Professional Documents

Culture Documents

HD Flyer Turntable Presses WEGA 11 17 e

Uploaded by

Bane Nikolic0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

HD_Flyer_Turntable_presses_WEGA_11_17_e

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesHD Flyer Turntable Presses WEGA 11 17 e

Uploaded by

Bane NikolicCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

The WEGA series is a time-tested pressing system that

Turntable presses

unites production diversity with economic efficiency.

WEGA

PDZ

PRODUCT INFORMATION SCOPE OF SUPPLY

The HÄNDLE-WEGA pressing system

Nowadays, market-appropriate roof-tile collections must tables equipped with 1 top-half mold and 3 bottom-half

include a diversity of standard and accessory tiles. The molds for a maximum stroke rate of 12/min = 720 pres-

situation poses a major challenge to any and all producers, sings/h

because the difficulty of keeping production processes econo- WEGA S IV with 4 synchronous 90°-rotating pressing

mical increases with the number of design variants. The tables equipped with 1 top-half mold and 4 bottom-half

WEGA pressing system optimally meets all such require- molds for a maximum stroke rate of 13/min = 780 pres-

ments. Three different versions are available for covering any sings/h

individual range of application (soft or stiff pressing with any The table measures 560 x 754 mm for a maximum mold

customary type of mold material like plaster, metal or rubber): mounting area of 500 – 650 mm. The useful mold-group

WEGA S II with 2 synchronous 90°-rotating pressing height is adjustable between 170 mm and 300 mm.

tables equipped with 1 top-half mold and 2 bottom-half The 300-mm working stroke can accommodate practically any

molds for a maximum stroke rate of 8/min = 480 pres- conceivable type of tile. A maximum pressing force of 1500 kN

sings/h or 2000 kN enables perfect forming / expression, even of

WEGA S III with 3 synchronous 120°-rotating pressing complicated models.

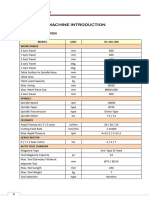

WEGA S II WEGA S III WEGA S IV

Defining characteristics Technical data

TYPE WEGA S II WEGA S III WEGA S IV

Pressing force max. kN 1500/ 2000 1500/ 2000 1500/ 2000

Automatic operating principle

Working stroke mm 300 300 300

High pressing force

Mold-group height min./ max. mm 170/ 300 170/ 300 170/ 300

Freely programmable pressing curves for achieving Mounting area (turntable) 560 x 754

mm 560 x 754 560 x 754

model-specific expression characteristics Overall capacity, incl. vacuum p. 112

kW 112 112

High pressing-curve reproducibility Volumetric flow through vacuum p.

m³/h 160 160 160

(100 bar)

Precise positioning and work cycles for bat place- Mold size mm 500 x 650 500 x 650 500 x 650

ment and removal of shaped products Positioning accuracy mm 0,1 - 0,3 0,1 - 0,3 0,1 - 0,3

No. of top-half working molds 1 1 1

Clean and tidy disposal of production scraps

No. of bottom-half working molds 2 3 4

Sufficient stroke rate for high throughput Pressings per minute 6-8 10 - 12 11 - 13

max.

Total weight kg 11200 11600 12000

Subject to technical modification due to ongoing development.

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- HÄNDLE Roof Tile Press Boosts EfficiencyDocument6 pagesHÄNDLE Roof Tile Press Boosts EfficiencyBane NikolicNo ratings yet

- SanderDocument32 pagesSanderЂорђе РегодаNo ratings yet

- DMH Machine Catalogue 2023Document41 pagesDMH Machine Catalogue 2023Carlos DiezNo ratings yet

- ONRAM 1000/3 ONRAM 1000/3: Diamond Core Drill Diamond Core DrillDocument4 pagesONRAM 1000/3 ONRAM 1000/3: Diamond Core Drill Diamond Core DrillTomasz TromasNo ratings yet

- 32.2021 KF7600L Leaflet ENG - v1.2Document8 pages32.2021 KF7600L Leaflet ENG - v1.2Mohamed EssamNo ratings yet

- Brochure Estefold 2300WDocument2 pagesBrochure Estefold 2300WFelix KopieeerNo ratings yet

- Prospekt-844 EN LowResDocument6 pagesProspekt-844 EN LowResIslam ElhabsheNo ratings yet

- BUSCH Pile Turner Information EnglishDocument1 pageBUSCH Pile Turner Information EnglishKBR Graphics CanadaNo ratings yet

- Cold Milling Machine W 1900: Efficient Milling in The 2-m ClassDocument24 pagesCold Milling Machine W 1900: Efficient Milling in The 2-m ClassKhaleelNo ratings yet

- CABEÇOTES - HTT - Stanki - Glubokogo - SverleniyaDocument12 pagesCABEÇOTES - HTT - Stanki - Glubokogo - Sverleniyacarolina lopesNo ratings yet

- SchulerDocument8 pagesSchuleraguswNo ratings yet

- Ams Series: Ams-210EN and Ams-224EDocument21 pagesAms Series: Ams-210EN and Ams-224EAshish KumarNo ratings yet

- VARIAXIS-C-600-BrochureDocument24 pagesVARIAXIS-C-600-Brochureadrienbridel80No ratings yet

- 06 1 Technspec1000eDocument6 pages06 1 Technspec1000eAnonymous Gh9egRKMNo ratings yet

- Treif Jaguar BrochureDocument2 pagesTreif Jaguar Brochureivan reyes TorresNo ratings yet

- HD Flyer De-Airing Double-Shaft Mixers 11 17 eDocument2 pagesHD Flyer De-Airing Double-Shaft Mixers 11 17 eBane NikolicNo ratings yet

- RASO Series en v001Document12 pagesRASO Series en v001silviolcNo ratings yet

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- MS-500 Twin Pallet Vertical Machining Center Technical SpecificationDocument8 pagesMS-500 Twin Pallet Vertical Machining Center Technical SpecificationCristian PavanNo ratings yet

- Beta fine roller mills offer effective 0.8mm gapsDocument2 pagesBeta fine roller mills offer effective 0.8mm gapsBane NikolicNo ratings yet

- DMH Website Maschine500 Datenblaetter en 210x297 RGBDocument5 pagesDMH Website Maschine500 Datenblaetter en 210x297 RGBCarlos DiezNo ratings yet

- Chapter 2 Machine IntroductionDocument4 pagesChapter 2 Machine IntroductionTech CIMNo ratings yet

- Variaxis I SeriesDocument22 pagesVariaxis I Seriesbhandge8850% (2)

- NETZSCH MasterMill ENDocument8 pagesNETZSCH MasterMill ENاحمد عدنانNo ratings yet

- Concrete PumpDocument2 pagesConcrete PumpwulanNo ratings yet

- Catalog of 150 CDocument6 pagesCatalog of 150 CJorge Barradas OsornoNo ratings yet

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Twinmaster 16 III EDocument2 pagesTwinmaster 16 III ECristian HenaoNo ratings yet

- sp4800 enDocument2 pagessp4800 enArden PoncioNo ratings yet

- VX Series - English - 2019 09Document8 pagesVX Series - English - 2019 09Kiril AngelovNo ratings yet

- Soil Mixing Wall System: Product InformationDocument8 pagesSoil Mixing Wall System: Product Informationnoto.sugiartoNo ratings yet

- WWW - Zenith.de: Fully Automatic Mobile Multilayer MachineDocument6 pagesWWW - Zenith.de: Fully Automatic Mobile Multilayer MachineMohamed Hussein100% (1)

- 1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementDocument12 pages1200 Tablet Press Extreme Versatility Economical Small Batches Very Low Space RequirementMIguel BotelloNo ratings yet

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocument6 pagesVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNo ratings yet

- TX Series Boring and Milling Centers High Precision Horizontal MachinesDocument12 pagesTX Series Boring and Milling Centers High Precision Horizontal MachinesDjuraTheHarpYNo ratings yet

- Edge Banding Trimming Machines EDGETEQ T 100 EDGETEQ T 200 ENDocument4 pagesEdge Banding Trimming Machines EDGETEQ T 100 EDGETEQ T 200 ENDaniel Mazón ToledoNo ratings yet

- Hermle c250Document32 pagesHermle c250Kiril AngelovNo ratings yet

- Avnd2300ah Avnd4000ah DB SL GB 14-07-02 HK2052 01Document1 pageAvnd2300ah Avnd4000ah DB SL GB 14-07-02 HK2052 01MinaSaeedNo ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Prosize®: An Innovative Breakthrough in SizingDocument2 pagesProsize®: An Innovative Breakthrough in SizingRodrigo Lopez GallegosNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Laser Cutting Machine Infinity f1Document6 pagesLaser Cutting Machine Infinity f1Divyaba DodiyaNo ratings yet

- NEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Document12 pagesNEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Marlon GilerNo ratings yet

- Bridgeport Series I - BrochureDocument2 pagesBridgeport Series I - BrochureVVNo ratings yet

- 05a - MSM 86 - e PDFDocument2 pages05a - MSM 86 - e PDFMuhammad Nur CahyadiNo ratings yet

- De 20220812162629y1ee0Document4 pagesDe 20220812162629y1ee0Raiyre RolandNo ratings yet

- PDF FanucDocument28 pagesPDF Fanucheart princeNo ratings yet

- Schüco ASE 60/80 Aluminum Sliding Element GuideDocument4 pagesSchüco ASE 60/80 Aluminum Sliding Element GuideRoberto ResendesNo ratings yet

- Centrifugal Machines BrochureDocument8 pagesCentrifugal Machines BrochureSiva VigneswaranNo ratings yet

- W1000Xd1_CatalogDocument11 pagesW1000Xd1_Catalogadrienbridel80No ratings yet

- VAV DamperDocument7 pagesVAV DamperAdades Safede EfdNo ratings yet

- Smooth Double Roll Crusher 800x800 Features and SpecsDocument2 pagesSmooth Double Roll Crusher 800x800 Features and SpecspatelchiragisNo ratings yet

- Mașină de Tăiat Piatră IMER MASONRY 750Document1 pageMașină de Tăiat Piatră IMER MASONRY 750diconNo ratings yet

- Pal KombiDocument4 pagesPal KombiIrfanNo ratings yet

- Increased Productivity with Powerful 5-Axis MachiningDocument9 pagesIncreased Productivity with Powerful 5-Axis MachiningHeineken Ya PraneetpongrungNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Vario-Tec: VARIO-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsDocument2 pagesVario-Tec: VARIO-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsBane NikolicNo ratings yet

- ZMB BRAUN Flyer MMT - eDocument2 pagesZMB BRAUN Flyer MMT - eBane NikolicNo ratings yet

- HD Flyer Siebrundbeschicker 05-18 eDocument2 pagesHD Flyer Siebrundbeschicker 05-18 eBane NikolicNo ratings yet

- Quick Change Die Loading SystemDocument2 pagesQuick Change Die Loading SystemBane NikolicNo ratings yet

- Modul-Tec: MODUL-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsDocument2 pagesModul-Tec: MODUL-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsBane NikolicNo ratings yet

- B-Tec: B-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsDocument2 pagesB-Tec: B-TEC One Step Ahead Trend-Setting Technology For The Production of High-Quality Brick ProductsBane NikolicNo ratings yet

- HD WSL-Flyer 2018 eDocument2 pagesHD WSL-Flyer 2018 eBane NikolicNo ratings yet

- Circular Silos: Händle GMBH Maschinen Und Anlagenbau Mühlacker (Germany)Document2 pagesCircular Silos: Händle GMBH Maschinen Und Anlagenbau Mühlacker (Germany)Bane NikolicNo ratings yet

- Circular Silos: Händle GMBH Maschinen Und Anlagenbau Mühlacker (Germany)Document2 pagesCircular Silos: Händle GMBH Maschinen Und Anlagenbau Mühlacker (Germany)Bane NikolicNo ratings yet

- HD Flyer Siebrundbeschicker 05-18 eDocument2 pagesHD Flyer Siebrundbeschicker 05-18 eBane NikolicNo ratings yet

- HD Flyer Box Feeders 11 17 eDocument2 pagesHD Flyer Box Feeders 11 17 eBane NikolicNo ratings yet

- Experience and leadership in extrusion technologyDocument2 pagesExperience and leadership in extrusion technologyBane NikolicNo ratings yet

- Roof Tile Press NOVA III with Eccentric CamDocument2 pagesRoof Tile Press NOVA III with Eccentric CamBane NikolicNo ratings yet

- Experience and leadership in extrusion technologyDocument2 pagesExperience and leadership in extrusion technologyBane NikolicNo ratings yet

- HD Gamma-Flyer 2018 eDocument2 pagesHD Gamma-Flyer 2018 eBane NikolicNo ratings yet

- HD Flyer Box Feeders 11 17 eDocument2 pagesHD Flyer Box Feeders 11 17 eBane NikolicNo ratings yet

- Wet and Mixing Pan Mills Duo / Quadro: Hmi / HmiqDocument2 pagesWet and Mixing Pan Mills Duo / Quadro: Hmi / HmiqBane NikolicNo ratings yet

- HD Flyer Roller Crushers 11 17 eDocument2 pagesHD Flyer Roller Crushers 11 17 eBane NikolicNo ratings yet

- Double-Shaft Screen Mixers: MDSG/ MDGDocument2 pagesDouble-Shaft Screen Mixers: MDSG/ MDGBane NikolicNo ratings yet

- HD MD-Flyer 2018 eDocument2 pagesHD MD-Flyer 2018 eBane NikolicNo ratings yet

- Beta fine roller mills offer effective 0.8mm gapsDocument2 pagesBeta fine roller mills offer effective 0.8mm gapsBane NikolicNo ratings yet

- HD Flyer De-Airing Double-Shaft Mixers 11 17 eDocument2 pagesHD Flyer De-Airing Double-Shaft Mixers 11 17 eBane NikolicNo ratings yet

- Combined De-Airing Extrusion Machines Futura Ii: PZG/ EDocument12 pagesCombined De-Airing Extrusion Machines Futura Ii: PZG/ EBane Nikolic100% (1)

- Clay Shredder: Product Information HÄNDLE Clay Shredder - Most Suitable For Crushing Soft Material Up To 2 MohsDocument6 pagesClay Shredder: Product Information HÄNDLE Clay Shredder - Most Suitable For Crushing Soft Material Up To 2 MohsBane NikolicNo ratings yet

- Crusher and Shredder: WMM / WMH WSB / WSBH WM WMSDocument8 pagesCrusher and Shredder: WMM / WMH WSB / WSBH WM WMSBane NikolicNo ratings yet

- Box Feeders: BKN/ BKNG/ BKSS/ BKSSGDocument2 pagesBox Feeders: BKN/ BKNG/ BKSS/ BKSSGBane NikolicNo ratings yet

- Fine Roller Mill Alpha Ii: Type ALPHA II: The Standard of Hydraulic High-Performance Roller Mills, For Roller GapsDocument8 pagesFine Roller Mill Alpha Ii: Type ALPHA II: The Standard of Hydraulic High-Performance Roller Mills, For Roller GapsBane NikolicNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Hospital NetworkDocument36 pagesHospital NetworkAbhishek MishraNo ratings yet

- Tata Steel-MDP SessionDocument69 pagesTata Steel-MDP Sessionsasharma82No ratings yet

- Cognitive Load Theory (John Sweller) : Information ProcessingDocument2 pagesCognitive Load Theory (John Sweller) : Information ProcessingNik ZazlealizaNo ratings yet

- Jun 2005 - AnsDocument13 pagesJun 2005 - AnsHubbak Khan100% (1)

- First Preliminary Music Video ScriptDocument1 pageFirst Preliminary Music Video Scriptapi-455734096No ratings yet

- Home BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionDocument1 pageHome BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionOliver AlfaroNo ratings yet

- tmp82D3 TMPDocument12 pagestmp82D3 TMPFrontiersNo ratings yet

- Clinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyDocument33 pagesClinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyRosiNo ratings yet

- Contoh Skripsi Bahasa Inggris Case StudyDocument18 pagesContoh Skripsi Bahasa Inggris Case StudyRizki Fajrita100% (14)

- Chemists 12-2023Document7 pagesChemists 12-2023PRC BaguioNo ratings yet

- Taxation Management AssignmentDocument11 pagesTaxation Management AssignmentniraliNo ratings yet

- Lembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Document11 pagesLembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Yahya Darmais FaridNo ratings yet

- SP Manual Addendum For OS 3 - 03Document2 pagesSP Manual Addendum For OS 3 - 03kevmac88No ratings yet

- Main Body Recruitment Process of Human Resource Division in Brac BankDocument55 pagesMain Body Recruitment Process of Human Resource Division in Brac BankAsfia PrantyNo ratings yet

- 3M SS Filters Data SheetDocument4 pages3M SS Filters Data SheetbinnisfquoteNo ratings yet

- TEFL I Course Prepares Students to Teach EnglishDocument8 pagesTEFL I Course Prepares Students to Teach EnglishErma DomosNo ratings yet

- Finite Element Analysis (FEA) Software MarketDocument3 pagesFinite Element Analysis (FEA) Software Marketsurendra choudharyNo ratings yet

- Dispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsDocument41 pagesDispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsSantiago OrtizNo ratings yet

- Module 3 - Tennnis: Cit Colleges of Paniqui Foundation IncDocument14 pagesModule 3 - Tennnis: Cit Colleges of Paniqui Foundation IncLahra BalanciaNo ratings yet

- K - LP - Week 24 - Journeys Unit 3 Lesson 14Document8 pagesK - LP - Week 24 - Journeys Unit 3 Lesson 14englishwithmslilyNo ratings yet

- Professional Education ReviewerDocument22 pagesProfessional Education ReviewerJustine WicoNo ratings yet

- Analisis Hasil Led Pada Jam Pertama Dan Jam KeduaDocument11 pagesAnalisis Hasil Led Pada Jam Pertama Dan Jam KeduavirafutmainnarNo ratings yet

- HackSpace - June 2021Document116 pagesHackSpace - June 2021Somnath100% (1)

- Lifeboat Equipment ListDocument1 pageLifeboat Equipment Listjosua albertNo ratings yet

- BISE Sukkur HSC Part 2 Results 2015Document12 pagesBISE Sukkur HSC Part 2 Results 2015ajayNo ratings yet

- 1) What Is Gloss ?Document14 pages1) What Is Gloss ?AvadhutNo ratings yet

- Perlis V. Composer's Voices From Ives To Ellington PDFDocument506 pagesPerlis V. Composer's Voices From Ives To Ellington PDFOleksii Ternovii100% (1)

- Labcir - Marwa - FinalDocument119 pagesLabcir - Marwa - FinalMashavia AhmadNo ratings yet

- Lesson 2 - Procedures in Cleaning Utensils and EquipmentDocument26 pagesLesson 2 - Procedures in Cleaning Utensils and EquipmentReizel TulauanNo ratings yet

- AS400 Config Audit Checklist Security BrigadeDocument4 pagesAS400 Config Audit Checklist Security BrigadeAlok DriveqNo ratings yet