Professional Documents

Culture Documents

Terex Vibrating Feeder Advantage-Series-VGF-Flyer

Uploaded by

Carlos Ediver Arias RestrepoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terex Vibrating Feeder Advantage-Series-VGF-Flyer

Uploaded by

Carlos Ediver Arias RestrepoCopyright:

Available Formats

Terex® Minerals Processing Systems

Cedarapids Advantage Series VGF

High Tonnage, Large Stroke Feeder

The large stroke of the Terex® Cedarapids Advantage Series Vibrating Grizzly Feeder (VGF)

produces high capacity along with superior separation of material at the grizzly.

High Strength, High Performance Design Features

Large stroke high agitation motion results in a high

capacity feeder with superior grizzly separation

High strength to weight ratio maximizes stroke

and production

Deep formed sides and tubular pan support matrix

maximize structural strength

High strength AR steel, replaceable feeder pan liner

Efficient and Reliable, Day after Day

The Advantage Series VGF provides high production and long Wide bearing center distance with in-line force transfer

service life in a wide range of rigorous applications. The feeder

design allows for better crushing equipment utilization. The large Long life bearings, timing gears and shafts

stroke produces high throughput tonnage with superior material

separation at the grizzly. You get the most out of your primary Tapered, bolt-in grizzly bars with deep profile

crusher by feeding only what needs to be crushed. Overall operating

costs are decreased, strengthening your return on investment.

Form 21981 (3/12)

Terex® Minerals Processing Systems

Cedarapids Advantage Series Vibrating Grizzly Feeders

Large, deep profile, tapered grizzly bars provide a

wide range of bar spacing and minimizes plugging/blinding

Cool running bearing temperatures

and low shaft speed extend bearing life

Large aggressive stroke with high G-force

Extremely durable feeder frame

with high strength steel pan

weldment, deep tubular supports

and deep formed steel side sheets

Adjustable vibrator timing optimizes

motion over entire feeder length

Modular bolt-together grizzly

sections enhance structural integrity Large gears for long life

and can be configured for various applications

Superior force transfer due to locating self-aligning spherical

Long life multi-lip oil seals roller bearings (cartridge-type) in-line with feeder skirt

Rugged Construction Adjustable Grizzly

The high strength to weight structural design of the Terex® Cedarapids The adjustable bolt-together

Advantage Series VGF handles both portable and stationary applications. grizzly section provides for

High strength steel in the pan and deep side sheets improve the overall optimum “fit” between grizzly

strength of the entire feeder weldment. This rugged feeder can handle side sheets and feeder frame.

the most rigourous shot-rock applications generally reserved for special The rear grizzly bar support is

heavy-duty feeders. bolted directly into the pan

The efficiently designed feeder features outboard coil spring suspension support for added strength

with removable support brackets which makes spring replacement easy. and rigidity.

The VGF design is available with a 60" (1524 mm) grizzly section in a

Large Stroke Vibrator flat or sloped arrangement. The 20' (6.1 m) long feeders are also available

A large 5/8" (15.9 mm) stroke and uniform motion over the entire with a 120" (3048 mm) grizzly section in a stepped arrangement.

feeder length provides for excellent feeding capability. This adds to the The grizzly bars are extra deep with an accentuated taper. This deep

overall efficiency of the feeder by stratifying the bed of material to assure profile combined with the taper minimizes the occurrence of plugging

superior separation through the grizzly. and blinding. The bolt-in bars allow for a wider range of bar spacing

For efficiency, the spherical roller bearings are aligned with the to better match the crusher setting in any given application. They also

feeder skirt providing direct force transfer from the vibrator shafts to the provide greater control over the separation of fines.

feeder frame. The oil flow control keeps bearing temperatures cooler

and the large gear circumference increases gear life. All of these design The Advantage Series VGF...

features mean long service life and high efficiency. making more product...more efficiently...more often.

www.terexmps.com

Effective Date: March 2012. Product specifications and prices are subject to change without notice or obligation. The photographs and/or drawings in

this document are for illustrative purposes only. Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment. Failure to

follow the appropriate Operator’s Manual when using our equipment or to otherwise act irresponsibly may result in serious injury or death. The only warranty

applicable to our equipment is the standard written warranty applicable to the particular product and sale and Terex makes no other warranty, express or

implied. Products and services listed may be trademarks, service marks or trade-names of Terex Corporation and/or its subsidiaries in the USA and other

countries. All rights are reserved. Terex is a registered trademark of Terex Corporation in the USA and many other countries. © 2012 Terex Corporation.

Terex® Minerals Processing Systems, 909 17th Street NE, Cedar Rapids, IA 52402 USA

Tel +1 319 363 3511 Fax +1 319 399 4871 www.terexmps.com Form 21981 (3/12)

You might also like

- California State Bar Order of Discipline of Louis "Skip" Miller For Jury TamperingDocument33 pagesCalifornia State Bar Order of Discipline of Louis "Skip" Miller For Jury TamperingAlan RomeroNo ratings yet

- Performance in every detail with Keestrack crushing and screening equipmentDocument43 pagesPerformance in every detail with Keestrack crushing and screening equipmentАнтон ЛазаровNo ratings yet

- Crusher Jaws: KLEEMANN Range ofDocument4 pagesCrusher Jaws: KLEEMANN Range ofJose PeresNo ratings yet

- Cone Orange GBDocument8 pagesCone Orange GBr mcleodNo ratings yet

- Talent Level 3 Grammar Tests Unit 2Document2 pagesTalent Level 3 Grammar Tests Unit 2ana maria csalinasNo ratings yet

- New Monasticism: An Interspiritual Manifesto For Contemplative Life in The 21st CenturyDocument32 pagesNew Monasticism: An Interspiritual Manifesto For Contemplative Life in The 21st CenturyWorking With Oneness100% (8)

- Balint Training System 1948Document16 pagesBalint Training System 1948Laura Acosta100% (2)

- JW Series Jaw Crushers: Terex Minerals Processing SystemsDocument16 pagesJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionNo ratings yet

- Close Side Setting Sensor SB-96BDocument4 pagesClose Side Setting Sensor SB-96Bjuanandres_martinezNo ratings yet

- Cone StandardDocument16 pagesCone StandardNguyễn LinhNo ratings yet

- 01-Hansy Company Presentation - 20200901 - Frank Woode - V11.8 - END - OfficialDocument48 pages01-Hansy Company Presentation - 20200901 - Frank Woode - V11.8 - END - OfficialJose Martinez MillaNo ratings yet

- Guangxi Crukings Machinery Equipment Co., Ltd. ProfileDocument26 pagesGuangxi Crukings Machinery Equipment Co., Ltd. ProfileJake HuangNo ratings yet

- 606561-414294 Alimentador + Mandibula k300Document121 pages606561-414294 Alimentador + Mandibula k300teddy fuentesNo ratings yet

- Cedarapids Overview BrochureDocument28 pagesCedarapids Overview BrochureJuan Marcos RodriguezNo ratings yet

- Cobra 230 Tech SpecDocument28 pagesCobra 230 Tech SpecJP BlancaNo ratings yet

- Hewitt (Nordberg), Low Profile Elip Vib For Screens FeedersDocument36 pagesHewitt (Nordberg), Low Profile Elip Vib For Screens FeedersCarlos anderson Sossa ChaverraNo ratings yet

- TBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualDocument44 pagesTBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualIruna HupaloNo ratings yet

- Trio CRP42A Permanent Magnet Manual (SN. 065)Document28 pagesTrio CRP42A Permanent Magnet Manual (SN. 065)GUILLERMO OSIMANINo ratings yet

- 1180 Premiertrak Crushing Brochure en 2014Document1 page1180 Premiertrak Crushing Brochure en 2014Max Rene Velazquez GarciaNo ratings yet

- Secondary Impact CrushersDocument8 pagesSecondary Impact CrushersKevin David Guao BolanoNo ratings yet

- Ref Book 19edDocument230 pagesRef Book 19edLuis LunaNo ratings yet

- Systems: WashingDocument6 pagesSystems: WashingVinNo ratings yet

- Hydraulic Diagram MM0346835 - 1Document4 pagesHydraulic Diagram MM0346835 - 1miguel. montañoNo ratings yet

- Evoquip Bison 120 March 2019Document7 pagesEvoquip Bison 120 March 2019Daniel BianchiniNo ratings yet

- Purchased Part Specification: Extended DescriptionDocument1 pagePurchased Part Specification: Extended DescriptionWilliam VillamizarNo ratings yet

- Heavy Duty Jaw & Cone Crusher Liner OptionsDocument3 pagesHeavy Duty Jaw & Cone Crusher Liner OptionsAndrey L'vovNo ratings yet

- Trio Grizzly Feeders - TF Series: Product CollectionDocument2 pagesTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNo ratings yet

- Hewiit, Eliptex ShakeoutDocument43 pagesHewiit, Eliptex ShakeoutCarlos anderson Sossa ChaverraNo ratings yet

- Rocksledger: Primary Jaw CrushersDocument2 pagesRocksledger: Primary Jaw CrushersMechanical department100% (2)

- Low Profile Vibrating Screen 8X20Document14 pagesLow Profile Vibrating Screen 8X20VladimirNo ratings yet

- Hewitt (Nordberg) Gyrex ScreenDocument36 pagesHewitt (Nordberg) Gyrex ScreenCarlos anderson Sossa ChaverraNo ratings yet

- Premiertrak 400X Technical Specification Rev 1 - 01.01.2019Document24 pagesPremiertrak 400X Technical Specification Rev 1 - 01.01.2019Andres AstudilloNo ratings yet

- Modular Plant Brochure 2013Document5 pagesModular Plant Brochure 2013Nancy ParvinaNo ratings yet

- 73.terex® WJ1175 Wheeled Jaw Plant - EDocument4 pages73.terex® WJ1175 Wheeled Jaw Plant - EHữu Dũng Nguyễn100% (2)

- Introducing The: Specification Xr400/206Document14 pagesIntroducing The: Specification Xr400/206Sergio RazoNo ratings yet

- Bearings For Cone Crushers: Serving Industries WorldwideDocument4 pagesBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezNo ratings yet

- Nordberg SUPERIOR® Gyratory CrushersDocument12 pagesNordberg SUPERIOR® Gyratory Crushersyauri30No ratings yet

- Sandvik Ud211 Wheeled Processing Unit: Technical SpecificationDocument2 pagesSandvik Ud211 Wheeled Processing Unit: Technical Specificationpmf engineering limited100% (1)

- Tertiary VSI Mobile PlantDocument1 pageTertiary VSI Mobile PlantPuzzolana Foundation For ExcellanceNo ratings yet

- ECT Symons 7s For SaleDocument2 pagesECT Symons 7s For SaleOrlando MelipillanNo ratings yet

- Jaw PDFDocument12 pagesJaw PDF채경호No ratings yet

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Excel Components For Symons Templates PDFDocument1 pageExcel Components For Symons Templates PDFAnonymous 8t0V9SNo ratings yet

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDocument27 pagesMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniNo ratings yet

- Canica 80 Vsi ManualDocument112 pagesCanica 80 Vsi ManualLuis VallecilloNo ratings yet

- Tough Crushing: Smooth OperatingDocument16 pagesTough Crushing: Smooth OperatingManuel GagnoNo ratings yet

- Leaflet One Piece Jaws 4482 10 21 en Cns LRDocument2 pagesLeaflet One Piece Jaws 4482 10 21 en Cns LRkhk84jfxchNo ratings yet

- Lokotrack Mobile Crushing PlantDocument6 pagesLokotrack Mobile Crushing PlantAleksandar GogovNo ratings yet

- Manual de Partes - AstecDocument34 pagesManual de Partes - AstecChristian Adan Rosas ZertucheNo ratings yet

- Rockon.: Messinger Has Replacement Bearings For Crushing Equipment Available For Fast DeliveryDocument3 pagesRockon.: Messinger Has Replacement Bearings For Crushing Equipment Available For Fast DeliveryMichele DeckerNo ratings yet

- Chieftain 2100X: Powerscreen Parts Manual Version 01eg FROM S/N 12410001Document173 pagesChieftain 2100X: Powerscreen Parts Manual Version 01eg FROM S/N 12410001ЕвгенийNo ratings yet

- Mobile granite crushing plant 150t/hDocument4 pagesMobile granite crushing plant 150t/hSolomon MiNo ratings yet

- Dokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeDocument14 pagesDokumen - Tips - Powerscreen Premiertrak 400 r400 Jaw Crusher Jaw Crusher Crusher TypeManuel dlHNo ratings yet

- v2.4 MOP2160 - E ZARANDADocument21 pagesv2.4 MOP2160 - E ZARANDAMartín Lescano ParedesNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- Hydraulic assembly bill of materialsDocument2 pagesHydraulic assembly bill of materialscapslive_001No ratings yet

- Poliuretano - Mallas WS85Document32 pagesPoliuretano - Mallas WS85Oscar C SotomayorNo ratings yet

- Pinion Rebuild 42-65Document19 pagesPinion Rebuild 42-65Oscar Aragon TejadaNo ratings yet

- Extec C12 PDF - 0 - 0Document21 pagesExtec C12 PDF - 0 - 0gugi100% (1)

- Jaw &cone Rsi Service Schedule - Sheet1Document2 pagesJaw &cone Rsi Service Schedule - Sheet1Kilton BiswasNo ratings yet

- Rollercone Service Manual: RC and RCII CrushersDocument237 pagesRollercone Service Manual: RC and RCII CrushersFory KliafasNo ratings yet

- Advantage Series VGF Specification SheetDocument4 pagesAdvantage Series VGF Specification SheetElijah TanNo ratings yet

- Adapter Listing For KORG ProdDocument2 pagesAdapter Listing For KORG ProdCarlos Ediver Arias RestrepoNo ratings yet

- Live Image ES0666ADocument7 pagesLive Image ES0666ACarlos Ediver Arias RestrepoNo ratings yet

- LP Accesories and Spare PartsDocument5 pagesLP Accesories and Spare PartsCarlos Ediver Arias RestrepoNo ratings yet

- Page 1 of 4 Buy Behringer PMP5000-B212XL PA Package - Live Sound Packages - Musician's FriendDocument4 pagesPage 1 of 4 Buy Behringer PMP5000-B212XL PA Package - Live Sound Packages - Musician's FriendCarlos Ediver Arias RestrepoNo ratings yet

- Buy Shure PGX24 - SM58 Handhe..Document5 pagesBuy Shure PGX24 - SM58 Handhe..Carlos Ediver Arias RestrepoNo ratings yet

- Speaker Power Handling - Pro-Audio ReferencesDocument4 pagesSpeaker Power Handling - Pro-Audio ReferencesCarlos Ediver Arias RestrepoNo ratings yet

- Tips and TricksDocument16 pagesTips and TrickszaklebreNo ratings yet

- Pro EQ PlatinumDocument16 pagesPro EQ PlatinumDavid negrete galarzaNo ratings yet

- Korg TR EasyStartDocument6 pagesKorg TR EasyStartZitlaliRosadoNo ratings yet

- QUICK CODE SIMPLIFIES PROGRAMMING WITH TEMPLATESDocument10 pagesQUICK CODE SIMPLIFIES PROGRAMMING WITH TEMPLATESCarlos Ediver Arias RestrepoNo ratings yet

- Star Award TurquoiseDocument1 pageStar Award TurquoiseCarlos Ediver Arias RestrepoNo ratings yet

- Item Code: AS Q C S FDocument11 pagesItem Code: AS Q C S FCarlos Ediver Arias RestrepoNo ratings yet

- Description: Victor Litz Music Center Labor Day Sale 2009 Price ListDocument26 pagesDescription: Victor Litz Music Center Labor Day Sale 2009 Price ListCarlos Ediver Arias RestrepoNo ratings yet

- Star Award BlueDocument1 pageStar Award BluenatalanNo ratings yet

- Microset: Wireless Omnidirectional Condenser Headworn MicrophonesDocument1 pageMicroset: Wireless Omnidirectional Condenser Headworn MicrophonesCarlos Ediver Arias RestrepoNo ratings yet

- Components HSI CrusherDocument3 pagesComponents HSI CrusherCarlos Ediver Arias RestrepoNo ratings yet

- Welcome 2002 WG Grand Cherokee Technical Publications: Click On The Icon For The Desired ManualDocument1 pageWelcome 2002 WG Grand Cherokee Technical Publications: Click On The Icon For The Desired ManualCarlos Ediver Arias RestrepoNo ratings yet

- Formulas ChartDocument1 pageFormulas ChartbobsledNo ratings yet

- Dodge LER Labyrinth USAF 500 SPLIT-SPHER Pillow Block SealsDocument1 pageDodge LER Labyrinth USAF 500 SPLIT-SPHER Pillow Block SealsCarlos Ediver Arias RestrepoNo ratings yet

- Dodge Nomenclature LER Labyrinth USAF 500 SPLIT-SPHER Pillow Block SealsDocument5 pagesDodge Nomenclature LER Labyrinth USAF 500 SPLIT-SPHER Pillow Block SealsCarlos Ediver Arias RestrepoNo ratings yet

- Page 1 of 2 Yorkville Sound: LoudspeakersDocument2 pagesPage 1 of 2 Yorkville Sound: LoudspeakersCarlos Ediver Arias RestrepoNo ratings yet

- (2083831X - Studia Geotechnica Et Mechanica) Application of The New Shape Crushing Plate in Machine Crushing ProcessesDocument14 pages(2083831X - Studia Geotechnica Et Mechanica) Application of The New Shape Crushing Plate in Machine Crushing ProcessesCarlos Ediver Arias RestrepoNo ratings yet

- Speaker Power Handling - Pro-Audio ReferencesDocument4 pagesSpeaker Power Handling - Pro-Audio ReferencesCarlos Ediver Arias RestrepoNo ratings yet

- WB140-2N, PS2NDocument16 pagesWB140-2N, PS2NLuisAlbertoVerdejoTapia100% (1)

- Design and Analysis of Swing Jaw Plates for a Jaw CrusherDocument5 pagesDesign and Analysis of Swing Jaw Plates for a Jaw CrusherCarlos Ediver Arias RestrepoNo ratings yet

- Troughing Idlers & Belt Conveyor ComponentsDocument7 pagesTroughing Idlers & Belt Conveyor ComponentsCarlos Ediver Arias RestrepoNo ratings yet

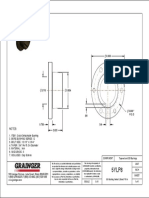

- Tapered and quick detach bushingsDocument1 pageTapered and quick detach bushingsCarlos Ediver Arias RestrepoNo ratings yet

- Mass Angle of Repose of Open-Graded Rock Riprap: Technical NoteDocument8 pagesMass Angle of Repose of Open-Graded Rock Riprap: Technical NoteCarlos Ediver Arias RestrepoNo ratings yet

- Of P.N.C 09101: W/ Free Wheel HubDocument43 pagesOf P.N.C 09101: W/ Free Wheel HubCarlos Ediver Arias RestrepoNo ratings yet

- Mild Steel FC ParametersDocument1 pageMild Steel FC ParametersCarlos Ediver Arias RestrepoNo ratings yet

- STS Lesson 1-2Document23 pagesSTS Lesson 1-2zarnaih SmithNo ratings yet

- Sadie's Drawing Materials: Buy Your Supplies atDocument5 pagesSadie's Drawing Materials: Buy Your Supplies atAlison De Sando ManzoniNo ratings yet

- IN SUNNY SPAIN, 1882-85: "My Country, My Love, My People, I Leave You Now, You Disappear, I Lose Sight of You"Document4 pagesIN SUNNY SPAIN, 1882-85: "My Country, My Love, My People, I Leave You Now, You Disappear, I Lose Sight of You"Mary Claire ComalaNo ratings yet

- Molar Mass, Moles, Percent Composition ActivityDocument2 pagesMolar Mass, Moles, Percent Composition ActivityANGELYN SANTOSNo ratings yet

- Kim Hoff PAR 117 JDF 1115 Separation AgreementDocument9 pagesKim Hoff PAR 117 JDF 1115 Separation AgreementlegalparaeagleNo ratings yet

- SD NEGERI PASURUHAN PEMERINTAH KABUPATEN TEMANGGUNGDocument5 pagesSD NEGERI PASURUHAN PEMERINTAH KABUPATEN TEMANGGUNGSatria Ieea Henggar VergonantoNo ratings yet

- Ky203817 PSRPT 2022-05-17 14.39.33Document8 pagesKy203817 PSRPT 2022-05-17 14.39.33Thuy AnhNo ratings yet

- Skills Test Unit 1 Test A EmailDocument4 pagesSkills Test Unit 1 Test A EmailЛиза ОмельченкоNo ratings yet

- Student (Mechanical Engineering), JECRC FOUNDATION, Jaipur (2) Assistant Professor, Department of Mechanical Engineering, JECRC FOUNDATION, JaipurDocument7 pagesStudent (Mechanical Engineering), JECRC FOUNDATION, Jaipur (2) Assistant Professor, Department of Mechanical Engineering, JECRC FOUNDATION, JaipurAkash yadavNo ratings yet

- TenorsDocument74 pagesTenorsaris100% (1)

- Indigo CaseDocument13 pagesIndigo Caseharsh sainiNo ratings yet

- Sivas Doon LecturesDocument284 pagesSivas Doon LectureskartikscribdNo ratings yet

- EasyGreen ManualDocument33 pagesEasyGreen ManualpitoupitouNo ratings yet

- 2010 Christian Religious Education Past Paper - 1Document1 page2010 Christian Religious Education Past Paper - 1lixus mwangiNo ratings yet

- OOD ch11Document31 pagesOOD ch11Pumapana GamingNo ratings yet

- Parking Garage Design GuidelinesDocument17 pagesParking Garage Design GuidelinesCarlos Benjamin BCNo ratings yet

- Stephen Mace Seizing PowerDocument168 pagesStephen Mace Seizing PowerLuke AndrewsNo ratings yet

- IFCRecruitment Manual 2009Document52 pagesIFCRecruitment Manual 2009Oklahoma100% (3)

- Buckley V UkDocument12 pagesBuckley V UkShriya ChandankarNo ratings yet

- Si Eft Mandate FormDocument1 pageSi Eft Mandate FormdSolarianNo ratings yet

- Performance Theory For Hot Air Balloons: The Balloon Works, Inc., Statesville, N.CDocument4 pagesPerformance Theory For Hot Air Balloons: The Balloon Works, Inc., Statesville, N.CEbubekir ErkanNo ratings yet

- Policy - SIM Cards Point of Sale Registration EngDocument6 pagesPolicy - SIM Cards Point of Sale Registration EngSHALOM SHUMBANo ratings yet

- Chapter 3 Professional Practices in Nepal ADocument20 pagesChapter 3 Professional Practices in Nepal Amunna smithNo ratings yet

- Weekly Capital Market Report Week Ending 22.07.2022 2022-07-22Document2 pagesWeekly Capital Market Report Week Ending 22.07.2022 2022-07-22Fuaad DodooNo ratings yet

- Thesis Chapter 123Document15 pagesThesis Chapter 123Chesca Mae PenalosaNo ratings yet

- Dictation TechniquesDocument12 pagesDictation TechniquesMuhamad IbrohimNo ratings yet