Professional Documents

Culture Documents

ACS-SP-MODU Special Survey of Hull & Structure

Uploaded by

saeed ghafooriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACS-SP-MODU Special Survey of Hull & Structure

Uploaded by

saeed ghafooriCopyright:

Available Formats

Service Specification of

MODU Special Survey of Hull & Structure

General & Close Visual Inspection,

Thickness Measurement

Asia Classification Society

No.31, 5th St. , North Kargar Ave.

Tehran-Iran Tel: +98 (21) 84396

www.asiaclass.org

Copyright © 2020 ACS

Revision 1 , 13 October 2020, Issues for Approval

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

From its foundation in 2005, supported by 25 (from 1980) years practical and technical

experiences of its originators IBS (Iranian Bureau of Shipping) and IGS (Iranian Group of

Surveyors), promoting maritime safety has been the core commitment of the Asia

classification society and today, we strive to be the most efficient provider of marine and

offshore classification services and oil and gas inspection in Iran and also in middle east. We

are achieving that goal through the innovative thinking, enthusiasm and professionalism of

our staff.

At ACS, setting standards of excellence in marine and offshore classification in

Islamic Republic of Iran and Middle East is more than a motto. It is the way we

conduct our business and improvement.

We put our mission to serve the public interest as well as the needs of our clients

by promoting the security of life and property and preserving the natural

environment.

Asia classification society after successful implementation of ISO9001-2017,

according to its development strategy has been awarded by ISO/IEC17020 certificate,

causing great development in its services especially in industrial, oil and energy

market.

ACS Offshore Services

Page 2 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Table of Contents

Provisions for Hull Survey ................................................... 5

GENERAL...................................................................................... 5

Definition ..................................................................................... 5

Ballast Tank ................................................................... 5

Preload Tank .................................................................. 5

Spaces .......................................................................... 6

Coating Condition ............................................................ 6

Close-Up Survey .............................................................. 6

Transverse Section (Girth Belt)............................................. 6

Representative Spaces ....................................................... 6

Critical Structural Area ...................................................... 6

Suspect Area .................................................................. 7

Substantial Corrosion ........................................................ 7

Excessive Diminution ......................................................... 7

Corrosion Prevention System ............................................... 7

Prompt and Thorough Repair ............................................... 7

Special consideration ........................................................ 7

PURPOSE AND SCOPE ....................................................................... 8

Special Survey ................................................................ 8

All Units and Self Elevating Drilling Unit................................................. 8

General Visual Inspection ................................................................ 10

Close Visual Inspection (CVI) ............................................................ 11

Non Destructive Test (NDT).............................................................. 13

Hull Thickness Deasurement ............................................................. 13

Corrosion Control ......................................................................... 13

SURVEY OF THE OUTSIDE OF UNIT'S BOTTOM AND RELATED ITEMS . 14

ACS Offshore Services

Page 3 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Schedule .................................................................................... 14

Parts to be Examined ..................................................................... 14

Surface-type Units (ship or barge type units) .......................... 14

Self-Elevating Units ........................................................ 14

Ballast Spaces.............................................................................. 15

All Units ...................................................................... 15

Surface type units .......................................................... 15

Self elevating units ......................................................... 15

PREPARATION FOR SURVEY ................................................ 16

Conditions for Survey ..................................................................... 16

Access to Structures ...................................................................... 16

Equipment for Survey..................................................................... 17

Survey Offshore or at Anchorage ....................................................... 17

Appendix A · Minimum Requirements for Thickness Measurements for

Special Survey 18

ACS Offshore Services

Page 4 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Provisions for Hull Survey

GENERAL

- The Surveyors are to be provided with necessary facilities for a safe execution of survey.

- The surveys at sea or at anchorages may be carried out provided necessary precautions

are taken while carrying out the survey and adequate assistance is provided.

- Tanks and spaces are to be safe for access, i.e. gas freed, ventilated, etc. Tanks and

spaces are to be reasonably clean and free from water, scale, dirt, oil residues, etc. to

reveal significant corrosion, deformation, fractures, damages and other structural

deterioration.

- Adequate illumination is to be provided to reveal significant corrosion, deformation,

fractures, damages or other structural deterioration.

- Means are to be provided to enable the Surveyor to examine the structure in a safe and

practical way.

- Thickness measurement is normally to be carried out by means of ultrasonic test

equipment. The accuracy of the equipment is to be proven to the Surveyor as required.

- One or more of the following fracture detection procedures may be required if deemed

necessary by the Surveyor:

Radiographic Equipment

Ultrasonic Equipment

Magnetic Particle Equipment

Dye Penetrant

Definition

Ballast Tank

A Ballast Tank is a tank which is used primarily for salt water ballast.

Preload Tank

A Preload Tank is a tank within the hull of a self-elevating unit. These tanks are

periodically filled with salt water ballast and used to preload the footings of the

unit prior to commencing drilling operations. Preload Tanks are considered

equivalent to Ballast Tanks.

ACS Offshore Services

Page 5 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Spaces

Spaces are separated compartments.

Coating Condition

Coating Condition is defined as follows:

GOOD condition with only minor spot rusting

FAIR condition with local breakdown at edges of stiffeners and weld

Connections and/or light rusting over 20% or more of areas under consideration,

but less than as defined for POOR condition

POOR condition with general breakdown of coating over 20% or more of

areas or hard scale at 10% or more of areas under consideration

Close-Up Survey

A Close-Up Survey is a survey where the details of structural components

are within the close visual inspection range of the surveyor i.e. normally

within reach of hand.

Transverse Section (Girth Belt)

A Transverse Section (Girth Belt) includes all continuous longitudinal

members such as plating, longitudinals and girders at a given section of

the unit.

Representative Spaces

Representative Spaces are those which are expected to reflect the conditions

of other spaces of similar type and service and with similar corrosion prevention

systems. When selecting

Representative Spaces, account is to be taken of the service and repair history

on board and identifiable Critical Structural Areas and/or Suspect Areas.

Critical Structural Area

Critical Structural Areas are locations which have been identified from

calculations to require monitoring or from the service history of the subject Unit

ACS Offshore Services

Page 6 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

or from similar Units or sister Units, if applicable, to be sensitive to cracking,

buckling or corrosion which would impair the structural integrity of the Unit.

Suspect Area

Suspect Areas are locations showing Substantial Corrosion and/or are

considered by the Surveyor to be prone to rapid wastage.

Substantial Corrosion

Substantial Corrosion is an extent of corrosion such that assessment of

corrosion pattern indicates a wastage in excess of 75% of allowable

margins, but within acceptable limits.

Excessive Diminution

Excessive Diminution is an extent of corrosion beyond allowable limits.

Corrosion Prevention System

A Corrosion Prevention System is normally considered a full hard protective

coating.

Hard Protective Coating is usually to be epoxy coating or equivalent. Other

coating systems, which are neither soft nor semi-hard coatings, may be

considered acceptable as alternatives provided that they are applied and

maintained in compliance with the manufacturer's specifications.

Prompt and Thorough Repair

A Prompt and Thorough Repair is a permanent repair completed at the time of

survey to the satisfaction of the Surveyor, therein removing the need for the

imposition of any associated condition of classification.

Special consideration

Special consideration or specially considered (in connection with close-up

surveys and thickness measurements) means sufficient close-up inspection and

thickness measurements are to be taken to confirm the actual average condition

of the structure under the coating.

ACS Offshore Services

Page 7 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

PURPOSE AND SCOPE

The examinations of the hull are to be supplemented by thickness measurements

and testing as required, to verify the structural integrity. The aim of the examination

is to discover Excessive Diminution, Substantial Corrosion, significant deformation,

fractures, damages or other structural deterioration, that may be present.

The scope of this document is as follows:

Special Survey

All Units and Self Elevating Drilling Unit

The following parts are to be examined:

- The hull or platform structure including tanks, watertight bulkheads and

deck, cofferdams, void spaces, sponsors, chain lockers, duct keels, helicopter

deck and its supporting structure, machinery spaces, peak spaces, steering

gear spaces, and all other internal spaces are to be examined externally and

internally for damage, fractures, or excessive diminution. Thickness gauging

of plating and framing may be required where wastage is evident or

suspected.

- All tanks, compartments and free-flooding spaces throughout the drilling unit

are to be examined externally and internally for excess wastage or damage.

- Internal examinations of spud cans and mats may be specially considered.

- Watertight integrity of tanks, bulkheads, hull, decks and other compartments

is to be verified by visual inspection.

- Suspect areas and critical structural areas should be examined and may be

required to be tested for tightness, non-destructive tested or thickness

gauged.

- All special and primary application structures (as defined in IACS

Recommendation No.11) and identified critical structural areas are to be

subjected to Close up survey.

- Tanks and other normally closed compartments are to be ventilated, gas

freed and cleaned as necessary to expose damages and allow meaningful

examination and thickness gauged in case of excessive diminution.

ACS Offshore Services

Page 8 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

- Internal examination and testing of void spaces, compartments filled with

foam or corrosion inhibitors, and tanks used only for lube oil, light fuel oil,

diesel oil, fresh water, drinking water or other non-corrosive products may

be waived provided that upon a general examination the Surveyor considers

their condition to be satisfactory. External thickness gauging may be required

to confirm corrosion control.

- Structures such as derrick substructure and supporting structure, jack-

houses, deck houses, superstructures, helicopter landing areas, raw water

(sea water intake) towers and their respective attachments to the deck or

hull.

- Windlass and attachments of anchor racks and anchor cable fairleads.

- Foundations and supporting headers, brackets, and stiffeners for drilling

related apparatus, where attached to hull, deck, superstructure or deck

house.

- Thickness gauging are to be carried out where wastage is evident or suspect.

- Where provided, the condition of corrosion prevention system of ballast tanks

is to be examined. Where a hard protective coating is found in POOR condition

and it is not renewed, where soft or semi-hard coating has been applied, or

where a hard protective coating was not applied from time of construction,

the tanks in question are to be examined at a frequency determined by the

classification society. Thickness measurements are to be carried out as

deemed necessary by the Surveyor.

- Thickness measurements are to be carried out in accordance with Appendix

B, tables 1, 2 or 3 as applicable. The Surveyor may extend the thickness

measurements as deemed necessary. When thickness measurements indicate

substantial corrosion, the

- extent of thickness measurements is to be increased to determine areas of

substantial corrosion. Table 4 of Appendix B may be used as guidance for

these additional thickness measurements. These extended thickness

measurements are to be carried out before the survey is credited as

completed.

ACS Offshore Services

Page 9 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

In addition to the requirements of the following items are to be examined:

- All legs, including chords, diagonal and horizontal braces, gussets, racks,

joints, together with leg guides. Tubular or similar type legs are to be examined

externally and internally, together with internal stiffeners and pinholes as

applicable.

- Structure in, around and under jack-house and leg wells. Non-destructive

testing of these areas may be required.

- Leg jacking or other elevating systems externally.

- Leg connections to bottom mats or spud cans, including non-destructive

testing of leg connections to mats or spud cans.

- Jetting piping systems or other external piping, particularly where penetrating

mats or spud cans.

- Spud cans or mats. Where the spud cans or mat are partly or entirely

obscured below the mud line where the Special Survey is otherwise being

completed, consideration may be given to postponement of the examinations

until the next Rig move.

- Column-Stabilized Units

- In addition to the requirements of 2.3.1 the following items are to be examined:

- • Connections of columns and diagonals to upper hull, structure or platform

and lower hull, structure or pontoons. Joints of supporting structure including

diagonals, braces and horizontals, together with gussets and brackets.

Internal continuation or back-up structure for the above. Non-destructive

examination may be required of these areas.

General Visual Inspection

- The hull or platform structure, including tanks, watertight bulkheads and

decks, cofferdams, void spaces, sponsons, chain lockers, duck keels,

helicopter pad, machinery spaces, peak spaces, and all other internal spaces,

are to be subjected to General Visual Inspection ;GVI externally and

internally for damage, fractures or excessive wastage. Thickness gauging of

plating and framing may be required where wastage is evident or suspected.

- Hull Attachments of Anchoring and Mooring System. Attachments of anchor

racks, anchor cable fairleads, and anchor windlasses are to be examined.

- Hull Attachments of Drilling Apparatus. &oundations and supporting headers,

brackets and stiffeners for drilling‐related apparatus, where attached to hull,

deck, superstructure or deck house.

ACS Offshore Services

Page 10 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

- Hull Attachments of other Structures. Structures such as derrick substructure

and supporting structure, skid‐base structure, jack houses, pipe racks, deck

houses, superstructures, helicopter landing areas, raw water ;seawater

intake towers and their respective attachments to the deck or hull.

- Bulkheads designated as primary application structures.

- Legs

o All legs, including chords, braces, diagonals, gussets, racks, joints,

together with leg guides are to be examined.

o On rigs with tubular or similar type legs, the legs are to be examined

externally and internally, together with internal stiffeners and

pinholes, as applicable.

o The extent of GVI may be limited to legs in way of the splash zone.

- Jack‐House and Leg Wells

o Structure in, around and under jack‐houses and leg wells.

- Leg Jacking or other Elevating Systems

o Leg jacking or other elevating systems externally.

- Jetting Piping System

o Jetting piping systems or other external piping, particularly where

penetrating mats or spud cans.

- Spud Cans or Mats

o Internal and external examination of spud cans or mat.

- Note: Spud cans and other bottom spaces subject to contact with, or

accumulation of, bottom soil should be thoroughly ventilated and carefully

monitored for pocketing or emission of hazardous gases prior to, and during,

internal inspection.

Close Visual Inspection

All special and primary application structures and identified critical structural areas

are to be subjected to extensive CVI.

The following is an outline of some of the areas that will be subjected to CVI:

ACS Offshore Services

Page 11 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

- Leg‐to‐spudcan connections plus 2 bays of leg above the top of the spudcan

Note: All leg‐to‐spudcan connections plus 2 bays of leg above the top of the spudcan and

associated structure are to be subjected to 100A CVI.

- Jackhouse/jackcase‐to‐deck connections

- Brace‐to‐chord connection in areas of leg that have been predominately in

way of the upper and lower guides

Note: Areas in way of the upper guides are to be examined and subjected to NDT to identify

any damage resultant from towing the drilling unit with its legs elevated. Areas in way of the

lower guides are to be examined and subjected to NDT to identify any damage as a

consequence of operating in the elevated/drilling mode.

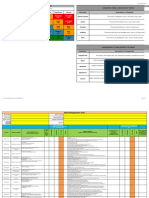

- As a visual guidance fiigure 1 illustrates some of the typical primary

application structures in way of leg‐to‐spud can connections that may be

subjected to CVI and NDT.

Figure 1

ACS Offshore Services

Page 12 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Non Destructive Test (NDT)

- To supplement this CVI if suspect or considered necessary by the Surveyor

random NDT of associated welds may be carried out to extent deemed

necessary by the Surveyor.

- The following is an outline of some of the areas that will be subjected to CVI:

- A Leg‐to‐spudcan connections plus 2 bays ;to extent deemed necessary

by the Surveyor of leg above the top of the spudcan

Note: All leg‐to‐spudcan connections plus 2 bays of leg above the top of the spudcan and

associated structure are to be subjected to 100A NDT.

- Jackhouse/jackcase‐to‐deck connections

- Brace‐to‐chord connection in areas of leg that have been predominately in

way of the upper and lower guides

Note: Areas in way of the upper guides are to be examined and subjected to NDT to identify

any damage resultant from towing the drilling unit with its legs elevated. Areas in way of the

lower guides are to be examined and subjected to NDT to identify any damage as a

consequence of operating in the elevated/drilling mode.

- If any defect found during the initial NDT or considered suspect by the

attending Surveyor NDT may be extended to other areas or leg joints.

Hull Thickness Measurement

- Gauging reports completed by the ACS approved external specialists and endorsed by

the Surveyor are to be maintained as a permanent record of the drilling unit and be

readily available to the attending Surveyors during subsequent periodical surveys of the

hull.

Corrosion Control

If coating condition of special application structures is found to be in "Poor" condition,

internal surfaces of such structures are to be subjected to CVI and gauging to the extent

deemed necessary by the attending Surveyor.

Where gauging results indicate "Substantial Corrosion" and no immediate structural

repair is carried

ACS Offshore Services

Page 13 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

out before completion of this Special Periodical Survey, the corroded areas are to be

subjected to extensive GVI, CVI and Gauging, during subsequent Annual Surveys.

In addition where gauging results indicate a global “Substantial corrosion” and

no immediate

structural repair is carried out before completion of this Special Periodical Survey the

Surveyor may also require global strength analysis to be verified by ABS engineering

before crediting the Special Periodical Survey – Hull.

SURVEY OF THE OUTSIDE OF UNIT'S BOTTOM AND

RELATED ITEMS

Schedule

There is to be a minimum of two examinations of the outside of the unit's bottom

and related items during each five-year special survey period. One such

examination is to be carried out in conjunction with the special survey. In all cases

the interval between any two such examinations is not to exceed 36 months. For

units operating in salt water for less than six (6) months each year, the survey

interval may be increased by the Society.

Consideration may be given at the discretion of the Society, to any

special circumstances justifying an extension of the interval.

Proposals for alternative means of examining the unit's bottom and related items

while afloat may be considered, provided they are in general agreement with

Appendix A.

Parts to be Examined

Surface-type Units (ship or barge type units)

- External surfaces of the hull, keel, stem, stern frame, rudder, nozzles, and sea

strainers are to be selectively cleaned to the satisfaction of the attending

Surveyor and examined together with appendages, the propeller, exposed

parts of stern bearing assembly, rudder pintle and gudgeon securing

arrangements, sea chest and strainers, and their fastenings.

Self-Elevating Units

- External surfaces of the upper hull or platform, spud cans, mat, underwater

areas of legs, together with their connections as applicable, are to be

ACS Offshore Services

Page 14 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

selectively cleaned to the satisfaction of the attending Surveyor and

examined.

- At each Drydocking Survey or equivalent, after Special Survey No. 2, the

Surveyor is to be satisfied with the condition of the internal structure of the mat

or spud cans. Leg connections to mat and spud cans are to be examined at

each Drydock Survey or equivalent. Non-destructive testing may be required

of areas considered to be critical by the Society or found to be suspect by the

Surveyor.

Ballast Spaces

In conjunction with Drydocking Surveys (or equivalent) after Special Survey No. 1

and between subsequent Special Surveys, the following ballast spaces are to be

internally examined, thickness gauged, placed in satisfactory condition as found

necessary,

reported upon. If such examination reveals no visible structural defects, the

examination may be limited to a verification that the corrosion prevention

arrangements remain effective.

All Units

Particular attention is to be given to corrosion prevention systems in ballast

spaces, free- flooding areas and other locations subjected to sea water from both

sides.

Surface type units

One peak tank and at least two other representative ballast tanks between the

peak bulkheads used primarily for water ballast.

Self elevating units

Representative ballast tanks or free-flooding compartments in mat or spud cans,

if accessible, and at least two representative hull pre-load tanks.

ACS Offshore Services

Page 15 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

PREPARATION FOR SURVEY

Conditions for Survey

- The Owner is to provide the necessary facilities for a safe execution of the

survey. For confined space entry, the requirements of IACS Procedural

Requirement PR37 should be followed.

- Tanks and spaces are to be safe for access, i.e. gas freed, ventilated and

illuminated.

- In preparation for survey and thickness measurements and to allow for a

thorough examination, all spaces are to be cleaned including removal from

surfaces of all loose accumulated corrosion scale. Spaces are to be

sufficiently clean and free from water, scale, dirt, oil residues etc. to reveal

corrosion, deformation, fractures, damages, or other structural deterioration.

However, those areas of structure whose renewal has already been decided

by the Owner need only be cleaned and descaled to the extent necessary to

determine the limits of the areas to be renewed.

- Sufficient illumination is to be provided to reveal corrosion, deformation,

fractures, damages or other structural deterioration.

- Where soft or semi-hard coatings have been applied, safe access is to be

provided for the surveyor to verify the effectiveness of the coating and to

carry out an assessment of the conditions of internal structures which may

include spot removal of the coating. When safe access cannot be provided,

the soft or semi-hard coating is to be removed.

Access to Structures

- For survey, means are to be provided to enable the surveyor to

examine the hull structure in a safe and practical way.

- For survey in void compartments and water ballast tanks, one or more of

the following means for access, acceptable to the Surveyor, is to be

provided:

• permanent staging and passages through structures;

• temporary staging and passages through structures;

• lifts and movable platforms;

• boats or rafts;

• other equivalent means.

ACS Offshore Services

Page 16 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Equipment for Survey

- Thickness measurement is normally to be carried out by means of ultrasonic

test equipment. The accuracy of the equipment is to be proven to the Surveyor

as required. Thickness measurements are to be carried out by a firm approved

by the society.

- One or more of the following fracture detection procedures may be required

if deemed necessary by the Surveyor:

• radiographic equipment;

• ultrasonic equipment;

• magnetic particle equipment;

• dye penetrant.

Other acceptable NOT Techniques.

Survey Offshore or at Anchorage

- Survey offshore or at anchorage may be accepted provided the Surveyor is

given the necessary assistance from the personnel onboard.

- A communication system is to be arranged between the survey party in the

tank or space and the responsible officer on deck. This system must also

include the personnel in charge of ballast pump handling if boats or rafts

are used.

- When boats or rafts are used, appropriate life jackets are to be available for all

participants. Boats or rafts are to have satisfactory residual buoyancy and

stability even if one chamber is ruptured. A safety checklist is to be provided.

- Surveys of tanks by means of boats or rafts may only be undertaken at

the sole discretion of the Surveyor, who is to take into account the safety

arrangements provided, including weather forecasting and ship response

in reasonable sea conditions.

Note: Reference is made to IACS Recommendation 39 - Guidelines for use of Boats or Rafts for

Close-up surveys

ACS Offshore Services

Page 17 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

Appendix A · Minimum Requirements for Thickness

Measurements for Special Survey

TABLE 1

Minimum Requirements for Thickness Measurements for Self Elevating

Units at Special Survey

Special Survey No.1 Special Survey No.2 Special Survey No.3 Special Survey No.4 and

Age < 5 <5 Age < 10 10 < Age < 15 subsequent

15 < Age

1) Suspect areas 1) Suspect areas 1) Suspect areas 1) Suspect areas

throughout the unit throughout the unit. throughout the unit. throughout the unit.

(particular attention to

be paid to the legs in

way of the Splash

Zone).

2) Legs in way of Splash 2) Legs in way of Splash 2) Legs in way of Splash

Zone. Zone. Zone.

3) Primary application 3) Representative 3) Comprehensive

structures where gaugings, throughout, gaugings, throughout, of

wastage is evident. of special and primary special and primary

application structures. application structures.

4) Representative gaugings 4) Leg well structure. 4) Leg well structure.

of upper hull deck and

bottom plating and

internals of one preload

(ballast) tank.

5) Representative 5) Representative

gaugings of deck, gaugings of deck,

bottom, and side shell bottom, and side shell

plating of hull and mat. plating of hull and mat.

6) Representative 6) Substructure of derrick

gaugings of upper hull as deemed necessary.

deck and bottom

plating and internals of

at least two preload

(ballast) tanks.

7) Representative

gaugings of internals of

all preload (ballast)

tanks.

ACS Offshore Services

Page 18 of 19

Asia Classification Society

MODU Special Survey of Hull & Structure

General & Close Visual Inspection

Thickness Measurement

TABLE 2

Guidance for Additional Thickness Measurements in way of Substantial

Corrosion

STRUCTURAL MEMBER EXTENT OF PATTERN OF

MEASUREMENT MEASUREMENT

Plating Suspect area and adjacent 5 point pattern over 1 square

plates. meter.

Stiffeners Suspect area. 3 measurements each in line

across web and flange.

ACS Offshore Services

Page 19 of 19

Asia Classification Society

You might also like

- ACS-DCI-2-Location-Assessment v1Document42 pagesACS-DCI-2-Location-Assessment v1saeed ghafooriNo ratings yet

- SAICE Code of Safety in Trial HolesDocument52 pagesSAICE Code of Safety in Trial HolesMatthew HolmwoodNo ratings yet

- Striving for Clean Air: Air Pollution and Public Health in South AsiaFrom EverandStriving for Clean Air: Air Pollution and Public Health in South AsiaNo ratings yet

- Ndi Guide Sept20Document136 pagesNdi Guide Sept20AmanSharmaNo ratings yet

- Sedimentary Processes: Quantification Using RadionuclidesFrom EverandSedimentary Processes: Quantification Using RadionuclidesNo ratings yet

- Construction Vessel Guideline For The Offshore Renewables Industry (Published)Document39 pagesConstruction Vessel Guideline For The Offshore Renewables Industry (Published)christianford9793100% (1)

- Wireless Sensor and Actuator Networks: Technologies, Analysis and DesignFrom EverandWireless Sensor and Actuator Networks: Technologies, Analysis and DesignNo ratings yet

- NES 779 Part 1 Requirements For 90 - 10 Copper Nickel Alloy MaterialDocument34 pagesNES 779 Part 1 Requirements For 90 - 10 Copper Nickel Alloy MaterialJEORJE100% (1)

- Caribbean Infrastructure Public Private Partnership RoadmapFrom EverandCaribbean Infrastructure Public Private Partnership RoadmapNo ratings yet

- Marine Transportation SpecificationDocument24 pagesMarine Transportation SpecificationNishant GuptaNo ratings yet

- General Specification: NO. 30-5-1 Offshore Pipelines InstallationDocument38 pagesGeneral Specification: NO. 30-5-1 Offshore Pipelines InstallationHanizakri Abu HassanNo ratings yet

- gp860109 ComDocument41 pagesgp860109 Comfahimidrus1No ratings yet

- Dis13628 4ewithAnnexLDocument104 pagesDis13628 4ewithAnnexLSrinivasan RajenderanNo ratings yet

- ITA Design Guidelines WaterproofingDocument74 pagesITA Design Guidelines WaterproofingTansel YılmazNo ratings yet

- Nondestructive Inspection of Hull Welds: Guide ForDocument111 pagesNondestructive Inspection of Hull Welds: Guide ForThanh Kieu0% (1)

- Institute of Petroleum Studies by 2013 o PDFDocument97 pagesInstitute of Petroleum Studies by 2013 o PDFFreddy Mendoza CoronelNo ratings yet

- Standards For Wellsite Supervision of Drilling Completion and WorkoversDocument26 pagesStandards For Wellsite Supervision of Drilling Completion and Workoverssantoso_hseNo ratings yet

- Guide To Non-Destructive ExaminationDocument146 pagesGuide To Non-Destructive Examinationdelta_scope100% (1)

- Ndi Guide Sept20Document146 pagesNdi Guide Sept20SrinivasanNo ratings yet

- AIEA-Guidebook On NDT of Concrete StructuresDocument242 pagesAIEA-Guidebook On NDT of Concrete StructuresMansour LassouedNo ratings yet

- PCI1Document830 pagesPCI1RensomNo ratings yet

- gp860103 ComDocument45 pagesgp860103 Comfahimidrus1No ratings yet

- Engineering Used of GeotextilesDocument63 pagesEngineering Used of GeotextilesAhmad ZulkifliNo ratings yet

- WIG AerodynamicsDocument86 pagesWIG AerodynamicsSenthil Kumar100% (1)

- Standard2 7 3Document22 pagesStandard2 7 3Chaker AmirNo ratings yet

- General Maintenance of Marine Vessels and Related EquipmentDocument207 pagesGeneral Maintenance of Marine Vessels and Related EquipmentWahyu SimatupangNo ratings yet

- Nondestructive Testing PDFDocument65 pagesNondestructive Testing PDFAnonymous S9qBDVkyNo ratings yet

- Mobile Offshore Drilling Unit - Crew HabitabilityDocument90 pagesMobile Offshore Drilling Unit - Crew Habitabilityhasmit1No ratings yet

- Sabp Q 012Document28 pagesSabp Q 012Hassan MokhtarNo ratings yet

- Engineering Use of GeotextileDocument62 pagesEngineering Use of GeotextileAdesh RamnarineNo ratings yet

- Onshore LNG Study - Rev - 2Document68 pagesOnshore LNG Study - Rev - 2kaspersky2009No ratings yet

- NES 729 Part 5 Requirements For Non-Destructive Examination MethodsDocument70 pagesNES 729 Part 5 Requirements For Non-Destructive Examination MethodsJEORJENo ratings yet

- ABS Guide For Nondestructive Inspection of Hull WeldsDocument71 pagesABS Guide For Nondestructive Inspection of Hull Weldsluis-12No ratings yet

- Previews 1555145 PreDocument8 pagesPreviews 1555145 Prejuan arturoNo ratings yet

- gp860106 ComDocument18 pagesgp860106 Comfahimidrus1No ratings yet

- Pipeline Guide E-Mar18Document142 pagesPipeline Guide E-Mar18Poligonio Man-PyNo ratings yet

- Construction & Erection of Bridge - BeamsDocument73 pagesConstruction & Erection of Bridge - Beamsahmad fakhruddinNo ratings yet

- Asme A90.1-2009Document34 pagesAsme A90.1-2009ManInBar50% (2)

- Self-Elevating Units Intended to Operate as Offshore Installation - 279-Seu-operating-As-oi-reqts-july22Document21 pagesSelf-Elevating Units Intended to Operate as Offshore Installation - 279-Seu-operating-As-oi-reqts-july22xavier chevalleyNo ratings yet

- Gasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsDocument36 pagesGasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsMichael Yap0% (1)

- Foundations in Expansive SoilsDocument99 pagesFoundations in Expansive SoilsJosh MunnNo ratings yet

- Technical Specifications FacadeDocument34 pagesTechnical Specifications Facadevijay rajanNo ratings yet

- 指导性文件 Guidance Notes GD 23-2019Document53 pages指导性文件 Guidance Notes GD 23-2019cui jackyNo ratings yet

- Brent Delta Topside Close Out ReportDocument53 pagesBrent Delta Topside Close Out ReportChatis HerabutNo ratings yet

- ABS - Certification of Drilling Systems - MODU PDFDocument94 pagesABS - Certification of Drilling Systems - MODU PDFvikrant911No ratings yet

- Marine SeismicDocument50 pagesMarine SeismicCholisina Anik PerwitaNo ratings yet

- 99-V820 2004Document52 pages99-V820 2004Nikesh KoliNo ratings yet

- Nzs 4121 2001 PDFDocument130 pagesNzs 4121 2001 PDFpaulNo ratings yet

- Anchoring Guidelines Draft V7 Send To ISTECDocument39 pagesAnchoring Guidelines Draft V7 Send To ISTECJayakumar Sankaran100% (1)

- RMRS Construction Equipment MODU FOP EngDocument416 pagesRMRS Construction Equipment MODU FOP EngDesedentNo ratings yet

- Fabrication, Inspection, and Testing of Pressure VesselsDocument75 pagesFabrication, Inspection, and Testing of Pressure VesselsAsad Iqbal Siddiqui71% (7)

- Offshore Spaceports May 2023Document24 pagesOffshore Spaceports May 2023RafaelGloriaPereiraNo ratings yet

- (Vol V), 2014 Rules For Materials, 2014-1Document444 pages(Vol V), 2014 Rules For Materials, 2014-1FirdausNo ratings yet

- ABS - Certification of Drilling UnitsDocument94 pagesABS - Certification of Drilling Unitsvikrant911No ratings yet

- Ut b-01-04Document62 pagesUt b-01-04Veeraiah AnbuNo ratings yet

- NSCV c7d Ed 1.4 February 2022 Commencing 1 April 2022Document34 pagesNSCV c7d Ed 1.4 February 2022 Commencing 1 April 2022sony2anggaraNo ratings yet

- Crew Habitability On Ships: Guide ForDocument128 pagesCrew Habitability On Ships: Guide ForJosua MartinezNo ratings yet

- SP0793-0000-1W05-003 Corrosion Protection - Rev0A (00D) - Sistemas de Pinturas de Barrick - Incluye Fabricante WEG Por Cada Sistemas (00C)Document46 pagesSP0793-0000-1W05-003 Corrosion Protection - Rev0A (00D) - Sistemas de Pinturas de Barrick - Incluye Fabricante WEG Por Cada Sistemas (00C)José Nicolás Valdéz BurgosNo ratings yet

- High Impact Risk Management Plan TemplateDocument11 pagesHigh Impact Risk Management Plan Templatesaeed ghafoori100% (1)

- Assessment Punch Through Sand Over ClayDocument14 pagesAssessment Punch Through Sand Over Claysaeed ghafooriNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- LNAS Marine Manual - Rev 04 - FinalDocument41 pagesLNAS Marine Manual - Rev 04 - Finalsaeed ghafooriNo ratings yet

- Case Histories Paper: Jackup Rig Spud Can Penetration: A 6,000 Ton Load TestDocument8 pagesCase Histories Paper: Jackup Rig Spud Can Penetration: A 6,000 Ton Load TestarpitNo ratings yet

- ACS Offshore Upstream Construction CoP SoW CoADocument32 pagesACS Offshore Upstream Construction CoP SoW CoAsaeed ghafooriNo ratings yet

- 3 ACS Offshore Installations Rules - 2017Document155 pages3 ACS Offshore Installations Rules - 2017saeed ghafooriNo ratings yet

- ACS Rules For Offshore Fixed Platform InstallationDocument31 pagesACS Rules For Offshore Fixed Platform Installationsaeed ghafooriNo ratings yet

- ACS Service Specification of Marine Warranty SurveyDocument11 pagesACS Service Specification of Marine Warranty Surveysaeed ghafooriNo ratings yet

- ACS Offshore Upstream Construction CoP SoW CoADocument32 pagesACS Offshore Upstream Construction CoP SoW CoAsaeed ghafooriNo ratings yet

- ACS Service Specification of Marine Warranty SurveyDocument11 pagesACS Service Specification of Marine Warranty Surveysaeed ghafooriNo ratings yet

- Jackup DRILLING Rig Data Requirments & Recommendation For LocationbapproachDocument4 pagesJackup DRILLING Rig Data Requirments & Recommendation For Locationbapproachsaeed ghafooriNo ratings yet

- 5 ACS SPM Rules - 2017Document92 pages5 ACS SPM Rules - 2017saeed ghafoori100% (1)

- Rig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: InitialsDocument1 pageRig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: Initialssaeed ghafooriNo ratings yet

- 1 ACS Part 1 Generic - 2017Document34 pages1 ACS Part 1 Generic - 2017saeed ghafooriNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- Marshall Island - Annex 02Document16 pagesMarshall Island - Annex 02saeed ghafooriNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- Interim Garbage Pollution Prevention Certificate: DP Hoormand 5IM 873 Zanzibar 474 45Document2 pagesInterim Garbage Pollution Prevention Certificate: DP Hoormand 5IM 873 Zanzibar 474 45saeed ghafooriNo ratings yet

- AMIR KABIR SSDU IWS Report Rev01Document6 pagesAMIR KABIR SSDU IWS Report Rev01saeed ghafoori0% (1)

- AMIR KABIR SSDU IWS Report Rev01Document6 pagesAMIR KABIR SSDU IWS Report Rev01saeed ghafoori0% (1)

- SeaBoss Pre-Move SurveyDocument8 pagesSeaBoss Pre-Move Surveysaeed ghafooriNo ratings yet

- Offshore Lift Certificate ReadyDocument1 pageOffshore Lift Certificate Readysaeed ghafooriNo ratings yet

- Rig Move Completion Approval: Offshore Services DivisionDocument1 pageRig Move Completion Approval: Offshore Services Divisionsaeed ghafooriNo ratings yet

- Permit To Anchore Running PDFDocument1 pagePermit To Anchore Running PDFsaeed ghafooriNo ratings yet

- Panama Marine Authority Administration Fees: Seafarers' LicencesDocument5 pagesPanama Marine Authority Administration Fees: Seafarers' Licencessaeed ghafooriNo ratings yet

- Offshore Rig Move CertificateDocument1 pageOffshore Rig Move Certificatesaeed ghafooriNo ratings yet

- MODU PASARGAD100-coaDocument1 pageMODU PASARGAD100-coasaeed ghafooriNo ratings yet

- HEAT EFFECTS (Cha 4) : Outline of Chapter OneDocument65 pagesHEAT EFFECTS (Cha 4) : Outline of Chapter OneAdam MekonnenNo ratings yet

- AbstractDocument2 pagesAbstractramyaNo ratings yet

- 11 Physics Test Paper Ch3 1Document4 pages11 Physics Test Paper Ch3 1Devendar SharmaNo ratings yet

- Sponge BobDocument4 pagesSponge BobchabriesNo ratings yet

- Introduction To Food and Beverage IndustryDocument3 pagesIntroduction To Food and Beverage IndustryRhyza BehaveNo ratings yet

- Chemistry of Food Changes During Storage: Group 7Document22 pagesChemistry of Food Changes During Storage: Group 7Sonny MichaelNo ratings yet

- Fair Directory 02-2016Document44 pagesFair Directory 02-2016Ravichandran SNo ratings yet

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- General Description: Effective Distance Depends On Antenna, Tag and EnvironmentDocument2 pagesGeneral Description: Effective Distance Depends On Antenna, Tag and EnvironmentSHASHANK BHUSHANNo ratings yet

- z1875 Caton (BMJ) Electric Currents of The BrainDocument23 pagesz1875 Caton (BMJ) Electric Currents of The BrainUnholy VladNo ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- Physics Formulas and Symbols: Physics I Symbol FormulaDocument5 pagesPhysics Formulas and Symbols: Physics I Symbol Formulakaparthy100% (9)

- Osha Top 25 Physical HazardsDocument100 pagesOsha Top 25 Physical HazardsHasan Shakeel100% (2)

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Mohair FiberDocument33 pagesMohair FiberMuhammad Ahsan AftabNo ratings yet

- Detailed Lesson Plan in General MathematicsDocument6 pagesDetailed Lesson Plan in General MathematicsAira Jane Irarum78% (18)

- Guillain Barre 3Document6 pagesGuillain Barre 3YON LEANDRO VILLAMIL ROJASNo ratings yet

- Radiological Investigations: UltrasonographyDocument42 pagesRadiological Investigations: UltrasonographyDeeptanu GhoshNo ratings yet

- 2GIG KEY2 345 Install GuideDocument2 pages2GIG KEY2 345 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Postmodern EthicsDocument1 pagePostmodern Ethicsgeorge elerickNo ratings yet

- Fault Codes: STO U AndriivDocument3 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Creation Story From LuzonDocument4 pagesCreation Story From LuzonMartin SantelicesNo ratings yet

- Treatment of Headaches in The ED With Lower Cervical Intramuscular Bupivacaine Injections: A 1-Year Retrospective Review of 417 PatientsDocument9 pagesTreatment of Headaches in The ED With Lower Cervical Intramuscular Bupivacaine Injections: A 1-Year Retrospective Review of 417 PatientsLarry B. Mellick, MDNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Bio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceDocument2 pagesBio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceLari GrossiNo ratings yet

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- A History of The Jewish People in The Time of Jesus Christ (1891) Index Schürer, Emil, 1844-1910Document132 pagesA History of The Jewish People in The Time of Jesus Christ (1891) Index Schürer, Emil, 1844-1910David Bailey100% (2)

- Factory made uPVC windows installationDocument2 pagesFactory made uPVC windows installationAmit Singh100% (2)

- yudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Document12 pagesyudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Fath TiaraNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Water 4.0: The Past, Present, and Future of the World's Most Vital ResourceFrom EverandWater 4.0: The Past, Present, and Future of the World's Most Vital ResourceRating: 3.5 out of 5 stars3.5/5 (9)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet