Professional Documents

Culture Documents

2.32 Lap Joints: Figure 2.11-Transition of Width (Cyclically Loaded Nontubular) (See 2.29.3)

2.32 Lap Joints: Figure 2.11-Transition of Width (Cyclically Loaded Nontubular) (See 2.29.3)

Uploaded by

gv Sathishkumar KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.32 Lap Joints: Figure 2.11-Transition of Width (Cyclically Loaded Nontubular) (See 2.29.3)

2.32 Lap Joints: Figure 2.11-Transition of Width (Cyclically Loaded Nontubular) (See 2.29.3)

Uploaded by

gv Sathishkumar KumarCopyright:

Available Formats

DESIGN OF WELDED CONNECTIONS AWS D1.

1:2000

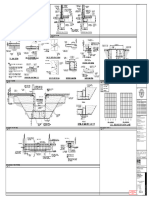

Figure 2.11—Transition of Width (Cyclically Loaded Nontubular) (see 2.29.3)

2.32 Lap Joints The thickness and width of a flange may be varied by

butt joint welding parts of different thickness or width

2.32.1 Longitudinal Fillet Welds. If longitudinal fillet with transitions conforming to the requirements of 2.29.

welds are used alone in lap joints of end connections, the

length of each fillet weld shall be no less than the perpen-

dicular distance between the welds. The transverse spac- 2.34 Cover Plates

ing of the welds shall not exceed 16 times the thickness

of the connected thinner part unless suitable provision is 2.34.1 Thickness and Width. Cover plates shall prefer-

made (as by intermediate plug or slot welds) to prevent ably be limited to one on any flange. The maximum

buckling or separation of the parts. The longitudinal fillet thickness of cover plates on a flange (total thickness of

weld may be either at the edges of the member or in all cover plates if more than one is used) shall not be

slots. greater than 1-1/2 times the thickness of the flange to

which the cover plate is attached. The thickness and

2.32.2 Hole or Slot Spacing. When fillet welds in holes width of a cover plate may be varied by butt joint weld-

or slots are used, the clear distance from the edge of the ing parts of different thickness or width with transitions

hole or slot to the adjacent edge of the part containing it, conforming to the requirements of 2.29. Such plates shall

measured perpendicular to the direction of stress, shall be assembled and welds ground smooth before being at-

be no less than five times the thickness of the part nor tached to the flange. The width of a cover plate, with rec-

less than two times the width of the hole or slot. The ognition of dimensional tolerances allowed by ASTM

strength of the part shall be determined from the critical A 6, shall allow suitable space for a fillet weld along each

net section of the base metal. edge of the joint between the flange and the plate cover.

2.34.2 Partial Length. Any partial length cover plate

shall extend beyond the theoretical end by the terminal

2.33 Built-Up Sections distance, or it shall extend to a section where the stress or

Girders (built-up I sections) shall preferably be made stress range in the beam flange is equal to the allowable

with one plate in each flange, i.e., without cover plates. fatigue stress permitted by 2.24, whichever is greater.

The unsupported projection of a flange shall be no more The theoretical end of the cover plate is the section at

than permitted by the applicable general specification. which the stress in the flange without that cover plate

19

You might also like

- Newspaper BillDocument1 pageNewspaper Billgv Sathishkumar Kumar75% (4)

- Procedimiento de Calibracion de Los TT1000A PDFDocument9 pagesProcedimiento de Calibracion de Los TT1000A PDFjose gutierrezNo ratings yet

- 2.30 Stiffeners: AWS D1.1:2000 Design of Welded ConnectionsDocument1 page2.30 Stiffeners: AWS D1.1:2000 Design of Welded Connectionsgv Sathishkumar KumarNo ratings yet

- Section 10 ConnectionsDocument17 pagesSection 10 ConnectionsThirupathi RajaNo ratings yet

- 2.18 Tension Members: Figure 2.5-Double-Fillet Welded Lap Joint (See 2.4.8.1)Document1 page2.18 Tension Members: Figure 2.5-Double-Fillet Welded Lap Joint (See 2.4.8.1)gv Sathishkumar KumarNo ratings yet

- D Tension Members: StressDocument2 pagesD Tension Members: StressJerry M. Davila MartelNo ratings yet

- Pages From AISC+ASD+9th+Edition+SpecificationDocument5 pagesPages From AISC+ASD+9th+Edition+SpecificationAdam JrNo ratings yet

- Minimum Thickness of MetalDocument15 pagesMinimum Thickness of MetalswatiNo ratings yet

- Development Length: AremaDocument7 pagesDevelopment Length: AremaBALRAJNo ratings yet

- Anchorage and Splices UBC-1997-Volume 2-4Document20 pagesAnchorage and Splices UBC-1997-Volume 2-4minedataNo ratings yet

- Unit - 4: Design of BeamsDocument27 pagesUnit - 4: Design of BeamsfarhanyazdaniNo ratings yet

- BeamDocument27 pagesBeamSandip BudhathokiNo ratings yet

- Ur s21 Rev5 pdf1338Document14 pagesUr s21 Rev5 pdf1338Huy ChínhNo ratings yet

- SADSt BeamsDocument27 pagesSADSt BeamsFrank JohnNo ratings yet

- Steel DesignDocument18 pagesSteel DesignJaninaRuzzleSilangNo ratings yet

- Chapter 2 - Tension MembersDocument13 pagesChapter 2 - Tension MembersSami IGNo ratings yet

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaNo ratings yet

- IRC Clauses For Retaining WallsDocument2 pagesIRC Clauses For Retaining WallsAvnish raiNo ratings yet

- Chapter B Design RequirementsDocument6 pagesChapter B Design RequirementsJerry M. Davila MartelNo ratings yet

- Inland Transport Committee: INF.47 Economic Commission For EuropeDocument7 pagesInland Transport Committee: INF.47 Economic Commission For EuropeStan HonNo ratings yet

- Section 13.2: 343R-154 Aci Committee ReportDocument2 pagesSection 13.2: 343R-154 Aci Committee ReportSana FatimaNo ratings yet

- Table J2.4 Minimum Size of Fillet Welds: 2b. LimitationsDocument2 pagesTable J2.4 Minimum Size of Fillet Welds: 2b. LimitationsJen Tan100% (2)

- ECDocument40 pagesECJosé CarlosNo ratings yet

- Footing Spec As Per Is 456 - 2000Document4 pagesFooting Spec As Per Is 456 - 2000prabhu81No ratings yet

- Free English GrammarDocument20 pagesFree English GrammarrajeshNo ratings yet

- Depth of FoundationDocument9 pagesDepth of FoundationSujan SinghNo ratings yet

- Module 2 Tension Members PDFDocument26 pagesModule 2 Tension Members PDFjomarie apolinarioNo ratings yet

- EC2-Shear and TorsionDocument9 pagesEC2-Shear and TorsionDonald HamiltonNo ratings yet

- 2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Document1 page2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Ibrahim shaikNo ratings yet

- Fdocuments - Us Ce2352 Design of Steel STR Design of Steel Structures 1 Introduction DesignDocument31 pagesFdocuments - Us Ce2352 Design of Steel STR Design of Steel Structures 1 Introduction DesignEpahNo ratings yet

- 2 Tension MembersDocument13 pages2 Tension MembersAbel MulugetaNo ratings yet

- 2.1 Bolts GeneralDocument54 pages2.1 Bolts GeneralIyrin JohnNo ratings yet

- Analysis and Design of Members For TensionDocument91 pagesAnalysis and Design of Members For TensionAL DANIEL VIN FULVADORANo ratings yet

- Analysis and Design of Members For TensionDocument84 pagesAnalysis and Design of Members For TensionicpertacortaNo ratings yet

- Is.456.2000 - Plain & Reinforced Concrete - Part16Document5 pagesIs.456.2000 - Plain & Reinforced Concrete - Part16pandey71087No ratings yet

- AISC - Límites de Soldadura de FileteDocument1 pageAISC - Límites de Soldadura de FileteErnesto MarinNo ratings yet

- Beam Column ConnectionDocument10 pagesBeam Column Connectionmaniram7No ratings yet

- Irc 21 2000Document87 pagesIrc 21 2000shaliniboddu521No ratings yet

- RCC NotesDocument13 pagesRCC Notesmadhav vijNo ratings yet

- Prying Forces in The Bolts Become Significant When Ninety Percent of The YieldDocument2 pagesPrying Forces in The Bolts Become Significant When Ninety Percent of The YieldRC Dela RocaNo ratings yet

- Srividya College of Engineering and Technology Question BankDocument7 pagesSrividya College of Engineering and Technology Question Bankindira subramoniapillaiNo ratings yet

- Plate GirderDocument74 pagesPlate Girderarif_rubin100% (1)

- Codal Provision For BeamDocument2 pagesCodal Provision For BeamNoor Mohd100% (1)

- Bolted ConnectionsDocument10 pagesBolted ConnectionsAbhi ANo ratings yet

- ChecklistDocument61 pagesChecklistjhunkujha11No ratings yet

- Welded Connections: Chapter Twenty OneDocument14 pagesWelded Connections: Chapter Twenty OnePaul RoqueNo ratings yet

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawaleNo ratings yet

- NOTATIONDocument1 pageNOTATIONNafidNo ratings yet

- General Specification (Building) 30-01-21 198-380Document183 pagesGeneral Specification (Building) 30-01-21 198-380shujaNo ratings yet

- Bolted Connection (Wk7-Wk10)Document20 pagesBolted Connection (Wk7-Wk10)Ma. Angelica TamayaoNo ratings yet

- Basics of Cold Form - INsdag PDFDocument21 pagesBasics of Cold Form - INsdag PDFCharu Sharma100% (1)

- Module 5-ADocument9 pagesModule 5-Adash1991No ratings yet

- ARCHABArch68898rSTRrAP - Detailing and CurtailmentDocument4 pagesARCHABArch68898rSTRrAP - Detailing and CurtailmentAditiNo ratings yet

- AITC Technical Note 19Document7 pagesAITC Technical Note 19klb75No ratings yet

- Cable TraysDocument6 pagesCable TrayssallammohamedNo ratings yet

- Tension Members DesignDocument42 pagesTension Members DesignVermuch CasioNo ratings yet

- Curtailment of Reinforcement in Concrete Beams and Slabs - The CDocument5 pagesCurtailment of Reinforcement in Concrete Beams and Slabs - The Cdamith sdNo ratings yet

- Flexure and Shear Strength of Pre Stressed Concrete SectionsDocument45 pagesFlexure and Shear Strength of Pre Stressed Concrete SectionsRakshitha c Rakshitha c100% (1)

- Chapter 2 - Shear Design SP 17-09-07Document37 pagesChapter 2 - Shear Design SP 17-09-07Alex FerrariNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- FO 301.00 - TYPICAL FOUNDATION DETAILS II - Rev05Document1 pageFO 301.00 - TYPICAL FOUNDATION DETAILS II - Rev05gv Sathishkumar KumarNo ratings yet

- TH Street: Cellar/Foundation Framing Partial PlanDocument1 pageTH Street: Cellar/Foundation Framing Partial Plangv Sathishkumar KumarNo ratings yet

- Fourth Floor/Stage 1 2 Roof Geometry Partial Plan A: Issued For ConstructionDocument1 pageFourth Floor/Stage 1 2 Roof Geometry Partial Plan A: Issued For Constructiongv Sathishkumar KumarNo ratings yet

- Third Floor Geometry Partial Plan C: Issued For ConstructionDocument1 pageThird Floor Geometry Partial Plan C: Issued For Constructiongv Sathishkumar KumarNo ratings yet

- GENERAL ENGLISH TNPSC PREVIOUS YEAR QUESTIONS PART I.pdf - 623dbfc37ab87Document22 pagesGENERAL ENGLISH TNPSC PREVIOUS YEAR QUESTIONS PART I.pdf - 623dbfc37ab87gv Sathishkumar KumarNo ratings yet

- Web Doubler Plate WeldDocument2 pagesWeb Doubler Plate Weldgv Sathishkumar KumarNo ratings yet

- Tax Invoice: Billing Address Installation Address Invoice DetailsDocument1 pageTax Invoice: Billing Address Installation Address Invoice Detailsgv Sathishkumar KumarNo ratings yet

- Bolt ClearenceDocument1 pageBolt Clearencegv Sathishkumar KumarNo ratings yet

- Steel Interchange: Steel's Monthly Steel Interchange Is For You! Send YourDocument2 pagesSteel Interchange: Steel's Monthly Steel Interchange Is For You! Send Yourgv Sathishkumar KumarNo ratings yet

- Beam Flange Width Reduction Bevel DimentionsDocument2 pagesBeam Flange Width Reduction Bevel Dimentionsgv Sathishkumar KumarNo ratings yet

- FO 302.00 - TYPICAL FOUNDATION DETAILS III - Rev05Document1 pageFO 302.00 - TYPICAL FOUNDATION DETAILS III - Rev05gv Sathishkumar KumarNo ratings yet

- Formulas: Determining Weld Size Using AllowablesDocument1 pageFormulas: Determining Weld Size Using Allowablesgv Sathishkumar KumarNo ratings yet

- TNPSC - Specimen: GS1MB-22Document9 pagesTNPSC - Specimen: GS1MB-22gv Sathishkumar KumarNo ratings yet

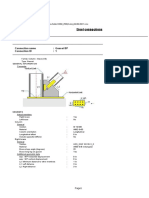

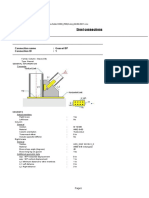

- Connection:-C003: (Code: CISC 10th Edition) Axial Vertical Shear Load: - (Given) (1/2 UDL)Document10 pagesConnection:-C003: (Code: CISC 10th Edition) Axial Vertical Shear Load: - (Given) (1/2 UDL)gv Sathishkumar KumarNo ratings yet

- Axial Capacity of HSS SectionsDocument61 pagesAxial Capacity of HSS Sectionsgv Sathishkumar KumarNo ratings yet

- Northwoods Software: Red Important NoteDocument10 pagesNorthwoods Software: Red Important Notegv Sathishkumar KumarNo ratings yet

- Steel Connections: Detailed ReportDocument18 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Automatic NumberingDocument4 pagesAutomatic Numberinggv Sathishkumar KumarNo ratings yet

- Current Affairs - Jan, Feb, March - em - PDF - 6210767557b91Document74 pagesCurrent Affairs - Jan, Feb, March - em - PDF - 6210767557b91gv Sathishkumar KumarNo ratings yet

- Steel Connections: Detailed ReportDocument4 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Steel Connections: Detailed ReportDocument11 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Steel Connections: Detailed ReportDocument7 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Article: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane BendingDocument5 pagesArticle: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane Bendinggv Sathishkumar KumarNo ratings yet

- Connection: C001 Code: AISC 14th Edition - LRFD) : Project: Job No.: Page: C001Document1 pageConnection: C001 Code: AISC 14th Edition - LRFD) : Project: Job No.: Page: C001gv Sathishkumar KumarNo ratings yet

- Connection: C021 Code: AISC 14th Edtion - LRFD)Document1 pageConnection: C021 Code: AISC 14th Edtion - LRFD)gv Sathishkumar KumarNo ratings yet

- Steel Connections: Detailed ReportDocument7 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Restrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"Document2 pagesRestrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"gv Sathishkumar KumarNo ratings yet

- Method Statement For Compaction and BackfillingDocument8 pagesMethod Statement For Compaction and BackfillingJohn MofireNo ratings yet

- Blake Mouton QuestionnaireDocument5 pagesBlake Mouton QuestionnaireSunanda Vig100% (1)

- Teks Kisah Nabi NuhDocument8 pagesTeks Kisah Nabi Nuhsyafiqahusna2611No ratings yet

- Service Manual: Power AmplifierDocument104 pagesService Manual: Power Amplifierjimmyboy111No ratings yet

- DLL - English 3 - Q3 - W8Document4 pagesDLL - English 3 - Q3 - W8Rovi ChellNo ratings yet

- Final Paper Mcqs - Pec Ibs 2024Document1 pageFinal Paper Mcqs - Pec Ibs 2024nmaqsood066No ratings yet

- Infusion PumpDocument8 pagesInfusion PumpAdeeb SalemNo ratings yet

- Chapter 23 Three-Phase Induction MotorsDocument9 pagesChapter 23 Three-Phase Induction MotorsteweleNo ratings yet

- Attacking Antivirus Software's Kernel DriverDocument33 pagesAttacking Antivirus Software's Kernel Driverdarkasterion2009No ratings yet

- Njock Et Al., 2020Document17 pagesNjock Et Al., 2020Paul Julbin NJOCKNo ratings yet

- ICOT - Brochure 2022Document32 pagesICOT - Brochure 2022Robson CordeiroNo ratings yet

- Paul F Building A Locost CarDocument3 pagesPaul F Building A Locost CarShalon MeloNo ratings yet

- Gujarat Technological University Mechanical EngineeringDocument4 pagesGujarat Technological University Mechanical EngineeringHaresh KapadiyaNo ratings yet

- Artificial Intelligence in Education - A ReviewDocument6 pagesArtificial Intelligence in Education - A ReviewyasmineNo ratings yet

- Transmittal 04175Document2 pagesTransmittal 04175Katik XalxoNo ratings yet

- Differentiation FormulasDocument1 pageDifferentiation FormulasAN NGUYENNo ratings yet

- ROB Design 35 Deg Skew - SuperstructureDocument25 pagesROB Design 35 Deg Skew - SuperstructureAnonymous sfkedkymNo ratings yet

- Excel Unit 3 Advanced Filter and Conditional Formatting (Autosaved)Document14 pagesExcel Unit 3 Advanced Filter and Conditional Formatting (Autosaved)Kyan VeeraNo ratings yet

- Vocabulary: Look at The Pictures. Write The Names of The Modes of Transport in The Boxes ProvidedDocument4 pagesVocabulary: Look at The Pictures. Write The Names of The Modes of Transport in The Boxes ProvidedNidhi ChandraNo ratings yet

- Technical Data MotorDocument12 pagesTechnical Data Motordaoquan222222No ratings yet

- JKTech Brochure - Statistics Training + Online (November2021) FINALv3Document2 pagesJKTech Brochure - Statistics Training + Online (November2021) FINALv3JD FCNo ratings yet

- MC - CC App Fillable Form 2021 10062021Document2 pagesMC - CC App Fillable Form 2021 10062021abantedimaatrasanNo ratings yet

- Resume of Basic Cost - Management ConceptDocument4 pagesResume of Basic Cost - Management ConceptismailkunNo ratings yet

- Relationships - Mini JournalDocument15 pagesRelationships - Mini JournalzuilinhaNo ratings yet

- Online Assignment SubmissionDocument20 pagesOnline Assignment SubmissionAnesu Mushate50% (2)

- Client Enquiry Form: NTPC Sail Power Co LTD Pratap Kumar Panda Durgapur West BengalDocument1 pageClient Enquiry Form: NTPC Sail Power Co LTD Pratap Kumar Panda Durgapur West BengalPratap PandaNo ratings yet

- Greatly Enhanced Photocurrent In Inorganic Perovskite (Knbo3) 0.9 (Bani0.5Nb0.5O3‐Σ) 0.1 Ferroelectric Thin‐Film Solar CellDocument18 pagesGreatly Enhanced Photocurrent In Inorganic Perovskite (Knbo3) 0.9 (Bani0.5Nb0.5O3‐Σ) 0.1 Ferroelectric Thin‐Film Solar Cellcbs78No ratings yet

- Adverbs 1 Advanced PDFDocument4 pagesAdverbs 1 Advanced PDFAMAECHI UGWUNo ratings yet

- RMS Value MeasurementDocument3 pagesRMS Value MeasurementGiovanni GonzalezNo ratings yet