Professional Documents

Culture Documents

Solvent in Paints and Coatings - Types, Uses and Properties

Uploaded by

yanri cahyoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solvent in Paints and Coatings - Types, Uses and Properties

Uploaded by

yanri cahyoCopyright:

Available Formats

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

Subscribe to Newsle e

Co

INGREDIENTS SELECTOR SELECTION RESOURCES NEWS & FEEDS

Home Selec on Guides Solvents Selec on for Industrial Coa ngs Pri nt

Solvents Selection for Industrial Coatings

In paints and coatings, solvents are majorly used to dissolve or disperse various components used in the formulation. Industrial Coatings made with solvents dry u

solvent alternatives at room temperature, making painting fast and easy along with other benefits such as long-lasting protection, brilliant performance in extreme

more.

Explore main factors to be considered while selecting the right solvent for your industrial coating formulations from a range provided by the coatings market. Also

of the different solvent families (hydrocarbons, ketones, esters, alcohols, glycol ethers….) and some specific solvents within them.

Role of Solvents in Paints and Role of Solvents in Paints and Coatings

Coa ngs

Solvents are added to paint and coa ngs formula ons to

dissolve other compounds like:

Pigments

Addi ves, and

Binders

A er the paint is applied on the surface, the solvent

evaporates, allowing the resin and pigment to produce a

film of paint and to dry quickly. Adding solvents in a paint formula on helps to op mize the whole

performance of the system.

Even if almost no solvents are present in the final dried coa ng due to evapora on, their role is

essen al in coa ng formula on.

Channel A

Receive weekl

Solvents control the viscosity for the applica on

Enter your Em

Solvents have an important effect on film quality, which is strongly dependent on the solvent's

evapora on rate during drying

As a result of this they can affect proper es such as film appearance, adhesion, or even corrosion.

» Select Right Solvent for Your Paints and Coa ngs Formula on

This coa ngs database is available to all, free of charge. You can filter down your op ons by suitable

resin, system or applica on (coa ngs, inks...), supplier and regional availability.

Before learning about what are the main families of solvents used in paints and coa ngs formula ons,

let’s understand more about solva ng power which is probably the most important parameter to

select a solvent apart from its vola lity and evaporate rate…

Hansen Solubility Parameters 2D map (δP and δH)

Solva ng Power describes the ability of a solvent to interact with other molecules and thus the

dissolu on of resins and formula on viscosity.

Hansen Solubility Parameters offer a good way to es mate the solva ng power of solvents

Back to Top

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 1/6

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

Basic Principles of Hansen Solubility Parameters

Hansen Solubility Parameters are a set of 3 numbers that describe the way solvents (but also

polymers) will behave with other molecules (Do they want to be near each other or not).

Each one of the 3 parameters, δD, δP and δH , represents a type of interac ons: London dispersion

forces, polar forces and hydrogen bonding forces respec vely.

As dispersion forces are similar for most of the common solvents/organic molecules δD does not

vary much.

δP and δH are more important here and can differ a lot from solvent to solvent. These numbers are

good indicators of the polar proper es and ability of a solvent to form hydrogen bonds

respec vely.

The smaller the δP the be er the ability to dissolve non-polar resin, the higher the δH the be er

the ability to form hydrogen bonds.

Although it remains important, when formula ng a solvent blend, to consider all Hansen Parameters

of the blend (the reader is encouraged to look for more informa on on Hansen Solubility Parameters)

here we will take into account only δP and δH. Below we have created a 2D map of the common

solvents/families that can complement the matrix and help visualize solvent solva ng proper es.

Main Types of Solvents Used in Paints and Coa ngs

The main types of solvents used in paints and coa ngs formula ons are:

Hydrocarbon Solvents

Ketones

Esters

Alcohols

Glycol Ethers

Hydrocarbon Solvents for Coa ngs

Hydrocarbons (molecules composed only of carbon and hydrogen atoms) can be divided in alipha cs,

aroma cs and blends

Alipha c solvents are linear, branched or cyclic hydrocarbon chains such as pure solvent like

hexane

Aroma c solvents feature a benzene group (cyclic structure of 6 carbons) like Toluene and Xylene

Alipha c and cyclic hydrocarbons blends are usually well known as Mineral or White Spirit and

Special Boiling Point Spirit. Blends of aroma c solvents are also available

Back to Top

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 2/6

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

1. Special Boiling Point Spirit (Flash Point < 21°C) include different grades with different flash points

and fixed boiling ranges. They are very fast evapora ng solvents and thus are used for fast drying

coa ngs

2. Mineral or White Spirit (Commonly with flash point > 21°C) are also available in different grades

with different flash points and fixed boiling range. Their names can usually refer to the flash point

(30°C, 40°C, 60°C …). They are commonly used for oil based and alkyd resins

3. Aroma c hydrocarbons blends (some mes called Naphtha solvents) are usually aroma c

petroleum frac ons (C9 to C13) with different grades having fixed boiling ranges. They are

commonly used in many industrial coa ngs as part of the solvent systems even if they try to be

avoided when possible. In general aroma c solvents have higher dissolving power than alipha cs

4. Toluene and xylene are commonly used with phenolic and amino formaldehyde in heat-curing

systems as well as with alkyd resins

5. Spirits of Turpen ne are specific solvents made from dis lla on of tree resins and composed of

different terpenes. There are commonly used for oil-based systems.

To help you select hydrocarbon solvents keeping in view the proper es they impart to the

formula on, below find an exclusive matrix focusing on the Solva ng Power, Evapora on Rate/

Vola lity, Solubility in Water, Flammability and Toxicological/eco-tox Profile of different types of

hydrocarbon solvents.

Solva ng

Power /

Solva ng Evapora on Solubility in

Ability to Tox/eco-

Subtype Power / Rate/ Water Flammability

form tox Profile

Polarity Vola lity (20°C)

hydrogen

bonds

Alipha c-Hexane -0 -0 Yes

Blend

Alipha c/Cycloalipha c Usually

Yes

Special Boiling Point Spirits

(Flash Point < 21°C)

Blend

Alipha c/Cycloalipha c

White spirits / Mineral Usually YES Usually

Spirits (60°C>Flash Point >

21°C)

Blend

Alipha c/Cycloalipha c

No

White spirits / Mineral

Spirits (Flash Point > 60°C)

Spirit of Turpen ne

Usually YES Usually

(terpenoids)

Aroma c Frac ons (Flash

Yes Usually

Point <60°C)

Aroma c Frac ons (Flash

No Usually

Point >60°C)

Toluene Yes

Xylene Yes

Ketones as Solvents for Coa ngs

Ketones solvents are considered to have good solva ng power thanks to their carbonyl group, a

hydrogen acceptor. Small ketones are good for polar resins and as the hydrocarbon chain get more

important for higher ketones; they become good for non-polar resins. Only small ketones are miscible

with water.

Ketones solvents can also decrease viscosity of resin systems by avoiding complex forma on between

polar resins (when hydrogen bonds are formed between resin molecules).

» View all Ketone Solvents Suitable for Paints & Coa ngs

Acetone, a fast evapora on solvent used in cellulosic coa ngs

Methyl isobutyl Ketone, a medium evapora on all around solvent used in many systems

Methyl Amyl Ketones a low evapora on solvent with good solving power proper es

Isophorone a very low evapora on solvent used in heat-curing systems. It is known to improve the

we ng of surfaces and pigments

Subtype Solva ng Solva ng Evapora on Solubility FlammabilityTox/eco-tox

Power / Power / Rate/ in Water Profile

Ability to Polarity Vola lity (20°C)

Back to Top

form

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 3/6

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

hydrogen

bonds

Acetone

Methyl Ethyl Ketone Yes

(MEK)

Methyl Isobutyl Ketone

Yes

(MIBK)

Methyl Amyl Ketone

Yes

(MAK)

Isophorone No

Diacetone Alcohol Yes

Diisobutyl Ketone Yes

Esters as Solvents for Coa ngs

Like ketones, esters are also hydrogen acceptors and thus have similar solva ng power. If small esters

are good solvents for polar resins, their dissolving power for non-polar material increases, like

ketones, with the size of their hydrocarbon chain.

They usually have a very limited miscibility with water but compared to ketones, their usually more

"fruity" odor makes them o en more pleasant. They can also be used to decrease viscosity when polar

resins molecules form complexes due to hydrogen bonds.

Ethyl Acetate, a fast evapora on solvent widely used in many fast drying systems

Butyl Acetate is also widely used, its moderate evapora on rate makes it perfect, during drying, to

avoid surface defects of the film (blushing, cratering...)

Propylene Glycol Mono Methyl Ether Acetate, a moderate evapora on, solvent is also used in lots

of systems. It has a greater (but limited) miscibility with water compared to other esters

Butyl Glycol Acetate is a slow evapora on solvent with very good solva ng power making it

suitable to improve the flow and gloss of coa ngs cured at high temperature

Solva ng

Power /

Solva ng Evapora on Solubility in

Ability to Tox/eco-tox

Subtype Power / Rate/ Water Flammability

form Profile

Polarity Vola lity (20°C)

hydrogen

bonds

-

General Esters

No/Slightly

miscible

Ethyl Acetate Yes

Butyl Acetate Yes

IsoPropyl Acetate Yes

IsoButyl Acetate Yes

Glycol Ether Esters

Propylene Glycol Mono

Methyl Ether Acetate Yes

(PGMEA)

Ethylene Glycol Mono

Butyl Ether Acetate No

(EGBEA)

Diethylene Glycol n-Butyl

No

Ether Acetate (DEGBEA)

Alcohols as Solvents for Coa ngs

Alcohols are both hydrogen donors and acceptors giving them a very good solva ng power for polar

resins. As the length of the hydrocarbon chain increases their solva ng power for polar resins

decreases. Of course the posi on of the OH group has also an influence.

Small alcohols are soluble in water but miscibility falls off as the hydrocarbon chain length becomes

longer. It is important to keep in mind that alcohols can react with isocyanates and thus, can interfere

with the drying process of such coa ngs. This effect can be reduced by using secondary or ter ary

alcohols.

» See All Suitable Alcohol Solvents for Paints and Coa ngs

Ethanol, a high evapora on solvent, able to dissolve very polar resins but unable to dissolve very

non-polar film formers like

Butanol, a moderate evapora on solvent widely used in many systems. Among other proper es,

this solvent is known to be able to decrease viscosity (even in small quan es) in non-polar resin Back to Top

systems like alkyds paints and in some waterborne coa ngs

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 4/6

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

Solva ng

Power/

Solva ng Evapora on Solubility in

Ability to Tox/eco-tox

Subtype Power/ Rate/ Water Flammability

form Profile

Polarity Vola lity (20°C)

hydrogen

bonds

General Alcohols

Ethanol Yes

Butanol Yes

Glycol Ether Solvents

Glycol ethers are usually divided in two categories: the ones based on ethylene, E-series and the ones

based on propylene, P-series. P-series are considered less toxic than E-series. Glycol Ether solvents

have usually a slow evapora on rate, which can limit their use to some specific applica ons. However,

due to their good solva ng proper es, these solvents have the advantage of improving flow and

surface quality of the paint film.

Ethylene Glycol MonoButyl Ether, usually known as Butyl Glycol, is a very versa le solvent. It has a

higher (even if very slow) evapora on rate than most of other glycol ethers and is widely used in

both solvent-borne and waterborne coa ngs.

Propylene Glycol Methyl Ether; its moderate evapora on rate and full miscibility with water make

it a strong candidate for lots of coa ng systems.

Dipropylene Glycol n-Butyl Ether is a very slow evapora ng solvent making it a very good

coalescing agent.

Solva ng Power Evapora on Solubility Tox/eco-

Solva ng Power

Subtype / Ability to form Rate/ in Water Flammability tox

/ Polarity

hydrogen bonds Vola lity (20°C) Profile

Ethylene

Glycol MonoButyl No

Ether (EGBE)

Ethylene Glycol

Mono- n-propyl Yes

Ether (EGPE)

Diethylene Glycol

Monobutyl Ether No

(DEGBE)

Dipropylene Glycol

Mono Methyl Ether No

(DPGME)

Propylene Glycol

Mono Methyl Ether Yes

(PGME)

Propylene Glycol n-

No

Butyl Ether (PGBE)

Dipropylen Glycol n-

No

Butyl Ether (DPGBE)

Follow 7,7

Spotlight

Lo

C

C

Enhanced Micro

Regulatory Supp

Be the first to comment on "Solvents Selec on for Industrial Coa ngs"

Leave a comment

Want to comment? Please, simply login or register. Back to Top

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 5/6

3/16/2021 Solvent in Paints and Coatings: Types, Uses and Properties

Your email password Login

No Account yet? Register for free Forgot Password ?

Comment *

Comment Text

Rate this Content

Your email address and name will not be published

submi ng a comment or ra ng implies your acceptance to SpecialChem Terms & Condi ons Publish Comment

Quick Navigation Stay connected

Subscribe to our Newsletters

Marketing solutions

Enter your professional email Subscribe

Online courses

Program analytics Follow us Follow us Subscribe to our

on LinkedIn on Twitter Youtube channel

Become an expert

About us

Industries Served

Careers

Contact us Plastics Coatings

Elastomers Ingredients

Cosmetics Polymer

Ingredients Additives

Copyright © SpecialChem 2021 Terms and Conditions

Back to Top

https://coatings.specialchem.com/selection-guide/select-solvents-for-industrial-coatings#glycol ethers?p=1 6/6

You might also like

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3From EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3No ratings yet

- Polishes, Coatings and SealersDocument30 pagesPolishes, Coatings and SealersIdkaNo ratings yet

- Paint ManufacturingDocument2 pagesPaint ManufacturingTamara FernandesNo ratings yet

- Additives in PaintsDocument18 pagesAdditives in PaintsShahri GhaniNo ratings yet

- Technical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Document1 pageTechnical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Fadi Magdy0% (1)

- 15.1.1h PaintDocument31 pages15.1.1h PaintvickyNo ratings yet

- Smooth Masonry PaintDocument1 pageSmooth Masonry Paintvanhung88No ratings yet

- Traffic Paint CharacteristicsDocument10 pagesTraffic Paint CharacteristicsCloudy DayNo ratings yet

- T6TYskLrXGMCXL93cXXEH9Ev9Document1 pageT6TYskLrXGMCXL93cXXEH9Ev9Sidrah RasoolNo ratings yet

- Classification of Water-Based Paints by CostDocument25 pagesClassification of Water-Based Paints by CostHà Phương Nguyễn100% (1)

- Evr Frekote Mold Release BrochureDocument18 pagesEvr Frekote Mold Release BrochureHugo Wizenberg100% (1)

- Dispersing AgentsDocument6 pagesDispersing AgentsEdward MenezesNo ratings yet

- Handbook On Textile Auxiliaries, Dyes and Dye Intermediates TechnologyDocument11 pagesHandbook On Textile Auxiliaries, Dyes and Dye Intermediates TechnologyLincoln HasanNo ratings yet

- Paint Manufacturing Quality ControlDocument16 pagesPaint Manufacturing Quality ControlAbhishek ChauhanNo ratings yet

- Shell SolDocument2 pagesShell Solpetrofacumar100% (1)

- Duroftal VPE 7186 Coil - e PDFDocument24 pagesDuroftal VPE 7186 Coil - e PDFPratik MehtaNo ratings yet

- Interior Paint FormulationDocument1 pageInterior Paint FormulationSrun Bunsroeun100% (1)

- Byk Ts-A5 Putties enDocument6 pagesByk Ts-A5 Putties enSebastian GonzalezNo ratings yet

- Paint AdditivesDocument3 pagesPaint AdditivesAnonymous yy8In96j0rNo ratings yet

- Nuosperse FA 196Document2 pagesNuosperse FA 196Sandra Rojas100% (1)

- Understanding Paint SystemDocument37 pagesUnderstanding Paint SystemMayank KumarNo ratings yet

- Brochure Antifoams Defoamers Tego AntifoamDocument8 pagesBrochure Antifoams Defoamers Tego AntifoamJuan CubasNo ratings yet

- Automotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesDocument7 pagesAutomotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesAmado ElzNo ratings yet

- Emulsion Polymerization MachanismDocument13 pagesEmulsion Polymerization MachanismLuan GabrielNo ratings yet

- Akzo Nobel's Duomeen TDO: PointDocument1 pageAkzo Nobel's Duomeen TDO: PointさいとはちこNo ratings yet

- Cymel® 303 LF: Product Description Typical PropertiesDocument2 pagesCymel® 303 LF: Product Description Typical Propertiesهیمن مNo ratings yet

- Material & Metalurgy: Organic Coatings Composition and Film FormationDocument24 pagesMaterial & Metalurgy: Organic Coatings Composition and Film Formationkevin100% (1)

- Paint TechnologyDocument63 pagesPaint TechnologyElhusseiny Fouda100% (1)

- Optical BrightnersDocument4 pagesOptical Brightnerseaglator100% (1)

- Mowital: Polyvinyl Butyral of Superior QualityDocument36 pagesMowital: Polyvinyl Butyral of Superior Qualityode3197No ratings yet

- Overview of Water-Based PaintDocument27 pagesOverview of Water-Based PaintHà Phương Nguyễn100% (4)

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDocument4 pagesPaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriNo ratings yet

- Falamine Plus Pages LQDocument1 pageFalamine Plus Pages LQSatish ChipkarNo ratings yet

- FoamStar ST 2412 August 2018 R3 ED2Document2 pagesFoamStar ST 2412 August 2018 R3 ED2APEX SONNo ratings yet

- Gel Antibacterial LubrizolDocument1 pageGel Antibacterial LubrizolMauricio BotiaNo ratings yet

- Attapulgite Overview: Properties and UsesDocument24 pagesAttapulgite Overview: Properties and UsesAnonymous yy8In96j0rNo ratings yet

- TDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03Document4 pagesTDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03JoeNo ratings yet

- Classification of PaintsDocument2 pagesClassification of Paints9440864459No ratings yet

- SS 70-70 - Eagle ChemicalsDocument2 pagesSS 70-70 - Eagle ChemicalsMoatz HamedNo ratings yet

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocument32 pagesOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNo ratings yet

- Stains and Stain RemovalDocument6 pagesStains and Stain Removallucymuchiri797No ratings yet

- Use of Soya Lecithin in Making PaintDocument1 pageUse of Soya Lecithin in Making PainttunlajiNo ratings yet

- Calculating Formulation Physical Constants of Paints and CoatingsDocument8 pagesCalculating Formulation Physical Constants of Paints and CoatingsArmando PosadaNo ratings yet

- Sudarshan PigmentsDocument20 pagesSudarshan Pigments44gurpreetNo ratings yet

- MODAFLOWDocument24 pagesMODAFLOWuzzy2100% (1)

- NeoCryl B-725 MsdsDocument3 pagesNeoCryl B-725 MsdsLeandro EsvizaNo ratings yet

- 6 Warna Water Based Inkjet InkDocument21 pages6 Warna Water Based Inkjet InksabunbeningNo ratings yet

- Waterborne Epoxy Coating SystemsDocument24 pagesWaterborne Epoxy Coating SystemsAPEX SONNo ratings yet

- Fundamentals of Waterborne Resin TechnologyDocument4 pagesFundamentals of Waterborne Resin TechnologyvaducNo ratings yet

- 2.2e Coating Formulation CalculationDocument6 pages2.2e Coating Formulation CalculationSwapnil SononeNo ratings yet

- BASF Printing Packaging Product Guide 201803Document15 pagesBASF Printing Packaging Product Guide 201803aaronNo ratings yet

- Solvent based printing inks applicationsDocument34 pagesSolvent based printing inks applicationsAmna liaquatNo ratings yet

- Paint Component AustraliaDocument146 pagesPaint Component AustraliaAnonymous HargxqRNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionFrom EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNo ratings yet

- VELP AM4 Digital PRODocument2 pagesVELP AM4 Digital PROyanri cahyoNo ratings yet

- Laudis MsdsDocument10 pagesLaudis Msdsyanri cahyoNo ratings yet

- Reference Color & Physical FormDocument1 pageReference Color & Physical Formyanri cahyoNo ratings yet

- Sieving For Perfect Quality Control: MillingDocument12 pagesSieving For Perfect Quality Control: Millingyanri cahyoNo ratings yet

- Bio SolarDocument1 pageBio Solaryanri cahyoNo ratings yet

- Insecticidal CompositionsDocument7 pagesInsecticidal Compositionsyanri cahyoNo ratings yet

- M5000 Melting Point Meter Measures Substances to 400°CDocument1 pageM5000 Melting Point Meter Measures Substances to 400°Cyanri cahyoNo ratings yet

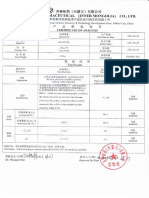

- COA of Abamectin TCDocument1 pageCOA of Abamectin TCyanri cahyoNo ratings yet

- 13 - Chapter 3Document24 pages13 - Chapter 3yanri cahyoNo ratings yet

- Jawaharlal Nehru University: Most UrgentDocument2 pagesJawaharlal Nehru University: Most Urgentyanri cahyoNo ratings yet

- 2,4 D AcidDocument9 pages2,4 D Acidyanri cahyoNo ratings yet

- Sieving For Perfect Quality Control: MillingDocument12 pagesSieving For Perfect Quality Control: Millingyanri cahyoNo ratings yet

- Quantitative Determination of Paraquat in A Fatal Intoxication by HPLC-DAD Following Chemical Reduction With Sodium BorohydrideDocument6 pagesQuantitative Determination of Paraquat in A Fatal Intoxication by HPLC-DAD Following Chemical Reduction With Sodium Borohydrideyanri cahyoNo ratings yet

- Fao Specifications and Evaluations For Agricultural PesticidesDocument58 pagesFao Specifications and Evaluations For Agricultural Pesticidesyanri cahyoNo ratings yet

- ChlotiahinidinDocument271 pagesChlotiahinidinyanri cahyoNo ratings yet

- Effervescent Tablets&Key FactsDocument4 pagesEffervescent Tablets&Key FactsMuanfan Suwan100% (1)

- 1 s2.0 S0308814608001088 MainDocument7 pages1 s2.0 S0308814608001088 Mainyanri cahyoNo ratings yet

- About CoatingsDocument1 pageAbout Coatingsyanri cahyoNo ratings yet

- E35 MTMethodsOverviewDocument48 pagesE35 MTMethodsOverviewmercuriusNo ratings yet

- E35 MTMethodsOverviewDocument48 pagesE35 MTMethodsOverviewmercuriusNo ratings yet

- Analysis of Nicosulfuron Residues in Maize Field Soil by High-Performance Liquid ChromatographyDocument8 pagesAnalysis of Nicosulfuron Residues in Maize Field Soil by High-Performance Liquid Chromatographyyanri cahyoNo ratings yet

- Product GuideDocument20 pagesProduct Guideyanri cahyoNo ratings yet

- Sieving For Perfect Quality Control: MillingDocument12 pagesSieving For Perfect Quality Control: Millingyanri cahyoNo ratings yet

- Trends in Analytical Chemistry for Detecting Dithiocarbamate FungicidesDocument11 pagesTrends in Analytical Chemistry for Detecting Dithiocarbamate Fungicidesyanri cahyoNo ratings yet

- Uji Kualitatif Kandungan Hara Kompos Campuran Beberapa Kotoran Ternak PeliharaanDocument11 pagesUji Kualitatif Kandungan Hara Kompos Campuran Beberapa Kotoran Ternak PeliharaanFurqon KocinsNo ratings yet

- Uji Kualitatif Kandungan Hara Kompos Campuran Beberapa Kotoran Ternak PeliharaanDocument11 pagesUji Kualitatif Kandungan Hara Kompos Campuran Beberapa Kotoran Ternak PeliharaanFurqon KocinsNo ratings yet

- Analysis AlphacypermetrinDocument22 pagesAnalysis Alphacypermetrinyanri cahyoNo ratings yet

- Analysis of Nicosulfuron Residues in Maize Field Soil by High-Performance Liquid ChromatographyDocument8 pagesAnalysis of Nicosulfuron Residues in Maize Field Soil by High-Performance Liquid Chromatographyyanri cahyoNo ratings yet

- 100% Clean, Renewable Energy and Storage For Everything: Mark Z. Jacobson Stanford UniversityDocument78 pages100% Clean, Renewable Energy and Storage For Everything: Mark Z. Jacobson Stanford UniversityLuis MariánNo ratings yet

- ENGINEERING PHYSICS SyllabusDocument2 pagesENGINEERING PHYSICS SyllabusRathinaKumarNo ratings yet

- Selective Desoldering Separation of Tin Lead Alloy For Dismantling of Electronic Components From Printed Circuit BoardsDocument6 pagesSelective Desoldering Separation of Tin Lead Alloy For Dismantling of Electronic Components From Printed Circuit BoardsSALAH NETNo ratings yet

- Experiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionDocument1 pageExperiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionRefisa JiruNo ratings yet

- Physics 12: JUNE 2000Document42 pagesPhysics 12: JUNE 2000Gkid GkidNo ratings yet

- EVS Unit-2 AIR POLLUTIONDocument6 pagesEVS Unit-2 AIR POLLUTIONrohithrock1181No ratings yet

- Bending Moments and Shearing ForcesDocument3 pagesBending Moments and Shearing ForcesThinnai TheniNo ratings yet

- Database MSDSDocument4 pagesDatabase MSDSRinto SilalahiNo ratings yet

- OjkhgkgghhgDocument1,150 pagesOjkhgkgghhgHotib PerwiraNo ratings yet

- Hydrogen Power Energy HHO Generators PDFDocument70 pagesHydrogen Power Energy HHO Generators PDFKiran Rangineni100% (4)

- Bio Respiration Chapter SummaryDocument2 pagesBio Respiration Chapter SummaryYoussef Abdurrahman WeinmanNo ratings yet

- Amines All SheetDocument9 pagesAmines All SheetMahendra ShahNo ratings yet

- Speciality Gases Like Nitrogen, Oxygen, Argon & HydrogenDocument15 pagesSpeciality Gases Like Nitrogen, Oxygen, Argon & HydrogenkumarneerajNo ratings yet

- Articulo Corrosion 2Document15 pagesArticulo Corrosion 2Juan Pablo AponteNo ratings yet

- Grade 6 DLL SCIENCE 6 Q3 Week 6Document5 pagesGrade 6 DLL SCIENCE 6 Q3 Week 6Mark neil a. GalutNo ratings yet

- Specification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemDocument46 pagesSpecification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemAmro HarasisNo ratings yet

- Elastic Bending Modulus of Monolayer GrapheneDocument20 pagesElastic Bending Modulus of Monolayer GrapheneKevin KuanNo ratings yet

- Powhumus Msds - enDocument7 pagesPowhumus Msds - enJawwad KaleemNo ratings yet

- M1A1 Equipotential SurfacesDocument5 pagesM1A1 Equipotential SurfacesBrian LillyNo ratings yet

- Western Blotting FINAL 2Document4 pagesWestern Blotting FINAL 2A NaNo ratings yet

- Ecoprocesstm SBR Design NotesDocument3 pagesEcoprocesstm SBR Design NotesTrilok ChandraNo ratings yet

- Physics 1Document6 pagesPhysics 1api-244640341No ratings yet

- Physics 443, Solutions To PS 2Document7 pagesPhysics 443, Solutions To PS 2Rajesh Kumar DasNo ratings yet

- Catalysts 03 00189 PDFDocument30 pagesCatalysts 03 00189 PDFKarel Sanchez HernandezNo ratings yet

- Chem 2 Q1 Module 1 Attractive ForcesDocument9 pagesChem 2 Q1 Module 1 Attractive ForcesPrincess Venita BerganteNo ratings yet

- Consequences of Zeeman Degeneracy For The Van Der Waals Blockade Between Rydberg Atoms PDFDocument18 pagesConsequences of Zeeman Degeneracy For The Van Der Waals Blockade Between Rydberg Atoms PDFnavpreet bhullarNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Lab Report - Theory of MachinesDocument21 pagesLab Report - Theory of MachinesTaha AneesNo ratings yet

- MCQ Fluid MechanicsDocument5 pagesMCQ Fluid MechanicsGoverdhan ShresthaNo ratings yet

- D. Study About AnsysDocument6 pagesD. Study About AnsysLaxmi RaoNo ratings yet