Professional Documents

Culture Documents

Im HP Crusher en 00pdf - Compress 181

Uploaded by

abcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Im HP Crusher en 00pdf - Compress 181

Uploaded by

abcCopyright:

Available Formats

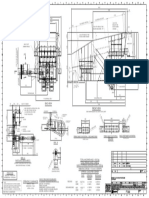

Eccentric assembly SECTION 8

8.1 Description eccentric and the lower thrust washer in steel is

fixed to the frame. These are there to reduce

This section describes the eccentric assembly, eccentric assembly wear through friction. The

comprising the eccentric, the eccentric play between and at the bottom of the teeth

bushing, the crown and the imbalance. The between the crown and the pinion is

outside of the eccentric is off-centre and maintained in this assembly by adding or

slightly at an angle to the vertical axis of removing adjusting wedges. The imbalance is

rotation, transmitting its movement to the dissymetrical, in such a way that the greatest

head. A bronze ring is mounted inside the weight is directly opposite the centrifugal

eccentric. A toothed crown bolted to the force generated by the swaying of the head.

bottom of the eccentric is driven by the This imbalance forms an oil and dust seal

countershaft pinion. The eccentric rotates between the rotating head and the fixed main

around the main shaft. The eccentric assembly frame, with a system of baffles with "U" and

rests on thrust bearings, the upper thrust "T" joints.

washer in bronze is fixed to the bottom of the

1 8

2 9

3

10

11

5

6

7

Ref. Description

1 Slings

2 Lifting rings

3 Lifting ring

4 Main shaft

5 Upper thrust washer

6 Lower thrust washer

7 Frame

8 Eccentric

9 Imbalance

10 Gear

11 Pinion

Figure 8-1 Mounting the eccentric assembly

TECHNICAL MANUAL NORDBERG CONE CRUSHERS HP100/200/300/400/500 8-1

You might also like

- Chancadora SecDocument138 pagesChancadora SecHerbert100% (1)

- STND & Short Head WeightsDocument1 pageSTND & Short Head WeightsDirceu ValadaresNo ratings yet

- Sandvik CA Series Folder 8sid A4 LowDocument8 pagesSandvik CA Series Folder 8sid A4 LowRelining MineralsNo ratings yet

- v2.4 MOP2160 - E ZARANDADocument21 pagesv2.4 MOP2160 - E ZARANDAMartín Lescano ParedesNo ratings yet

- Valu King Screen 1Document3 pagesValu King Screen 1RAUL PEREZ NEGREIROSNo ratings yet

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- Peças CH430Document9 pagesPeças CH430Adriano MessiasNo ratings yet

- Bushing QD SpecDocument11 pagesBushing QD Speceng_moh04No ratings yet

- Technical Bulletin: Bleeding Air From The Hydroset SystemDocument5 pagesTechnical Bulletin: Bleeding Air From The Hydroset SystemMf Lui100% (1)

- Eirez Vibratory Feeders and Conveyors BrochureDocument20 pagesEirez Vibratory Feeders and Conveyors BrochureJay Ryan SantosNo ratings yet

- Modular Plant Brochure 2013Document5 pagesModular Plant Brochure 2013Nancy ParvinaNo ratings yet

- Trituradora Symons 4 14Document52 pagesTrituradora Symons 4 14kryzcj altamiranoNo ratings yet

- Leaflet One Piece Jaws 4482 10 21 en Cns LRDocument2 pagesLeaflet One Piece Jaws 4482 10 21 en Cns LRkhk84jfxchNo ratings yet

- ZARANDASDocument3 pagesZARANDASRaphael PalaciosNo ratings yet

- Trio TC51 Series Cone Crusher.Document2 pagesTrio TC51 Series Cone Crusher.Enso E Rosales FNo ratings yet

- Quotation of Wheel Type Mobile Granite Crushing & Screening Plant About 150TPH 20110429Document4 pagesQuotation of Wheel Type Mobile Granite Crushing & Screening Plant About 150TPH 20110429Solomon MiNo ratings yet

- Manual: STPEF0710 and STPEF0912 Jaw CrusherDocument14 pagesManual: STPEF0710 and STPEF0912 Jaw CrusherMANUEL ALBERTO CORTES ZARATENo ratings yet

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionNo ratings yet

- Casting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HDocument1 pageCasting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HCarlos Ediver Arias RestrepoNo ratings yet

- PTSC 3618VM TelesmithDocument93 pagesPTSC 3618VM TelesmithDoneys Jesus Perez Vasquez100% (1)

- Maxwell Make Single Toggle Jaw Crusher 4230Document3 pagesMaxwell Make Single Toggle Jaw Crusher 4230Hritika PatelNo ratings yet

- Screen in The Middle Position (27DEG, 5480MM) : Drawing ST4.8Document2 pagesScreen in The Middle Position (27DEG, 5480MM) : Drawing ST4.8Dorin IlasNo ratings yet

- Vibrating Grizzly Drawing P1566Document1 pageVibrating Grizzly Drawing P15663568No ratings yet

- Trio Materials Washers.Document3 pagesTrio Materials Washers.SinaiNo ratings yet

- Raptor XL2000: High-Performance Cone CrusherDocument4 pagesRaptor XL2000: High-Performance Cone CrusherCristian Riquelme ContrerasNo ratings yet

- E-ABRASIC P 12 To P 220: For Coated Abrasives ProductsDocument2 pagesE-ABRASIC P 12 To P 220: For Coated Abrasives ProductsBas100% (1)

- Operator's Manual: Doc. No. S 214.555 enDocument42 pagesOperator's Manual: Doc. No. S 214.555 enLucky OkoteNo ratings yet

- DE140 Spec Sheet 02 2018Document5 pagesDE140 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- TV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsDocument8 pagesTV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsShawn ChenNo ratings yet

- TV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsDocument4 pagesTV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsJose grievis Giron pericheNo ratings yet

- Barmac Sales Manual April2011Document66 pagesBarmac Sales Manual April2011NelsonNo ratings yet

- I44v2 Parts Manual 04-05-2018Document201 pagesI44v2 Parts Manual 04-05-2018brianpung.122No ratings yet

- XL1100 Brochure PDFDocument8 pagesXL1100 Brochure PDFDanny Joel Espinoza CastañedaNo ratings yet

- Terex Jaques - Apron FeederDocument12 pagesTerex Jaques - Apron FeederJoseph Amoateng Appiah-kubi WadaadaNo ratings yet

- Boring Head DrawingsDocument7 pagesBoring Head DrawingsR WilkinsonNo ratings yet

- Improper Crusher Feeding: Jaw CrushersDocument1 pageImproper Crusher Feeding: Jaw CrushersbfygNo ratings yet

- Shineking Cone Crusher Manual BookDocument32 pagesShineking Cone Crusher Manual BookRiki D. PrastyoNo ratings yet

- Belt Conveyor Maxwell 500BW X 17.5MTRDocument1 pageBelt Conveyor Maxwell 500BW X 17.5MTRHritika PatelNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- HP HidráulicaDocument72 pagesHP HidráulicaRafaelaNo ratings yet

- Paneles Autolimpiantes MetsoDocument4 pagesPaneles Autolimpiantes Metsodaniel floresNo ratings yet

- RAPTOR Cone CrusherDocument4 pagesRAPTOR Cone CrusherLuis Miguel La TorreNo ratings yet

- PitmanDocument7 pagesPitmanjlfyNo ratings yet

- Mvi Vertical ShaftDocument4 pagesMvi Vertical ShaftMarcel BaqueNo ratings yet

- Manual PartsDocument125 pagesManual PartsAlejandro AguirreNo ratings yet

- CH440-01 WPC R223.1325-01中文Document23 pagesCH440-01 WPC R223.1325-01中文fengyuhang199757No ratings yet

- Roll Crusher 1 SingleDocument3 pagesRoll Crusher 1 SingleBobby A. Palem100% (1)

- EXCEL High Performance Parts For GP Cone-CrusherDocument4 pagesEXCEL High Performance Parts For GP Cone-CrusherGires TocheNo ratings yet

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDocument2 pagesWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- Secondary Station Op 7Document1 pageSecondary Station Op 7patelchiragisNo ratings yet

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Document15 pagesSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselNo ratings yet

- ECT Symons 7s For SaleDocument2 pagesECT Symons 7s For SaleOrlando MelipillanNo ratings yet

- H-E Parts Case Study Improved Cone Crusher PerformanceDocument1 pageH-E Parts Case Study Improved Cone Crusher PerformanceJorge VillalobosNo ratings yet

- A1753037 48 Conveyor Parts Manual CON 203 1 J1349Document19 pagesA1753037 48 Conveyor Parts Manual CON 203 1 J1349waltergvNo ratings yet

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoNo ratings yet

- Mineralizaciones de Cu de Tipo SkarnDocument10 pagesMineralizaciones de Cu de Tipo SkarnJorge Rios RNo ratings yet

- Paginas TELsmithHP3Document5 pagesPaginas TELsmithHP3Dennis AlexanderNo ratings yet

- 3409 PDFDocument8 pages3409 PDFACNo ratings yet

- AA04173 - Pines de DireccionDocument4 pagesAA04173 - Pines de DireccionJose A. Basanta H.No ratings yet

- Maintenance Manual Front AxleDocument65 pagesMaintenance Manual Front Axlehebert perezNo ratings yet

- Office H&S ActivationDocument1 pageOffice H&S ActivationabcNo ratings yet

- EN Chapter VEGAPULSDocument6 pagesEN Chapter VEGAPULSabcNo ratings yet

- Minerals: Fit-for-Purpose VSI Modelling Framework For Process SimulationDocument11 pagesMinerals: Fit-for-Purpose VSI Modelling Framework For Process SimulationabcNo ratings yet

- Heating Elements Thermostats & Controls Heating Systems & UnitsDocument11 pagesHeating Elements Thermostats & Controls Heating Systems & UnitsabcNo ratings yet

- Bi Fold Hangar Doors: Part 1 - General 1.01 ReferencesDocument6 pagesBi Fold Hangar Doors: Part 1 - General 1.01 ReferencesabcNo ratings yet

- Krono: External Automations For Swing Gates Up To 3 and 5 M Per Gate LeafDocument2 pagesKrono: External Automations For Swing Gates Up To 3 and 5 M Per Gate LeafabcNo ratings yet

- EXCEL High Performance Parts For HP-Cone-Crushers - MetsoDocument7 pagesEXCEL High Performance Parts For HP-Cone-Crushers - MetsoabcNo ratings yet

- Input Flange and Hollow Shaft Details: Inline Helical Gearbox Gearbox Output Speed (N)Document1 pageInput Flange and Hollow Shaft Details: Inline Helical Gearbox Gearbox Output Speed (N)abcNo ratings yet

- EXCEL Identification Spare Parts Poster For HP Cone CrushersDocument1 pageEXCEL Identification Spare Parts Poster For HP Cone CrushersabcNo ratings yet

- Integral: Rotary SwitchesDocument3 pagesIntegral: Rotary SwitchesabcNo ratings yet

- 9.1.2 Assembling The Countershaft Housing - HP300, HP400 and HP500Document1 page9.1.2 Assembling The Countershaft Housing - HP300, HP400 and HP500abcNo ratings yet

- 6.3.13 Checking The Feeder Cone Screw - HP100, HP200 and HP300 6.3.14 Fitting The Feeder Cone - HP100, HP200 and HP300Document1 page6.3.13 Checking The Feeder Cone Screw - HP100, HP200 and HP300 6.3.14 Fitting The Feeder Cone - HP100, HP200 and HP300abcNo ratings yet

- Dustfix: Conditioners For Industrial DustsDocument4 pagesDustfix: Conditioners For Industrial DustsabcNo ratings yet

- 50 NB Double Diaphragm, Pulse Jet Solenoid Valve: FeaturesDocument2 pages50 NB Double Diaphragm, Pulse Jet Solenoid Valve: FeaturesabcNo ratings yet

- Konecranes Brochure Waste To Energy en 2013Document12 pagesKonecranes Brochure Waste To Energy en 2013abcNo ratings yet

- Krebs Gmax CycloneDocument8 pagesKrebs Gmax CycloneLuis Miguel La TorreNo ratings yet

- Pro WashDocument2 pagesPro WashabcNo ratings yet

- 450 Series: Articulating Boom LiftsDocument6 pages450 Series: Articulating Boom Liftsl_aguilar_mNo ratings yet

- Jgr02in2111 Jgr03in2111 by Sea Ci-PlDocument18 pagesJgr02in2111 Jgr03in2111 by Sea Ci-PlheruNo ratings yet

- DL250 (K1023773e)Document800 pagesDL250 (K1023773e)Edmilson Ribeiro100% (1)

- 389 2017Document188 pages389 2017Paulo SouzaNo ratings yet

- VW Jetta 2011 2013 Suspension Steering EngDocument390 pagesVW Jetta 2011 2013 Suspension Steering Engcloantaf0% (1)

- CASE 1190 Shop ManualDocument23 pagesCASE 1190 Shop ManualRytis SiaulysNo ratings yet

- Land Rover V8: and ToolDocument56 pagesLand Rover V8: and ToolAntonio OliveiraNo ratings yet

- Gd663a 2 - Cen00472 01Document8 pagesGd663a 2 - Cen00472 01kazemiNo ratings yet

- Final Rear Forward Axle Housing SnorkelDocument38 pagesFinal Rear Forward Axle Housing SnorkeltarunNo ratings yet

- Fortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2012 Hyster Company 10/2012Document950 pagesFortis® H80, H90, H100, H110, H120FT (P005) : 1698691 ©2012 Hyster Company 10/2012Vilson SilvaNo ratings yet

- Operating Instructions Parts List: FH1025-SMS-001 - ENDocument9 pagesOperating Instructions Parts List: FH1025-SMS-001 - ENХелфор УкраинаNo ratings yet

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocument13 pagesExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerNo ratings yet

- Mobile Crane - ZLJ5390JQZR3Special Purpose Chassis For Crane Spare Parts CatalogDocument270 pagesMobile Crane - ZLJ5390JQZR3Special Purpose Chassis For Crane Spare Parts Catalogrusdis.2017No ratings yet

- fünyíróAIPL1999 167140Document18 pagesfünyíróAIPL1999 167140Vtr RiderNo ratings yet

- Design and Analysis of The Drivetrain System For Formula SAE Race CarDocument24 pagesDesign and Analysis of The Drivetrain System For Formula SAE Race Carpreejaiswal0% (1)

- Ipl Tf545deDocument53 pagesIpl Tf545deFabio GonzalezNo ratings yet

- Catalogo de Partes Caliber 2007 PDFDocument456 pagesCatalogo de Partes Caliber 2007 PDFpatricio_marcelo1976No ratings yet

- Understanding TribologyDocument7 pagesUnderstanding Tribologyemad sabriNo ratings yet

- Cat 793f (Eng)Document2 pagesCat 793f (Eng)Arturo Arellano Alcaide100% (1)

- RUNFLATS and Wheels PresentationDocument22 pagesRUNFLATS and Wheels PresentationHassnain ShafqatNo ratings yet

- WM90-Parts Manual CompressedDocument66 pagesWM90-Parts Manual CompressedDuala MaquinariaNo ratings yet

- Volvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetDocument4 pagesVolvo FMX 460 8X4 20 3 Cu M Tipper BS VI Data SheetPandey BoardNo ratings yet

- Spare Parts Catalog: MT-B 3070 Material Number: 4475.057.022 Current Date: 07.05.2018Document27 pagesSpare Parts Catalog: MT-B 3070 Material Number: 4475.057.022 Current Date: 07.05.2018Евгений Викторович75% (4)

- 477 - 2.3 Tonne - T0512Document88 pages477 - 2.3 Tonne - T0512Patrice GuilhaumonNo ratings yet

- Div2779 Hyundai 6x4 Rear TipperDocument7 pagesDiv2779 Hyundai 6x4 Rear Tipperedwin ortega medinaNo ratings yet

- Data-Tech 1993 Isuzu Amigo-Front SuspensionDocument14 pagesData-Tech 1993 Isuzu Amigo-Front SuspensionRuben AyalaNo ratings yet

- Re13 Eng WebDocument68 pagesRe13 Eng WebBenjamin PeterNo ratings yet

- Yale Warranty 2020Document6 pagesYale Warranty 2020Lực NguyễnNo ratings yet

- Buyer Information On Mercedes Benz W111 Cabriolets and CoupesDocument12 pagesBuyer Information On Mercedes Benz W111 Cabriolets and CoupesCsaba LőrinczNo ratings yet

- Fulltext02 PDFDocument64 pagesFulltext02 PDFAbhishek AroraNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)