Professional Documents

Culture Documents

Crosby JB Jpv-A

Uploaded by

Daniel ReyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby JB Jpv-A

Uploaded by

Daniel ReyCopyright:

Available Formats

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Engineered to provide high quality, dependable

overpressure protection for air, gas, vapor and

steam applications.

Features and Benefits

• Broadest product offering in the

industry.

• Ten sizes available.

• Reduced installation and labor

costs (1 valve versus multiple

smaller valves).

• Fewer discharge lines.

• Fewer inlet connections.

• Reduced maintenance costs.

• Fatigue resistant bellows material.

Applications Technical Data

• Turbine exhaust lines Sizes: 10" V 14" to 20" BB2 24"

• Main steam lines to process plants Orifices: V to BB2

• Low pressure gas service in refineries Inlet Rating: 300 lbs. ANSI

• Polyvinyl chloride reactors Temperature Range: -20°F to +450°F

• Deaerators

• Oil refinery coke drums

• Beet sugar plant evaporators

• Moisture separator reheaters in

nuclear power plants

Crosby is either a trademark or registered trademark of Tyco International Services AG or its affiliates in

the United States and/or other countries. All other brand names, product names, or trademarks belong

to their respective holders.

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290-US-0906

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Introduction

Crosby large orifice pressure relief smaller API Standard 526 pressure relief Crosby manufactures the broadest

valves were originally developed in valves. The largest, with a relief capacity scope of large orifice relief valves

response to the growing size of nearly seven times that of a T-orifice ranging from 10 V 14 to 20 BB2 24 with

commercial power plants and resultant valve, can relieve approximately actual orifice areas ranging from 47.85

increased generating capacities. 3,000,000 pounds per hour of saturated square inches to 213.82 square inches.

steam at 300 psig set pressure.

Traditionally, overpressure protection for Style JB-TD relief valves are

large piping and vessels in power and These “Above T” orifice relief valves manufactured in accordance with ASME

process plants has been satisfied by represent a low cost alternative. The Boiler and Pressure Vessel Code,

multiple pressure relief valves. Style large orifice relief valve product line is an Section VIII and their air and steam

JB-TD large orifice relief valves were extension of the traditional API Standard capacities are certified by the National

designed to eliminate the high costs of 526 JOS-E/JBS-E product line and Board of Boiler and Pressure Vessel

installation labor, inlet and discharge provides the same dependability and Inspectors (UV and NB).

piping, maintenance and spare parts reliable performance.

associated with the use of multiple,

Operation

Construction of the Style JB relief valve The Bellows Protector (24), Bellows and area of the secondary orifice, called the

is somewhat different than the API Disc Holder are one assembly. A large, huddling chamber, which overhangs the

Standard 526 Style JBS-E design. The non-adjustable Disc Ring is pinned to disc. Full lift is developed by the dynamic

standard cast Body has a 300# ANSI the Disc Holder. The effective area of the forces of the stream flowing through the

flanged inlet as standard construction Bellows is designed to be the same as conical nozzle. The velocity, the mass of

and a 150# ANSI flanged outlet. The the area of the Disc Insert exposed to the process fluid and the pressure-area

inlet and outlet flanges are integrally inlet pressure before the valve opens. relationship collectively keep the valve

cast with the valve Body. The Bellows isolates the Bonnet from fully open. The valve will be relieving its

discharge back pressure and because full rated capacity when the pressure at

The large diameter Nozzle (2) is

of the equal areas mentioned, the valve the valve inlet has risen 10 percent

threaded into the Body and seal welded.

set pressure is independent of back above the set pressure of the valve.

To help ensure tight shutoff, the Disc

pressure.

Insert (6) is free to float within the Disc As long as the inlet pressure continues to

Holder (20) providing uniform seat In operation, system pressure increases remain at or above the set pressure, the

contact with the Nozzle seating surface. until the static pressure acting against valve will remain open. When the inlet

the disc generates an upward force pressure diminishes, the flow forces

Low friction guiding is provided by a

equal to the downward force of the diminish and the valve begins to close.

Bearium B10 Disc Holder Sleeve (21)

valve spring. When these two forces are At a pressure less than the set pressure,

and a Bearium B10 Spindle Guide

in balance, the valve starts to simmer, the spring force is sufficient to reseat the

Sleeve (28).

which is the initial indication of valve disc against the reduced flow force and

The Nozzle, Disc Insert, Disc Holder, opening. On vapor or gas service, the the valve reseats.

Nozzle Ring (3) and Disc Ring (25) are valve will open with a pop action. The

manufactured from 300 Series stainless first stage of lift is caused by the forces

steel. The Bellows (23) is manufactured that are generated as the nozzle

from fatigue-resistant Inconel® alloy 625. pressure reacts against the increased

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

2

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Standard Materials of Construction

18 Part No. Part Name Material

16 1 Body ASME SA216 Gr. WCB

19 Carbon Steel

17

2 Nozzle ASME SA182 F316

12 Stainless Steel

11 3 Nozzle Ring 316 Stainless Steel

10 4 Set Screw 416 Stainless Steel

5 Set Screw Gasket2 Steel

6 Disc Insert2 ASME SA182 F316

Stainless Steel

7 Spindle1 416 Stainless Steel

13

8 Spring1, 4 Carbon Steel

9 Spring Washer (bottom)1 ASME SA216 Gr. WCB

Carbon Steel

8 10 Spring Washer (top)1 ASME SA216 Gr. WCB

Carbon Steel

11 Thrust Bearing3 Commercial

27 12 Thrust Bearing Adapter3 416 Stainless Steel

14 9 13 Bonnet Assembly

15 Top Flange ASME SA216 Gr. WCB

Carbon Steel

28 Pipe ASME SA285 Grade C

24 Carbon Steel

23 Thredolet ASME SA105 Carbon Steel

Bottom Flange ASME SA181 Grade 1

Carbon Steel

21

14 Bonnet Stud ASME SA193 Grade B7

7

20 15 Bonnet Stud Nut ASME SA194 Grade 2H

22 16 Adjusting Bolt 416 Stainless Steel

17 Adjusting Bolt Nut 416 Stainless Steel

26 6 18 Cap (Type A) Carbon Steel

4 19 Cap Gasket2 Steel

25

5 20 Disc Holder1 316/316L Stainless Steel

2 3 21 Disc Holder Sleeve1 Bearium B10

1 22 Disc Bushing1 Stainless Steel

23 Bellows1 Inconel® 625

Style JB 24 Bellows Protector1 Carbon Steel

25 Disc Ring 300 Series Stainless Steel

26 Disc Ring Pin2 Stainless Steel

27 Spindle Guide1 Carbon Steel

28 Spindle Guide Sleeve1 Bearium B10

Notes

1. Furnished as a sub-assembly only.

2. Recommended spare part.

3. Thrust bearing and adapter not used

on AA-BB2.

4. Spring may be single or dual design

(nested) depending on set pressure

and valve design.

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

3

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Caps and Lifting Gear

Crosby Style JB large orifice pressure Regular: Type C regular lifting gear is not

relief valves are usually furnished with a sealed unit. Valves with Type C lifting

Type A threaded cap with gasket. The cap gear may be furnished with a gagging

is sealed in place with a lead seal to device on special order at extra charge.

prevent tampering with the adjusting bolt.

Packed: Type D packed lifting gear is

If a test rod is provided, the Type A

designed for service where tightness

designation changes to Type B.

on the discharge side is necessary. The

Lifting Gear lifting gear linkage is sealed with O-rings

or standard packing. The main working

Where desired, valves may be furnished

parts of the valve are as free to operate

with regular or packed lifting gear. Such

as with a standard valve. The packed

lifting gear is mandatory for air and

lifting gear designation changes to

steam service when the requirements of

Type E when a test rod is provided.

the ASME Boiler and Pressure Vessel

Code, Section VIII (UV stamp) must

be met. Type A (standard)

Threaded Cap

Part No. Part Name Material

29 Cap Set Screw Steel

37

30 Lever Steel

35

31 Lever Pin Steel 34

36

32 Lever Cotter Pin2 Steel 33

33 Forked Lever Ductile Iron

34 Forked Lever Pin Steel

29

35 Forked Lever Cotter Pin2 Steel

32

36 Spindle Nut Steel 31

37 Spindle Nut Cotter Pin2 Steel

38 Cap Stud ASME SA193 Gr. B7 30

39 Cap Stud Nut ASME SA194 CL 2H

40 Dog Steel

41 Dog Shaft Stainless Steel Type C

42 Dog Shaft Bearing1 Stainless Steel Regular Lifting Gear

43 Dog Shaft Bearing Gasket1, 2 Steel

44 Dog Shaft Bearing O-ring1, 2 Viton® - A

45 Cap Top Steel

46 Cap Top Gasket2 Steel

47 Nut1 Steel 45

48 Lock Washer1 Steel

49 Test Gag1 Steel

46

50 Test Rod Plug1 Steel

51 Test Rod Plug Gasket1,2 Steel 40

Notes 41

38

1. Part not shown. 39

2. Recommended spare part.

Type D

Packed Lifting Gear

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

4

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Dimensions - Style JB

ASME Connections Dimensions (inches)

Actual Maximum H H H

Orifice Inlet Outlet Set Pressure Backpressure Type Type C Type D & E Approx.

Area Flange1 Flange psig Limit3 @ A & B Lifting Lifting Weight

Size (sq.in) (ANSI) (ANSI) -20°F to 450°F2 100°F (psig) E P G Cap Lever Lever X (lbs)

10 V 14 47.85 10” 300# 14” 150# 300 120 12 16 29 73 76 79 17/8 2250

12 W 16 68.90 12” 300# 16” 150# 300 175 14 16 30 77 79 83 2 2500

12 W1 16 72.00 12” 300# 16” 150# 300 175 14 16 30 77 79 83 2 2500

14 Y 18 93.78 14” 300# 18” 150# 300 175 16 20 37 85 88 93 2 1/8 4500

16 Z 18 103.15 16” 300# 18” 150# 300 175 16 20 37 85 88 93 2 1/4 5000

16 Z1 18 110.00 16” 300# 18” 150# 300 175 16 20 37 85 88 93 2 1/4 5000

16 Z2 20 123.47 16” 300# 20” 150# 300 175 17 21 39 90 93 98 2 1/4 5700

18 AA 24 155.04 18” 300# 24” 150# 300 175 20 25 48 103 106 108 2 3/8 6500

20 BB 24 191.38 20” 300# 24” 150# 300 175 20 25 48 103 106 108 2 1/2 7500

20 BB2 24 213.82 20” 300# 24” 150# 225 175 20 25 48 103 106 108 2 1/2 7500

Notes

1. Optional Class 150# inlet flange available on

application.

2. Optional materials of construction for

temperatures above 450°F available on

application.

3. Higher backpressure limits may be

achievable on application. Consult your

sales representative for more information.

E

Valve Body

Drain: 1” NPT

P

X

G

Style Designations

Size

Inlet x Orifice Style Pressure/Temperature Caps and Lifting Levers (Type) Available Options

x Outlet Inlet Flange Range Ratings

10 V 14 JB-TD 26-3 Type A - Threaded Cap Set pressures below 25 psig

12 W 16 ANSI Class 300# Inlet x 150# Outlet Type B - Threaded Cap with Test Rod Temperatures above 450°F

12 W1 16 (Maximum Set Pressure 300 psig) Type C - Regular Lifting Lever Conventional (non-bellows)

14 Y 18 -20°F to 450°F Type D - Packed Lifting Lever Inlet flange ratings above Class 300#

16 Z 18 BB2 Maximum Set Pressure: 225 psig Type E - Packed Lifting Lever with Fully rated Class 300# outlet connection

16 Z1 18 Test Rod Open bonnet construction

16 Z2 20 Full nozzle construction

18 AA 24 Class 150# inlet flange

20 BB 24 Special materials

20 BB2 24 Non-destructive testing (LP, MP, etc.)

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

5

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Air Capacities, USCS Units - Style JB

Capacity Formula Capacity in standard cubic feet per minute

W = 18.331 * A * P * K of Air at 60°F and 10 percent overpressure.

Valve discharging to atmospheric pressure.

where

Capacities certified by the National Board

W = Rated capacity in SCFM of Boiler and Pressure Vessel Inspectors

A = Nozzle throat (orifice) area, sq. in. and in accordance with the ASME Boiler

and Pressure Vessel Code, Section VIII.

P = Flowing pressure in absolute pressure, psia: = (Set Pressure x 1.10) + 14.7 or

(Set Pressure + 3) + 14.7, whichever is higher

K = Average coefficient of discharge

= 0.856 for orifices V thru BB

= 0.840 for BB2

Set Orifice Designation and Area (sq.in.)

Pressure V W W1 Y Z Z1 Z2 AA BB BB2

(psig) 47.85 68.90 72.00 93.78 103.15 110.00 123.47 155.04 191.38 213.82

25 32,060 46,164 48,241 62,834 69,112 73,702 82,727 103,879 128,228 140,585

30 35,814 51,570 53,890 70,192 77,205 82,332 92,414 116,043 143,243 157,047

40 44,073 63,462 66,317 86,379 95,009 101,318 113,725 142,804 176,276 193,264

50 52,332 75,354 78,745 102,565 112,813 120,305 135,037 169,565 209,309 229,480

60 60,592 87,247 91,172 118,752 130,617 139,291 156,348 196,325 242,342 265,697

70 68,851 99,139 103,600 134,939 148,422 158,278 177,660 223,086 275,375 301,913

80 77,110 111,032 116,028 151,126 166,226 177,265 198,971 249,846 308,408 338,130

90 85,369 122,924 128,455 167,313 184,030 196,251 220,283 276,607 341,441 374,346

100 93,628 134,817 140,883 183,500 201,834 215,238 241,594 303,368 374,475 410,563

110 101,887 146,709 153,310 199,687 219,638 234,224 262,906 330,128 407,508 446,779

120 110,146 158,602 165,738 215,873 237,442 253,211 284,217 356,889 440,541 482,996

130 118,405 170,494 178,165 232,060 255,247 272,197 305,529 383,650 473,574 519,212

140 126,665 182,387 190,593 248,247 273,051 291,184 326,840 410,410 506,607 555,429

150 134,924 194,279 203,020 264,434 290,855 310,170 348,152 437,171 539,640 591,645

160 143,183 206,172 215,448 280,621 308,659 329,157 369,463 463,932 572,673 627,862

170 151,442 218,064 227,875 296,808 326,463 348,143 390,775 490,692 605,706 664,078

180 159,701 229,956 240,303 312,995 344,267 367,130 412,086 517,453 638,739 700,295

190 167,960 241,849 252,730 329,182 362,072 386,116 433,398 544,213 671,772 736,511

200 176,219 253,741 265,158 345,368 379,876 405,103 454,709 570,974 704,805 772,728

210 184,479 265,634 277,586 361,555 397,680 424,089 476,021 597,735 737,839 808,944

220 192,738 277,526 290,013 377,742 415,484 443,076 497,332 624,495 770,872 845,161

230 200,997 289,419 302,441 393,929 433,288 462,062 518,644 651,256 803,905 –

240 209,256 301,311 314,868 410,116 451,093 481,049 539,955 678,017 836,938 –

250 217,515 313,204 327,296 426,303 468,897 500,035 561,267 704,777 869,971 –

260 225,774 325,096 339,723 442,490 486,701 519,022 582,578 731,538 903,004 –

270 234,033 336,989 352,151 458,676 504,505 538,008 603,890 758,299 936,037 –

280 242,292 348,881 364,578 474,863 522,309 556,995 625,201 785,059 969,070 –

290 250,552 360,774 377,006 491,050 540,113 575,981 646,513 811,820 1,002,103 –

300 258,811 372,666 389,433 507,237 557,918 594,968 667,824 838,580 1,035,136 –

Notes

1. For set pressures below 25 psig,

psig, consult

consultyour C=

= Constant

Constant for

for gas

gas oror vapor

vaporwhich

whichisisthe

the M - Molecular weight

weight

sales representative.

your sales representative. function

function of

of the

the ratio

ratio of

of specific

specificheats,

heats, T = Absolute temperature

temperature at

at inlet,

inlet,

2. To calculate rated

rated capacities

capacitiesfor

forgas/vapor

gas/vaporinin k=cp/cv

k=cp/cv deg

deg FF ++ 460°F

460°F

lbs/hr. use

use the

the following

following formula:

formula: K=

= Coefficient

Coefficient of

of discharge

discharge 3. To convert capacities

capacities in

in lbs./hr.

lbs./hr.totoSCFM,

SCFM,

W = C*K*A*P * √ (M /T) A=

= Nozzle

Nozzle throat

throat (orifice)

(orifice) area,

area, sq.

sq. in.

in. multiply the capacity

capacityby

by6.234,

6.234,then

thendivide

divideby

where P = Flowing pressure in absolute

absolute the molecular

by the weight

molecular of the

weight gas/vapor.

of the gas/vapor.

W = rated

rated capacity,

capacity,lbs./hr.

lbs./hr. pressure, psia

psia

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

6

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Saturated Steam Capacities, USCS Units - Style JB

Capacity Formula Capacity in pounds per hour of Steam at

W = 51.5 * A * P * K 10 percent overpressure. Valve discharging

to atmospheric pressure. Capacities certified

where

by the National Board of Boiler and

W = Rated capacity, lbs./hr. Pressure Vessel Inspectors and in

A = nozzle throat (orifice) area, sq. in. accordance with the ASME Boiler and

Pressure Vessel Code, Section VIII.

P = Flowing pressure in absolute pressure, psia: = (Set Pressure x 1.10) + 14.7 or

(Set Pressure+ 3) + 14.7, whichever is higher

K = Average coeffecient of dscharge

= .856 for V to BB orifice

= .840 for BB2 orifice

Set Orifice Designation and Area (sq.in.)

Pressure V W W1 Y Z Z1 Z2 AA BB BB2

(psig) 47.85 68.90 72.00 93.78 103.15 110.00 123.47 155.04 191.38 213.82

25 90,072 129,696 135,531 176,530 194,168 207,062 232,418 291,845 360,251 394,968

30 100,619 144,883 151,402 197,201 216,904 231,308 259,633 326,019 402,435 441,217

40 123,822 178,294 186,316 242,677 266,924 284,650 319,507 401,201 495,239 542,966

50 147,026 211,705 221,231 288,153 316,944 337,992 379,380 476,384 588,044 644,714

60 170,230 245,117 256,145 333,629 366,964 391,333 439,254 551,567 680,849 746,463

70 193,433 278,528 291,060 379,105 416,984 444,675 499,127 626,749 773,654 848,211

80 216,637 311,939 325,974 424,582 467,004 498,016 559,001 701,932 866,458 949,959

90 239,840 345,350 360,889 470,058 517,023 551,358 618,874 777,114 959,263 1,051,708

100 263,044 378,762 395,803 515,534 567,043 604,700 678,748 852,297 1,052,068 1,153,456

110 286,248 412,173 430,718 561,010 617,063 658,041 738,622 927,480 1,144,873 1,255,205

120 309,451 445,584 465,632 606,486 667,083 711,383 798,495 1,002,662 1,237,677 1,356,953

130 332,655 478,996 500,547 651,962 717,103 764,725 858,369 1,077,845 1,330,482 1,458,701

140 355,859 512,407 535,461 697,439 767,123 818,066 918,242 1,153,027 1,423,287 1,560,450

150 379,062 545,818 570,376 742,915 817,143 871,408 978,116 1,228,210 1,516,092 1,662,198

160 402,266 579,229 605,290 788,391 867,163 924,750 1,037,989 1,303,393 1,608,896 1,763,947

170 425,469 612,641 640,205 833,867 917,183 978,091 1,097,863 1,378,575 1,701,701 1,865,695

180 448,673 646,052 675,120 879,343 967,203 1,031,433 1,157,737 1,453,758 1,794,506 1,967,443

190 471,877 679,463 710,034 924,819 1,017,223 1,084,774 1,217,610 1,528,941 1,887,311 2,069,192

200 495,080 712,874 744,949 970,296 1,067,243 1,138,116 1,277,484 1,604,123 1,980,116 2,170,940

210 518,284 746,286 779,863 1,015,772 1,117,262 1,191,458 1,337,357 1,679,306 2,072,920 2,272,688

220 541,487 779,697 814,778 1,061,248 1,167,282 1,244,799 1,397,231 1,754,488 2,165,725 2,374,437

230 564,691 813,108 849,692 1,106,724 1,217,302 1,298,141 1,457,104 1,829,671 2,258,530 –

240 587,895 846,519 884,607 1,152,200 1,267,322 1,351,483 1,516,978 1,904,854 2,351,335 –

250 611,098 879,931 919,521 1,197,677 1,317,342 1,404,824 1,576,852 1,980,036 2,444,139 –

260 634,302 913,342 954,436 1,243,153 1,367,362 1,458,166 1,636,725 2,055,219 2,536,944 –

270 657,506 946,753 989,350 1,288,629 1,417,382 1,511,508 1,696,599 2,130,401 2,629,749 –

280 680,709 980,164 1,024,265 1,334,105 1,467,402 1,564,849 1,756,472 2,205,584 2,722,554 –

290 703,913 1,013,576 1,059,179 1,379,581 1,517,422 1,618,191 1,816,346 2,280,767 2,815,358 –

300 727,116 1,046,987 1,094,094 1,425,057 1,567,442 1,671,533 1,876,219 2,355,949 2,908,163 –

Notes

1. For set pressures below 25 psig, consult

your sales representative.

2. For superheated steam, multiply the

saturated steam capacity by Correction

Factor Ksh, found on page 8.

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290

7

Crosby JB and JPV-A

Large Orifice Pressure Relief Valve

Superheat Correction Factor -Ksh

Flowing* Total Temperature Superheated Steam

Pressure, psia 400°F 450°F 500°F 550°F 600°F 650°F 700°F 750°F 800°F 850°F 900°F 950°F 1000°F 1050°F 1100°F

50 .987 .957 .930 .905 .882 .861 .841 .823 .805 .789 .774 .759 .745 .732 .719

100 .998 .963 .935 .909 .885 .864 .843 .825 .807 .790 .775 .760 .746 .733 .720

150 .984 .970 .940 .913 .888 .866 .846 .826 .808 .792 .776 .761 .747 .733 .721

200 .979 .977 .945 .917 .892 .869 .848 .828 .810 .793 .777 .762 .748 .734 .721

250 .972 .951 .921 .895 .871 .850 .830 .812 .794 .778 .763 .749 .735 .722

300 .968 .957 .926 .898 .874 .852 .832 .813 .796 .780 .764 .750 .736 .723

350 .968 .963 .930 .902 .877 .854 .834 .815 .797 .781 .765 .750 .736 .723

*Flowing pressure is the valve set pressure plus the overpressure plus the atmospheric pressure 14.7 psia [1.014 bara].

Style JPV-A Pilot Operated Valves

The Crosby Style JPV-A Valve is a pilot They are available in the sizes shown

operated valve primarily used for low below and set pressures from 50 psig

pressure power or process system (minimum) to 300 psig (maximum).

overpressure protection where space

Their capacities are different from those

and weight are primary considerations.

of the Style JB valves and may be

Using a basic 300 lb. x 150 lb. ANSI

obtained by contacting your sales

flanged body this design features a

representative.

pressure loaded main valve with metal

seats as the standard. The main valve is A soft seat design is offered as an option

actuated by a small spring-loaded pilot and provides maximum seat tightness

valve and shuttle valve assembly. The up to the opening point of the valve. The

combination of pilot and shuttle valve soft seat design utilizes a 25 percent

assembly provides sharp, rapid glass filled Teflon® O-ring that is rated to

operation, and use of a pressure loaded a maximum temperature of 500°F. The

main valve disc in place of a spring O-ring seat is designed such that in the

loaded disc permits maximum seat load unlikely event that the O-ring should fail,

up to the opening point of the valve. the metal seating surfaces would still

provide a seal.

The JPV-A valve meets the

requirements of Section VIII of the

ASME Boiler and Pressure Vessel Code. Style JPV-A

Orifice

Designation V W Y Z Z2 AA BB

Inlet x Outlet (in.) 10 x 14 12 x 16 14 x 18 16 x 18 16 x 20 18 x 24 20 x 24

Actual Area (sq. in.) 44.18 63.62 86.59 95.21 144.04 143.14 176.71

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services.

Individuals using this data sheet must exercise their independent judgment in evaluating product selection and determining product appropriateness for their particular purpose and system requirements. TFC MAKES NO

REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR DAMAGES (OF ANY KIND OR NATURE, INCLUDING

INCIDENTAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and Patents Pending in the U.S. and foreign countries. Tyco

reserves the right to change product designs and specifications without notice. All registered trademarks are the property of their respective owners. Printed in the USA.

Copyright © 2009 Tyco Flow Control. All rights reserved. CROMC-0290 www.tycoflowcontrol.com

8

You might also like

- Lamborghini - Auxiliary Oil PumpDocument10 pagesLamborghini - Auxiliary Oil PumpDaniel Rey100% (1)

- Paint Insp ICorr Level 2 Notes PDFDocument133 pagesPaint Insp ICorr Level 2 Notes PDFravi00098100% (1)

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- Nireco Servojet Sj2: GeneralDocument8 pagesNireco Servojet Sj2: GeneralKen JunNo ratings yet

- Proyecto de Modernización Refineria Talara: Document Code / Codigo: Purchase Order/Orden de Compra N°Document10 pagesProyecto de Modernización Refineria Talara: Document Code / Codigo: Purchase Order/Orden de Compra N°Michael H. PrevooNo ratings yet

- Natural Gas ProcessingDocument41 pagesNatural Gas Processingjomafeba100% (2)

- JET 1 Treating EquipmentDocument60 pagesJET 1 Treating Equipmentmasterab100% (3)

- 75 Civil Engineering Interview QuestionsDocument2 pages75 Civil Engineering Interview QuestionsZakir AliNo ratings yet

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- Banco de Baterias SBM 184-2Document48 pagesBanco de Baterias SBM 184-2jorge28csNo ratings yet

- Compressor Over-Lubrication PresentationDocument38 pagesCompressor Over-Lubrication Presentation1mmahoneyNo ratings yet

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- Lampiran 1 Standar InspectionDocument7 pagesLampiran 1 Standar InspectionFitra SNo ratings yet

- Specification of Breather Valve With Flame ArrestorDocument2 pagesSpecification of Breather Valve With Flame ArrestorsadatNo ratings yet

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- SECTION 5.35: Exhaust SystemDocument30 pagesSECTION 5.35: Exhaust SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Donaldson Differential Pressure Switches & Gauges GuideDocument2 pagesDonaldson Differential Pressure Switches & Gauges GuideManikandan SenthilNo ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- F3514 GsiDocument2 pagesF3514 Gsikman548No ratings yet

- Bulletin 7 - Heat Recovery From DG Set Jacket Cooling WaterDocument2 pagesBulletin 7 - Heat Recovery From DG Set Jacket Cooling WaterSivaram KrishnamoorthyNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Steam Turbine Basic TheoryDocument34 pagesSteam Turbine Basic TheoryEliyanto E BudiartoNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- 4396-13.0-01-04 - 0 Operation & Maintenance InstructionDocument56 pages4396-13.0-01-04 - 0 Operation & Maintenance InstructionJAIME100% (1)

- SECTION 5.40: Crankcase Breather SystemDocument24 pagesSECTION 5.40: Crankcase Breather SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Standard Design of Wazu (Wadu) KhanaDocument3 pagesStandard Design of Wazu (Wadu) KhanaSohail ShaikhNo ratings yet

- ELP End User Rev10Document38 pagesELP End User Rev10hugoheloNo ratings yet

- H2S & Total Sulfur AnalyzersDocument16 pagesH2S & Total Sulfur AnalyzersBryan TungNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Project ReportDocument36 pagesProject Reportvishi89No ratings yet

- RT700 Capacity Chart PDFDocument6 pagesRT700 Capacity Chart PDFhenry ariasNo ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- Centrifugal Compressor: Key Components and ApplicationsDocument14 pagesCentrifugal Compressor: Key Components and ApplicationsAnis FarhanaNo ratings yet

- San Diego Lean 6 Sigma Solar Turbines PDFDocument91 pagesSan Diego Lean 6 Sigma Solar Turbines PDFarmin heidariNo ratings yet

- Bom Chan KhongDocument78 pagesBom Chan KhongKhổng C. PhongNo ratings yet

- Cooling Water System Control Philosophy (25Mw) : ObjectiveDocument8 pagesCooling Water System Control Philosophy (25Mw) : ObjectiveEric TaylorNo ratings yet

- Performance of Industrial GasturbinesDocument28 pagesPerformance of Industrial Gasturbinessomporn duangbuntaoNo ratings yet

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874No ratings yet

- Manual W300H 01780455 90Document2 pagesManual W300H 01780455 90Daniel LanderoszNo ratings yet

- Lube Oil System: MLN Block 405, Algeria Operator TrainingDocument10 pagesLube Oil System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Surface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16Document16 pagesSurface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16tuynvNo ratings yet

- Question. The Percentage Composition of Sample of Liquid Fuel by Weight IsDocument2 pagesQuestion. The Percentage Composition of Sample of Liquid Fuel by Weight IsAli Jarrar JafriNo ratings yet

- Emergency Generator CoolingDocument7 pagesEmergency Generator CoolingJay JayNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- Altronic V Installation Manual (FORM AV II)Document12 pagesAltronic V Installation Manual (FORM AV II)francis_mouille_iiNo ratings yet

- Ariel compressor instrumentation requirementsDocument8 pagesAriel compressor instrumentation requirementsFaisal NaeemNo ratings yet

- Solar Centaur 40 - Mechanical DriveDocument2 pagesSolar Centaur 40 - Mechanical Driverezzz7No ratings yet

- Data Sheet TDD-GD100T PDFDocument2 pagesData Sheet TDD-GD100T PDFjhon peñaNo ratings yet

- ARIEL Maint intervalSEK PDFDocument7 pagesARIEL Maint intervalSEK PDFMargaret Daugherty100% (1)

- Industrial gas generator parts catalogueDocument62 pagesIndustrial gas generator parts cataloguejuanaNo ratings yet

- ERT Calder PDFDocument8 pagesERT Calder PDFHatem JafouraNo ratings yet

- Ebara Horizontal Multistage PumpDocument27 pagesEbara Horizontal Multistage PumpYohanes KrisNo ratings yet

- Pump ZM B PDFDocument12 pagesPump ZM B PDFRamon PachecoNo ratings yet

- 275GL Series 12V 275GL+: Gas Engine With ESM 2Document2 pages275GL Series 12V 275GL+: Gas Engine With ESM 2Jaadi 786100% (1)

- Maintenance Preventive / Preventive Maintenance Lot Rep QT REF DesignationDocument1 pageMaintenance Preventive / Preventive Maintenance Lot Rep QT REF DesignationMedjahdi RafikNo ratings yet

- 8C Throttle Trip ValvesDocument4 pages8C Throttle Trip Valvesjr110livecom100% (1)

- Gas Turbine in Cairo North Power StationDocument38 pagesGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- GT24/GT26 Operation Training Module: Jacking Oil SystemDocument15 pagesGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNo ratings yet

- Válvula de SeguridadDocument8 pagesVálvula de Seguridadmark_59No ratings yet

- Cryogenic Pressure Regulator GuideDocument4 pagesCryogenic Pressure Regulator GuidedhaktodesatyajitNo ratings yet

- Expansion Tank & Air Separator Deviation SheetDocument1 pageExpansion Tank & Air Separator Deviation SheetLi LiuNo ratings yet

- J4675 Component List Rev FDocument2 pagesJ4675 Component List Rev FDaniel ReyNo ratings yet

- ZOOK Graphite Ruptur DiscsDocument8 pagesZOOK Graphite Ruptur DiscsDaniel ReyNo ratings yet

- Manual InductiosnMotorsDocument147 pagesManual InductiosnMotorsclickanant4171No ratings yet

- SondexDocument1 pageSondexDaniel ReyNo ratings yet

- Catalogue CVAP0495Document63 pagesCatalogue CVAP0495Juan Pablo Angel EspejoNo ratings yet

- TLV T8N Flow IndicatorDocument2 pagesTLV T8N Flow IndicatorDaniel ReyNo ratings yet

- 67C RegulatorsDocument12 pages67C RegulatorsDaniel ReyNo ratings yet

- Versa V Series ValvesDocument72 pagesVersa V Series ValvesDaniel ReyNo ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- Versa V Series Brass Solenoid Valves PDFDocument72 pagesVersa V Series Brass Solenoid Valves PDFvilegual1No ratings yet

- CBB Double-Acting Series Pneumatic Actuators: Disassembly and ReassemblyDocument33 pagesCBB Double-Acting Series Pneumatic Actuators: Disassembly and ReassemblyDaniel ReyNo ratings yet

- Design ET and EAT Easy-E Valves Class 125 Through 600Document44 pagesDesign ET and EAT Easy-E Valves Class 125 Through 600Ahmed ShawkeyNo ratings yet

- 98H Series Backpressure/Relief Valves: Industrial RegulatorsDocument4 pages98H Series Backpressure/Relief Valves: Industrial RegulatorsDaniel ReyNo ratings yet

- Neo-Dyn Series 130PDocument2 pagesNeo-Dyn Series 130PDaniel ReyNo ratings yet

- GE A Series Natural Gas CompressorsDocument2 pagesGE A Series Natural Gas CompressorsDaniel ReyNo ratings yet

- F7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualDocument43 pagesF7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualDaniel ReyNo ratings yet

- User Guide Ams Trex Device Communicator en Us 171738Document214 pagesUser Guide Ams Trex Device Communicator en Us 171738Daniel ReyNo ratings yet

- Series 3725 Electropneumatic Positioner Type 3725: Mounting and Operating Instructions EB 8394 EN (1300-1621)Document56 pagesSeries 3725 Electropneumatic Positioner Type 3725: Mounting and Operating Instructions EB 8394 EN (1300-1621)rizky ListyawanNo ratings yet

- Manual F7000 RevL SpanishDocument43 pagesManual F7000 RevL SpanishDaniel ReyNo ratings yet

- Type 3730-1 Electropneumatic PositionerDocument112 pagesType 3730-1 Electropneumatic PositionerDaniel ReyNo ratings yet

- Type 3730-1 Electropneumatic PositionerDocument112 pagesType 3730-1 Electropneumatic PositionerDaniel ReyNo ratings yet

- Series 3725 Electropneumatic Positioner Type 3725: Mounting and Operating Instructions EB 8394 EN (1300-1621)Document56 pagesSeries 3725 Electropneumatic Positioner Type 3725: Mounting and Operating Instructions EB 8394 EN (1300-1621)rizky ListyawanNo ratings yet

- Ful Flo A SeriesDocument10 pagesFul Flo A Seriesrodruren01No ratings yet

- Air Preparation: Regulators, Pressure Regulators, Lubricators and AccessoriesDocument40 pagesAir Preparation: Regulators, Pressure Regulators, Lubricators and AccessoriesDaniel ReyNo ratings yet

- Dimensiones de BridasDocument60 pagesDimensiones de BridasDaniel ReyNo ratings yet

- Air Preparation: Regulators, Pressure Regulators, Lubricators and AccessoriesDocument40 pagesAir Preparation: Regulators, Pressure Regulators, Lubricators and AccessoriesDaniel ReyNo ratings yet

- Ge FanucDocument147 pagesGe FanucDaniel Rey100% (1)

- Tablero NfsDocument76 pagesTablero NfsDaniel ReyNo ratings yet

- Catalogue - Hilux - 2021 (1) - 0Document6 pagesCatalogue - Hilux - 2021 (1) - 0Hermawan AnggraeniNo ratings yet

- Component-Based Development Ben Fairfax Thursday 21st September 2006Document65 pagesComponent-Based Development Ben Fairfax Thursday 21st September 2006sdimi51No ratings yet

- P16NF06FP STMicroelectronicsDocument9 pagesP16NF06FP STMicroelectronicsSoniaNo ratings yet

- Report on Materials and SuppliersDocument4 pagesReport on Materials and SuppliersVivek S SurendranNo ratings yet

- Rock Mass Classification SystemsDocument33 pagesRock Mass Classification Systemsmortaza7094No ratings yet

- Torre Sauter 4 PosiçõesDocument22 pagesTorre Sauter 4 PosiçõesPaulo Henrique ValérioNo ratings yet

- Pedestal Column For Tower-Usd: Ast (MM 2) Ab (MM 2)Document18 pagesPedestal Column For Tower-Usd: Ast (MM 2) Ab (MM 2)Joy lauriaNo ratings yet

- Notifier Compatible EquipmentDocument2 pagesNotifier Compatible EquipmentHesams EnamoradoNo ratings yet

- Inspection Request FormDocument1 pageInspection Request FormNieves GuardianNo ratings yet

- RRU and BBU Configurations 02-08-2012Document20 pagesRRU and BBU Configurations 02-08-2012Mohammed UD100% (2)

- TransformerDocument17 pagesTransformerRunNo ratings yet

- Wire Size Chart NEC 2011Document1 pageWire Size Chart NEC 2011Gustavo TovarNo ratings yet

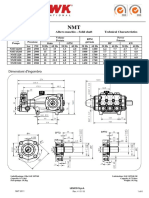

- NMT pump technical specificationsDocument6 pagesNMT pump technical specificationsazkNo ratings yet

- Backscatter and Seabed Image ReflectivityDocument5 pagesBackscatter and Seabed Image ReflectivityJuan David SantanaNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Complete Lesson 4 Assessment Task On The Maneuver of The ShipDocument2 pagesComplete Lesson 4 Assessment Task On The Maneuver of The ShipMixed VideosNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Lte Epc Umts 3GPPDocument222 pagesLte Epc Umts 3GPPjbarriospNo ratings yet

- Lux Level BSI StandardDocument24 pagesLux Level BSI StandardSomsitt ThudsuriyawongNo ratings yet

- DBMS Lab ManualDocument199 pagesDBMS Lab ManualMoulika Chowdary100% (1)

- CV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBDocument7 pagesCV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBTeguh Agung KusumaNo ratings yet

- ANSYS IGBT Inverter Multiphysics SolutionDocument56 pagesANSYS IGBT Inverter Multiphysics Solution黃宋儒100% (1)

- Reinforced Concrete DesignDocument3 pagesReinforced Concrete DesignRodel100% (2)

- Jurnal ErielDocument5 pagesJurnal ErielPaste GigiNo ratings yet

- Medical Equipment MaintenanceDocument6 pagesMedical Equipment Maintenancever_at_workNo ratings yet