Professional Documents

Culture Documents

12 ASME Secc VIII Part UCD Requirements For Pressure Vessels Co

12 ASME Secc VIII Part UCD Requirements For Pressure Vessels Co

Uploaded by

Dio MiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 ASME Secc VIII Part UCD Requirements For Pressure Vessels Co

12 ASME Secc VIII Part UCD Requirements For Pressure Vessels Co

Uploaded by

Dio MiCopyright:

Available Formats

PART UCD

General

UCD-1 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

UCD-2 Service Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

UCD-3 Pressure–Temperature Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Materials

UCD-5 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

UCD-12 Bolt Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Design

UCD-16 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-23 Maximum Allowable Stress Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-28 Thickness of Shells Under External Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-32 Heads With Pressure on Concave Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-33 Heads With Pressure on Convex Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-35 Spherically Shaped Covers (Heads) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

UCD-36 Openings and Reinforcements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

UCD-37 Corners and Fillets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Fabrication

UCD-75 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

UCD-78 Repairs in Cast Ductile Iron Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Inspection and Tests

UCD-90 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

UCD-99 Standard Hydrostatic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

UCD-101 Hydrostatic Test to Destruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Marking and Reports

UCD-115 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Pressure Relief Devices

UCD-125 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Tables

UCD-23 Maximum Allowable Stress Values in Tension for Cast Ductile Iron, ksi (MPa) . . 243

UCD-78.1 ........................................................................... 244

UCD-78.2 ........................................................................... 245

241

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

PART UCD

REQUIREMENTS FOR PRESSURE VESSELS

CONSTRUCTED OF CAST DUCTILE IRON

GENERAL part of a pressure vessel at the pressure–temperature

ratings listed in that standard.

UCD-1 SCOPE

The rules in Part UCD are applicable to pressure NOTE: Cast ductile iron flanges and fittings conforming in dimension

vessels and pressure vessel parts that are constructed to the Class 125 and 250 American National Standard for cast iron

flanges and fittings may be used in whole or as a part of a pressure

of cast ductile iron,1 and shall be used in conjunction vessel at the pressure–temperature ratings listed in ASME /ANSI

with the general requirements in Subsection A insofar B16.42, except that NPS 31⁄2 and smaller screwed and tapped flanges

as these requirements are applicable to cast material. conforming in dimensions to the Class 125 ASME /ANSI B16.1 for

cast iron flanged fittings shall have identical ratings specified in

ASME /ANSI B16.1.

UCD-2 SERVICE RESTRICTIONS

(c) Cast ductile iron flanges and fittings, Class 400

Cast ductile iron pressure vessels shall not be used and higher, conforming in dimension to the carbon

for services as follows: steel pipe flanges and flanged fittings in ASME /ANSI

(a) to contain lethal2 substances, either liquid or B16.5 may be used in whole or as a part of a pressure

gaseous; vessel at the pressure–temperature ratings for carbon

(b) for unfired steam boilers as defined in U-1(g); steel, material category 1.4, in that standard provided

(c) for direct firing [see UW-2(d)]. the temperature is not less than −20°F (−29°C) nor

greater than 650°F (343°C) and provided that the

pressure does not exceed 1000 psi (6900 kPa).

UCD-3 PRESSURE–TEMPERATURE

LIMITATIONS

(a) The maximum design temperature shall not be

higher than 650°F (343°C). The minimum design tem-

perature shall not be less than −20°F (−29°C), and the MATERIALS

design pressure shall not exceed 1000 psi (6900 kPa)

unless the requirements in UG-24 for a casting quality UCD-5 GENERAL

factor of 90% are met, and the vessel contains liq- All cast ductile iron material subject to stress due

uids only. to pressure shall conform to the specifications given

(b) Cast ductile iron flanges and fittings covered by in Section II and shall be limited to those listed in

ASME /ANSI B16.42 may be used in whole or as a Table UCD-23 except as otherwise provided in UG-11.

1

It is the intent that cast ductile irons with an elongation of less

than 15% in 2 in. (51 mm) be treated as cast iron and that vessels

or pressure parts of such material be designed and fabricated in

accordance with the rules in Part UCI.

2

By lethal substances are meant poisonous gases or liquids of such UCD-12 BOLT MATERIALS

a nature that a very small amount of the gas or of the vapor of

the liquid mixed or unmixed with air is dangerous to life when The requirements for bolt materials, nuts, and washers

inhaled. For purposes of this Division, this class includes substances

of this nature which are stored under pressure or may generate a shall be the same as for carbon and low alloy steels

pressure if stored in a closed vessel. in UCS-10 and UCS-11.

242

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

UCD-16 PART UCD — CAST DUCTILE IRON VESSELS UCD-35

TABLE UCD-23 (b) Examples illustrating the use of charts in the

MAXIMUM ALLOWABLE STRESS VALUES IN figures for the design of vessels under external pressure

TENSION FOR CAST DUCTILE IRON, ksi (MPa) are given in Appendix L.

For Metal

Temp., °F

Specified (°C) Not Ext.

Min. Exceeding Pressure UCD-32 HEADS WITH PRESSURE ON

Tensile −20 (−29) Chart Fig. CONCAVE SIDE

Spec. Strength to 650 No.

No. Class Note [Note (1)] (343) [Note (2)] Heads with pressure on the concave side (plus heads)

shall be designed in accordance with the formulas in

SA-395 ... (1) 60 (414) 12.0 (82.7) CD-1

UG-32.

GENERAL NOTE:

To these stress values, a quality factor as specified in UG-24 shall

be applied.

NOTES: UCD-33 HEADS WITH PRESSURE ON

(1) The yield stresses in compression and tension for cast ductile iron

are not sufficiently different to justify an increase in the allowable

CONVEX SIDE

stress for bending except as permitted in 2-8(a).

(2) Refer to Subpart 3 of Section II, Part D.

The thickness of heads with pressure on the convex

side (minus heads) shall not be less than the thickness

required in UG-33.

DESIGN

UCD-35 SPHERICALLY SHAPED COVERS

UCD-16 GENERAL (HEADS)

The rules in the following paragraphs apply spe- (a) Circular cast ductile iron spherically shaped heads

cifically to the design of pressure vessels and pressure with bolting flanges, similar to Fig. 1-6 sketches (b),

vessel parts of cast ductile iron and shall be used in (c), and (d) shall be designed in accordance with the

conjunction with the general requirements for Design provisions in 1-6, except that corners and fillets shall

in Subsection A insofar as these requirements are comply with the requirements of UCD-37.

applicable to cast materials. (b) Circular cast ductile iron spherically shaped heads

For components for which the Code provides no with bolting flanges other than those described in (a)

design rules, the provisions of UG-19(b) and (c) apply. above shall be designed in accordance with the following

If a proof test is performed, the rules of UCD-101 requirements.

apply.

(1) The head thickness shall be determined in

accordance with the requirements in UG-32.

(2) The spherical and knuckle radii shall conform

UCD-23 MAXIMUM ALLOWABLE STRESS

VALUES to the requirements in UG-32.

(3) Flanges made of cast ductile iron in compliance

Table UCD-23 gives the maximum allowable stress with SA-395 and conforming in dimensions to American

values at the temperatures indicated for castings con- National Standard for carbon steel given in ASME /

forming to the Specification listed therein. These stress ANSI B16.5 may be used at pressures not exceeding

values shall be limited to the stress values in Table 80% of the pressures permitted in those standards at

UCD-23 multiplied by the applicable casting quality their listed temperatures provided the temperature is

factor given in UG-24. not less than −20°F (−29°C) nor greater than 650°F

(343°C) and provided that the adjusted service pressure

does not exceed 1000 psi (6900 kPa).

UCD-28 THICKNESS OF SHELLS UNDER

EXTERNAL PRESSURE NOTE: Cast ductile iron flanges conforming in dimension to the

125 and 250 lb American National Standard for cast iron flanges

(a) Cylindrical and spherical shells under external may be used for pressures not exceeding 80% of the American

pressure shall be designed by the rules in UG-28, using National Standard pressure ratings for 150 lb and 300 lb carbon

steel flanges, respectively, at their listed temperatures provided the

the applicable figures in Subpart 3 of Section II, Part temperature is not less than −20°F (−29°C) nor greater than 650°F

D and the temperature limits of UG-20(c). (343°C), except as in Note to UCD-3(b).

243

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

UCD-36 2001 SECTION VIII — DIVISION 1 UCD-78

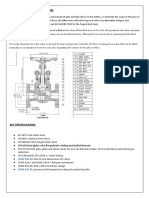

UCD-36 OPENINGS AND TABLE UCD-78.1

REINFORCEMENTS Minimum Thickness

(a) The dimensional requirements in UG-36 through NPS Plug or of Repaired

Equivalent (DN) Section, in. (mm)

UG-46 are applicable to cast ductile iron and shall be

used in the design of openings and reinforcements in 1

⁄8 (. . .) 11

⁄32 (9)

1 7

pressure vessels and pressure vessel parts which are ⁄4 (. . .) ⁄16 (11)

3 1

cast integrally with the vessel or vessel part. In no ⁄8 (10) ⁄2 (13)

1 21

⁄2 (15) ⁄32 (17)

case shall the thickness of the reinforcement, including 3

⁄4 (20) 3

⁄4 (19)

the nominal thickness of the vessel wall, exceed twice

the nominal thickness of the vessel wall. 1 (25) 13

⁄16 (21)

(b) Cast ductile iron flanges, nozzles, and openings 11⁄4 (32) 7

⁄8 (22)

shall not be attached to steel or nonferrous pressure 11⁄2 (40) 15

⁄16 (24)

2 (50) 1 (25)

vessels or pressure parts by welding or brazing, nor

shall they be considered to contribute strength to the

vessel or part.

(1) the vessel or vessel parts operate within the

UCD-37 CORNERS AND FILLETS

temperature limits of UCD-3(a), and the design pressure

A liberal radius shall be provided at projecting edges does not exceed 1000 psi (6900 kPa);

and in reentrant corners in accordance with good foundry (2) no welding is performed;

practice. Abrupt changes in surface contour and in wall (3) the diameter of the plug shall not exceed the

thickness at junctures shall be avoided. Fillets shall

diameter of a standard NPS 2 (DN 50) pipe plug;

conform to the following.

(4) the plugs, where practical, shall conform in

(1) Fillets forming the transition between the pres-

all dimensions to standard NPS pipe plugs, and in

sure containing walls and integral attachments, such as

addition they shall have full thread engagement corres-

brackets, lugs, supports, nozzles, flanges, and bosses,

ponding to the thickness of the repaired section. (See

shall have a radius not less than one-half the thickness of

Table UCD-78.1.) Where a tapered plug is impractical

the pressure containing wall adjacent to the attachment.

because of excess wall thickness in terms of plug

(2) Transitions between pressure containing walls diameter and coincident thread engagement, other types

of different contours shall have a radius not less than of plugs may be used provided both full thread engage-

three times the thickness of the thinner wall. ment and effective sealing against pressure are obtained.

Where possible, the ends of the plug should be ground

smooth after installation to conform to the inside and

outside contours of the walls of the pressure vessel or

FABRICATION

pressure part;

UCD-75 GENERAL (5) the material from which the plug is manufac-

The rules in the following paragraphs apply spe- tured shall conform in all respects to the material

cifically to the fabrication of pressure vessels and specification which applies to the pressure vessel or

pressure vessel parts of cast ductile iron and shall be pressure vessel part;

used in conjunction with the general requirements for (6) the machined surface of the drilled or bored

Fabrication in Subsection A insofar as these require- hole before tapping shall be free from visible defects and

ments are applicable to cast materials. the adjacent metal shown to be sound by radiographic

examination;

(7) the thickness of any repaired section in relation

to the size of plug used shall not be less than that

UCD-78 REPAIRS IN CAST DUCTILE IRON given in Table UCD-78.1;

MATERIAL (8) the minimum radius of curvature of repaired

(a) Imperfections which permit leakage in cast ductile sections of cylinders or cones in relation to the size

iron materials may be repaired by using threaded plugs of plug used shall not be less than that given in Table

provided: UCD-78.2;

244

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

UCD-78 PART UCD — CAST DUCTILE IRON VESSELS UCD-101

TABLE UCD-78.2 INSPECTION AND TESTS

Minimum Radius UCD-90 GENERAL

of Curvature of

NPS Plug or Cylinder or Cone, The rules in the following paragraphs apply spe-

Equivalent (DN) in. (mm) cifically to the inspection and testing of pressure vessels

1

⁄8 (. . .) 9

⁄16 (14)

and pressure vessel parts of cast ductile iron and shall

1

⁄4 (. . .) 11

⁄16 (18) be used in conjunction with the general requirements

3

⁄8 (10) 11⁄16 (27) of Inspection and Tests in Subsection A insofar as

1

⁄2 (15) 1 1 ⁄4 (32) these requirements are applicable to cast material.

3

⁄4 (20) 2 (51)

1 (25) 2 1 ⁄2 (64)

11⁄4 (32) 4 (102) UCD-99 STANDARD HYDROSTATIC TEST

11⁄2 (40) 5 1 ⁄4 (134)

2 (50) 81⁄8 (207) Cast ductile iron pressure vessels and pressure vessel

parts shall be hydrostatically tested by the method

prescribed in UG-99 except that the test pressure shall

be two times the maximum allowable working pressure.

UCD-101 HYDROSTATIC TEST TO

(9) the ligament efficiency between any two adja-

DESTRUCTION

cent plugs shall not be less than 80% where

(a) The maximum allowable working pressure of

identical cast ductile iron vessels, based on testing one

of them to destruction in accordance with UG-101(m),

冢 冣

d1 + d2

p− shall be

2

Ep

p

Specified min.

冢 冣冢 冣

PB f tensile strength

PR p **

5 Avg. tensile strength of

test specimens

and

Ep ligament efficiency where

pp distance between plug centers fp casting quality factor as defined in UG-24,

d1, d2p respective diameters of the two plugs under con- which applies only to identical cast ductile iron

sideration vessels put into service

(10) the pressure vessel or pressure vessel part meets PBp destruction test pressure, psi (kPa)

the standard hydrostatic test prescribed in UCD-99. PRp maximum allowable working pressure of identi-

(b) Surface imperfections, such as undue roughness, cal cast ductile iron vessels, psi (kPa)

which do not permit leakage in cast ductile iron materials The principle of UG-101(c) shall be followed.

may be repaired using driven plugs provided: (b) The value of the average tensile strength of test

(1) the vessel or vessel parts are to operate within specimens in the foregoing equation shall be determined

the limits of UCD-3(a); from the test results of three test bars from the same

(2) no welding is performed; ladle of iron as used in the part, or from three test

(3) the material from which the plug is manufac- specimens cut from the part.

(c) All pressure vessels or pressure vessel parts of

tured shall conform in all respects to the material

the same material, design, and construction, whose

specification which applies to the pressure vessel or

maximum allowable working pressure is based on the

pressure vessel part;

destruction test of a sample vessel or part, shall be

(4) the depth of the plug is not greater than 20% subjected to a hydrostatic test pressure of not less

of the thickness of the section and its diameter is not

greater than its engaged length;

** For some of the terms of the above equation(s), it may be

(5) the pressure vessel or pressure vessel part meets necessary to convert millimeters to meters to obtain a rational result

the standard hydrostatic test prescribed in UCD-99. in SI units.

245

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

UCD-101 2001 SECTION VIII — DIVISION 1 UCD-125

than twice the maximum allowable working pressure

determined by the application of the rules in (a).

MARKING AND REPORTS

UCD-115 GENERAL

The provisions for marking and preparing reports in

UG-115 through UG-120 shall apply without supple-

ment to vessels constructed of cast ductile iron.

PRESSURE RELIEF DEVICES

UCD-125 GENERAL

The provisions for the application of pressure relief

devices in UG-125 through UG-136 shall apply without

supplement to vessels constructed of cast ductile iron.

246

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- SP-2342 Rev 4Document68 pagesSP-2342 Rev 4sakthidharan100% (1)

- The Hydrocyclone: International Series of Monographs in Chemical EngineeringFrom EverandThe Hydrocyclone: International Series of Monographs in Chemical EngineeringRating: 5 out of 5 stars5/5 (3)

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Nuva Feeder UCCDocument2 pagesNuva Feeder UCCSEINASNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- 31 Samss 001Document38 pages31 Samss 001nadeem shaikh100% (1)

- Steam Tracer Header and Branch Connection DetailsDocument1 pageSteam Tracer Header and Branch Connection DetailsSathiyaseelan Sakthi ShanmugamNo ratings yet

- Ebara PumpDocument25 pagesEbara PumpMark CentenoNo ratings yet

- Horizontal MultiStage Pump Data SheetDocument6 pagesHorizontal MultiStage Pump Data Sheetسمير البسيونىNo ratings yet

- Vacuum PumpDocument50 pagesVacuum PumpsuryakanthareddyNo ratings yet

- Butterfly Valve Catalogue PDFDocument25 pagesButterfly Valve Catalogue PDFPriyanka rajpurohitNo ratings yet

- Dome Valve BrochureDocument8 pagesDome Valve BrochurecpsusinNo ratings yet

- SCORG Pumplinx Setup V5.1Document22 pagesSCORG Pumplinx Setup V5.1kamlzNo ratings yet

- Bag Filter Vs ESPDocument5 pagesBag Filter Vs ESPAmerMahmutbegovicNo ratings yet

- Grating Weight - CalculationDocument1 pageGrating Weight - CalculationMuthuram NNo ratings yet

- Fabricated Basket Strainers: Features OptionsDocument3 pagesFabricated Basket Strainers: Features OptionsmusaveerNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Alfa Laval Gasketed Plate Heat ExchangersDocument14 pagesAlfa Laval Gasketed Plate Heat Exchangersrajpvik100% (1)

- Static Pressure Calculation SheetDocument24 pagesStatic Pressure Calculation SheetMuhammad ZubairNo ratings yet

- Din 1685 1 1998Document4 pagesDin 1685 1 1998bel_izabelNo ratings yet

- Bandlock2 LiteratureDocument2 pagesBandlock2 LiteraturelaiminhtheNo ratings yet

- Q245R PDFDocument2 pagesQ245R PDFAnonymous 9zykaX6T100% (1)

- Materials Used For Construction: 1. Reciprocating CompressorDocument6 pagesMaterials Used For Construction: 1. Reciprocating CompressorEdemNo ratings yet

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- Design Calculation Report Job No. Building No. Rev. No. Customer Date Description Designed by Checked byDocument7 pagesDesign Calculation Report Job No. Building No. Rev. No. Customer Date Description Designed by Checked bysprasannaaNo ratings yet

- Is 4894 1987Document18 pagesIs 4894 1987sajay2010No ratings yet

- Astm A48Document6 pagesAstm A48Santiago RamosNo ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Vertical MultiStage Pump Data SheetDocument6 pagesVertical MultiStage Pump Data Sheetسمير البسيونى100% (1)

- Ledeen Actuator General Catalogue - Entire LineDocument24 pagesLedeen Actuator General Catalogue - Entire LineJair LamasNo ratings yet

- Corken Compresores Amoniaco PDFDocument100 pagesCorken Compresores Amoniaco PDFNicolas BurgosNo ratings yet

- 06-Klitzke Sidwell Jensen Presentation Part 123Document89 pages06-Klitzke Sidwell Jensen Presentation Part 123Nguyễn Thanh TùngNo ratings yet

- ASME B31.3 Chapter IX-An Insight Into The Basis of Various Technical RequirementsDocument10 pagesASME B31.3 Chapter IX-An Insight Into The Basis of Various Technical Requirementsعبد اللهNo ratings yet

- BPCL Training ReportDocument34 pagesBPCL Training ReportVishalVaishNo ratings yet

- Asme Section II A-2 Sa-453 Sa-453mDocument10 pagesAsme Section II A-2 Sa-453 Sa-453mAnonymous GhPzn1xNo ratings yet

- Rotary Valve Selector Guide PDFDocument28 pagesRotary Valve Selector Guide PDFtradehouseNo ratings yet

- BS 1306 1975 Copper - Copper Alloy Pressure Piping YstemDocument14 pagesBS 1306 1975 Copper - Copper Alloy Pressure Piping YstemFenner Electromechanical0% (1)

- All About ImpellersDocument9 pagesAll About ImpellersMohammad RizwanNo ratings yet

- P04 - General Arrangement Drawings.Document1 pageP04 - General Arrangement Drawings.bmanojkumar16No ratings yet

- Is 3224 2002Document47 pagesIs 3224 2002suresh kumar100% (1)

- Wall Thickness Calculation-12 InchDocument23 pagesWall Thickness Calculation-12 InchChirag ShahNo ratings yet

- Cti Atp 105Document12 pagesCti Atp 105swatantar17100% (2)

- Special Process Items - Excerpt From Mihir's HandbookDocument17 pagesSpecial Process Items - Excerpt From Mihir's HandbookPedrito CalapuchaNo ratings yet

- BB1 Vs BB2Document1 pageBB1 Vs BB2bomthanhphuNo ratings yet

- Presentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurDocument29 pagesPresentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurdeepchotiNo ratings yet

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- Feed Pump, HDA PumpDocument49 pagesFeed Pump, HDA Pumpscploperation.2x50 CommonNo ratings yet

- Comp Shell Heat Transffer Oil S2 and Servo Therm SDocument1 pageComp Shell Heat Transffer Oil S2 and Servo Therm SarghyadeepjanaNo ratings yet

- Ductile Iron Castings: Standard Specification ForDocument6 pagesDuctile Iron Castings: Standard Specification ForLuis F. LoachamínNo ratings yet

- Boiler O&M - DESCONDocument218 pagesBoiler O&M - DESCONppraveenkumar79100% (1)

- Selection of Gasket MaterialsDocument6 pagesSelection of Gasket MaterialsswatkoolNo ratings yet

- GTM-COM-SA-DS-0004-08 - Fire Water PumpDocument4 pagesGTM-COM-SA-DS-0004-08 - Fire Water PumpFranscois Van RooyenNo ratings yet

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishNo ratings yet

- HK 40Document2 pagesHK 40hawyegNo ratings yet

- Chemistry and Metallurgy: Second Revised and Enlarged EditionFrom EverandChemistry and Metallurgy: Second Revised and Enlarged EditionA. SherryNo ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Current Advances in Mechanical Design & Production IV: Proceedings of the Fourth Cairo University MDP Conference, Cairo, 27-29 December 1988From EverandCurrent Advances in Mechanical Design & Production IV: Proceedings of the Fourth Cairo University MDP Conference, Cairo, 27-29 December 1988Y. H. KabilNo ratings yet

- Forest Product Conversion FactorsFrom EverandForest Product Conversion FactorsNo ratings yet

- Asme Sec Viii D3 Art KD-1Document12 pagesAsme Sec Viii D3 Art KD-1Boz Van DuynNo ratings yet

- Asme Sec Viii D1 C PT Ucl PDFDocument7 pagesAsme Sec Viii D1 C PT Ucl PDFsuraj kumarNo ratings yet

- 11 ASME Secc VIII Part UCL Requirements For Welded Pressure Ves PDFDocument7 pages11 ASME Secc VIII Part UCL Requirements For Welded Pressure Ves PDFAnthony Bare Huané SalcedoNo ratings yet

- Application of Bearings: Buyers GuideDocument46 pagesApplication of Bearings: Buyers Guidekcp1986No ratings yet

- Kirloskar Brothers Limited: Cross Section Assembly of Pump KPD 25/16Qf inDocument2 pagesKirloskar Brothers Limited: Cross Section Assembly of Pump KPD 25/16Qf inkcp1986No ratings yet

- 2 Basic Principles: 2.1 Hydro Energy Potential, Flash and DecreaseDocument10 pages2 Basic Principles: 2.1 Hydro Energy Potential, Flash and Decreasekcp1986No ratings yet

- Steam Engine Valves and Reversing Gears: Theory of MachinesDocument41 pagesSteam Engine Valves and Reversing Gears: Theory of Machineskcp1986No ratings yet

- Planning, Preparation, and Implementation of Turbomachinery Turnarounds by Robert W. Parker Douglas H. CollierDocument10 pagesPlanning, Preparation, and Implementation of Turbomachinery Turnarounds by Robert W. Parker Douglas H. Collierkcp1986No ratings yet

- Appendix: Standard Pipe SizesDocument7 pagesAppendix: Standard Pipe Sizesmepatel79No ratings yet

- Piping Ebook by Atul Singla (Mobile Version) PDFDocument153 pagesPiping Ebook by Atul Singla (Mobile Version) PDFKalaiYarasanNo ratings yet

- Crude Storage Tanks Rev.CDocument9 pagesCrude Storage Tanks Rev.CdhahiNo ratings yet

- Design Problem and SolutionDocument36 pagesDesign Problem and SolutionAndrew Bien100% (1)

- Mason Seismic-Restraint-Guidelines (Pipe Weights)Document6 pagesMason Seismic-Restraint-Guidelines (Pipe Weights)Onur ONARNo ratings yet

- Piping Design Layout and Stress AnalysisDocument19 pagesPiping Design Layout and Stress AnalysisSolomon EmavwodiaNo ratings yet

- Dimensions of Spiral Wound Gaskets ASME B16Document3 pagesDimensions of Spiral Wound Gaskets ASME B16Almir PendekNo ratings yet

- Conexiones Soldables Catalog 63 English MetricDocument186 pagesConexiones Soldables Catalog 63 English MetricManuel CastroNo ratings yet

- Solidworks Toolbox TutorialDocument3 pagesSolidworks Toolbox TutorialrobbyNo ratings yet

- Burkert Type2000, PneumaticDocument29 pagesBurkert Type2000, PneumaticGL Thiết Bị Công NghiệpNo ratings yet

- MSS SP-42-2009Document17 pagesMSS SP-42-2009Manual Source100% (1)

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- Design Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Document22 pagesDesign Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Muhammad.SaimNo ratings yet

- Black Seamless Carbon Steel PipeDocument4 pagesBlack Seamless Carbon Steel PipeTarek AlmahdyNo ratings yet

- Abbreviations For PipingDocument9 pagesAbbreviations For PipingKrishnamoorthyNo ratings yet

- Astm A105 2014Document5 pagesAstm A105 2014duvanp92No ratings yet

- MSS SP 97 01Document15 pagesMSS SP 97 01Allan SousaNo ratings yet

- Nor-Par A.s: Chemcad 7.1.2 - User-Defined Pipe Schedules For The "Pipe" Unit OperationDocument12 pagesNor-Par A.s: Chemcad 7.1.2 - User-Defined Pipe Schedules For The "Pipe" Unit OperationidmNo ratings yet

- Carbon Steel Forgings For Piping ApplicationsDocument5 pagesCarbon Steel Forgings For Piping ApplicationsMaki Salim HussainNo ratings yet

- Image Sp100Document99 pagesImage Sp100Almacen SertecNo ratings yet

- Astm A53-A53m-12Document23 pagesAstm A53-A53m-12abidaliabid1100% (2)

- Anson Forged Manifold FittingsDocument2 pagesAnson Forged Manifold FittingsEduardo RateikeNo ratings yet

- Steam Injectors ARI CONA 651Document2 pagesSteam Injectors ARI CONA 651CalinNo ratings yet

- 560 000 GD P 007 - 1Document243 pages560 000 GD P 007 - 1Juan TorresNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- Pipeline Design BasisDocument51 pagesPipeline Design Basisgv gowrav100% (2)

- Process Industry Practices PipingDocument4 pagesProcess Industry Practices PipingjojonNo ratings yet