Professional Documents

Culture Documents

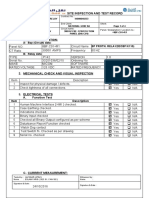

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Uploaded by

Azli FitriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Uploaded by

Azli FitriCopyright:

Available Formats

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Refer No : QMS16\WI\FOP\ACOND

Site Name / LRD : Performed by :

Region : Date / Time in / Time out :

No A/Cond Brand Name Capacity (hp) Model Location Serial No. (IDU / ODU) Asset Tag # (Maxis)

Item Service Descriptions Unit No. Status Observation / Remarks Expected Result & Specification

1.0 Air-Conditioning System Info Check

1.1 Record the change (Model, S/N & HP) of air-cond system 1 Yes No NA Change of air-cond info (Model,

2 Yes No NA S/N & HP) must be recorded.

3 Yes No NA

4 Yes No NA

1.2 Service & maintenance details: 1 Yes No NA

a) Last service date : ( ) 2 Yes No NA Last & next service date must be

b) Next service date : ( ) 3 Yes No NA recorded.

4 Yes No NA

1.3 Measure the individual air-cond unit temperature Temperature before & after service

Before service: ( )°C 1 Pass Fail NA are recorded. The temperature

( )°C 2 Pass Fail NA should be +/- 2°C from the setting

( )°C 3 Pass Fail NA temperature after servicing.

( )°C 4 Pass Fail NA TOC battery room: 22°C;

After service: ( )°C 1 Pass Fail NA TOC equipment room: 22°C;

( )°C 2 Pass Fail NA TOC office area: 25°C;

( )°C 3 Pass Fail NA BTS cabin BSC/Trunk/Hub: 24°C;

( )°C 4 Pass Fail NA BTS cabin End site: 26°C.

2.0 Outdoor Unit (ODU)

2.1 Measure the current of the compressor ( )A 1 Pass Fail NA Running amp shoud be +/-20% from

( )A 2 Pass Fail NA the manufacturer specification.

( )A 3 Pass Fail NA (refer to Appendix 1)

( )A 4 Pass Fail NA

2.2 Measure the pressure at the suction / ( / ) Psi 1 Pass Fail NA Suction pressure: 60 Psi to 70 Psi.

discharge valve ( / ) Psi 2 Pass Fail NA Discharge pressure: 260 Psi to

( / ) Psi 3 Pass Fail NA 275 Psi. (Not applicable for 2HP AC)

( / ) Psi 4 Pass Fail NA

2.3 Test for gas leaking for ODU 1 Pass Fail NA No gas leakage.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

2.4 Clean condensor coil and fin 1 Pass Fail NA Condensor coil and fin cleaned.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

2.5 Measure the capacitance of capacitor for both compressor The capacitance are recorded.

and fan and IDU ( / / ) µF 1 Pass Fail NA The capacitance value should be

( / / ) µF 2 Pass Fail NA as stated in the capacitor label.

( / / ) µF 3 Pass Fail NA

( / / ) µF 4 Pass Fail NA

Refer No : QMS16\WI\FOP\ACOND Date : 20 Oct 2010 Revision : 3

1 of 4

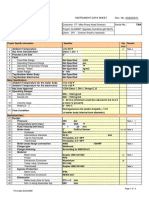

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Item Service Descriptions Unit No. Status Observation / Remarks Expected Result & Specification

2.6 Check pressure setting of High / Low Pressure Switch 1 Pass Fail NA High = 400 Psi; Low = 0 Psi.

(>4HP only) 2 Pass Fail NA Tolerance: +/-5 Psi.

3 Pass Fail NA

4 Pass Fail NA

2.7 Check wiring system (ODU internal wiring) 1 Pass Fail NA No physical damage and cables

2 Pass Fail NA are in good condition.

3 Pass Fail NA

4 Pass Fail NA

2.8 Check support bracket inclusive of bolts and nuts 1 Pass Fail NA Support bracket mounted firmly.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

2.9 Check the turning of the motor bearing for fan motor 1 Pass Fail NA Smooth turning of bearing.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

2.10 Check chassis grounding of ODU 1 Pass Fail NA Grounded to EGB or earth chamber.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

2.11 Check mounting & physical condition of grill cage / bracket / 1 Pass Fail NA Grill cage / bracket / platform

platform 2 Pass Fail NA mounted firmly and paint if the

3 Pass Fail NA corrosion has deteriorated the

4 Pass Fail NA mounting structure.

3.0 Indoor Unit (IDU)

3.1 Clean the filter 1 Pass Fail NA Filter cleaned.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

3.2 Clean the evaporator coil and fin 1 Pass Fail NA Evaporator coil and fin cleaned.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

3.3 Test for gas leaking for IDU 1 Pass Fail NA No gas leakage.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

3.4 Flush drain pipe 1 Pass Fail NA Water is able to flow through

2 Pass Fail NA smoothly.

3 Pass Fail NA

4 Pass Fail NA

3.5 Check the turning of the motor bearing for blower motor 1 Pass Fail NA Smooth turning of bearing

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

3.6 Measure the supply voltage at the ( )V 1 Pass Fail NA Single phase: 240VAC ;

terminal block of ODU ( )V 2 Pass Fail NA Three Phase: 415VAC;

( )V 3 Pass Fail NA Tolerance: +/- 10%.

( )V 4 Pass Fail NA

3.7 Measure the IDU current ( )A 1 Pass Fail NA Running amp shoud be +/-20% from

( )A 2 Pass Fail NA the manufacturer specification.

( )A 3 Pass Fail NA (refer to Appendix 1)

( )A 4 Pass Fail NA

Refer No : QMS16\WI\FOP\ACOND Date : 20 Oct 2010 Revision : 3

2 of 4

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Item Service Descriptions Unit No. Status Observation / Remarks Expected Result & Specification

3.8 Set indoor console units setting to: 1 Pass Fail NA Indoor console unit is set at:

TOC battery room: 22°C 2 Pass Fail NA TOC battery room: 22°C;

TOC equipment room: 22°C 3 Pass Fail NA TOC equipment room: 22°C;

TOC office area: 25°C 4 Pass Fail NA TOC office area: 25°C;

BTS cabin BSC/Trunk/Hub: 24°C BTS cabin BSC/Trunk/Hub: 24°C;

BTS cabin End site: 26°C BTS cabin End site: 26°C.

Setting sealed with tape.

3.9 Check wiring system (IDU internal wiring) 1 Pass Fail NA No physical damage and cables

2 Pass Fail NA are in good condition.

3 Pass Fail NA

4 Pass Fail NA

3.10 Check chassis grounding of IDU 1 Pass Fail NA Indoor unit should be grounded to

2 Pass Fail NA EGB or earth chamber.

3 Pass Fail NA

4 Pass Fail NA

3.11 Verify functionality of indoor console units 1 Pass Fail NA Console units respond to setting.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

4.0 Air-Conditioning Distribution Board

4.1 Measure incoming voltage ( )V 1 Pass Fail NA Single phase: 240VAC ;

( )V 2 Pass Fail NA Three Phase: 415VAC;

( )V 3 Pass Fail NA Tolerance: +/- 10%.

( )V 4 Pass Fail NA

4.2 Check the overload functionality. 1 Pass Fail NA The overload cut-off and trip

2 Pass Fail NA the air-conditioning system.

3 Pass Fail NA

4 Pass Fail NA

4.3 Check the air-cond timer functionality 1 Pass Fail NA Air-cond changeover.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

4.4 Check wiring system (air-cond DB wiring) 1 Pass Fail NA No physical damage and cables

2 Pass Fail NA are in good condition.

3 Pass Fail NA

4 Pass Fail NA

4.5 Test the relay and contactor by setting selector switch 1 Pass Fail NA Relay and contactor energise.

to manual 2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

5.0 Path

5.1 Test for gas leaking from IDU to ODU 1 Pass Fail NA No gas leakage.

2 Pass Fail NA

3 Pass Fail NA

4 Pass Fail NA

5.2 Check piping insulation 1 Pass Fail NA No physical damage and

2 Pass Fail NA exposed copper piping.

3 Pass Fail NA

4 Pass Fail NA

5.3 Check wiring system inclusive of trunking (IDU to ODU) 1 Pass Fail NA No physical damage, cables are

2 Pass Fail NA in good condition and trunking

3 Pass Fail NA is mounted firmly.

4 Pass Fail NA

Refer No : QMS16\WI\FOP\ACOND Date : 20 Oct 2010 Revision : 3

3 of 4

Air Conditioner Split System Preventive Maintenance & Service Checksheet

Item Service Descriptions Unit No. Status Observation / Remarks Expected Result & Specification

6.0 Room Temperature Verification

6.1 Align the temperature setting of the Opto 2 alarm sensor 1 Pass Fail NA Opto 2 sensor temperature reading

2 Pass Fail NA tally with thermometer.

3 Pass Fail NA

4 Pass Fail NA

6.2 Check room temperature after service 1 Pass Fail NA Must be within:

2 Pass Fail NA TOC battery room: 22°C;

3 Pass Fail NA TOC equipment room: 22°C;

4 Pass Fail NA TOC office area: 25°C;

BTS cabin BSC/Trunk/Hub: 24°C;

BTS cabin End site: 26°C;

Tolerance: +/- 2°C.

Observation / Recommendation / Remarks by the Checkers:

Confirmation Of Work Executed

Done By: Checked By: Verified By:

Sign: _______________ Sign: _______________ Sign: _______________

Name: _______________ Name: _______________ Name: _______________

Date: _______________ Date: _______________ Date: _______________

Refer No : QMS16\WI\FOP\ACOND Date : 20 Oct 2010 Revision : 3

4 of 4

You might also like

- 940-20059 - 01 MFG Doc PCAMAP Mobile EV ChargerDocument3 pages940-20059 - 01 MFG Doc PCAMAP Mobile EV ChargerRoberto QuinteroNo ratings yet

- PMDT - Aircond Template V3Document8 pagesPMDT - Aircond Template V3Aemi Nadia Ahmad SauffiNo ratings yet

- Datos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Document1 pageDatos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Julio César Samamé VegaNo ratings yet

- Credit Suise All The ReportsDocument5 pagesCredit Suise All The ReportsvheoncygracenNo ratings yet

- Distribution Calculations and SchedulesDocument20 pagesDistribution Calculations and Schedulesvranceanu bogdanNo ratings yet

- Rhm60L Mass Flow Sensor (M60L) For Rhe2X: For More Options Please Look Up 'General Options' Tab / Price SheetDocument3 pagesRhm60L Mass Flow Sensor (M60L) For Rhe2X: For More Options Please Look Up 'General Options' Tab / Price SheetJhon SierraNo ratings yet

- Oil CentrifugeDocument2 pagesOil CentrifugeMuttappa T JainapurNo ratings yet

- 10P149 E0028 102 - R0Document73 pages10P149 E0028 102 - R0PrasadNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- Sl. No. Description Requirements ABB RemarksDocument1 pageSl. No. Description Requirements ABB Remarksmohan babuNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Document17 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Arun KumarNo ratings yet

- ERTAF - ERTAF-2 Maco-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 Maco-2 - Product ReportKaran GnaniNo ratings yet

- SA 980 P 11433 CS Plug Valve Rev T02Document3 pagesSA 980 P 11433 CS Plug Valve Rev T02altipatlarNo ratings yet

- 7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDDocument8 pages7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDAnonymous dH3DIEtzNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- 8BFF-C01+R2 - K230Document6 pages8BFF-C01+R2 - K230wazakifyNo ratings yet

- Data Sheet For Pressure TransmitterDocument2 pagesData Sheet For Pressure TransmitterDavinder Singh BhattiNo ratings yet

- API Motor Data Sheet Temp LetDocument6 pagesAPI Motor Data Sheet Temp LetkhalidNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- PE LBS No. 1 (Fault)Document14 pagesPE LBS No. 1 (Fault)Zul AtfiNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDocument12 pagesBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Inspeccion Ta2 Serial Pab Cat-320cDocument11 pagesInspeccion Ta2 Serial Pab Cat-320cRAMON CALDERONNo ratings yet

- T-Doble Test Details Report: NameplateDocument2 pagesT-Doble Test Details Report: NameplateBilly Baute BornacelliNo ratings yet

- 00000-JDS-015 (ERV Manhole) Rev 0Document10 pages00000-JDS-015 (ERV Manhole) Rev 0sithulibraNo ratings yet

- 8BFF-C03+R1 - K110Document4 pages8BFF-C03+R1 - K110MahdiNo ratings yet

- b1x b2x Ds PDFDocument2 pagesb1x b2x Ds PDFscibduser001No ratings yet

- 3-4 HD - Api - 617 PDFDocument8 pages3-4 HD - Api - 617 PDFkagasaw023No ratings yet

- Siemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3Document6 pagesSiemens Motor 2HP - 1800 Rpm1MB2121-1AB41-6AG3marco antonio ramos melendezNo ratings yet

- Pa Ash 7776Document2 pagesPa Ash 7776milton1987No ratings yet

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlarNo ratings yet

- Terminal Block Diaphragm Switch: D1T, D2T SeriesDocument2 pagesTerminal Block Diaphragm Switch: D1T, D2T Serieschris a gutierrexNo ratings yet

- 01 Epc Di HD 002 - B Instrumentos de FlujoDocument8 pages01 Epc Di HD 002 - B Instrumentos de FlujoDebye101No ratings yet

- SA - 980 - P - 11405 - Tank Level Transmitter Rev T02Document1 pageSA - 980 - P - 11405 - Tank Level Transmitter Rev T02altipatlarNo ratings yet

- Tally Insp. LC2 Rev. 03Document1 pageTally Insp. LC2 Rev. 03Jorge Ignacio Lara CeballosNo ratings yet

- End To End - DifferentialDocument1 pageEnd To End - DifferentialRichard RegidorNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: End To End Test - DifferentialDocument1 pageCommissioning Service Department Commissioning Standard Test Formats Description: End To End Test - DifferentialAshrafReyadNo ratings yet

- OQ Procedure & Report ALP autoclaveDocument12 pagesOQ Procedure & Report ALP autoclavePhong LeNo ratings yet

- 7ss - Busbar Low Imp Relay Test-1Document17 pages7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- Specification Sheets For On-Off Manual ValvesDocument5 pagesSpecification Sheets For On-Off Manual ValvesMichell TurbayNo ratings yet

- Api 617Document14 pagesApi 617ecsuperal100% (1)

- Roxar - 20092851 IDSDocument4 pagesRoxar - 20092851 IDSDidik WahyudiNo ratings yet

- NST3946DP6T5G Dual Complementary General Purpose Transistor: FeaturesDocument9 pagesNST3946DP6T5G Dual Complementary General Purpose Transistor: FeaturesLenin EspinozaNo ratings yet

- Nav Iii Phase 1Document20 pagesNav Iii Phase 1carl reevesNo ratings yet

- bb2 Pump-DatasheetDocument14 pagesbb2 Pump-DatasheetMojtabaNo ratings yet

- Data - Sheet - Ac - DC - 82a R-1Document6 pagesData - Sheet - Ac - DC - 82a R-1Aashish MoyalNo ratings yet

- 4-20 Ma Output Velocity Sensor: 641B00 Performance English SI Op Tion A L Version SDocument1 page4-20 Ma Output Velocity Sensor: 641B00 Performance English SI Op Tion A L Version SachrafNo ratings yet

- Step by Step WCCADocument18 pagesStep by Step WCCAJohn R Walsh100% (1)

- Bottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionDocument1 pageBottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionSubodh Murkewar0% (1)

- UPG2035T5F Nec'S Broadband Gaas Mmic DPDT Switch For 2.4 GHZ and 5 GHZ WlanDocument13 pagesUPG2035T5F Nec'S Broadband Gaas Mmic DPDT Switch For 2.4 GHZ and 5 GHZ WlanKSNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- Cooper Analogue SensorsDocument2 pagesCooper Analogue SensorsvimalNo ratings yet

- (TDB) +VRF+DVM+S+Eco+HR+For+America Ver.1.5 201214 PDFDocument67 pages(TDB) +VRF+DVM+S+Eco+HR+For+America Ver.1.5 201214 PDFLuis Angulo CaroNo ratings yet

- CSSP Report 1. Project Informa On: 2.1equipment ListDocument7 pagesCSSP Report 1. Project Informa On: 2.1equipment ListIssam LaamiriNo ratings yet

- Rhm40L Mass Flow Sensor (M40L) For Rhe2X: Not With A0Document3 pagesRhm40L Mass Flow Sensor (M40L) For Rhe2X: Not With A0Jhon SierraNo ratings yet

- Start-Up & Commissioning ReportDocument2 pagesStart-Up & Commissioning ReportsadiqNo ratings yet

- Packaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference SheetDocument30 pagesPackaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference Sheetfebry alwan putraNo ratings yet

- rs40 SpecDocument6 pagesrs40 SpecNur ImansyahNo ratings yet

- BSCE - MiniTPDocument27 pagesBSCE - MiniTPAzli Fitri100% (1)

- Senai International Airport - NAIP - 29072011 - Rev0Document21 pagesSenai International Airport - NAIP - 29072011 - Rev0Azli Fitri100% (1)

- MasterTec CatalogueDocument127 pagesMasterTec CatalogueAzli Fitri100% (1)

- Tesco Kepong 2121aDocument35 pagesTesco Kepong 2121aAzli FitriNo ratings yet

- Catalogue Power CableDocument28 pagesCatalogue Power CableAzli FitriNo ratings yet

- Maxis Broadband SDN BHD: Technical Proposal For The Installation of Maxis Mobile Telecommunication Facilities ATDocument11 pagesMaxis Broadband SDN BHD: Technical Proposal For The Installation of Maxis Mobile Telecommunication Facilities ATAzli FitriNo ratings yet

- KMI-Infrared Asphalt Heater 2-18XDocument1 pageKMI-Infrared Asphalt Heater 2-18XAzli FitriNo ratings yet

- KMI-Infrared Asphalt Heater 4-40Document1 pageKMI-Infrared Asphalt Heater 4-40Azli FitriNo ratings yet

- Rhinopatch HAPAS BBA Certificate - 31 - 05 - 2011Document6 pagesRhinopatch HAPAS BBA Certificate - 31 - 05 - 2011Azli FitriNo ratings yet

- KMI-Infrared Asphalt Heater 4-48Document1 pageKMI-Infrared Asphalt Heater 4-48Azli FitriNo ratings yet

- KM - International-Infrared Asphalt Heater-LB 2-16Document2 pagesKM - International-Infrared Asphalt Heater-LB 2-16Azli FitriNo ratings yet

- Compare PASS To PME - Apr 2016Document10 pagesCompare PASS To PME - Apr 2016Azli FitriNo ratings yet

- Rhinopatch 7 Step Process in Road Repair PDFDocument1 pageRhinopatch 7 Step Process in Road Repair PDFAzli FitriNo ratings yet

- Tanah Kebun Di Ulu Muar Kuala PilahDocument2 pagesTanah Kebun Di Ulu Muar Kuala PilahAzli FitriNo ratings yet

- 1612 - Hi-Brite Reflective Road Studs - IntroductionDocument17 pages1612 - Hi-Brite Reflective Road Studs - IntroductionAzli FitriNo ratings yet

- Tanah Kebun Kelapa Sawit 5.29 Ekar Di Kuala Kangsar PerakDocument2 pagesTanah Kebun Kelapa Sawit 5.29 Ekar Di Kuala Kangsar PerakAzli FitriNo ratings yet

- New Text Document R8W5W-5SPZ4-SCHNS R5Wfw-5Bbuf-Xfk5S R8Wvp-5Spzr-Sxhss WV5VV-55VTK-5F8WS WYWCB-58VU4-5XBNSDocument1 pageNew Text Document R8W5W-5SPZ4-SCHNS R5Wfw-5Bbuf-Xfk5S R8Wvp-5Spzr-Sxhss WV5VV-55VTK-5F8WS WYWCB-58VU4-5XBNSAzli FitriNo ratings yet

- Electrode BoilerDocument7 pagesElectrode BoilerBrijendra MathurNo ratings yet

- Peltier GüneşDocument16 pagesPeltier GüneşTaşkın TezNo ratings yet

- MG-880 Specification PDFDocument3 pagesMG-880 Specification PDFMartin HasskelNo ratings yet

- Intake-Air System (ZM)Document13 pagesIntake-Air System (ZM)Sebastian SirventNo ratings yet

- Steam HammeringDocument5 pagesSteam HammeringMuhammad JunaidNo ratings yet

- Domestic Gas PipingDocument2 pagesDomestic Gas Pipingvalentinlupascu33No ratings yet

- Study F&G SysDocument3 pagesStudy F&G SysYousuf RanaNo ratings yet

- Marble Mania GalaxyDocument80 pagesMarble Mania Galaxyhitomi furugawaNo ratings yet

- EPC - Magnus Power BrochureDocument8 pagesEPC - Magnus Power BrochuremanojNo ratings yet

- Virtual Labs - Control Valve SizingDocument31 pagesVirtual Labs - Control Valve SizinglvrevathiNo ratings yet

- Centrifugal Pumps (2 HP To 10 HP) : Performance Range MotorDocument2 pagesCentrifugal Pumps (2 HP To 10 HP) : Performance Range MotorSherin PaulNo ratings yet

- Solvingweek 9Document22 pagesSolvingweek 9Christopher Lennon Dela Cruz0% (1)

- Mtu538 120095 09092563Document2 pagesMtu538 120095 09092563Chaiwat PrssatpornNo ratings yet

- Sulzer Centrifugal Pumps - Basic OperationDocument26 pagesSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiNo ratings yet

- Thermal EdgeDocument2 pagesThermal EdgeQuantumAutomationNo ratings yet

- Fundamentals of Hydraulic PumpsDocument19 pagesFundamentals of Hydraulic Pumpslopez8a100% (1)

- Robert Bosch Type VE Diesel Injection PumpDocument3 pagesRobert Bosch Type VE Diesel Injection PumpPubudu de Silva80% (5)

- Manufacturing Status of E&M EquipmentDocument4 pagesManufacturing Status of E&M Equipmenttaimur ahmadNo ratings yet

- WPSPQR Feb2009Document22 pagesWPSPQR Feb2009Mohammad ElhedabyNo ratings yet

- Carrier FloorceilingDocument3 pagesCarrier FloorceilingNathaly HernándezNo ratings yet

- R41024112018 JNTUK Question PaperDocument2 pagesR41024112018 JNTUK Question PaperYellaji AllipilliNo ratings yet

- ICB Boiler Book PDFDocument28 pagesICB Boiler Book PDFfauzi endraNo ratings yet

- Hydraulic Jet PumpDocument2 pagesHydraulic Jet PumpYaqoob IbrahimNo ratings yet

- Needle Flame TesterDocument9 pagesNeedle Flame TesterGregorio ToroNo ratings yet

- Flash Steam Geothermal TechnologyDocument7 pagesFlash Steam Geothermal TechnologyMearegNo ratings yet

- The Basics of Electric Heat Trace TechnologyDocument8 pagesThe Basics of Electric Heat Trace Technologyvladimir rosas ayalaNo ratings yet

- 500KVA Diesel Generator Set - Comments For Cummins DG Set PDFDocument5 pages500KVA Diesel Generator Set - Comments For Cummins DG Set PDFJoanna BaileyNo ratings yet

- Inventory: Warehouse PO No. Bin UOM Quantity Unit Price (S) Total Price (S)Document10 pagesInventory: Warehouse PO No. Bin UOM Quantity Unit Price (S) Total Price (S)Mohamed MusaNo ratings yet

- Ra Me 05501 Refrigeration and Air ConditioningDocument1 pageRa Me 05501 Refrigeration and Air ConditioningsivabharathamurthyNo ratings yet

- PID PVOBox TI en 10 PDFDocument8 pagesPID PVOBox TI en 10 PDFbalajiiconNo ratings yet