Professional Documents

Culture Documents

Hydraulic Jet Pump

Uploaded by

Yaqoob IbrahimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Jet Pump

Uploaded by

Yaqoob IbrahimCopyright:

Available Formats

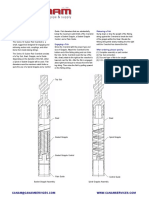

Hydraulic Jet Pumps

Casing Casing Tubing

Lock &

Upper Lock

Tubing Coiled Packer

Seal

or Nose

Upper

Macaroni

Tubing Coiled Tubing

Packer or

Macaroni

Tubing “Free”

Jet

Pump

Bottom

Hole

Assembly

Gas Nozzle

Lift

Mandrel

Sliding Throat

Sleeve

Diffuser

Bottom

Lower Hole

Seal Assembly

Equalizing

Retrievable Check

Standing Valve

Lower Pump Valve

Tubing Seat

Packer Packer

Packer

Casing

Sliding Sleeve Tubing / Packer Fixed Insert Fixed Casing Standard Single High Volume Reverse

Seal Jet Circulation

The Standard Single Seal Jet Pump is shown landed in a bottom

Applications & Designs hole assembly designed for a hydraulic piston pump. This design

permits adaptation to a wide assortment of bottom hole

assemblies from many manufacturers. As a “Free Pump”, the unit

Weatherford's Jet Pumps can be adapted to may be retrieved merely by changing the flow of power fluid down

run in a wide variety of bottom hole cavities the casing annulus, unseating the pump and returning it to the

and downhole tools. The actual working surface.

components of the Jet Pump the nozzle,

throat and diffuser are assembled in a The High Volume Jet Pump is also shown in a “Free Pump”

variety of configurations and materials to configuration. Due to the enlarged fluid passageways of the High

suit the production requirements and the Volume Jet, a special bottom hole assembly is required. The High

downhole environment. Shown above are Volume Jet Pump can also be run in a reverse circulation mode.

some of the more common Jet Pump As shown, the reverse circulation design is not a “Free Pump”, but

applications. is held in place by means of a top lock/mechanical holddown. It is

easily installed and retrieved using conventional wireline fishing

tools.

The Sliding Sleeve Jet Pump design has become popular in

particular with offshore operators. Primarily run in a reverse

circulation mode with a top lock, the Sliding Sleeve version can

also be run on tubing if desired. Platform operators using electric

submersible pumps have found that the Sliding Sleeve Jet The Fixed Insert and Fixed Casing Jet Pump were

Pump can be run in, to continue to produce a well when the designed to be run in existing production tubing or

ESP has shut down. Weatherford's Sliding Sleeve Jet casing. The Fixed Insert is normally run inside

Pumps have been widely accepted and are especially production tubing on a macaroni string and seated

suited for drill stem testing, because surface pumps are metal-to-metal on the previous pump seat.

already in place and well production capacity is uncertain Produced fluid and exhausted power fluid flow up

(jet pumps can operate at less than 5 percent of rated the production tubing annulus. The Fixed Casing

capacity without damage to the pump). design also run in on macaroni tubing seats on a

casing packer. Production is returned up the

The Tubing/Packer Jet Pump can be installed in a well by casing annulus.

wireline methods without first pulling the tubing. As shown,

this design has wireline-set tubing packers at the top and

bottom of the pump and straddling a gaslift mandrel. An

alternate design straddles wireline perforated tubing

perforations. If a seating nipple exists at the proper depth, it

can be substituted for the bottom tubing packer. Circulation

can be up or down the tubing.

How it Works Power Fluid

Pressure

Power fluid at high pressure (low velocity)

is converted to a low pressure (high

velocity) jet by the nozzle. The pressure at

the entrance of the throat becomes lower

as the power fluid rate is increased. When

this pressure becomes lower than the

pressure in the suction passageway, fluid is

drawn in from the wellbore. The suction

fluid becomes entrained with the high

velocity jet and the pumping action then

begins. After mixing in the throat, the

combined power fluid and suction fluid is Power Fluid

slowed down by the diffuser. Because the Velocity

velocity is reduced, the pressure increases

rising to a value sufficient to pump the fluid Nozzle Throat Diffuser

to the surface.

A full range of nozzle and throat sizes are

available to allow power fluid rate and

pressure to be varied to meet various

requirements.

WESTERN HEMISPHERE EASTERN HEMISPHERE

Canada Europe

Phone: (403) 269-7788 Phone: (44) 1224 331 331

Latin America CIS & Middle East

North - Lecheria, Venezuela Phone: (43) 9714-3325999

Tel.: 58 281 2814211

Worldwide Customer Service

515 Post Oak Blvd. · Houston, Texas 77027 South - Buenos Aires, Argentina Weatherford products and services are subject to Weatherford’s standard terms and

Phone: (713) 693-4800 · als@weatherford.com Phone: 54 (11) 5077 0077 conditions. For more information concerning the full line of Weatherford products and

services, please contact your authorized Weatherford representative. Unless noted

otherwise, trademarks and service marks noted herein are the property of Weatherford.

© Copyright 2002-2004 Weatherford · All rights reserved · ALS 5003 · 7/03 · Printed in U.S.A.

You might also like

- ODST Armor Kit Instructionsa PDFDocument81 pagesODST Armor Kit Instructionsa PDFArrow RoweNo ratings yet

- MD Totco Series 2000 Instruments Installation, Calibration, & OperationDocument160 pagesMD Totco Series 2000 Instruments Installation, Calibration, & OperationDenzil Stephenson100% (1)

- Flow Scanner: Production Logging in Multiphase Horizontal WellsDocument8 pagesFlow Scanner: Production Logging in Multiphase Horizontal WellsFernando TorresNo ratings yet

- Isolation Barrier Valves - CatalogDocument8 pagesIsolation Barrier Valves - CatalogMarcos CecilianoNo ratings yet

- Landing Nipple 2,31 XNDocument1 pageLanding Nipple 2,31 XNEdwin AbelloNo ratings yet

- 350 Direct Pump Setting tool-DPSTDocument2 pages350 Direct Pump Setting tool-DPSTAdarsh HegdeNo ratings yet

- Polypak SealDocument2 pagesPolypak SealZAMFERLENONo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsmahsaNo ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Botil Model BTCN Mechanical Set PackerDocument2 pagesBotil Model BTCN Mechanical Set PackerReivaj JavierNo ratings yet

- Sliding SleveDocument4 pagesSliding SleveMarceloNo ratings yet

- Bimbar Inflatable PDFDocument36 pagesBimbar Inflatable PDFcarlosdh_03No ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- DST Tools Catalog PDF FreeDocument103 pagesDST Tools Catalog PDF FreeReza AsakerehNo ratings yet

- BTU Retreivable PlugDocument1 pageBTU Retreivable Plugbrunolb1No ratings yet

- Retrievable Packer SystemsDocument2 pagesRetrievable Packer SystemsArenita WrightNo ratings yet

- Annexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFDocument7 pagesAnnexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFMehdi NorouziNo ratings yet

- Ps 0958 1214obh WDocument1 pagePs 0958 1214obh WLoreleiNo ratings yet

- RTTS Forced Circulation Valve and RTTS Positive Circulating ValveDocument14 pagesRTTS Forced Circulation Valve and RTTS Positive Circulating ValveMohamed ShafieNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- Hydro Trip Pressure SubsDocument5 pagesHydro Trip Pressure SubsyasirismNo ratings yet

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- WH6 2005Document19 pagesWH6 2005annNo ratings yet

- Ps 0412 0600obh WDocument1 pagePs 0412 0600obh WHunterNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- DDocument26 pagesDBalkis FatihaNo ratings yet

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- Introduction To Well Completion: (Part - IV)Document36 pagesIntroduction To Well Completion: (Part - IV)Mohamed MahmoudNo ratings yet

- Half Mule Shoe Guide 88050307Document2 pagesHalf Mule Shoe Guide 88050307satyendraNo ratings yet

- WPCE Slick Cable Pack-OffDocument1 pageWPCE Slick Cable Pack-OffMARIONo ratings yet

- 9.625'' Inspection SheetDocument3 pages9.625'' Inspection SheetMohamed Mahmoud Rezk DimoNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- Polar RB (Regular Bore) Seal Bore PackerDocument3 pagesPolar RB (Regular Bore) Seal Bore PackerAlexander KlmNo ratings yet

- Venturetech XK 90 Power Swivel Spec SheetDocument1 pageVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonNo ratings yet

- Equipment Schematic - For P5 DualDocument4 pagesEquipment Schematic - For P5 DualrahulNo ratings yet

- Plug and Ball CatcherDocument48 pagesPlug and Ball CatcherDoni KurniawanNo ratings yet

- CatalogDocument424 pagesCatalogLuis David Concha CastilloNo ratings yet

- Sect 06 Full-Opening EquipmentDocument44 pagesSect 06 Full-Opening EquipmentpaimanNo ratings yet

- 3in BOP Inner & Outer SealsDocument1 page3in BOP Inner & Outer SealsusamakhattakNo ratings yet

- Assy Vol IDocument4 pagesAssy Vol IFernando CastelblancoNo ratings yet

- File3e - Propellants - and - Perf - Damage Stimgun PDFDocument4 pagesFile3e - Propellants - and - Perf - Damage Stimgun PDFLuis Alfonso EstebanNo ratings yet

- Guide To Types 'X' and 'R' Otis Landing NipplesDocument1 pageGuide To Types 'X' and 'R' Otis Landing NipplesAnthony LakpahNo ratings yet

- 3.500 Heavy Duty Tubing SwivelDocument2 pages3.500 Heavy Duty Tubing SwivelJack Foster100% (1)

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- Ps 0412 0612obh WDocument1 pagePs 0412 0612obh WHunterNo ratings yet

- Completion 4Document36 pagesCompletion 4AboZaidNo ratings yet

- Parveen PRHP Packer: Downhole Completion EquipmentDocument5 pagesParveen PRHP Packer: Downhole Completion EquipmentsambhajiNo ratings yet

- 34 Model AD-1 Tension PackerDocument2 pages34 Model AD-1 Tension PackerDenier RubianoNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- MH Hyd Tac Tm-353!01!3Document6 pagesMH Hyd Tac Tm-353!01!3David MannNo ratings yet

- ETI-CPW Packer Manual Spare PartDocument4 pagesETI-CPW Packer Manual Spare PartDidin DelgadoNo ratings yet

- TRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596Document3 pagesTRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596alejandromarinch7No ratings yet

- Wellhead Products Catalog vFEB2015 PDFDocument20 pagesWellhead Products Catalog vFEB2015 PDFRatnakar PatilNo ratings yet

- BakerDocument4 pagesBakerWilliam EvansNo ratings yet

- (General Assembly) : MRP PackerDocument1 page(General Assembly) : MRP PackerAli AliNo ratings yet

- 7 X 9.625 With TSP, DWPDocument5 pages7 X 9.625 With TSP, DWPRahima RahoumaNo ratings yet

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoNo ratings yet

- Camesa TechBulletin-022Document1 pageCamesa TechBulletin-022FauzanNo ratings yet

- WBR Bicycle Maintenance Manual PDFDocument11 pagesWBR Bicycle Maintenance Manual PDFMaxNo ratings yet

- Hydrochloric - Rubber Lined Tank Valves & FittingsDocument1 pageHydrochloric - Rubber Lined Tank Valves & FittingsARMANDONo ratings yet

- Proposed 6 Hole Logging StringDocument4 pagesProposed 6 Hole Logging StringYaqoob IbrahimNo ratings yet

- Daily Production Report OMVDocument1 pageDaily Production Report OMVYaqoob IbrahimNo ratings yet

- Colour Code Assurance Hilong-5 Jugan-2Document6 pagesColour Code Assurance Hilong-5 Jugan-2Yaqoob IbrahimNo ratings yet

- HARCDocument8 pagesHARCYaqoob IbrahimNo ratings yet

- Tube Move Calculation ParametersDocument1 pageTube Move Calculation ParametersYaqoob IbrahimNo ratings yet

- UEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Document14 pagesUEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Yaqoob IbrahimNo ratings yet

- TLC ProceduresDocument14 pagesTLC ProceduresYaqoob IbrahimNo ratings yet

- 2-Phase With Sand TrapDocument2 pages2-Phase With Sand TrapYaqoob IbrahimNo ratings yet

- Mdata Miano-26: 660256622Document14 pagesMdata Miano-26: 660256622Yaqoob IbrahimNo ratings yet

- Errata: Date of Issue: Affected PublicationDocument88 pagesErrata: Date of Issue: Affected PublicationYaqoob IbrahimNo ratings yet

- Color Code System For Lifting Equipment: Hilong-21Document3 pagesColor Code System For Lifting Equipment: Hilong-21Yaqoob IbrahimNo ratings yet

- IADC Classification ChartDocument2 pagesIADC Classification ChartYaqoob IbrahimNo ratings yet

- Colour Code System Compliance UET-1 KK-DT-4Document8 pagesColour Code System Compliance UET-1 KK-DT-4Yaqoob IbrahimNo ratings yet

- PDC Drill BitsDocument22 pagesPDC Drill BitsYaqoob IbrahimNo ratings yet

- Color Coding Assurance at HL-09 (Qabul-2)Document13 pagesColor Coding Assurance at HL-09 (Qabul-2)Yaqoob IbrahimNo ratings yet

- PDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberDocument16 pagesPDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberYaqoob IbrahimNo ratings yet

- Anti Stall Tool For Drilling BHA by ATSDocument4 pagesAnti Stall Tool For Drilling BHA by ATSYaqoob IbrahimNo ratings yet

- Mexicos Deepest Well Drill String SPE-52822-MSDocument10 pagesMexicos Deepest Well Drill String SPE-52822-MSYaqoob IbrahimNo ratings yet

- Drillers Istructions 21 Oct 2013 - BOP Pressure TestDocument2 pagesDrillers Istructions 21 Oct 2013 - BOP Pressure TestYaqoob IbrahimNo ratings yet

- Hazard Hunt Report TCPDC-2001 (Halipota-5)Document8 pagesHazard Hunt Report TCPDC-2001 (Halipota-5)Yaqoob Ibrahim0% (1)

- Understanding Toolface: Angus JamiesonDocument32 pagesUnderstanding Toolface: Angus JamiesonYaqoob Ibrahim100% (2)

- Stop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)Document20 pagesStop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)Yaqoob IbrahimNo ratings yet

- UEP-HL Stop Cards Feb - 2017Document59 pagesUEP-HL Stop Cards Feb - 2017Yaqoob Ibrahim100% (1)

- Safe Cards TCPDC-2001: Reported By: Dilawar KhanDocument8 pagesSafe Cards TCPDC-2001: Reported By: Dilawar KhanYaqoob IbrahimNo ratings yet

- Hazard Hunt Report TCPDC-2001 (Halipota-5)Document8 pagesHazard Hunt Report TCPDC-2001 (Halipota-5)Yaqoob Ibrahim0% (1)

- Safe Cards TCPDC-2001: Reported By: Dilawar KhanDocument8 pagesSafe Cards TCPDC-2001: Reported By: Dilawar KhanYaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- UEP-HL Stop Cards Jan - 2017Document54 pagesUEP-HL Stop Cards Jan - 2017Yaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Hazard Hunt Status 26-08-2017Document28 pagesHazard Hunt Status 26-08-2017Yaqoob IbrahimNo ratings yet

- Modi Bus Wale BrochureDocument15 pagesModi Bus Wale BrochureVeeresh RathodNo ratings yet

- DMD Documentation Error - Freetronics ForumDocument3 pagesDMD Documentation Error - Freetronics ForumapofviewNo ratings yet

- Microsoft Power Bi TrainingDocument2 pagesMicrosoft Power Bi TrainingYazanMohamedNo ratings yet

- Psychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltDocument6 pagesPsychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltMirela Cojocaru StetcoNo ratings yet

- Ending The Houthi Threat To Red Sea ShippingDocument7 pagesEnding The Houthi Threat To Red Sea ShippingKevin ParkerNo ratings yet

- MessageDocument5 pagesMessageธีรพิชญ์ ศรีสมวงศ์No ratings yet

- 7 - Modified Slenderness Ratio For Built-Up MembersDocument13 pages7 - Modified Slenderness Ratio For Built-Up Membersخوێندن لە ئەوروپاNo ratings yet

- Marginal CallDocument3 pagesMarginal Calllexredondo22No ratings yet

- Critical Theory of Social Suffering - Emmanuel RenaultDocument22 pagesCritical Theory of Social Suffering - Emmanuel RenaultFilosofo São Paulo100% (1)

- Major Themes in The Poetry of Ted HughesDocument23 pagesMajor Themes in The Poetry of Ted Hughesपुष्प समब्याल100% (4)

- Assignment #1Document2 pagesAssignment #1Kenneth HerreraNo ratings yet

- Jee Main Physics Super ThirtyDocument170 pagesJee Main Physics Super ThirtyAnil KumarNo ratings yet

- Full CCNP Service Provider Routing LabDocument14 pagesFull CCNP Service Provider Routing LabMksNo ratings yet

- DLP-ENG-APR-25-Differentiate Tone From MoodDocument4 pagesDLP-ENG-APR-25-Differentiate Tone From MoodFrancis AbaigarNo ratings yet

- Review of LiteratureDocument18 pagesReview of LiteratureVimal VickyNo ratings yet

- Santosh BharatiDocument2 pagesSantosh Bharatisan_bharNo ratings yet

- Q3eSE RW2 U02A StudentDocument8 pagesQ3eSE RW2 U02A StudentNawal ALMALKINo ratings yet

- Spare Parts List: Hydraulic BreakersDocument24 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- نصوص الاهرام THE ANCIENT EGYPTIAN PYRAMID TEXTS by Timofey T. Shmakov Upload by (Dr-Mahmoud Elhosary)Document410 pagesنصوص الاهرام THE ANCIENT EGYPTIAN PYRAMID TEXTS by Timofey T. Shmakov Upload by (Dr-Mahmoud Elhosary)Dr-Mahmoud Elhosary100% (2)

- Grabar FTPDocument6 pagesGrabar FTPSergio Martín CorderoNo ratings yet

- PDF The Women of Lemuria Ancient Wisdom For Modern Times Nodrm CompressDocument60 pagesPDF The Women of Lemuria Ancient Wisdom For Modern Times Nodrm Compressguoxing weiNo ratings yet

- MCQ NetworkingDocument3 pagesMCQ NetworkingNamita SahuNo ratings yet

- Page 1 of 5: Guidelines/green-Top-Guidelines/gtg - 67 - Endometrial - Hyperplasia PDFDocument5 pagesPage 1 of 5: Guidelines/green-Top-Guidelines/gtg - 67 - Endometrial - Hyperplasia PDFfitrah fajrianiNo ratings yet

- CARDIOVASCULAR - SYSTEM Group No.3 MODULEDocument12 pagesCARDIOVASCULAR - SYSTEM Group No.3 MODULEDavid Paul LanuzaNo ratings yet

- Undergraduate Admissions by Apply Centre 2022 CycleDocument47 pagesUndergraduate Admissions by Apply Centre 2022 CycleSaranNo ratings yet

- SPGMI Preview Fintech 2024 FINALDocument15 pagesSPGMI Preview Fintech 2024 FINALVignesh RaghunathanNo ratings yet

- LR-Fuel InjectorDocument27 pagesLR-Fuel Injectorjesusmorales6215No ratings yet

- Guias ESC para Insuficiencia Cardiaca CronicaDocument128 pagesGuias ESC para Insuficiencia Cardiaca CronicaKarla HernandezNo ratings yet