Professional Documents

Culture Documents

SOP Foam Operation.

Uploaded by

Muhammad AbbasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP Foam Operation.

Uploaded by

Muhammad AbbasCopyright:

Available Formats

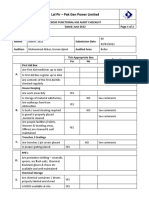

SOP’S FOR FOAM OPERATION ON FIRE (FIRE TRUCK )

1. All necessary PPE (Personal Protective Equipment) including i.e fire suit, safety

gloves, safety shoes, safety helmet, shall be wear by the person/ crew member.

2. Ensure vehicle is parked in safe area.

3. Check the foam level in foam tank.

4. Check the water level in water tank.

5. 102 liter foam in required for 3300 liter water and 216 liter foam is required for 7000

liters water if the foam and water proportion is kept 3% and 97% respectively.

6. Check the availability of Foam Making Branch Pipe (FMBP).

7. Ensure the by-pass valve is shut off. To avoid mixing of foam with water in water

tank.

8. Open the main valve of water tank.

9. Start the pump at the normal pressure.

10. Open at least one delivery out let or monitor.

11. Open the water to foam proportion valve (full).

12. Set the percentage of foam by opening the foam proportion valve at required rate.

(e.g) 3% or more.

13. After completion of foam operation the system must be “flushed”. i.e pipe-lines,

delivery hoses, all delivery outlet valves, monitor, hose real etc.

14. While flushing, the water to foam proportion valve shall be opened and foam

proportion %age valve shall be fully closed.

15. Flushing process will continue until all pipe lines are cleaned of foam.

16. After complete cleaning, all valves of water to foam valve shall be closed.

You might also like

- Ammonia Unloading Sop ZaclDocument2 pagesAmmonia Unloading Sop ZaclHARRY SINGHNo ratings yet

- Air Receiver Tank Hazard ChecklistDocument2 pagesAir Receiver Tank Hazard ChecklistJade JavierNo ratings yet

- Standard Operating Procedure For HSDDocument3 pagesStandard Operating Procedure For HSDisjglfdskNo ratings yet

- Foam InductorDocument6 pagesFoam InductorDipanjan Chakrabarti100% (1)

- Method For Cleaning Concrete TankDocument3 pagesMethod For Cleaning Concrete TankSpecial MahooNo ratings yet

- MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and PurposeDocument2 pagesMSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purposesarge18100% (1)

- Inflatable Life JacketsDocument6 pagesInflatable Life Jacketsade maulanaNo ratings yet

- Fire Fighting Equipment Monthly Inspection ReportDocument2 pagesFire Fighting Equipment Monthly Inspection Reportnadeem mallickNo ratings yet

- PRF - Preloading Checklist.Document2 pagesPRF - Preloading Checklist.kirandevi1981No ratings yet

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNo ratings yet

- SOP-Pumps 20161031Document4 pagesSOP-Pumps 20161031SubburajMechNo ratings yet

- Standard Procedures For Tank CleaningDocument7 pagesStandard Procedures For Tank CleaningDhitya Agil Harnowo100% (1)

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Cargo Change Over ChecklistDocument2 pagesCargo Change Over ChecklistRajat K. ChauhanNo ratings yet

- Emergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTDocument3 pagesEmergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTSyifa Ula HamidyaNo ratings yet

- Baling Machine - ChecklistDocument5 pagesBaling Machine - ChecklistRajeswaran Rajachockalingam100% (1)

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- NOHSC 1005-1994 Hazardous Substances Model RegsDocument23 pagesNOHSC 1005-1994 Hazardous Substances Model RegsAdiguna DhanaNo ratings yet

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Tanker Safety ProceduresDocument4 pagesTanker Safety Proceduresramnath008No ratings yet

- Vacuum Truck Plant Pre-Acceptance ChecklistDocument3 pagesVacuum Truck Plant Pre-Acceptance Checklistحماية منتجNo ratings yet

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- Spill Response Plan.Document2 pagesSpill Response Plan.Carlo March Notarte100% (1)

- PPE Disposal SOPDocument2 pagesPPE Disposal SOPAmit MakwanaNo ratings yet

- JSA For Cable Joint & Termination WorkDocument2 pagesJSA For Cable Joint & Termination WorkVivek Verma100% (1)

- Training Report On Self Contained Breathing ApparatusDocument4 pagesTraining Report On Self Contained Breathing ApparatusHiren MahetaNo ratings yet

- Master File - MOS Water Storage Tank Cleaning and Disinfection ProceduresDocument6 pagesMaster File - MOS Water Storage Tank Cleaning and Disinfection ProceduresKaran SuleNo ratings yet

- Personnel Transfer Procedure (PEX), RevaDocument33 pagesPersonnel Transfer Procedure (PEX), RevaHSE PULAI ANo ratings yet

- 2000 Rigsafe Air Booster CompressorDocument2 pages2000 Rigsafe Air Booster CompressorLauren'sclub EnglishBimbel Sd-sma100% (1)

- Chemical Hazard Bulletin: OPT D 1127Document1 pageChemical Hazard Bulletin: OPT D 1127HaleemUrRashidBangashNo ratings yet

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- Emergency Response Planning Guidelines (ERPG)Document5 pagesEmergency Response Planning Guidelines (ERPG)btjajadiNo ratings yet

- GGFZCO Crew 9932: Oil Spillage Drill ReportDocument2 pagesGGFZCO Crew 9932: Oil Spillage Drill Reportsagvan mustafaNo ratings yet

- Chemical Cleaning and Steam Blowing Application Sheet Rev.1Document12 pagesChemical Cleaning and Steam Blowing Application Sheet Rev.1Eslam ShiblNo ratings yet

- Spill Kit HandlingDocument2 pagesSpill Kit HandlingHanan SarwarNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- JSA Sump CleaningDocument2 pagesJSA Sump CleaningPanchdev Kumar100% (1)

- RFQ - Tank DemuckingDocument12 pagesRFQ - Tank Demuckingmuhamadrafie1975100% (1)

- Job Safety Analysis: 1. Removing Spool From Existing Pipe LinesDocument5 pagesJob Safety Analysis: 1. Removing Spool From Existing Pipe Lineskaremkoko100% (1)

- Hse Training Manual TwoDocument47 pagesHse Training Manual TwoEneyo VictorNo ratings yet

- Medivac Drill MAn Over Boat-2Document2 pagesMedivac Drill MAn Over Boat-2yogakharismaNo ratings yet

- Hydro Blasting 3Document6 pagesHydro Blasting 3Robinson Ysasis100% (1)

- Sop of ScaffoldingDocument3 pagesSop of ScaffoldingSanjeet Singh100% (1)

- Confined Space Entry Risk AssessmentDocument9 pagesConfined Space Entry Risk Assessmentkoketso0% (1)

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshse100% (1)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- Compressed Gas Cylinder SafetyDocument3 pagesCompressed Gas Cylinder SafetyrishibarathiNo ratings yet

- Nitrogen Handling PurgingDocument9 pagesNitrogen Handling PurgingJeet Singh100% (1)

- JSA For Purging NitrogenDocument1 pageJSA For Purging Nitrogenlina ekawatiNo ratings yet

- Clean Tank WaterDocument1 pageClean Tank Waterblahblah100% (1)

- Hydrojetting SafetyDocument5 pagesHydrojetting SafetyHeryNo ratings yet

- Check List For Hse Marine Rig SurveyDocument5 pagesCheck List For Hse Marine Rig SurveynadyNo ratings yet

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocument1 pageSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNo ratings yet

- ENA Procedure Instructions For ProcurementDocument4 pagesENA Procedure Instructions For ProcurementMilind Pandey0% (1)

- 02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPDocument8 pages02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPB&R HSE BALCO SEP SiteNo ratings yet

- ETP Risk AssesmentDocument20 pagesETP Risk Assesmentvikkas verma0% (1)

- Filling & Decanting SOP'sDocument4 pagesFilling & Decanting SOP'sMian Abdul RehmanNo ratings yet

- Sop For Chlorine Cylinder&TonnerDocument1 pageSop For Chlorine Cylinder&Tonnersaikumar selaNo ratings yet

- Foam Fire Fighting System, RequirementsDocument16 pagesFoam Fire Fighting System, RequirementsKedar AltekarNo ratings yet

- The Skipper's Pocketbook: A Pocket Database For The Busy SkipperFrom EverandThe Skipper's Pocketbook: A Pocket Database For The Busy SkipperNo ratings yet

- Stoppage Due To Fuel ShoratgeDocument4 pagesStoppage Due To Fuel ShoratgeMuhammad AbbasNo ratings yet

- SwitchyardDocument13 pagesSwitchyardMuhammad AbbasNo ratings yet

- Log Sheets 2008 Jan FebDocument2 pagesLog Sheets 2008 Jan FebMuhammad AbbasNo ratings yet

- Shift Rota 2019Document7 pagesShift Rota 2019Muhammad AbbasNo ratings yet

- CCTV Cameras RateDocument2 pagesCCTV Cameras RateMuhammad AbbasNo ratings yet

- Air & GasDocument22 pagesAir & GasMuhammad AbbasNo ratings yet

- Plant Operations: Page 1 of 2Document2 pagesPlant Operations: Page 1 of 2Muhammad AbbasNo ratings yet

- A.Waheed: Name Total Milk Total Amount Amount Received BalanceDocument8 pagesA.Waheed: Name Total Milk Total Amount Amount Received BalanceMuhammad AbbasNo ratings yet

- Boiler CFA March 2021Document2 pagesBoiler CFA March 2021Muhammad AbbasNo ratings yet

- Operation Shift Rota 2021: A B C DDocument2 pagesOperation Shift Rota 2021: A B C DMuhammad AbbasNo ratings yet

- Performance Appraisal Form-BlankDocument3 pagesPerformance Appraisal Form-BlankMuhammad AbbasNo ratings yet

- Steam DrumDocument10 pagesSteam DrumMuhammad AbbasNo ratings yet

- BCP Water Cooler Cleaning Through BackflushingDocument1 pageBCP Water Cooler Cleaning Through BackflushingMuhammad AbbasNo ratings yet

- From One-Month CFD To One-Day CFD - Efforts For Reducing Time and Cost of CFDDocument2 pagesFrom One-Month CFD To One-Day CFD - Efforts For Reducing Time and Cost of CFDMuhammad AbbasNo ratings yet

- Thermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFDocument8 pagesThermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFMuhammad AbbasNo ratings yet

- PG Valves Passing July-2019Document5 pagesPG Valves Passing July-2019Muhammad AbbasNo ratings yet

- Steam Drum PDFDocument59 pagesSteam Drum PDFMuhammad AbbasNo ratings yet