Professional Documents

Culture Documents

QT 16Cr Technical Data Sheet

Uploaded by

hafsaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QT 16Cr Technical Data Sheet

Uploaded by

hafsaCopyright:

Available Formats

QT-16Cr Technical Data Sheet

As supplied, QT-16Cr may contain tube-to-tube welds and is not manufactured as Flash-Free or TRUE-TAPERTM. QT-16Cr is manufactured

from a nitrogen-strengthened austenitic stainless steel. The chemical requirements of QT-16Cr parent tubing will meet the chemical

requirements of UNS S20400.

Mechanical Properties

Minimum Yield Strength, psi (MPa) 90,000 (621)

Minimum Tensile Strength, psi (MPa) 110,000 (758)

Minimum Elongation 35%

Maximum Hardness 38 HRC

Technical Data

Specified

Outside Wall Calculated Inside Plain End Mass, Pipe Metal Cross Pipe Body Yield Internal Yield *Hydro Test Torsional

Tensile Load, LT

Diameter, D Thickness, t Diameter, d Mpe Sectional Area, A Load, Ly Pressure, Pr Pressure, P T Yield Strength, Tf

in mm in mm in mm lb/ft kg/m in2 mm2 lb kg lb kg psi MPa psi MPa ft-lb N-m

1¼ 31.8 0.109 2.8 1.032 26.2 1.330 1.979 0.391 252 35,160 15,950 42,980 19,500 14,980 103 9,600 66.1 890 1,210

1½ 38.1 0.109 2.8 1.282 32.5 1.621 2.412 0.476 307 42,870 19,450 52,400 23,770 12,480 86 8,000 55.1 1,340 1,820

1½ 38.1 0.145 3.7 1.210 30.7 2.100 3.126 0.617 398 55,530 25,180 67,870 30,780 16,800 115 13,400 68.3 1,650 2,230

1¾ 44.5 0.109 2.8 1.532 38.9 1.912 2.846 0.562 362 50,570 22,940 61,810 28,040 10,700 73 6,800 47.2 1,880 2,550

1¾ 44.5 0.145 3.7 1.460 37.1 2.488 3.707 0.731 472 65,790 29,830 80,410 36,460 14,400 99 11,500 58.5 2,340 3,170

1¾ 44.5 0.188 4.8 1.374 34.9 3.139 4.672 0.923 595 83,030 37,660 101,480 46,030 18,820 129 12,000 83.1 2,820 3,820

2 50.8 0.145 3.7 1.710 43.4 2.875 4.280 0.845 545 76,050 34,480 92,950 42,150 12,600 86 10,000 51.2 3,160 4,280

2 50.8 0.188 4.8 1.624 41.2 3.642 5.420 1.070 690 96,320 43,690 117,720 53,400 16,470 113 10,500 72.7 3,840 5,210

2⅜ 60.3 0.145 3.7 2.085 52.9 3.457 5.142 1.016 655 91,440 41,460 111,760 50,680 10,610 73 8,400 43.1 4,620 6,260

2⅜ 60.3 0.188 4.8 1.999 50.7 4.395 6.542 1.292 833 116,250 52,730 142,090 64,450 13,870 95 8,900 61.2 5,670 7,690

2⅞ 73.0 0.188 4.8 2.499 63.4 5.400 8.037 1.587 1,023 142,830 64,790 174,570 79,180 11,460 79 7,500 51.5 8,670 11,750

A Minimum wall thickness is 0.005" (0.13 mm) less than specified wall thickness. C Maximum hydrostatic test pressure is 15,000 psi (103 MPa).

B Pressures calculated based on t – 0.005" (0.13 mm). D Additional diameters and wall thicknesses may be available upon request.

* Assumes 64% specified minimum yield strength

Disclaimer: Coiled tubing grades and related information are provided for general information dissemination purposes only. All reasonable efforts were made to ensure the accuracy of all such information,

but Quality Tubing makes no representation and gives no warranty with respect to the validity or fitness of such information for any particular customer’s coiled tubing operations. The customer

acknowledges that any use or interpretation of this information is at his own risk.

qualitytubing@nov.com nov.com/qualitytubing

© 2016 National Oilwell Varco - All Rights Reserved - 11056_ENG_v01

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Mechanical Properties: QT-900 Technical Data SheetDocument2 pagesMechanical Properties: QT-900 Technical Data SheetIshmael WoolooNo ratings yet

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- Aplisens PEM-1000Document4 pagesAplisens PEM-1000CalcRodVerNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- 20CV321-MOS-Kaware AkshayDocument68 pages20CV321-MOS-Kaware AkshayYashvardhan TodmalNo ratings yet

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Document2 pages1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNo ratings yet

- Catalogue Wire StrandDocument18 pagesCatalogue Wire StrandbronsenwijayaNo ratings yet

- Test Report CP16-210 - Y5K23F2515 PSIDocument1 pageTest Report CP16-210 - Y5K23F2515 PSIDieguin SuárezNo ratings yet

- Bolt Torque Chart FAQs: Tension vs. Torque, Torque Charts & Anchor BoltsDocument7 pagesBolt Torque Chart FAQs: Tension vs. Torque, Torque Charts & Anchor BoltsRuben GutierrezNo ratings yet

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- 20CV080 MOS Navnath PandharmiseDocument41 pages20CV080 MOS Navnath PandharmiseYashvardhan TodmalNo ratings yet

- Technical information on tensile strength, tightening torque and stainless steelDocument13 pagesTechnical information on tensile strength, tightening torque and stainless steelAngelo PereiraNo ratings yet

- BS5467 PVC CableDocument1 pageBS5467 PVC CableJuan AdrianzenNo ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- DESIGN OF TWO WAY SLABDocument3 pagesDESIGN OF TWO WAY SLABSyeda NafeezaNo ratings yet

- Mediumvoltage 1Document41 pagesMediumvoltage 1Yolanda Leah UrbanoNo ratings yet

- Aquarius+ UPVC Industrial Pipe & FittingsDocument16 pagesAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNo ratings yet

- 5 - Offshore Wire - RopesDocument8 pages5 - Offshore Wire - RopesSuelen BarbosaNo ratings yet

- Torque ChartDocument1 pageTorque Chartjyoti prakash singhNo ratings yet

- Welded Bollard ISO 3913 PDFDocument2 pagesWelded Bollard ISO 3913 PDFbintang heruNo ratings yet

- Welded Bollard ISO 3913Document2 pagesWelded Bollard ISO 3913fredy2212No ratings yet

- Welded Bollard PDFDocument2 pagesWelded Bollard PDFZainul Arifin FatahillahNo ratings yet

- anexala0117s3021r_30373_45_1710210153Document2 pagesanexala0117s3021r_30373_45_1710210153Valcu GabrielNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Transformer DesignDocument8 pagesTransformer DesignAzminAg100% (1)

- Process Datasheet For Relief ValveDocument3 pagesProcess Datasheet For Relief Valvemadhu8087No ratings yet

- IWF Wide Flange Steel Beams GuideDocument4 pagesIWF Wide Flange Steel Beams GuideandNo ratings yet

- Spec25051 - Teck CableDocument4 pagesSpec25051 - Teck Cablecrfg2003No ratings yet

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- Bare Overhead Conductors-2015Document63 pagesBare Overhead Conductors-2015Weber HahnNo ratings yet

- GT DURACOIL 130 DATASHEET US 3-22 v2Document3 pagesGT DURACOIL 130 DATASHEET US 3-22 v2Ahmed BenayadNo ratings yet

- KabelmetaDocument1 pageKabelmetaLinda Soraya SeptianaNo ratings yet

- Nyy - Iec PDFDocument5 pagesNyy - Iec PDFbenryNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- Label Type Diameter A B C D e Jumlah BatangDocument34 pagesLabel Type Diameter A B C D e Jumlah BatangSteffi StevanieNo ratings yet

- Chain Din766 PDFDocument5 pagesChain Din766 PDFMiguelRagas100% (1)

- RTD Thermistor Z202030 0NDocument1 pageRTD Thermistor Z202030 0NcesarNo ratings yet

- PT. Mulya Adhi Paramita Certificate of AnalysisDocument5 pagesPT. Mulya Adhi Paramita Certificate of AnalysisRistian Agil Yan SagilNo ratings yet

- Average TZDocument4 pagesAverage TZErwinNo ratings yet

- American Wire Gauge Conductor Size TableDocument6 pagesAmerican Wire Gauge Conductor Size TableGaming PCNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- Omni GearDocument198 pagesOmni GearCong Han NguyenNo ratings yet

- 58 Lpg-Aaa A2016 SrreportDocument122 pages58 Lpg-Aaa A2016 SrreportCire Lop CastroNo ratings yet

- Experiment #1 Raynold Number Flow CharacteristicsDocument7 pagesExperiment #1 Raynold Number Flow CharacteristicsMir Masood ShahNo ratings yet

- P-17531Document1 pageP-17531etaferaw beyeneNo ratings yet

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 pagesAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98No ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- Specifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Document3 pagesSpecifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Manish StauffenbergNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- vatan cable datasheetDocument4 pagesvatan cable datasheetolcayNo ratings yet

- Electromagnetic CatalogueDocument4 pagesElectromagnetic Cataloguetechhustler2No ratings yet

- SonnenscheinDocument1 pageSonnenscheinelard cardenasNo ratings yet

- Well Control Homework HandoutDocument1 pageWell Control Homework HandouthafsaNo ratings yet

- Coiled Tubing Manufacturing Homwork HandoutDocument4 pagesCoiled Tubing Manufacturing Homwork HandouthafsaNo ratings yet

- اساسيات الهيدروليك PDFDocument221 pagesاساسيات الهيدروليك PDFMahmoud ElemamNo ratings yet

- Coiled Tubing Calculation Homework HandoutDocument6 pagesCoiled Tubing Calculation Homework HandouthafsaNo ratings yet

- Snaptite PDFDocument113 pagesSnaptite PDFLider F CohaNo ratings yet

- Coil Tubing Manual NOV PDFDocument913 pagesCoil Tubing Manual NOV PDFMaria Camila Laguado100% (1)

- DART ManualDocument25 pagesDART ManualBrayan ONo ratings yet

- 10128688-400-EnG-MKT41-02 - Coiled Tubing Tools Catalog - Distribution FileDocument100 pages10128688-400-EnG-MKT41-02 - Coiled Tubing Tools Catalog - Distribution Filetao.han100% (1)

- National Power Corporation vs Philipp Brothers Oceanic Ruling on Moral DamagesDocument2 pagesNational Power Corporation vs Philipp Brothers Oceanic Ruling on Moral DamagesRandy SiosonNo ratings yet

- Yct Rrb Math 2024 (Eng)Document897 pagesYct Rrb Math 2024 (Eng)Digital WorldNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Assignment For LawDocument9 pagesAssignment For LawFeroze IshtiaqueNo ratings yet

- Digital Transducers: Group 3Document76 pagesDigital Transducers: Group 3Jasmine RaiNo ratings yet

- 9211 4 PR PE Utility Industry Low Product Range 2017Document226 pages9211 4 PR PE Utility Industry Low Product Range 2017Soporte SyeNo ratings yet

- Inglés C2 Corrector Septiembre 2021Document11 pagesInglés C2 Corrector Septiembre 2021CRISTINA MARTINEZ SANCHEZNo ratings yet

- Republic vs. Roque - JD1ADocument4 pagesRepublic vs. Roque - JD1AQueenie Boado100% (1)

- Measuring The Sustainability of Urban Water ServicesDocument10 pagesMeasuring The Sustainability of Urban Water ServicesWalter RodríguezNo ratings yet

- MSG 01084Document4 pagesMSG 01084testiandiniNo ratings yet

- Thk2e BrE L3 Vocabulary Standard Unit 3Document2 pagesThk2e BrE L3 Vocabulary Standard Unit 3Suki ChuahNo ratings yet

- Final Investigative Report - MaSUDocument4 pagesFinal Investigative Report - MaSUinforumdocsNo ratings yet

- Volume 7 Issue 4Document12 pagesVolume 7 Issue 4thestuyvesantstandardNo ratings yet

- UI UX Research DesignDocument7 pagesUI UX Research DesignSomya ShrivastavaNo ratings yet

- 10 Days 7 NightsDocument5 pages10 Days 7 NightsSisca SetiawatyNo ratings yet

- If An Existing Amazon Account Exists For Your Work Email Address, Skip To Step 4Document3 pagesIf An Existing Amazon Account Exists For Your Work Email Address, Skip To Step 4ThaiNo ratings yet

- Chapter OneDocument14 pagesChapter Oneogunseyeopeyemi2023No ratings yet

- Notaries Act 1999 rules for Dutch notariesDocument45 pagesNotaries Act 1999 rules for Dutch notariesAnt1603No ratings yet

- BABOK V3 10. Glossary PDFDocument16 pagesBABOK V3 10. Glossary PDFAakash ChhibberNo ratings yet

- EI2 Public Benefit Organisation Written Undertaking External FormDocument1 pageEI2 Public Benefit Organisation Written Undertaking External Formshattar47No ratings yet

- 121-Ugong Issue 5.2 - FINAL - Doc - With Corrections-2nd RevisionDocument16 pages121-Ugong Issue 5.2 - FINAL - Doc - With Corrections-2nd RevisionMarq QoNo ratings yet

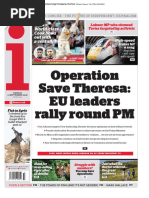

- The I NewspaperDocument60 pagesThe I Newspaperfagner barretoNo ratings yet

- Baranda v. GustiloDocument2 pagesBaranda v. GustiloRiena MaeNo ratings yet

- Health 10 Performance TaskDocument4 pagesHealth 10 Performance TaskMary Kryss DG SangleNo ratings yet

- BIM Implementation - Brenner Base Tunnel ProjectDocument10 pagesBIM Implementation - Brenner Base Tunnel ProjectHichemNo ratings yet

- Gmail - DFA Passport Appointment System - Confirmation Notification PDFDocument2 pagesGmail - DFA Passport Appointment System - Confirmation Notification PDFGarcia efrilNo ratings yet

- Radiant Heating and Cooling SystemDocument8 pagesRadiant Heating and Cooling SystemLaurentiuNo ratings yet

- Addition Polymerization: PolymerDocument3 pagesAddition Polymerization: PolymerSVNo ratings yet

- ODMP Hydrology and Water Resources Inception ReportDocument68 pagesODMP Hydrology and Water Resources Inception ReportAse JohannessenNo ratings yet