Professional Documents

Culture Documents

v2.4 MOP2160 - E ZARANDA

Uploaded by

Martín Lescano ParedesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

v2.4 MOP2160 - E ZARANDA

Uploaded by

Martín Lescano ParedesCopyright:

Available Formats

MINYU

VIBRATING SCREEN

MOP2160D / MOP2160T / MOP2160F

Parts and Service Manual

MINYU MACHINERY CORP.

No. 188, Lane 800, Zhongshan S. Rd.,

Yangmei Dist., 32669 Taoyuan City, Taiwan.

Tel: 886-3-4781168 Fax: 886-3-4781111

CONTENTS

1 PREFACE .................................................................................................................. 1

2 MAIN STRUCTURE ................................................................................................... 1

2.1 Type ························································································································ 1

2.2 Structure And Parts ····································································································· 1

3 TRANSPORTATION .................................................................................................. 2

3.1 Inspection ················································································································· 2

3.2 Transportation ··········································································································· 2

4 INSTALLATION ......................................................................................................... 3

4.1 Foundation and Installation ··························································································· 3

4.2 Special Adjustment of the Motor Base and the V-Belt Tension ················································ 4

5 RUNNING .................................................................................................................. 5

5.1 Starting and Stopping ··································································································· 5

5.2 Feeding ····················································································································· 6

5.3 Lubricating Grease ······································································································ 7

6 MAINTENANCE AND INSPECTION ......................................................................... 8

6.1 Inspection on Slackness of Screen ···················································································· 8

6.2 Inspection of V-Belt Tension ·························································································· 8

6.3 Inspection on the Amount of Lubricating Oil ······································································ 8

6.4 Inspection of Wiring for the Motor ·················································································· 8

6.5 Inspection on Bolts for Each Part ···················································································· 8

6.6 Anomalous Sound ······································································································· 8

6.7 Stopping and Starting the Machine ·················································································· 8

7 REPLACEMENT OF SCREEN NET AND CUSHION RUBBER................................ 9

8 OTHERS .................................................................................................................. 10

9 GENERAL ASSEMBLY ........................................................................................... 11

9.1 Main Frame………………………………………………………………………………………………11

9.2 Main Shaft Unit…………………………………………………………………………………………..13

9.3 Motor Unit………………………………………………………………………………………………..15

10 MODELS AND SPECIFICATIONS ........................................................................ 17

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

LIST OF FIGURES

Figure 1 Lifting .......................................................................................................................... 2

Figure 2 Installation Arrangement ............................................................................................. 3

Figure 3 Setting Up the Special Motor Base ............................................................................. 5

Figure 4 Revolving Direction .................................................................................................... 6

Figure 5 Feeding ........................................................................................................................ 6

Figure 6 Lubrication .................................................................................................................. 8

Figure 7 Fitting Section of Screen Net ...................................................................................... 9

Figure 8 General Assembly……………………..……………………………………………10

Figure 9 Main Frame…………………………………………………………………………11

Figure 10 Main Shaft Unit……………………………………………………………………13

Figure 11 Motor Unit…………………………………………………………………………15

MOP VER. 1.0 iii

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

1 PREFACE

Thank you very much for purchasing our Vibrating Screen, MOP 2160 type. This is the result

of many years of research and development efforts, developed and designed by adopting

features of each Low-head, Elliptical and Ripple-flow type vibrating screens. The MOP

vibrating screen is highly efficient and durable. It is the right equipment, if properly used in

accordance with the content of this manual, will bring you results that meet your expectations.

This translation is based on the Chinese version of the instruction manual, the latest Chinese

edition prevails.

2 MAIN STRUCTURE

2.1 TYPE

The MOP Type Inclined Vibrating Screens consist of 3 main parts: main frame, vibrator

assembly, and motor base.

2.2 STRUCTURE AND PARTS

The main frame is constructed of SS41 steel plates, flat iron, and support beams, with the

screen net spread over the main frame. Four springs on spring stands each left and right support

the main frame and let it vibrate smoothly during operation.

The vibrator assembly as core part includes eccentric shaft, unbalance weights, bearings, and

sheave. Due to rotation of the eccentric shaft, the screen will vibrate; vibrating amplitude can

be changed by adjusting the unbalance weights. The vibrating assembly is installed on both

sides of the main frame.

As a vibrating screen will jump upon start and stop, a special motor base equipped with a spring

as buffer is necessary, to avoid the V-Belt coming loose. The special motor base comes also

with a slide plate, to adjust V-Belt tension.

MOP VER. 1.0 1

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

3 TRANSPORTATION

3.1 INSPECTION

The vibrating screen unit is delivered disassembled into several components parts: main frame,

vibrator, spring stand, supporting springs, motor and motor base, V-belt, etc. Upon delivery of

the unit, carefully inspect the quantity of parts and any damage by matching the shipped

component with the attached list. If items are missing or damaged such that they cannot easily

be repaired on site, please inform “MINYU MACHINERY CORP.” immediately.

3.2 TRANSPORTATION

To lift up a MOP Vibrating Screen unit, use the lifting holes provided as shown in Figure 1.

Besides, the vibrator unit can be lifted with the screen altogether but DO NOT hook any lifting

cable to the vibrator.

Figure 1 Lifting

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

2 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

4 INSTALLATION

4.1 FOUNDATION AND INSTALLATION

The recommended dimensions in preparing the foundation are shown in Figure 2. Since this

model is an inclined one, the installation should be leveled as much as possible. The position of

the spring stands should be adjusted so that the main frame maintains an inclination angle of 15

degrees. The MOP type Vibrating Screen is supported by 8 springs so that little vibration is

propagated to the frame. The performance or efficiency of the screen could be reduced if the

foundation bolt comes to loosen up due to the micro-vibration or to an unleveled installation.

Therefore, care should be taken to properly build the foundation and install the equipment.

Discharge

Figure 2 Installation Arrangement

Vibrator installation:

MOP VER. 1.0 3

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

1. Insert the smaller end of the vibrating assembly through the larger hole (B) of the screen

box so that flange A of the assembly can be bolted to hole B. (Be sure to sand/clean any

dirt, grease, paint, etc. from the mounting surfaces of flange A and B to ensure tight fit.)

2. Tighten bolt/washer/nut sets 3,4,5 on flange A in a star tightening pattern. Tighten

bolt/washer/nut sets 6,8,9 on the non-drive side flange to the screen main body box in a

star pattern.

3. Tighten bolt/washer/nut sets 3,4,5 on flange A in a star tightening pattern. Tighten

bolt/washer/nut sets 6,8,9 on the non-drive side flange to the screen main body box in a

star pattern.

4. Tighten nuts to 309ft lbs

5. Install safety covers 13 and 14 with bolts 15.

6. Retighten all screen bolts after 8hrs, 24hrs, 72hrs, and as needed there after to ensure

proper tighteness and prevent damage or inefficient operation.

4.2 SPECIAL ADJUSTMENT OF THE MOTOR BASE AND THE V-BELT TENSION

The principle of vibration of the Vibrating Screen lies in the weight unbalance between the

Eccentric Shaft and the Drive. This is why the amplitude of the vibration is relatively bigger

while starting or stopping the machine. And in order to avoid that the excess of vibration causes

the V-Belt to loosen, the Motor should be installed on a special motor base as shown in Figure

4 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

3. Use a fixing bolt to fix one side of the motor base. On the other side are two springs – upper

and lower – which will buffer the vibration of the motor when it starts or stops. If the tension of

the V-Belt is not adequate or does not meet the requirement, once the special motor base is

installed on the foundation, please proceed to its adjustment in the following order (see Figure

3):

1. Loosen the Fixing Bolt (39) so that the Sliding Plate (32) can move.

2. Turn the Adjustment Bolt (40) to adjust the V-Belt to an appropriate tension.

3. Tighten the Fixing Bolt (39).

4. Every Bolt & Nut shall be properly tightened to prevent them from loosening up

because of internal vibrations.

Figure 3 Setting Up the Special Motor Base

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

5 RUNNING

5.1 STARTING AND STOPPING

The HPx4P motor used for the Vibrating Screens needs to come with a Starter. As to the

Starter, it is preferable to use a Compensator Starter or a Reactor Starter, otherwise it will not

be possible to start the machine at times when it lacks of starting torque. Feeding should only

take place once the motor has reached its rated speed. For the motor belt rotation direction,

MOP VER. 1.0 5

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

please refer to Figure 4. The normal and appropriate situation corresponds to that where the

direction of the motor is in accordance with Figure 4.

Figure 4 Revolving Direction

5.2 FEEDING

The chute should be shaped so as to throw materials onto the screen evenly to its full width.

Feeding is made as far back as possible from the screen. If the feed chute is insufficient, it

causes lag in spreading and laminating. Moreover, due to inefficient use of screen surface,

screening efficiency is lowered and local wear occurs on the screen surface.

Figure 5 Feeding

6 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

In order to avoid excessive acceleration of the feeding material and allow effective screening, it

is recommended to install a dead stock at the end of the chute to lower the velocity of the

materials falling down on the screen.

The feeding is preferably conducted in a parallel direction to the screen. If it is impossible,

however (for example, when feeding is made perpendicular to the screen) the structure of the

chute should be considered so that the materials at the feed opening are spread evenly on the

screen to its full width.

5.3 LUBRICATING GREASE

5.3.1 Type of Lubrication Grease: SPACLUB EP713 (high temperature grease)

Mobilux EP2 mineral grease (1.4oz added every 50hrs) or Mobil SHC32 synthetic

grease (1.4oz added every 200 hrs) are recommended.

5.3.2 Applying of Grease

Lubricate by applying the recommended amount of grease to the Grease Inlet (Cf. Figure 6)

while the adjacent grease point is sealed. Please make sure you check the grease level every

day and start the machine with the adequate amount of grease required. Just squeeze in

lubrication grease, neither replacement nor draining of lubrication grease necessary.

MOP VER. 1.0 7

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

Figure 6 Lubrication

6 MAINTENANCE AND INSPECTION

6.1 INSPECTION ON SLACKNESS OF SCREEN

Inspection on slackness of screen is made as frequently as possible. Slackness of screen will

result in increase of blinding to lower the screening efficiency, which is one of the main factors

in damaging screens.

6.2 INSPECTION OF V-BELT TENSION

Regular inspection shall be performed to check whether each clamp screw on the motor base is

loosened or tight, and to check whether the V-belt is loosened by its own expansion.

6.3 INSPECTION ON THE AMOUNT OF LUBRICATING GREASE

As described before, since improper amount of lubricating grease damages the inner

mechanism of the machine, inspection on the amount of grease should be made before starting

the machine at all times.

6.4 INSPECTION OF WIRING FOR THE MOTOR

Regular inspection shall be performed to check whether the three wires connected to the motor

are disconnected or improperly contracted. When one of these three wires is disconnected, the

motor may burn out because of single-phase running.

6.5 INSPECTION ON BOLTS FOR EACH PART

Regular inspection shall also be made on the bolts other than described before.

6.6 ANOMALOUS SOUND

In case anomalous sounds occur while the machine is running, we strongly recommend you to

immediately stop the machine for inspection.

6.7 STOPPING AND STARTING THE MACHINE

Bear in mind that the screening surface shall be cleared of any material before turning the

engine on or off.

8 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

7 REPLACEMENT OF SCREEN NET AND CUSHION

RUBBER

The fitting section of the screen net is shown in Figure 7. Refer to it for the replacement of the

screen net and the cushion rubber:

Figure 7 Fitting Section of Screen Net

1. Unscrew the Clamping Bolt (36) which will cause the Clamping Bar (37) to completely

loosen. Remove the Clamping Bar.

2. Remove the Screen Net (13) by pulling it out either forward or backward. (When screen

net is pushed out forward, remove discharge chute, and when pulled backward, remove

feed side cover.)

3. Remove the Cushion Rubber (38). Do so only and if only it is damaged.

4. Mount a new Cushion Rubber (38) and fix it tightly to the screen supporting plate.

5. Fit in the new Screen Net (13), which is inserted either from forward or backward and

held tightly by the Clamping Bar (37).

6. Tighten the Clamping Bolts (36) on both sides alternatively. Make sure that there is no

clearance between the Screen Net and the Cushion Rubber.

MOP VER. 1.0 9

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

8 OTHERS

(1) This vibrating screen is designed and manufactured according to your specifications.

If it is remodeled or foreign matter is fitted to the body or vibrator, or any original part is

removed, anomalous vibration may occur. When any remodeling is necessary, we will assist

you in any way to meet your requirements. DO NOT perform any transformation on the

machines by yourself.

(2) If the vibrator is dismantled, reassembly is rather difficult and normal operation may

not be possible. Therefore, please contact us, when vibrator dismantling is required, and we

will promptly provide you with the necessary support. DO NOT disassemble the equipment by

yourself.

(3) For ordering parts, please indicate Item No. and name according to the attached part

drawing and parts list.

(4) This machine is delivered with the screen cloth as per attached specifications. For

alteration of specifications or replacement of the screen cloth, see attached specifications for

the screen cloth. For ordering screen cloth from us, please indicate Screen Cloth No. shown in

the specifications.

(5) For further inquiries on this machine, please contact our office.

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

10 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

9 GENERAL ASSEMBLY

Figure 8 General Assembly

MOP VER. 1.0 11

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

9.1 MAIN FRAME

Figure 9 Main Frame

12 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

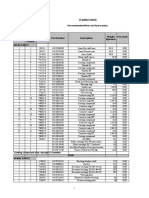

QUANTITY

ITEM NO. PART NO. PART NAME

D T F

1 1011 Main Frame 1 1 1

2 1021 Feed Chute 1 1 1

3 1031 Frame (Upper) 1 1 1

4 1041 Frame (Middle) 0 1 1

5 105A Frame (Middle/Lower) 0 0 1

6 1051 Frame (Lower) 1 1 1

7 1061 Spring Stand (Set) 1 1 1

8 106A Spring Stand (Set) 1 1 1

9 1071 Back Plate 1 2 2

10 1081 Spring Seat (Upper) 4 4 4

11 1091 Clamping Bar *16 *24 *32

12 1101 Screen Net Cushion 72 108 144

13 110A Clamping Screw 72 108 144

14 1111 Spring Seat (Lower) 4 4 4

15 1121 Spring 8 8 8

16 1141 Rubber Strip 10 15 20

17 1151 Screen Cloth - - -

18 1211 Protective Cover (L.H.) 1 1 1

19 1311 Protective Cover (R.H.) 1 1 1

Note:

* Clamping Bars will be sold as whole Set (1091+109A+109B+109C).

- Screen cloth made to order, screen cloth for one deck consists of 4~5 sheets, will be sold as whole Set.

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

MOP VER. 1.0 13

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

9.2 MAIN SHAFT UNIT

Figure 10 Main Shaft Unit

14 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

ITEM NO. PART NO. PART NAME QUANTITY

1 3011 Main Shaft 1

2 3021 Barrel 1

3 302A Plug 1

4 3031 Bearing Seat 1

5 3041 Bearing Seat 1

6 3051 Unbalance Weight 2

7 305A Key 2

8 3061 Roller Bearing 2

9 3071 Bearing Cover 1

10 307A Oil Seal 2

11 3081 Bearing Cover 1

12 3091 Driven Sheave 1

13 309A Key 1

14 3101 Collar 2

15 3111 Cushion 2

16 3121 Cushion 2

17 3161 Adjusting Balance Weight -

18 3181 Protective Cover (Barrel) 1

19 3191 Collar 2

20 3211 Collar 1

21 3221 Cover 2

Note:

- Adjusting Balance Weight is optional.

MOP VER. 1.0 15

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

9.3 MOTOR UNIT

Figure 11 Motor Unit

ITEM NO. PART NO. PART NAME QUANTITY

1 21 Support 1

2 22 Pivot Axis 1

3 23 Spring (upper) 1

4 24 Spring (lower) 1

5 25 Nut 2

6 26 Spring Rod 1

7 27 Motor 1

8 28 Drive Sheave 1

9 29 Motor Base 1

10 30 Adjust Rod 1

11 31 Hexagonal Bolt 4

12 32 Drive Shaft 1

This manual has been translated by Minyu Machinery Corp./Vera Karpischek.

16 MOP VER. 1.0

MINYU VIBRITING SCREEN PARTS AND SERVICE MANUAL

10 MODELS AND SPECIFICATIONS

Main Dimensions (mm) Motor Weight

Model No. Size (mm) Deck

A B C D E F G H I (kW) (KG)

MOP2160D 2 2100 6000 5689 1243 2542 3537 3759 1323 1015 22 6693

MOP2160T 2100 x 6000 3 2100 6000 5689 1600 2542 3908 3978 1703 1015 30 8963

MOP2160F 4 2100 6000 5700 1805 2542 4127 3978 1921 801 37 10650

Note: Design & Specification Subject to Change Without Notice。

Edition 2.2 (2015/09/04)

MOP VER. 1.0 17

You might also like

- Sandvik CA Series Folder 8sid A4 LowDocument8 pagesSandvik CA Series Folder 8sid A4 LowRelining MineralsNo ratings yet

- Chancadora SecDocument138 pagesChancadora SecHerbert100% (1)

- Trituradora Symons 4 14Document52 pagesTrituradora Symons 4 14kryzcj altamiranoNo ratings yet

- STND & Short Head WeightsDocument1 pageSTND & Short Head WeightsDirceu ValadaresNo ratings yet

- Im HP Crusher en 00pdf - Compress 181Document1 pageIm HP Crusher en 00pdf - Compress 181abcNo ratings yet

- Manual: STPEF0710 and STPEF0912 Jaw CrusherDocument14 pagesManual: STPEF0710 and STPEF0912 Jaw CrusherMANUEL ALBERTO CORTES ZARATENo ratings yet

- Trio TV85B VSI Parts Manual AbelDocument34 pagesTrio TV85B VSI Parts Manual AbelvictorpalaciossNo ratings yet

- Mantos A Pedir para El Cono k200Document1 pageMantos A Pedir para El Cono k200Vladimir Illich Pinzon BallenNo ratings yet

- Technical Bulletin: Bleeding Air From The Hydroset SystemDocument5 pagesTechnical Bulletin: Bleeding Air From The Hydroset SystemMf Lui100% (1)

- Recommended Wear and Spare PartsDocument5 pagesRecommended Wear and Spare PartsAndrey StrukovNo ratings yet

- 694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Document549 pages694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Martín Lescano ParedesNo ratings yet

- CH440-01 WPC R223.1325-01中文Document23 pagesCH440-01 WPC R223.1325-01中文fengyuhang199757No ratings yet

- 606561-414294 Alimentador + Mandibula k300Document121 pages606561-414294 Alimentador + Mandibula k300teddy fuentesNo ratings yet

- Soldadura de Seat LinerDocument3 pagesSoldadura de Seat LinerWilson Muñoz Araya100% (1)

- Leaflet One Piece Jaws 4482 10 21 en Cns LRDocument2 pagesLeaflet One Piece Jaws 4482 10 21 en Cns LRkhk84jfxchNo ratings yet

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionNo ratings yet

- I44v2 Parts Manual 04-05-2018Document201 pagesI44v2 Parts Manual 04-05-2018brianpung.122No ratings yet

- Technical Specifications: Original InstructionsDocument34 pagesTechnical Specifications: Original InstructionsEduardoNo ratings yet

- Secondary Impact CrushersDocument8 pagesSecondary Impact CrushersKevin David Guao BolanoNo ratings yet

- Bulletin 1047Document2 pagesBulletin 1047Cesar Casachagua DavilaNo ratings yet

- GP200SDocument155 pagesGP200SLina JiaNo ratings yet

- HPT Operation ManualDocument188 pagesHPT Operation ManualJan Reymark PanuncioNo ratings yet

- TV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsDocument8 pagesTV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsShawn ChenNo ratings yet

- Lokotrack LT300HP S N 77726Document761 pagesLokotrack LT300HP S N 77726Jaime RestrepoNo ratings yet

- J-1480 Mastercopy Spare PartsDocument163 pagesJ-1480 Mastercopy Spare PartsbrunoNo ratings yet

- Gravik Crusher and Parts CatalogueDocument21 pagesGravik Crusher and Parts Cataloguemartinez gerardoNo ratings yet

- Cone StandardDocument16 pagesCone StandardNguyễn LinhNo ratings yet

- Jaw Crusher Broch 2Document12 pagesJaw Crusher Broch 2Nanjappa K NuchumaniandaNo ratings yet

- J11 Operator ManualDocument74 pagesJ11 Operator ManualKasix Dunda MalembekaNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Operator's Manual: Doc. No. S 214.555 enDocument42 pagesOperator's Manual: Doc. No. S 214.555 enLucky OkoteNo ratings yet

- Screen in the middle position dimensional drawingDocument2 pagesScreen in the middle position dimensional drawingDorin IlasNo ratings yet

- Modular Plant Brochure 2013Document5 pagesModular Plant Brochure 2013Nancy ParvinaNo ratings yet

- Manual PartsDocument125 pagesManual PartsAlejandro AguirreNo ratings yet

- Peças CH430Document9 pagesPeças CH430Adriano MessiasNo ratings yet

- Rockon.: Messinger Has Replacement Bearings For Crushing Equipment Available For Fast DeliveryDocument3 pagesRockon.: Messinger Has Replacement Bearings For Crushing Equipment Available For Fast DeliveryMichele DeckerNo ratings yet

- CV115-129 01 Interlock S226.037 01Document22 pagesCV115-129 01 Interlock S226.037 01Lmf DanielNo ratings yet

- DE140 Spec Sheet 02 2018Document5 pagesDE140 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- HP5 Rock-Machinery Parts ListDocument3 pagesHP5 Rock-Machinery Parts Listxin daiNo ratings yet

- TSV Series Specification SheetDocument12 pagesTSV Series Specification SheetOmar German100% (1)

- Lokotrack LT300HP S N 77532Document817 pagesLokotrack LT300HP S N 77532edycarlos7No ratings yet

- Model ListDocument1 pageModel ListKing KhanNo ratings yet

- Shanbao PE60X100 Crusher Parts ManualDocument1 pageShanbao PE60X100 Crusher Parts ManualTomas ChienNo ratings yet

- Bearings For Cone Crushers: Serving Industries WorldwideDocument4 pagesBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- Heavy Duty Jaw & Cone Crusher Liner OptionsDocument3 pagesHeavy Duty Jaw & Cone Crusher Liner OptionsAndrey L'vovNo ratings yet

- 73.terex® WJ1175 Wheeled Jaw Plant - EDocument4 pages73.terex® WJ1175 Wheeled Jaw Plant - EHữu Dũng Nguyễn100% (2)

- Introducing The: Specification Xr400/206Document14 pagesIntroducing The: Specification Xr400/206Sergio RazoNo ratings yet

- Excel Components For Symons Templates PDFDocument1 pageExcel Components For Symons Templates PDFAnonymous 8t0V9SNo ratings yet

- Performance in every detail with Keestrack crushing and screening equipmentDocument43 pagesPerformance in every detail with Keestrack crushing and screening equipmentАнтон ЛазаровNo ratings yet

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDocument2 pagesWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- QJ341 Jaw Crusher Features & Benefits OverviewDocument48 pagesQJ341 Jaw Crusher Features & Benefits OverviewJesusFloresRodriguezNo ratings yet

- A1753037 48 Conveyor Parts Manual CON 203 1 J1349Document19 pagesA1753037 48 Conveyor Parts Manual CON 203 1 J1349waltergvNo ratings yet

- Rocksledger: Primary Jaw CrushersDocument2 pagesRocksledger: Primary Jaw CrushersMechanical department100% (2)

- CJ409-01 WPC R222.341.en-02Document14 pagesCJ409-01 WPC R222.341.en-02Marcos Guardia100% (1)

- Trio Grizzly Feeders - TF Series: Product CollectionDocument2 pagesTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNo ratings yet

- Catalogo Cone CrushersDocument16 pagesCatalogo Cone Crushersvictor fredyNo ratings yet

- Mvgh1360-E GrizlyDocument18 pagesMvgh1360-E GrizlyMartín Lescano ParedesNo ratings yet

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Document15 pagesSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselNo ratings yet

- Mvgh1360-E GrizlyDocument18 pagesMvgh1360-E GrizlyMartín Lescano ParedesNo ratings yet

- MV90-ROR Vertical Impact Crusher Spare Parts ManualDocument10 pagesMV90-ROR Vertical Impact Crusher Spare Parts ManualMartín Lescano ParedesNo ratings yet

- Msp300#0078-ConicaDocument69 pagesMsp300#0078-ConicaMartín Lescano ParedesNo ratings yet

- 684 Illustrated Parts Catalog - Revision 4.4 From Serial No. TRX01684CDGI26281Document585 pages684 Illustrated Parts Catalog - Revision 4.4 From Serial No. TRX01684CDGI26281Martín Lescano ParedesNo ratings yet

- C-1540 Prescreen & Hydrostatic Illustrated Parts Catalog - Revision 1.4 - From Serial No. TRX1540SLOMG11559Document345 pagesC-1540 Prescreen & Hydrostatic Illustrated Parts Catalog - Revision 1.4 - From Serial No. TRX1540SLOMG11559Martín Lescano ParedesNo ratings yet

- 693+ Illustrated Parts Catalog Revision 5.5 From Serial No. TRX01693LDGL22323Document82 pages693+ Illustrated Parts Catalog Revision 5.5 From Serial No. TRX01693LDGL22323Martín Lescano ParedesNo ratings yet

- 694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Document549 pages694+ Illustrated Parts Catalog Revision 3.1 FROM SERIAL TRX01694CDGL11965Martín Lescano ParedesNo ratings yet

- 683 Illustrated Parts CatalogDocument245 pages683 Illustrated Parts CatalogMartín Lescano Paredes100% (1)

- Sandvik Cths440: Spare Parts CatalogDocument32 pagesSandvik Cths440: Spare Parts CatalogAndrey L'vovNo ratings yet

- Hypertech WireDocument5 pagesHypertech WirejopaypagasNo ratings yet

- HYTORC J Washer Cut Sheet 021320 CompressedDocument2 pagesHYTORC J Washer Cut Sheet 021320 CompressedAdeoti OladapoNo ratings yet

- The Complete Metal Raceway SolutionsDocument14 pagesThe Complete Metal Raceway Solutionscetc qatarNo ratings yet

- Baat Reversing Gearbox Service ManualDocument16 pagesBaat Reversing Gearbox Service ManualAfranio Martins de Melo Franco JúniorNo ratings yet

- Milling Machine Service Manual with Parts ListDocument8 pagesMilling Machine Service Manual with Parts Listbill_gator20059105No ratings yet

- Shangair alta presion 83SH spare parts list (1)Document19 pagesShangair alta presion 83SH spare parts list (1)jvicher61No ratings yet

- Crankshaft TerminologyDocument16 pagesCrankshaft TerminologySathistrnpcNo ratings yet

- ZOLLERN-Broschuere ZAT Drewerksgetriebe ENGDocument20 pagesZOLLERN-Broschuere ZAT Drewerksgetriebe ENGMomin G.S.100% (1)

- Set Up 01Document32 pagesSet Up 01septian wahyu widodoNo ratings yet

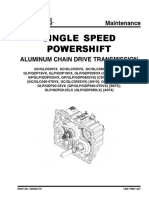

- 550030170-Single Speed Powershift Aluminum Chain Drive-UsDocument86 pages550030170-Single Speed Powershift Aluminum Chain Drive-UsFrancisco DiazNo ratings yet

- Engineering - Data - Setting ValuesDocument60 pagesEngineering - Data - Setting Valuescarlos morales100% (5)

- Compact Knife Gate Valve Handles Sludge and BiomassDocument9 pagesCompact Knife Gate Valve Handles Sludge and BiomassJuan Almanza MosquedaNo ratings yet

- Husqvarna Service Manual For Cutters Trimmers Pruners Hedge Trimmers BlowersDocument224 pagesHusqvarna Service Manual For Cutters Trimmers Pruners Hedge Trimmers BlowersJames Allen CaldwellNo ratings yet

- Check Chart Common - Specs - Metric - All BRIGGS & STRATTON - EnginesDocument1 pageCheck Chart Common - Specs - Metric - All BRIGGS & STRATTON - Enginesvulpinor0% (7)

- My Caliper Catalogue PDFDocument29 pagesMy Caliper Catalogue PDFMiljkovic NesaNo ratings yet

- Lub Oil System and Lub Oil PropertiesDocument31 pagesLub Oil System and Lub Oil PropertiestfdfurkananNo ratings yet

- Install Remote Controller for Air ConditionerDocument12 pagesInstall Remote Controller for Air ConditionerUzman HassanNo ratings yet

- Clark 24000 Parts ListDocument39 pagesClark 24000 Parts Listoleg79620% (1)

- Dynapower Gen II 4.8 & 6.0cuDocument19 pagesDynapower Gen II 4.8 & 6.0cugleisongg86No ratings yet

- Using EngMod2T To Investigate Transfer Port StaggerDocument6 pagesUsing EngMod2T To Investigate Transfer Port StaggerpachukiNo ratings yet

- The Best Choice for Network Solutions - Zimmlink IndonesiaDocument21 pagesThe Best Choice for Network Solutions - Zimmlink IndonesiapuspitagdNo ratings yet

- Here are the conversions:1. #14 AWG = 1.628 mm2. #8 AWG = 4.177 mm 3. #12 AWG = 2.053 mm4. #6 AWG = 8.255 mm5. #10 AWG = 3.226 mm6. 0.088 mm = #22 AWGDocument17 pagesHere are the conversions:1. #14 AWG = 1.628 mm2. #8 AWG = 4.177 mm 3. #12 AWG = 2.053 mm4. #6 AWG = 8.255 mm5. #10 AWG = 3.226 mm6. 0.088 mm = #22 AWGstfup zeliaNo ratings yet

- HCPI2019 AAaa DM280 2012-01Document13 pagesHCPI2019 AAaa DM280 2012-01Bary Chaves FonsecaNo ratings yet

- Club Bed Assembly Instructions: Charles P - Rogers. Bed Makers Since 1855Document1 pageClub Bed Assembly Instructions: Charles P - Rogers. Bed Makers Since 1855oliverNo ratings yet

- ZF W33100 NR2Document4 pagesZF W33100 NR2duyanh54ktttNo ratings yet

- Parts List TMFXII-C PDFDocument70 pagesParts List TMFXII-C PDFNilton RovedaNo ratings yet

- Unidad Rotacion Serie L30 PDFDocument22 pagesUnidad Rotacion Serie L30 PDFJairo BVNo ratings yet

- Gear Box Design ReportDocument12 pagesGear Box Design ReportKhalil Raza93% (29)

- User Manual Fz150i 2008 PDFDocument58 pagesUser Manual Fz150i 2008 PDFMie EeNo ratings yet

- Internship ReportDocument13 pagesInternship Reporttanvi tamhaneNo ratings yet