Professional Documents

Culture Documents

Paten US4223163

Uploaded by

rahman0 ratings0% found this document useful (0 votes)

15 views7 pagesThis patent describes a process for making ethoxylated fatty alcohols with narrow polyethoxy chain distributions and low fatty alcohol content. Specifically, it involves reacting fatty alcohols with alkali metal or alkali metal hydride catalysts in approximately equimolar ratios. This produces alkyl polyether precursors with narrow ranges of ethoxylation and less than 6% fatty alcohol. These precursors can then be used to make improved carboxyalkylated alkyl polyether surfactants for use in detergent compositions.

Original Description:

1

Original Title

paten US4223163

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a process for making ethoxylated fatty alcohols with narrow polyethoxy chain distributions and low fatty alcohol content. Specifically, it involves reacting fatty alcohols with alkali metal or alkali metal hydride catalysts in approximately equimolar ratios. This produces alkyl polyether precursors with narrow ranges of ethoxylation and less than 6% fatty alcohol. These precursors can then be used to make improved carboxyalkylated alkyl polyether surfactants for use in detergent compositions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views7 pagesPaten US4223163

Uploaded by

rahmanThis patent describes a process for making ethoxylated fatty alcohols with narrow polyethoxy chain distributions and low fatty alcohol content. Specifically, it involves reacting fatty alcohols with alkali metal or alkali metal hydride catalysts in approximately equimolar ratios. This produces alkyl polyether precursors with narrow ranges of ethoxylation and less than 6% fatty alcohol. These precursors can then be used to make improved carboxyalkylated alkyl polyether surfactants for use in detergent compositions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

United States Patent (19) (11) 4,223,163

Guilloty 45) Sep. 16, 1980

(54 PROCESS FOR MAKING ETHOXYLATED FOREIGN PATENT DOCUMENTS

FATTY ALCOHOLS WITH NARROW

POLYETHOXY CHAN DISTRIBUTION 1240062 5/1967 Fed. Rep. of Germany ....... 260/615 B

1300540 8/1969 Fed. Rep. of Germany ....... 260/615 B

75 Inventor: Haydée R. Guilloty, Cincinnati, Ohio

Primary Examiner-Howard T. Mars

73) Assignee: The Procter & Gamble Company, Attorney, Agent, or Firm-Robert B. Aylor; Richard C.

Cincinnati, Ohio Witte; Thomas H. O'Flaherty

21 Appl. No.: 749,653 (57) ABSTRACT

(22 Filed: Dec. 10, 1976 Improved process for making alcohol polyethoxylates

51) Int. Cl. .............................................. CO7C 41/02 with narrow polyethoxy chain distributions using ap

52U.S. Cl. .................................... 568/618; 252/170; proximately equimolar ratios of alcohol and alkali metal

252/559; 562/587 or alkali metal hydride catalyst. The products are useful

58 Field of Search ....................... 260/615 B, 615 R; in making improved carboxyalkylated alkyl polyether

568/618 surfactants having specific narrow ranges of ethoxyla

tion and containing less than about 6% fatty alcohol.

(56) References Cited Detergent compositions containing said alkyl carbox

U.S. PATENT DOCUMENTS yalkylated polyether surfactants and having less than

2,623,875 12/1952 Schlosser et al............. 260/615 B X

about 6% fatty alcohol by weight of said alkyl carbox

2,782,240 2/1957 Hefner et al. ................ 260/615 B X yalkylated polyether surfactants. Processes of making

2,841,479 7/1958 Hefner et al. ................ 260/615 B X said alkyl carboxyalkylated polyether surfactants.

2,872,432 2/1959 Metzger ...... . 260/615 B X

3,778,479 12/1973 Morrisroe et al. ............... 260/615 B 5 Claims, No Drawings

4,223,163

1. 2

DETALED DESCRIPTION OF THE

PROCESS FOR MAKENGETHOXYLATED FATTY INVENTION

ALCOHOLS WITH NARROW POLYETHOXY

CHAN DISTRIBUTION The carboxyalkylated alkyl polyether surfactants of

5 this invention contain an alkyl chain having from about

BACKGROUND OF THE INVENTION 8 to about 18 carbon atoms. The alkyl chain can be

This invention relates to alkyl carboxyalkylated poly derived from fatty alcohols, olefins, etc. Normally, and

preferably, the alkyl chain will be a mixture of alkyl

ether surfactants of the type disclosed in U.S. Pat. Nos. chains, preferably having a narrow distribution. How

2,183,853; 2,653,972; 3,003,954; 3,038,862; 3,741,911; 10 ever, pure alkyl chains can be used. The alkyl chain is

and 3,941,710; British Pat. Nos. 456,517 and 1,169,496; desirably a straight saturated alkyl chain, but it may also

Canadian Pat. No. 912,395; French Pat. Nos. 2,014,084 be a branched and/or unsaturated alkyl chain.

and 2,042,793; Netherland patent applications . Suitable alcohol precursors of the carboxyalkylated

7,201,735-Q and 7,406,336; and Japanese patent applica alkyl polyether surfactants of this invention are primary

tions 96,579/71 and 99,331/71 (both in the name of Kao 15 aliphatic alcohols containing from about 8 to about 18

Soap Company, Ltd.) all of said patents and said patent carbon atoms and containing not more than about 70%

applications being incorporated herein by reference. by weight of the alcohol of 2-alkyl branched material.

Such carboxy alkylated alkyl polyether surfactants Other suitable primary aliphatic alcohols are the linear

are typically prepared from alkyl polyether nonionic primary alcohols obtained from the hydrogenation of

surfactants having a distribution of analogs of varying 20 vegetable or animal fatty acids such as coconut, palm

oxyethylene chain length including a level of unethox kernel, and tallow fatty acids or by ethylene build up

ylated alcohol. It has been discovered that these fatty reactions and subsequent hydrolysis as in the Ziegler

alcohols are acceptable if they are carboxyalkylated, type processes. Preferred alcohols are n-octyl, n-nonyl,

but are a detriment if they are not reacted. However, it n-decyl, u-undecyl, n-dodecyl, n-tridecyl, n-tetradecyl,

is known that the fatty alcohol is the least reactive spe 25 n-pentadecyl, n-hexadecyl, n-heptadecyl, and n-octade

cies in the normal process of, e.g., carboxymethylation. cyl. Other suitable alcohol precursors include primary

It is therefore an object of this invention to provide alcohols having a proportion of branching on the beta

carboxyalkylated alkyl polyether surfactants having a or 2-carbon atom wherein the alkyl branch contains

low level of fatty alcohol. from 1 to 4 carbon atoms. In such alcohols at least 30%

It is a further object of this invention to provide pro 30 of the alcohol of each specific chain length is desirably

cesses for producing said carboxyalkylated alkyl poly linear and the branching preferably comprises about

ether surfactants having a low level of fatty alcohol. 50% of methyl groups with smaller amounts of ethyl,

It is a further object of this invention to provide de propyl and butyl groups. These alcohols are conve

tergent compositions containing said carboxyalkylated niently produced by reaction of linear olefins having

from about 11 to about 17 carbon atoms with carbon

alkyl polyether surfactants and having a low level of 35 monoxide and hydrogen. Both linear and branched

fatty alcohol. chain alcohols are formed by these processes and the

It is a further object to provide processes for prepar mixtures can either be used as such or can be separated

ing alkyl polyether precursors which are nonionic sur into individual components and then recombined to

factants having narrow ranges of ethoxylation and low give the desired blend.

fatty alcohol contents. Typical processes for producing "Oxo' halides

It is a still further object to provide a process for which are then used to prepare alcohols are disclosed in

preparing said alkyl polyethers without a solvent. U.S. Pat. Nos. 2,564,456 and 2,587,858 and the direct

SUMMARY OF THE INVENTION hydroformylation of olefins to give alcohols is disclosed

45 in U.S. Pat. Nos. 2,504,682 and 1,581,988. All of these

In accordance with this invention, a carboxyalk patents are specifically incorporated herein by refer

ylated alkyl polyether surfactant is provided having the eCe.

formula The equivalent secondary alcohols can also be used.

It will be apparent that using a single chain length olefin

50 as starting material, a corresponding single chain length

wherein R is an alkyl group containing from about 8 to alcohol will result, but it is generally more economic to

utilize mixtures of olefins having a spread of carbon

about 18 carbon atoms; x is a number averaging from chain length around the desired mean. This will, of

about 1 to about 12; y is 1 or 2, preferably 1; and M is course, provide a mixture of alcohols having the same

selected from the group consisting of hydrogen; so 55 distribution of chain lengths around the mean.

dium; potassium; ammonium; mono-, di- and tri Primary aliphatic alcohols derived from vegetable

ethanolammonium; mono-, di- and tri-alkylammonium; oils and fats and from other petroleum feed stocks hav

magnesium and calcium cations and mixtures thereof. ing alkyl or alkylene groups as part of their structure

Said carboxyalkylated alkyl polyether surfactant com will also contain a range of chain lengths. Since the

prises at least two homologs having polyoxyethylene 60 range of chain lengths is C8-C20 and beyond, it is there

chains of different lengths in which each homolog is fore normal practice to separate the product from such

from about 0% to about 70% by weight of the mixture; feed stocks into different chain length ranges which are

said surfactant contains less than about 6%, preferably chosen with reference to their ultimate use.

less than about 4%, of free fatty alcohol; and the distri As mentioned previously, commercially available

bution of the polyethoxy analogs is such that at least 65 alcohol precursors normally comprise mixtures of alco

about 40% by weight of the surfactant has polyethoxy hols while materials suitable for the purposes of the

chains within-1 ethoxy groups of the average ethoxy present invention desirably have a relatively narrow

group content. distribution of chain lengths.

3

4,223,163

4.

The polyoxyethylene portion of the surfactant desir Carboxyalkylation can also be achieved by oxidation

ably contains a relatively narrow distribution of the of an alkyl polyoxyethylene nonionic surfactant. How

homologous chain lengths. "Narrow distribution' ever, reacting alkali metal salts of chloroacetic or chlo

means that at least 40% by weight of the surfactant, ropropionic acids with the fatty alcohol polyoxyethyl

preferably 55% or greater, contains polyethoxy groups ene surfactant in alkaline medium to effect a coupling is

which are within about one ethoxy group of the aver preferred for completeness. Preferably, the carboxy

age. A more preferred distribution for C12-14 alcohols is alkyl group is a carboxy methyl group. If carboxyalky

55% within one ethoxy group and for C16-18 alcohols, lation is around 94% complete, there will, of course, be

45%. However, it is highly desirable that no more than no more than 6% residual alcohol and/or alkyl ethoxy

70% of the polyoxyethylene groups have the same 10 lates.

length since to provide very pure materials for deter In summary, the desired low level of fatty alcohol

gent compositions is economically unfeasible. Narrow and narrow distribution can be achieved either by re

distributions can be obtained by using acid catalyzed moval of the fatty alcohol from the fatty alcohol poly

ethoxylation processes and by distillation or steam strip oxyethylene nonionic surfactant prior to carboxyalkyla

ping of the fatty alcohol polyethoxylate prior to, or 15 tion; extraction or distillation of the fatty alcohols etc.

following, carboxyalkylation. However, acid catalysis after carboxyalkylation; utilizing a fatty alcohol poly

gives rise to undesirable by-products such as low molec oxyethylene nonionic surfactant which does not contain

ular weight polyethylene glycols, olefins, decomposi excessive fatty alcohols etc. because of the process by

tion products, etc. and the preferred method for prepa which the nonionic surfactant is prepared; or by carbox

ration is the one described hereinafter. 20 yalkylation to a completeness greater than 94%. The

The preferred process of preparing the preferred resulting alkyl polyether carboxylate surfactants have

alcohol polyethoxylates having narrow distributions of improved performance with respect to removal of body

polyethoxylate chain lengths involves utilizing an essen soil, grease and oil and particulate soil.

tially 1:1 molar ratio of alkali metal or alkali metal hy Detergent Compositions

dride catalyst and fatty alcohol in the ethoxylation step. 25 The carboxyalkylated alkyl polyether surfactants of

Suitable alkaline catalysts include sodium and potassium this invention can be used to formulate desirable deter

hydrides and the sodium and potassium metals them gent compositions which are neutral or alkaline during

selves. The ratio of the catalyst to the fatty alcohol on use. Such detergent compositions will normally contain

a molar basis can be from about 0.9 to about 1.5, prefera 30 from about 2% to about 50% of said carboxyalkylated

bly from about 1.0 to about 1.2 to avoid or minimize alkyl polyether surfactants, preferably from about 10%

ester formation in the subsequent optional carboxyalky to about 40% and most preferably from about 15% to

lation step. about 30%. Since the carboxyalkylated alkyl polyether

A non-reactive solvent may be added to improve the surfactants of this invention are deliberately prepared so

fluidity of the reaction mix and is essential if the catalyst 35 as to contain low levels of fatty alcohol, it is, of course,

and the alcohol are mixed together for a long time be required that the detergent compositions also contain a

fore the addition of the ethylene oxide. This is required very low level of fatty alcohols so as to meet the limits

because the alkali metal fatty alcohol alkoxides are set forth with respect to the carboxyalkylated alkyl

solids at all conceivable reaction temperatures, e.g., polyether surfactant. The detergent composition of this

from room temperature to about 200° C., preferably invention can also contain additional surfactants, deter

from about 100 C. to about 150 C.

In an even more preferred process, the catalyst is gency builders, and minor ingredients as follows.

added to the fatty alcohol first and before the complete Surfactants

displacement of the hydrogen from the OH group on Optional surfactants include additional anionic sur

the alcohol can occur and while the mixture is still fluid, 45 factants of conventional types, nonionic surfactants,

ethylene oxide is added to start the ethoxylation reac Zwitterionic surfactants, ampholytic surfactants, and

tion. This process optimizes the distribution of the cationic surfactants. These optional surfactants are typi

ethoxylates while maintaining a fluid reaction mixture cally present at a level from 0% to about 40%, prefera

without the need for adding a solvent. In effect, the bly from about 1% to about 20%, and most preferably

alcohol acts as the solvent for the initial part of the 50 from about 2% to about 10%. Specific surfactants and

reaction and the alkoxide of the fatty alcohol polyethox mixtures that can be used in the compositions of the

ylated is fluid and acts as a solvent for the last part of the present invention are disclosed in U.S. Pat. Nos.

reaction. Preferably the ethoxylation reaction is started 3,664,961; 3,954,632; 3,936,537; 3,932,316; 3,929,678;

from about 1 to about 5 minutes after the mixing of the 3,925,262; 3,915,903; 3,862,058; 3,755,429; and

fatty alcohol and the catalyst, and after the alkoxide 55 3,729,431; all of said patents being incorporated herein

formation is from about 0% to about 75% complete. by reference.

The product of the above reaction has a distribution Alkyl ether sulfates of value in compositions of the

of polyethoxy homologs in which there is from about 0 present invention are disclosed in Belgian Pat. Nos.

to about 70% of each of the homologs and has a "nar 807,262 and 807,263 issued on May 13, 1974 and specifi

row distribution' as defined hereinbefore. These alkali 60 cally incorporated herein by reference.

metal alkyl polyethoxides can be reacted with an acid to Other useful detergent compounds herein include the

generate highly desirable nonionic surfactants. But pref. water-soluble salts of esters of o-sulfonated fatty acids

erably the alkyl polyethoxides are reacted with e.g., containing from about 6 to 20 carbon atoms in the fatty

alkali metal salts of chloroacetic acid or bromoacetic acid group and from about 1 to 10 carbon atoms in the

acid or the corresponding alkali metal salts of chloro 65 ester group; water-soluble salts of 2-acyloxy-alkane-1-

and bromo-propionic acids to generate the desirable sulfonic acids containing from about 2 to 9 carbon

carboxymethyl and carboxyethyl alkyl polyethoxylates atoms in the acyl group and from about 9 to about 23

of this invention. carbon atoms in the alkane moiety and 3-alkyloxy al

4,223,163

5 6

kane sulfonates containing from about 1 to 3 carbon amples of these and other phosphorus builder com

atoms in the alkyl group and from about 8 to 20 carbon pounds are disclosed in U.S. Pat. Nos. 3, 159,581;

atoms in the alkane moiety. 3,213,030; 3,422,021; 3,422,137; 3,400, 176; and

Alkane sulfonates useful in the present invention are 3,400,148, incorporated herein by reference.

usually mixed secondary alkyl sulfonates having from Non-phosphorus-containing builder salts such as the

10 to 20 carbon atoms in the alkyl chain. Preferably at alkali metal carbonates, bicarbonates and silicates are

least 80% and most preferably at least 90% by weight of also useful herein.

the alkyl group lies in the C10-17 chain length range. Water soluble, organic builders are also useful herein.

Alkane sulfonates are preferably prepared by treating a For example, the alkali metal, ammonium and substi

selected paraffin material of the desired chain length 10 tuted ammonium polyacetates, carboxylates, polycar

distribution with sulfur dioxide and oxygen to give a boxylates and polyhydroxy-sulfonates are useful build

secondary sulfonic acid, which is then neutralized with ers in the present compositions and processes. Specific

a suitable base. An alternative process utilizes chlorine examples of the polyacetate and polycarboxylate

and sulfur dioxide in the presence of UV light to give builder salts include sodium, potassium, lithium, ammo

sulfuryl chlorides which are then hydrolyzed and neu 15 nium and substituted ammonium salts of ethylenedi

tralized to form the secondary alkyl sulfonates. aminetetraacetic acid, nitrilotriacetic acid, oxydisuc

Specific preferred detergents for use herein include: cinic acid, mellitic acid, benzene polycarboxylic acids,

sodium linear C10-C18 alkylbenzene sulfonate; trietha and citric acid.

nolamine C10-C18 alkyl benzene sulfonate; sodium tal Preferred examples of polycarboxylate builders are

low alkyl sulfate, sodium coconut alkyl glyceryl ether 20 set forth in U.S. Pat. No. 3,308,067, Diehl, incorporated

sulfonate; the sodium salt of a sulfated condensation herein by reference. Examples of such materials include

product of a tallow alcohol with from about 1 to about the water-soluble salts of homo- and co-polymers of

3 moles of ethylene oxide; 3-(N,N-dimethyl-N- aliphatic carboxylic acids such as maleic acid, itaconic

coconutalkylammonio)-2-hydroxypropane-1-sulfonate; acid, measconic acid, fumaric acid, aconitic acid, citra

3-(N,N-dimethyl-N-coconut-alkylammonio)-propane 25 conic acid and methylenemalonic acid.

1-sulfonate; 6-(N-dodecyl-benzyl-N,N-dimethylam Additional preferred builders herein include the

monio) hexanoate; and the water-soluble sodium and water-soluble salts, especially the sodium and potassium

potassium salts of higher fatty acids containing 8 to 24 salts, of carboxymethyloxymalonate, carboxymethylox

carbon atoms. ysuccinate, cis-cyclohexanehexacarboxylate, cis

It is to be recognized that any of the foregoing deter 30 cyclopentanetetracarboxylate and phloroglucinol tri

gents can be used separately herein or as mixtures. sulfonate. -

Detergency Builders A further class of detergency builder materials useful

in the present invention are insoluble sodium aluminosil

The detergent compositions of this invention can icates, particularly those disclosed in Belgian Pat. No.

contain all manner of detergency builders commonly 35 814,874 issued Nov. 12, 1974 and incorporated herein

taught for use in detergent compositions. However, by reference. This discloses and claims detergent com

because of the superior performance characteristics of positions containing sodium aluminosilicates of the for

the alkyl polyether carboxylate surfactants of this in mula

vention, it is possible to formulate detergent composi

tions which are effective and which do not contain 40

phosphate builders or other sequestering builders. The

builders are normally employed in the present composi whereinz and y are integers of at least 6, the molar ratio

tions at concentrations of from about 0% to about 70%, of z to y is in the range from 1.0:1 to about 0.5:1 and x

preferably from about 20% to about 60%, and most is an integer from about 15 to about 264, said aluminosil

preferably from about 30% to about 50%. Useful build 45 icates having a calcium ion exchange capacity of at least

ers herein include any of the conventional inorganic and 200 mg. eq/gr. and a calcium ion exchange rate of at

organic water soluble builder salts. least about 2 grains/gallon/minute/gram. A preferred

Such inorganic detergency builders can be, for exam material is

ple, water-soluble salts of pyrophosphates, orthophos

phates, polyphosphates, phosphonates, carbonates, bi 50 Na12(AlO2)12(SiO2)12.27 H2O

carbonates and silicates. Specific examples of inorganic

phosphate builders include sodium and potassium tri Another type of detergency builder material useful in

polyphosphates, pyrophosphates and hexametaphos the present compositions and processes comprises a

phates. Detergent compositions incorporating pyro water-soluble material capable of forming a water

phosphate builders form the subject of the following 55 insoluble reaction product with water hardness cations

commonly assigned copending applications and patent in combination with a crystallization seed which is ca

that are hereby incorporated by reference, Ser. No. pable of providing growth sites for said reaction prod

618,303, Benson, Cherney and Collier, PROCESS FOR uct. Builder materials of this type are disclosed in Bel

PREPARING A PYROPHOSPHATE-SILICATE gian Pat. No. 798,856 issued Oct. 29, 1973 and incorpo

DETERGENT PRODUCT; filed Sept. 29, 1975 and 60 rated herein by reference.

Ser. No. 713,725, Hau and Cherney, DETERGENT Minor Ingredients

BUILDER AND DETERGENT COMPOSITION,

filed Aug. 12, 1976 and U.S. Pat. No. 3,939,100. The compositions herein can optionally contain all

The polyphosphonates specifically include, for exam manner of additional materials commonly found in laun

ple, the sodium and potassium salts of ethylene diphos 65 dering and cleaning compositions. Specifically, oxidiz

phonic acid, the sodium and potassium salts of ethane ing bleaches such as sodium perborate, sodium percar

1-hydroxy-1,1-diphosphonic acid and the sodium and bonate, optionally with bleach precursors such as

potassium salts of ethane-1,1,2-triphosphonic acid. Ex phthalic anhydride, tetra acetyl ethylene diamine, tetra

4,223,163

7 8

acetyl methylene diamine or tetra acetylglycoluril may 5%-20% by weight of the composition. The balance of

be incorporated at levels of 1% to 25% of the composi such compositions normally comprise minor ingredients

tion. such as viscosity and gel control agents, perfumes,

Suds suppressors such as blends of silanated silica and brighteners, colors, pH control agents and water which

silicone fluids, C20-22 fatty acids and certain microcrys conventionally is present at a level of at least 25% by

talline waxes, e.g. Mobilwax 2305 may be employed weight.

alone or as mixtures at levels of 0.005% to 5%, prefera The following examples illustrate the preparation of

bly 0.01% to 3% and most preferably 0.1% to 1% of the the alkyl polyether carboxylate surfactants of this in

composition. vention and detergent compositions containing said

Viscosity and anticalking aids such as sodium salts of O surfactants.

lower alkyl aromatic sulphonic acids are conveniently

employed at levels of 0.5% to 5%, particularly if other EXAMPLE I

anionic surfactants are used as part of the surfactant Part A

mixture. Other useful anticaking ingredients include the A sample of carboxymethylated alkyl polyethoxylate

alkali metal salts of sulphosuccinic acid and benzene 15

surfactant was synthesized by reacting an alkyl polye

sulphonic acid. thoxylate in which the alkyl group contains primarily

Certain clays may also be present as emulsification 12 and 13 carbon atoms and the polyethoxylate portion

and processing aids in accordance with the teachings in contains an average of about 3.2 ethoxy groups per

Belgian Pat. No. 821,094, incorporated herein by refer

eCe. 20 molecule with sodium chloroacetate and 50% aqueous

Soil suspending agents such as sodium carboxy sodium hydroxide at 70-80 C. and 5-10 millimeters of

methyl cellulose and hydroxyethyl cellulose may also mercury pressure. After completion of the reaction, the

be used in amounts of 0.25% to 5% by weight. Other product was heated to about 150° C. and a stream of

suitable materials useful for this purpose include co water was added to the reactor. Heat was maintained

polymers of maleic anhydride with ethylene or methyl 25 until most of the unreacted polyethoxy compound was

vinyl ether and certain polymeric glassy metaphos removed by the steam distillation. This unreacted mate

phates. rial was collected and found to contain about 95% une

Enzymes such as the proteolytic enzymes sold under thoxylated fatty alcohols, the remainder being mono

the trade names “Alcalase' and "Esterase' (Novo In and di-ethoxy alcohols.

dustries A/S, Denmark) Maxatase and AZ-Protease 30 Another sample was reacted to the same reaction

(Gist-Brocades NV, The Netherlands) may be incorpo completeness (i.e., about 88% of the alkyl polyethoxy

rated at levels of up to 1% by weight, preferably from late are reacted), but was not steam distilled as was the

0.25% to 0.75% by weight. Such enzymatic materials original paste sample.

may be coated or prilled to aid their stability and to The above samples were then acidified, separated

minimize the formation of dust during processing and 35 from the water-soluble salts, and then neutralized to

subsequent storage. give the following compositions.

Typical but non-limiting examples of granular com

positions in accordance with the present invention com Surfactant Steam Distilled Not Distilled

prise by weight of the composition: 2%-30%, prefera Paste Analyses A. B

bly 10%-25% and most preferably 15%-20% surfac 40

Anionic in paste 65.2% 49.3%

tant; 10%–80%, preferably 25%-70% by weight of a Unreacted nonionic 2.1% 5.5%

detergent builder salt; and 1%-50% of other optional By-product Salt 0.3% 0.8%

ingredients such as bleaches, suds suppressors, viscosity Water 32.4% 44.4%

and anti-caking aids, anti-redeposition agents, fluoresc Fatty alcohol as %

of unreacted 14% 70%

ers, enzymes, perfumes, colors, processing aids, corro 45 Fatty alcohol as %

sion control agents, and antibacterial agents. of total active 0.4% 7.0%

Typical but non-limiting liquid detergent composi % alkyl polyethoxylate w

tions embodying the present invention comprise (by within 1 ethoxy

weight of the compositions) 5%–50%, preferably group of the average 43% 38%

20%-40% and most preferably 25%-35% of an alkyl 50

polyether carboxylate surfactant; in accordance with In the above table, sample A is representative of the

the present invention and 5%-35%, preferably preferred surfactants of this invention and Sample B is

10%-30% and most preferably 10%-20% of an addi representative of the prior art.

tional surfactant which is either another anionic surfac Surfactant A and Surfactant B were tested in a prod

tant or a nonionic surfactant. In a preferred embodi 55 uct which was composed of 18% surfactant, 25% hy

ment, a source of alkalinity is included at a level suffi drated sodium Zeolite A having an average particle size

cient to raise the pH to a value of at least 7.0. For this of about 3 microns, 20% of 1.6 ratio of sodium silicate,

purpose, free base should be added in excess of that 24% sodium sulfate, and 10% sodium carbonate.

necessary to provide the cation for the anionic surfac The two detergent compositions were tested versus a

tant. Any source of free alkalinity can be employed but 60 commercial product (Tide containing about 6% phos

preferred materials are sodium and potassium hydrox phorus), the products were tested at a level equivalent

ide and alkanolamines. Usage of the latter is normally to one cup usage for the removal of body soil relative to

1%-20%, preferably 2%-15%, and most preferably the reference product. The test involves washing soiled

5%-10% by weight of the composition. Optionally cloth fabrics which are then graded by a panel of ex

builder materials such as pyrophosphates, silicates, and 65 perts as to relative cleanness. The body soil removal

the previously-described synthetic aluminosilicates, performance of the reference product (Tide) was arbi

citrates, borates, or nitrilotriacetates may be present in trarily normalized to zero, so the performance of deter

solution or dispersed and suspended at levels of gent compositions A and B is stated relative to Tide

4,223,163

9 10

performance. A value of +2.5 units represents a com metal at 100° C. and diglyme (Bis-2-methoxyethylether)

pletely clean fabric. The results were as follows: solvent. During the reaction the temperature increased

by 15 C. and the liquid turned dark although it became

Wash Conditions Composition Composition lighter thereafter. The formation of the alkoxide turned

Hardness gragal/Temp. (F) A. B the mixture opaque. The mixture was then heated up to

2/70 +0.18 --0.32 150° C. and 3.5 moles of ethylene oxide per mole offatty

7/70 --2.20 -- 1.29 alcohol were added over a period of about 4 hours.

9/70

2/100

-- 1.17

--0.50

-0.63

--0.16

The mixture became clear and light yellow. The reac

9/100 --0.82 -0.40 10

tion was carried out under a flowing nitrogen blanket.

The average molecular weight was about 352 and the

ethylene average per mole was about 3.8. The distribu

Part B tion of polyethoxy homologs was as follows:

E0-0.7%

Two samples of carboxymethylated alkyl polye E1-6.3%

thoxylate surfactants were prepared. Both were derived 15

E2-17.3%

from fatty alcohols containing approximately the same E3-22.4%

alkyl chain lengths and distributions and the polyethoxy E4-21.2%

portions of the compounds had the same average chain E5-15.6%

length, but the samples, differed in distribution of the E6-8.6%

various polyethoxy homologs. 20

E7-5.6%

The alkyl polyethoxylate feed stock was derived by E8-2.3%

reacting a C12-13 fatty alcohol with approximately three The alkyl polyethoxylate was carboxymethylated by

moles of ethylene oxide per mole of alcohol. The alkyl

polyethoxylate contained roughly 14% fatty alcohol. adding one mole of sodium chloroacetate slurried in

This alkyl polyethoxy surfactant was steam stripped 25 diglyme at 80 C. The mixture turned creamy color and

until there was only about 1% fatty alcohol present. the temperature increased approximately 10° C. The

Both of these materials were carboxylakylated giving reaction continued for about 35 minutes at which point

samples as follows: the temperature was 65° C. The heat was then turned on

to increase the temperature to 90° C. Agitation was

Composition Composition

30 stopped five minute later and the reactor was left over

A B night under nitrogen. The pH at the end of the reaction

Average number carbons in

was close to neutral. The percentage completeness was

alkyl chain 12.9 12.8 about 85.2% leaving about 9.55% of alkyl polyethoxy

Average number ethoxy groups 4.5 4.7 late surfactant present in the finished reaction mix.

Portion of alkyl polyethoxylate 35

reacted to give an anionic 72% 67% Part D

Portion of alkyl polyethoxy

material which is unreacted 28% 33% A primary fatty alcohol containing from 12 to 14

Fraction of

the alkyl polyethoxylate

carbon atoms was mixed with sodium metal pellets and

which is still an alcohol 7.5% 1.0%

before the reaction was complete, when the tempera

Estimated alcohol in final com ture was about 150 F. and prior to solidification, ethyl

position as a percent of the alkyl ene oxide gas was added in a ratio of about 3 moles of

polyethoxylate feed stock 5.3% 0.8% ethylene oxide per mole of alcohol. The reaction con

% of alkyl polyethoxylate within tinued for about four hours during which time the tem

it lethoxy group of the average 30% 45%

45

perature increased to about 185 F. The resulting mate

rial had a molecular weight of about 311 and ethylene

The above samples were performance tested in accor oxide content of about 2.54 moles of ethylene oxide per

dance with the procedures set forth hereinbefore using mole of fatty alcohol. The polyethylene oxide homolog

a formula containing 18% surfactant, 18% of the afore distribution was as follows:

mentioned zeolite A, 20%. 1.6 ratio sodium silicate, 26% E0-3.8%

sodium sulfate, and 7.7% sodium pyrophosphate. The 50

E1-15.3%

reference product in this series of tests was a commer E2-25.9%

cial Tide detergent composition containing 0% phos E3-23.8%

phorus. V

Results were as follows: E4-15.9%

55 E5-10.7%

E6-3.5%

Stripped Unstripped E7-1.2%

Wash Conditions

surfactant

body soil

surfactant

body soil

This alkyl polyethoxylate surfactant was carboxyme

Hardness gr./gal/temp. (F) removal removal thylated by the addition of 0.05 moles of sodium hy

2/70 0.31 --0.32 droxide in powder form per mole of fatty alcohol and

7/70 -- 1.31 - 0.91 1.05 moles of sodium chloroacetate per mole of fatty

9/70 - 1.47 --0.80 alcohol. The mixture which was light yellow turned

12/70 -- 1.23 --0.96 creamy. The temperature of the reaction was originally

60° C. and after one-half hour, it increased to 70° C. The

Part C

65 reaction mixture was left overnight under a nitrogen

blanket and the percentage completeness was 71% and

One mole of a primary fatty alcohol containing 12 the percent of alkyl polyethoxylate surfactant present

carbon atoms was reacted with one mole of sodium was about 20%,

4,223,163

11 12

Part E. advantages for the higher ratios of catalyst to fatty

alcohol and for addition of the ethylene oxide shortly

Samples of the surfactant from the foregoing process after the addition of the sodium catalyst without a sol

were performance tested according to the procedure in vent being present.

Part A using a formula with 18% surfactant, 25% of the 5 Similar results are obtained when potassium metal

zeolite, 20% of 1.6 ratio sodium silicate, 24% sodium and sodium and lithium hydrides are substituted for the

sulfate, and 10% sodium carbonate. The results were as sodium metal and octanol, nonanol, decanol, undecanol,

follows: tridecanol, tetradecanol, pentadecanol, hexadecanol,

10

heptadecanol, octadecanol and mixtures thereof are

Stripped Unstripped substituted for the alcohols.

surfactant surfactant Part B

Wash Conditions body soil body soil

Hardness gr./gal/temp. (F) removal removal When the above fatty alcohol polyethoxylates from

2/70 -0.78 --0.45 Runs 1-8 are carboxylakylated as in Example I, superior

7/70 --0.95 -0.43 15 carboxyalkylated alkyl polyethoxylate surfactants are

9/70 --0.75 --0.25

obtained. When substituted into the detergent composi

tions of Example I on a part for part basis for the car

In the above test the reference product was a com boxyalkylated alkyl polyethoxylate surfactants, essen

mercial detergent, Tide, containing about 6% phospho tially equivalent performance is obtained.

U.S. 20

Part C

EXAMPLE II

Part A

Samples of the above surfactants 1, 2, 6 and 7 were

performance tested according to the procedure of Part

Sodium metal was used as an ethoxylation catalyst in 25 E of Example I against the unstripped surfactant. The

preparing the following polyethoxylated fatty alcohols. results were as follows:

The first two runs were with essentially pure dodecanol

and the rest were with mixtures of C12-C14 fatty alco Wash Conditions 70 F.

hols. The ratio of ethylene oxide to fatty alcohol is -- Hardness gr/gal.

given in column 1; the temperature of the initial ethoxy 30 Surfactant 2 6 9 12

lation reaction in column 2; the time of ethylene oxide Run 1 --0.33 -- 1.38 - 1.00 -

addition in column 3; the molar ratio of sodium metal to Run 2 -0.5 --0.55 --0.44 -0.61

fatty alcohol in column 4; the percent of fatty alcohol in Run 6 --0.10 --O.09 --0.37 -0.51

the product in column 5; and the poisson fatty alcohol Run 7 -0.65 -0.46 -0.10 --0.20

content in column 6. Diglyme solvent was added to the 35

first two runs, but no solvent was used for the rest. All What is claimed:

reactions were under nitrogen. Runs 12-15 were in an 1. The process of preparing fatty alcohol polyethoxy

autoclave (12-13 rocking; 14-15 stirred). lates having a narrow distribution of polyethoxylate

chain lengths in which a fatty alcohol containing from

Temp. Time % OH 40 about 8 to about 18 carbon atoms is reacted with ethyl

Run

No. EO/OH Add.

at EO

Add.

at EO

NaOH

Un-

reacted

Poisson

9%, OH

ene oxide in a ratio of ethylene oxide to fatty alcohol of

from about 1 to about 20 at a temperature which is

1

2

3.8

4.0

150 C. 45 min.

160 C. 90 min,

1.00

1.00

0.70

1.02

1.80

0.95

between room temperature and about 200° C. in the

3 3.9 110 C. at 75% 100 0.33 1.00 45 presence of an alkali metal or alkali metal hydride cata

Add. of Na lyst which is present in a molar ratio of catalyst to fatty

(1-2 min) alcohol of from about 0.9 to about 1.5 in which said

4.

5

3.5

3.5

120

10

C.

C.

1-3

1-3

min.

min.

0.75

0.90

3.89

3.83

.60

1.60

ethylene oxide is added to the mixture of fatty alcohol

6 2.5 185 C. 1-3 min. .00 3.8 5.00 and catalyst after the addition of the catalyst and before

7 4.5 190 C. 1-3 min. 1.00 0.19 0.50 the formation of the fatty alcohol alkoxide is about 75%

8 4.1 60 C. 15-20 min. 0.90 1.17 0.80 50 complete.

9

10

2.2

3.5

125

110

C.

C.

20 min.

23 min.

0.50

0.25

14.63

8.43

7.50

1.80

2. The process of claim 1 wherein the ethylene oxide

1.3 110 C. 10-15 min. 0.05 34.84 22.50 is added to the fatty alcohol within from about 1 to

12 3.2 100 C, 35 min. 1.00 3.30 2.40 about 5 minutes after the addition of the catalyst.

13

14

2.7

3.0

75

105

C.

C.

50 min.

35 min.

1.00

1.00

7.65

12.28

4.10

2.80 55

3. The process of claim 1 wherein the ratio of fatty

15 2.8 105 C. 1-3 min. 1.00 0.60 4.00

alcohol to catalyst is from about 1.0 to about 1.2.

4. The process of claim 1 wherein said alchol is a

primary alcohol.

The higher ratios of ethylene oxide to fatty alcohol 5. The process of claim 1 temperature is from about

will naturally result in lower fatty alcohol contents, 100 C. to about 150 C.

regardless of the process. However, there are clear 60 k x k

65

You might also like

- Aliphatic Compounds: Trihydric Alcohols, Their Oxidation Products and Derivatives, Penta- and Higher Polyhydric Alcohols, Their Oxidation Products and Derivatives; Saccharides, Tetrahydric Alcohols, Their Oxidation Products and DerivativesFrom EverandAliphatic Compounds: Trihydric Alcohols, Their Oxidation Products and Derivatives, Penta- and Higher Polyhydric Alcohols, Their Oxidation Products and Derivatives; Saccharides, Tetrahydric Alcohols, Their Oxidation Products and DerivativesNo ratings yet

- United States Patent (191: Anchor (45) Date of Patent: May 6, 1986Document5 pagesUnited States Patent (191: Anchor (45) Date of Patent: May 6, 1986Parth DevNo ratings yet

- Process of Deodourizing of Iso Prpopyl AlcoholDocument4 pagesProcess of Deodourizing of Iso Prpopyl AlcoholMani ChemistNo ratings yet

- US3891683Document5 pagesUS3891683Risma Dewi SNo ratings yet

- US4133786Document5 pagesUS4133786Ilham Kiki ShahilaNo ratings yet

- Separación de AzeotropoDocument2 pagesSeparación de AzeotropoLaura GarciaNo ratings yet

- United States PatentDocument5 pagesUnited States Patentهیمن مNo ratings yet

- United States Patent (19) : Charleston, Both of W. Va.Document10 pagesUnited States Patent (19) : Charleston, Both of W. Va.andari yuta palwaNo ratings yet

- Acetaldehido A01 031Document4 pagesAcetaldehido A01 031DwiPurwatiNo ratings yet

- United States Patent (19) : 75) Inventors: Vlastimil Kadlec, Litvinov VojtéchDocument3 pagesUnited States Patent (19) : 75) Inventors: Vlastimil Kadlec, Litvinov VojtéchGraciaVelitarioNo ratings yet

- Us4371456 PDFDocument3 pagesUs4371456 PDFGraciaVelitarioNo ratings yet

- US8269048Document6 pagesUS8269048Lara MartinezNo ratings yet

- United States Patent (19) : ZiegenhainDocument4 pagesUnited States Patent (19) : ZiegenhainOpet BikesNo ratings yet

- US4976743Document6 pagesUS4976743ozgurNo ratings yet

- Diluție! PatentDocument7 pagesDiluție! PatentMarina ButuceaNo ratings yet

- Us4018815 PDFDocument4 pagesUs4018815 PDFFatih AkmanNo ratings yet

- Unsat Pol EsterDocument9 pagesUnsat Pol EsterAmr Abdelmegid abdelsalam husseinNo ratings yet

- US3624147 PatentDocument3 pagesUS3624147 PatentSantiago BorgesNo ratings yet

- Role - E.: United States Patent 19Document6 pagesRole - E.: United States Patent 19prasanNo ratings yet

- United States Patent 0: Patented Feb. 4, 1969Document3 pagesUnited States Patent 0: Patented Feb. 4, 1969Stella AguirreNo ratings yet

- United States Patent Office: Ch-Ch-OnDocument3 pagesUnited States Patent Office: Ch-Ch-OnChanachai PuckNo ratings yet

- 4-Hydroxy Coumarin PatentDocument4 pages4-Hydroxy Coumarin PatentAfzal PathanNo ratings yet

- Alcohols, Higher Aliphatic, SurveyDocument26 pagesAlcohols, Higher Aliphatic, SurveyEmmanuel Chang100% (1)

- @ Gradeff US3869517 1975 Process For Preparing Hydroxy Citronellal Via 1,1-DiacetatesDocument10 pages@ Gradeff US3869517 1975 Process For Preparing Hydroxy Citronellal Via 1,1-DiacetatesLouisNo ratings yet

- United States Patent (19) : Daly Et Al. 11) 4,436,836Document9 pagesUnited States Patent (19) : Daly Et Al. 11) 4,436,836arif thoha bariklanaNo ratings yet

- FGFHGHJHJKDocument9 pagesFGFHGHJHJKMary Grace VelitarioNo ratings yet

- Alcohol EtoxilateDocument23 pagesAlcohol Etoxilatefajar1234180No ratings yet

- Hidrogenación 2Document8 pagesHidrogenación 2Adrian vilariño gonzalezNo ratings yet

- United States Patent (191: Gardiner Et AlDocument7 pagesUnited States Patent (191: Gardiner Et Alvzimak2355No ratings yet

- US3903185Document6 pagesUS3903185Muhammad Akbar FahleviNo ratings yet

- Us6093841.1 Method For Preparing Nonreactive Aminosilicone OilsDocument7 pagesUs6093841.1 Method For Preparing Nonreactive Aminosilicone OilsA. Vafaie ManeshNo ratings yet

- TOLUENEDocument7 pagesTOLUENEAlzahra AliNo ratings yet

- Method of Hydrolyzing PolyacrylamideDocument5 pagesMethod of Hydrolyzing PolyacrylamidePutri Nadya KamilaNo ratings yet

- Teste3 K2optDocument157 pagesTeste3 K2optPauloNo ratings yet

- Ullmann S Enc of Industrial Chemistry PLANTA PDFDocument12 pagesUllmann S Enc of Industrial Chemistry PLANTA PDFTaylor PennaNo ratings yet

- Us 5164107Document4 pagesUs 5164107AlexNo ratings yet

- Us 3717672Document5 pagesUs 3717672eschim.civNo ratings yet

- United States Patent (19) : Jun. 9, 1987 11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (19) : Jun. 9, 1987 11) Patent Number: (45) Date of Patentnelson bessoneNo ratings yet

- United States Patent (19) : MansfieldDocument7 pagesUnited States Patent (19) : MansfieldLeandro Alberto Villanueva MancillaNo ratings yet

- Gauthier-Lafeye. CARBONYLATION OF METHYL ACETATE TO ACETIC ANHYDRIDEDocument4 pagesGauthier-Lafeye. CARBONYLATION OF METHYL ACETATE TO ACETIC ANHYDRIDEJohn Patrick DagleNo ratings yet

- KKKK Us4297264Document4 pagesKKKK Us4297264هیمن مNo ratings yet

- US3093691Document2 pagesUS3093691Ayu GirlsNo ratings yet

- Us3423341 Process For Making Ol Modified Alkyd ResinDocument7 pagesUs3423341 Process For Making Ol Modified Alkyd ResinIlham Kiki ShahilaNo ratings yet

- US4882397Document19 pagesUS4882397MorkizgaNo ratings yet

- Us 2845438Document5 pagesUs 2845438Pat22 22patNo ratings yet

- 360exp10-02 EsterificationDocument14 pages360exp10-02 EsterificationlewisrahimiNo ratings yet

- 2006, Production of Alkyd Resin - Effect of CatalystDocument5 pages2006, Production of Alkyd Resin - Effect of CatalystNhu TranNo ratings yet

- US5723679 Paten MEK 1Document3 pagesUS5723679 Paten MEK 1Lathifa Rahma AstutiNo ratings yet

- US4684750Document4 pagesUS4684750Deep PatelNo ratings yet

- United States Patent (19) : 54 Process For Producing AcrylicacidDocument10 pagesUnited States Patent (19) : 54 Process For Producing AcrylicacidKatia Gutierrez GalaNo ratings yet

- Patent US4317926Document9 pagesPatent US4317926Santiago BorgesNo ratings yet

- US4880550Document6 pagesUS4880550Sachin PatilNo ratings yet

- Catalysts 03 00954Document12 pagesCatalysts 03 00954Darian HerascuNo ratings yet

- US3639461Document5 pagesUS3639461M. IDRISNo ratings yet

- United States Patent (191: Z2 20) Woter - I 18JDocument7 pagesUnited States Patent (191: Z2 20) Woter - I 18JZulfi ZumalaNo ratings yet

- April 19, 1966 N. Fragen 3,247,246: Filed Nov. 6, 196lDocument6 pagesApril 19, 1966 N. Fragen 3,247,246: Filed Nov. 6, 196lHerbertKohNo ratings yet

- US5481059 Settling Aids Ashes SlurryDocument4 pagesUS5481059 Settling Aids Ashes SlurryDavid Diaz PadillaNo ratings yet

- 1985年OMI-High speed copper electroplating process and bath thereforDocument5 pages1985年OMI-High speed copper electroplating process and bath thereforamicjhcjyNo ratings yet

- Alkali Dye FixingDocument5 pagesAlkali Dye Fixingdebmallya4037No ratings yet

- New Doc 2018-12-06Document11 pagesNew Doc 2018-12-06rahmanNo ratings yet

- US5157168 (Patent Fatty Alcohol)Document29 pagesUS5157168 (Patent Fatty Alcohol)rahmanNo ratings yet

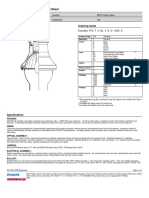

- Spray DryerDocument1 pageSpray DryerrahmanNo ratings yet

- Daftar Buku Pustaka Ebook 2Document4 pagesDaftar Buku Pustaka Ebook 2rahmanNo ratings yet

- Daftar Buku Kumpulan Buku Teknik KimiaDocument2 pagesDaftar Buku Kumpulan Buku Teknik KimiarahmanNo ratings yet

- Physical and Chemical Equilibrium For Chemical Engineers - N. de NeversDocument197 pagesPhysical and Chemical Equilibrium For Chemical Engineers - N. de NeversWilliamNo ratings yet

- 2639 - Rekap Nilai TotalDocument7 pages2639 - Rekap Nilai TotalrahmanNo ratings yet

- 10 1016@j Cogsc 2017 03 010Document5 pages10 1016@j Cogsc 2017 03 010rahmanNo ratings yet

- RK RahmanDocument1 pageRK RahmanrahmanNo ratings yet

- Msds Etanol 2005Document7 pagesMsds Etanol 2005Puput Trisnayanti Inanto PutriNo ratings yet

- Tugas Bahasa Inggris 1Document2 pagesTugas Bahasa Inggris 1rahmanNo ratings yet

- Analytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoDocument9 pagesAnalytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoFirda PratiwiNo ratings yet

- Palm Oil 2Document1 pagePalm Oil 2rahmanNo ratings yet

- Tugas Bahasa Inggris 1Document2 pagesTugas Bahasa Inggris 1rahmanNo ratings yet

- OkeeyDocument2 pagesOkeeyrahmanNo ratings yet

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocument16 pagesChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanNo ratings yet

- Benito 2015Document13 pagesBenito 2015rahmanNo ratings yet

- Characterization of Methyl Ester Compound of Biodiesel From Industrial Liquid Waste of Crude Palm Oil ProcessingDocument2 pagesCharacterization of Methyl Ester Compound of Biodiesel From Industrial Liquid Waste of Crude Palm Oil ProcessingrahmanNo ratings yet

- Msds Etanol 2005Document7 pagesMsds Etanol 2005Puput Trisnayanti Inanto PutriNo ratings yet

- Tugas Bahasa InggrisDocument3 pagesTugas Bahasa InggrisrahmanNo ratings yet

- Chem-E-Car Sefter ConceptionDocument16 pagesChem-E-Car Sefter ConceptionrahmanNo ratings yet

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocument16 pagesChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanNo ratings yet

- 01 TK 205 Process Flow Diagram 01Document15 pages01 TK 205 Process Flow Diagram 01rahman100% (1)

- Habonim Cryo ValveDocument8 pagesHabonim Cryo ValveashishpearlNo ratings yet

- Application Guide: Shrink-Wrapping With Zerust ICT 510-OPS Outdoor Preservation VCI Shrink FilmDocument4 pagesApplication Guide: Shrink-Wrapping With Zerust ICT 510-OPS Outdoor Preservation VCI Shrink Filmparagaloni8365No ratings yet

- Heat Shrink Sleeves Install Manual 2005 PDFDocument3 pagesHeat Shrink Sleeves Install Manual 2005 PDFkalai0% (1)

- Restek GC ColumnsDocument4 pagesRestek GC ColumnsdchyNo ratings yet

- Appendixes: Appendix Particle Size - 1 - A - AluminumDocument19 pagesAppendixes: Appendix Particle Size - 1 - A - AluminumIbrahim HeaderNo ratings yet

- Mag Foam - Puf / PirDocument2 pagesMag Foam - Puf / Pirsumit travelerNo ratings yet

- Chemistry Pocket Lab ManualDocument27 pagesChemistry Pocket Lab ManualShivam SinghNo ratings yet

- Mendoza Nowella BT122 RSW-02 Masonry-And-ConcreteDocument21 pagesMendoza Nowella BT122 RSW-02 Masonry-And-ConcreteNowella MendozaNo ratings yet

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavateNo ratings yet

- Nitofill UR63: Constructive SolutionsDocument3 pagesNitofill UR63: Constructive SolutionsrayNo ratings yet

- The Future of Productivity: Wire Arc Additive Manufacturing: 3dprintDocument4 pagesThe Future of Productivity: Wire Arc Additive Manufacturing: 3dprintItziarNo ratings yet

- Basoflux Paraffin Control For The Oil IndustryDocument6 pagesBasoflux Paraffin Control For The Oil Industryyugatha100% (1)

- Separating Mixtures Virtual Lab 1qxnw09Document2 pagesSeparating Mixtures Virtual Lab 1qxnw09Asher De La CruzNo ratings yet

- Teardrop (TF2) : Specification SheetDocument2 pagesTeardrop (TF2) : Specification SheetMichael AzamarNo ratings yet

- Gcse Ocr DT FlashcardsDocument8 pagesGcse Ocr DT Flashcardsapi-256027312No ratings yet

- Rehau - PPR Pipe and FittingDocument12 pagesRehau - PPR Pipe and FittingharefiezNo ratings yet

- Experimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationDocument4 pagesExperimental Investigation On TIG Welded Aluminium Alloy 6082 Weldment Using Non Destructive EvaluationEditor IJTSRDNo ratings yet

- Hot Work Permit: Project Name: - Name of Subcontractor/CompanyDocument2 pagesHot Work Permit: Project Name: - Name of Subcontractor/CompanyJoey Stanley GuzmanNo ratings yet

- Product Catalogue: Global EditionDocument19 pagesProduct Catalogue: Global EditionKhiro DbNo ratings yet

- ASME IIC SFA5.16 - TiDocument10 pagesASME IIC SFA5.16 - TitragaldabasNo ratings yet

- Cable DetailDocument3 pagesCable Detailrajeshpalla4No ratings yet

- Pansy Flower UsDocument6 pagesPansy Flower UsmartincarrieNo ratings yet

- Practical 27 EsterificationDocument2 pagesPractical 27 EsterificationDavid LuNo ratings yet

- Hydrogel Formation From Poly (NIPAAm-co-BIS)Document9 pagesHydrogel Formation From Poly (NIPAAm-co-BIS)Adrian SödergrenNo ratings yet

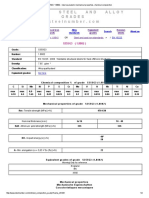

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandNo ratings yet

- 094 Pressure Gauge Cocks and ValvesDocument3 pages094 Pressure Gauge Cocks and ValvesRISHABH VERMANo ratings yet

- Tper Expansion Board Cap Seal System: PatentedDocument4 pagesTper Expansion Board Cap Seal System: PatentedMickaelNo ratings yet

- Shelgaon Bridge QuantitesDocument8 pagesShelgaon Bridge Quantitessantosh yevvariNo ratings yet

- Property Manipulation of Steels With Variation in %C-Fracture Toughness vs. Yield StrengthDocument5 pagesProperty Manipulation of Steels With Variation in %C-Fracture Toughness vs. Yield StrengthSaumya SuyalNo ratings yet

- British Gypsum WB DriLyner DabDocument6 pagesBritish Gypsum WB DriLyner DabManu FraguelaNo ratings yet