ChoiceDocument120 pages2013 Readers' ChoiceMatthew SaintNo ratings yet

- BestBuy Strategic Analysis.Document6 pagesBestBuy Strategic Analysis.Jackie S LaymanNo ratings yet

- Page 1 Women's Bags Shop Exclusive Styles CHARLES & KEITH AEDocument1 pagePage 1 Women's Bags Shop Exclusive Styles CHARLES & KEITH AEHumaid AlkindiNo ratings yet

- Differences Between Offensive and Defensive MarketingDocument3 pagesDifferences Between Offensive and Defensive Marketingsuhaspatel84No ratings yet

- 100% Cotton Combed Hosiery YarnsDocument13 pages100% Cotton Combed Hosiery YarnscottontradeNo ratings yet

- Pauline's Bra Making ClassesDocument38 pagesPauline's Bra Making ClassesHasna Farrukh100% (8)

- Tanishq JRM 090729172938 Phpapp01Document25 pagesTanishq JRM 090729172938 Phpapp01Niket VarmaNo ratings yet

- Head Office: Apex Holdings Ltd. (Factory)Document3 pagesHead Office: Apex Holdings Ltd. (Factory)shironum hinNo ratings yet

- Tarea Semana 10 InglésDocument4 pagesTarea Semana 10 InglésRle LópezNo ratings yet

- Omelette Maker: Instruction BookletDocument16 pagesOmelette Maker: Instruction BookletAristoclesNo ratings yet

- Scrambled MerchandisingDocument12 pagesScrambled MerchandisingNisha ChauhanNo ratings yet

- DR Noor Denim IndustryDocument3 pagesDR Noor Denim IndustrystfhjNo ratings yet

- BAL Perfect Office Alle SprachenDocument253 pagesBAL Perfect Office Alle Sprachenpedro960No ratings yet

- K14 50Document4 pagesK14 50carlos8005No ratings yet

- Amir Adnan - The Man, The LabelDocument4 pagesAmir Adnan - The Man, The LabelNabeel AejazNo ratings yet