Professional Documents

Culture Documents

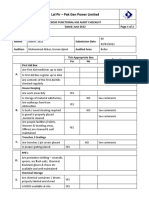

BCP Water Cooler Cleaning Through Backflushing

Uploaded by

Muhammad Abbas0 ratings0% found this document useful (0 votes)

20 views1 pageOriginal Title

Bcp Water Cooler Cleaning Through Backflushing

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views1 pageBCP Water Cooler Cleaning Through Backflushing

Uploaded by

Muhammad AbbasCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

BCP water coolers online back flushing can be done if needed due to consistent temperature rise of BCP

motor cavity.

CBP cavity normal temperatures are around 50 C

High temp alarm is sounded at 57 C

BCP trip set point is at 66 C

Steps:

Online cooler backwashing is done as per following steps:

1. Unit load should be minimum

2. Inform CCR to keep an eye on the BCP cavity temperature

3. Contact MMD engineer available for men power and other arrangements

4. Close cooling water supply and return isolation valves

5. MMD will open cooling water supply flange located at 2 nd floor

6. Open cooling water return isolation valve (IPGB20 AA210 for LP) to back flush and remove the

debris, corrosion particles, clay, algae, shells etc

7. Close cooling water return isolation valve (1PGB 30 AA210 for LP) after sufficient flushing and

cleaning of the impurities

8. Open cooling water supply isolation valve and flush the supply pipe

9. Close supply and return isolation valves and get the get supply line flange installation by MMD

10. Open cooling water supply valve and vent the line

11. Open cooling water isolation valve and normalize the circuit

12. Keep the system under observation for leakages, temperature trend etc

Precautions:

1. Closely watch the cavity temperatures during the activity, ask CCR for coordination

2. Plan with MMD to manage the resources adequately to minimize the activity duration

3. Plan activity on minimum load

4. Ensure safety measures and coordination

You might also like

- Standard Operating Procedure - HVAC - V01 - 29082010Document10 pagesStandard Operating Procedure - HVAC - V01 - 29082010Karthik MandyaNo ratings yet

- CH126P Lec 8 - Ch9Document20 pagesCH126P Lec 8 - Ch9kumiristineNo ratings yet

- Refractory Dry Out Procedures PDFDocument18 pagesRefractory Dry Out Procedures PDFTamer Abd Elrasoul0% (2)

- Industrial RefrigerationDocument5 pagesIndustrial RefrigerationApet GriffinNo ratings yet

- BCWDocument13 pagesBCWRohit100% (2)

- Cooling Tower SOPDocument8 pagesCooling Tower SOPBoiler Scrubber50% (2)

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Projektbericht FRB-Davit2 AnoDocument3 pagesProjektbericht FRB-Davit2 AnoM. K.No ratings yet

- IPCDocument2 pagesIPCjeeldhameliya82No ratings yet

- RacDocument26 pagesRacgurunakhale123No ratings yet

- Experiment 1-Refrigeration CycleDocument15 pagesExperiment 1-Refrigeration CycleFarrah DiyanaNo ratings yet

- Prelab Exp1 Refrigeration CycleDocument7 pagesPrelab Exp1 Refrigeration CycleDean Joyce AlborotoNo ratings yet

- Experiment 1: Refrigeration and Mechanical Heat Pump ExperimentDocument12 pagesExperiment 1: Refrigeration and Mechanical Heat Pump ExperimentMohamad FaizNo ratings yet

- Indiabulls Power Limited: Sop/Opns/ Operations DepartmentDocument2 pagesIndiabulls Power Limited: Sop/Opns/ Operations Departmentarvidkumar87060100% (1)

- Operation & Maintenance Manual: For Khartoum North Power Station-Phase Iii (2×100Mw) ProjectDocument7 pagesOperation & Maintenance Manual: For Khartoum North Power Station-Phase Iii (2×100Mw) ProjectVivek SakthiNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- Boiler Hydro TestDocument2 pagesBoiler Hydro TestKarthi KeyanNo ratings yet

- 660mw Sop LancoDocument17 pages660mw Sop Lancokalyanm203515No ratings yet

- tentativeBoilerCleanUp 230509 112910Document2 pagestentativeBoilerCleanUp 230509 112910sarojdubey0107No ratings yet

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JNo ratings yet

- 4TH Class Part B Review QuestionsDocument14 pages4TH Class Part B Review QuestionsCalvin Jude GoveiaNo ratings yet

- Heat Exchanger Lab Manual ELABDocument15 pagesHeat Exchanger Lab Manual ELAB유지No ratings yet

- Adsobtion Chiller SpecDocument6 pagesAdsobtion Chiller Specioan1946No ratings yet

- Boiling Heat Transfer ModuleDocument10 pagesBoiling Heat Transfer ModuleD7ooM_612No ratings yet

- 01.SOP Cold Start Up.r3Document16 pages01.SOP Cold Start Up.r3K R Kumar RanjanNo ratings yet

- BAC MaintenanceVL MVLv10EN PDFDocument16 pagesBAC MaintenanceVL MVLv10EN PDFWissam JarmakNo ratings yet

- Alfa LavalDocument29 pagesAlfa LavallipovanychNo ratings yet

- LDO-Firing 001Document21 pagesLDO-Firing 001Prakash Choudhary100% (1)

- Apv H35Document18 pagesApv H35petrakou aglaia100% (1)

- Adsorption Chiller Guide SpecificationsDocument6 pagesAdsorption Chiller Guide Specificationsmdalt9180No ratings yet

- Academia Summary - Shell and Tube Heat Exchangers Using Cooling WaterDocument3 pagesAcademia Summary - Shell and Tube Heat Exchangers Using Cooling WaterRanjani J DeepakNo ratings yet

- Operation of Condensate and Feed Water System HPDocument8 pagesOperation of Condensate and Feed Water System HPlp mishraNo ratings yet

- R59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMDocument22 pagesR59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMRamon Bochaca SandiumengeNo ratings yet

- 20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLDocument6 pages20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLSoficu DanielNo ratings yet

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Shut Down1Document2 pagesShut Down1moturuappalasreenuNo ratings yet

- 5.3 Experimental MethodologyDocument9 pages5.3 Experimental MethodologySiva Prasad IngetiNo ratings yet

- Method-Ct (Lab 1)Document4 pagesMethod-Ct (Lab 1)Berry101No ratings yet

- Desalt JWP 26 C Series PDFDocument4 pagesDesalt JWP 26 C Series PDFRavindar AnandanNo ratings yet

- MET Building ChillersDocument12 pagesMET Building Chillersoth369No ratings yet

- Cobe Centrysystem 3 Dialysis - Service ManualDocument35 pagesCobe Centrysystem 3 Dialysis - Service ManualHernan Vallenilla Rumildo MixNo ratings yet

- Practical Boom 2Document11 pagesPractical Boom 2Potter A. VijayNo ratings yet

- Project Standard Specification: Sequence of Operations 15940 - Page 1/6Document6 pagesProject Standard Specification: Sequence of Operations 15940 - Page 1/6adel rihanaNo ratings yet

- 500 MW Volume 2Document319 pages500 MW Volume 2api-19984595100% (7)

- General ServiceBulletins AuroraDocument40 pagesGeneral ServiceBulletins AuroraEduardo Aguero ValdezNo ratings yet

- Plate Type Heat ExchangerDocument7 pagesPlate Type Heat ExchangersenthilNo ratings yet

- ELS10-8HV-B700-SIE-S06-F4001-A-Sequence of OperationDocument21 pagesELS10-8HV-B700-SIE-S06-F4001-A-Sequence of OperationMohamed AshrafNo ratings yet

- Time: 2 Hours Total Marks: 50: Sub Code: Roll NoDocument2 pagesTime: 2 Hours Total Marks: 50: Sub Code: Roll NoAtul SharmaNo ratings yet

- Preparation and RequirementDocument2 pagesPreparation and RequirementAdy FardyNo ratings yet

- Desalt DPU-36-C Series: Titanium Plate Type Fresh Water GeneratorDocument4 pagesDesalt DPU-36-C Series: Titanium Plate Type Fresh Water GeneratorDwi Tri CahyonoNo ratings yet

- Data TTG AcDocument5 pagesData TTG AcMya Diggory SikukangzNo ratings yet

- Ppe Exp.3 ROLLNO 1Document9 pagesPpe Exp.3 ROLLNO 1Aniket SinghNo ratings yet

- Heat and Mass Transfer: Experiment No - 7Document9 pagesHeat and Mass Transfer: Experiment No - 7Sakshi YadavNo ratings yet

- COO 11 Cargo Heating Ver 0Document5 pagesCOO 11 Cargo Heating Ver 0imgesu tahtaNo ratings yet

- Perfusion for Congenital Heart Surgery: Notes on Cardiopulmonary Bypass for a Complex Patient PopulationFrom EverandPerfusion for Congenital Heart Surgery: Notes on Cardiopulmonary Bypass for a Complex Patient PopulationRating: 5 out of 5 stars5/5 (2)

- Log Sheets 2008 Jan FebDocument2 pagesLog Sheets 2008 Jan FebMuhammad AbbasNo ratings yet

- Shift Rota 2019Document7 pagesShift Rota 2019Muhammad AbbasNo ratings yet

- Stoppage Due To Fuel ShoratgeDocument4 pagesStoppage Due To Fuel ShoratgeMuhammad AbbasNo ratings yet

- SwitchyardDocument13 pagesSwitchyardMuhammad AbbasNo ratings yet

- CCTV Cameras RateDocument2 pagesCCTV Cameras RateMuhammad AbbasNo ratings yet

- Plant Operations: Page 1 of 2Document2 pagesPlant Operations: Page 1 of 2Muhammad AbbasNo ratings yet

- Air & GasDocument22 pagesAir & GasMuhammad AbbasNo ratings yet

- Operation Shift Rota 2021: A B C DDocument2 pagesOperation Shift Rota 2021: A B C DMuhammad AbbasNo ratings yet

- SOP Foam Operation.Document1 pageSOP Foam Operation.Muhammad Abbas100% (2)

- A.Waheed: Name Total Milk Total Amount Amount Received BalanceDocument8 pagesA.Waheed: Name Total Milk Total Amount Amount Received BalanceMuhammad AbbasNo ratings yet

- Performance Appraisal Form-BlankDocument3 pagesPerformance Appraisal Form-BlankMuhammad AbbasNo ratings yet

- Boiler CFA March 2021Document2 pagesBoiler CFA March 2021Muhammad AbbasNo ratings yet

- Steam Drum PDFDocument59 pagesSteam Drum PDFMuhammad AbbasNo ratings yet

- Steam DrumDocument10 pagesSteam DrumMuhammad AbbasNo ratings yet

- PG Valves Passing July-2019Document5 pagesPG Valves Passing July-2019Muhammad AbbasNo ratings yet

- From One-Month CFD To One-Day CFD - Efforts For Reducing Time and Cost of CFDDocument2 pagesFrom One-Month CFD To One-Day CFD - Efforts For Reducing Time and Cost of CFDMuhammad AbbasNo ratings yet

- Thermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFDocument8 pagesThermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFMuhammad AbbasNo ratings yet