Professional Documents

Culture Documents

Transformer MVA Sizing

Uploaded by

Francisco Andrade0 ratings0% found this document useful (0 votes)

27 views19 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views19 pagesTransformer MVA Sizing

Uploaded by

Francisco AndradeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 19

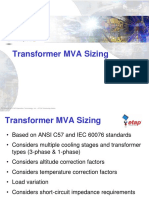

Transformer MVA Sizing

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes

Transformer MVA Sizing

• Based on ANSI C57 and IEC 60076 standards

• Considers multiple cooling stages and transformer

types (3-phase & 1-phase)

• Considers altitude correction factors

• Considers temperature correction factors

• Load variation

• Considers short-circuit impedance requirements

• Use connected load or operating load to size the

transformer

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 2

MVA Sizing Page

Transformer

MVA Loading

Short-Circuit

Impedance

Correction limits

Factors & Load

Variation

Sizing Results Consider

Section Growth Factor

for Max. MVA

•Larger

•Required

•Smaller

•Impedance

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 3

Temperature Correction

• Ambient temperature in degree Celsius

• For air cooled transformers use the air

ambient temperature

• For water cooled transformers use the water

temperature

• Based on C57.92-1981 and IEC 76-2

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 4

Altitude Correction

• Derate the transformer capacity based on

altitude of the installation

• Derating starts above 1000 m or 3300 ft

• Based on C57.92-1981 and IEC 76-2

800 900 1000 1100 1200

meter meter meter meter meter

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 5

Load Variation

• Growth Factor

– Allowance for future load growth

• Load Factor

– The ratio of the average load to the peak load

over a designated period of time

– Load Factor = 100 x ( kWi x Ti ) / ( kWp x Tt )%

– Load Factor = 100 x E / ( kWi x Tt )%

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 6

Where:

I = interval of time when the load is non-zero

kWi = load at interval i

Ti = number of hours of interval i

kWp = peak load

Tt = Ton + Toff

Ton = total hours when the load is on

Toff = total hours when the load is off

E = energy (kWh) consumed by load over the

interval

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 7

Short-Circuit Impedance

Size Requirement

• Use Primary Short-Circuit kA and FLA to

Calculate Impedance

• Primary 3-Phase FLA = MVA / (kVLL * 3)

• Primary 1-Phase FLA= MVA / (kVprimary)

• Zcalculated =100*(FLAprimary / ISC_primary)

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 8

Connected or Operating Load

• Connected Load

– Determine the radial load connected to the transformer

secondary

– Can include spare loads for conservative results

• Operating Load

– PowerStation’s load flow program determines the power

flow through the transformer

– Automatically updated in the transformer required MVA

field (load flow study case info page option)

– Can determine loading in radial or looped systems

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 9

Sizing Results and

Automatic Updating

• Sizing results include MVA and % Z for

– Required Size (Actual calculated Size)

– Next Standard Larger Size

– Next Standard Smaller Size

• Automatically Update the calculated rated

MVA, Max MVA and % Z into the Rating

page of the transformer

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 10

Transformer MVA Sizing Page

Update automatically

when you press these

buttons

Transformer Rating Page

Transformer Rating Page

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 11

Unit Transformer Sizing

Presented by Farrokh Shokooh

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes

Unit Transformer Sizing

• Based on IEEE C5F-116 Standard

• Optimize unit transformer turn ratio

• Consider system voltage variation

• Consider generation station auxiliary load

• Automatically detect generator, cable

impedance and bus nominal kV

• Generator reactive vs. capacitive plots

• Optimization reports

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 13

Transformer Tap Optimization

Page

Transformer

Impedance

Section System kV

Information

Primary / Secondary

Cable Impedance

Generator

Information

Auxiliary Load

Information

Optimization

Results Section

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 14

Automatic System Parameter

Update

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 15

Primary Fixed Tap Editor

• Use 0.1% Tap Step to obtain best

Optimization results

• Set the maximum/minimum fixed tap range

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 16

MVAR Delivery Curve

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 17

Unit Transformer Tap

Optimization Reports

• Input Data

• Optimal Tap Position

• Transformer Power Input and output at

different system voltage levels (system

voltage variation)

• Generator Power Output at different system

voltage levels

• Generator and System voltage at different

system voltage levels

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 18

© 1996-2010 ETAP/Operation Technology, Inc. – ETAP Workshop Notes Slide 19

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- TRANSFORMER MVA SIZING IN ETAPDocument24 pagesTRANSFORMER MVA SIZING IN ETAPkhalidNo ratings yet

- TRANSFORMER MVA SIZING IN ETAPDocument24 pagesTRANSFORMER MVA SIZING IN ETAPkhalidNo ratings yet

- Trafo SizingDocument19 pagesTrafo SizingTorrez JeanNo ratings yet

- 04 - Transformer SizingDocument19 pages04 - Transformer Sizingashraf-84No ratings yet

- Transformer SizingDocument19 pagesTransformer Sizingjokanov0% (1)

- Transient Stability 2Document29 pagesTransient Stability 2Carlos Ortiz de ZevallosNo ratings yet

- Transient StabilityDocument30 pagesTransient StabilityJose AlejandroNo ratings yet

- Transformer Sizing CalculationDocument9 pagesTransformer Sizing CalculationMirko Yanque TomasevichNo ratings yet

- Protective Device Coordination ETAP Star PDFDocument89 pagesProtective Device Coordination ETAP Star PDFTadala Maluwa0% (1)

- 17 - Ocp PDFDocument15 pages17 - Ocp PDFJose AlejandroNo ratings yet

- Presentasi Full VersionDocument30 pagesPresentasi Full VersionIan AndriNo ratings yet

- Release Notes For PSS/ADEPT™ 5.0: Removed FunctionalityDocument4 pagesRelease Notes For PSS/ADEPT™ 5.0: Removed FunctionalitysubasratnaNo ratings yet

- CM20170619 43609 08733Document26 pagesCM20170619 43609 08733Jonas CrixelNo ratings yet

- 20 - Optimal Capacitor PlaceOptimal Capacitor Placement - PdfmentDocument15 pages20 - Optimal Capacitor PlaceOptimal Capacitor Placement - PdfmentEgyptman JanNo ratings yet

- 9 - Turbine Governor Control Upgrades - PapillaDocument19 pages9 - Turbine Governor Control Upgrades - PapillaMilton NastNo ratings yet

- Continuous Professional Development Program - 2017Document70 pagesContinuous Professional Development Program - 2017dilipgmNo ratings yet

- Motor Starting Exercises 3 To 6: ETAP Workshop Notes Page 1 of 7Document7 pagesMotor Starting Exercises 3 To 6: ETAP Workshop Notes Page 1 of 7Royer CcosiNo ratings yet

- MS OtiDocument16 pagesMS OtiAhmed Abd El WahabNo ratings yet

- Battery Sizing & DischargeDocument19 pagesBattery Sizing & DischargemarkNo ratings yet

- 21a - BSD PDFDocument19 pages21a - BSD PDFJose AlejandroNo ratings yet

- © 1996-2009 Operation Technology, Inc. - Workshop Notes: Battery Sizing & DischargeDocument19 pages© 1996-2009 Operation Technology, Inc. - Workshop Notes: Battery Sizing & DischargeKazeemNo ratings yet

- 21a - BSD PDFDocument19 pages21a - BSD PDFashraf-84No ratings yet

- Megger 550503, TTRDocument4 pagesMegger 550503, TTRandyNo ratings yet

- 03 - Load Flow and PanelDocument75 pages03 - Load Flow and PanelVijay MohanNo ratings yet

- MS Exercise 3Document8 pagesMS Exercise 3Samir AlzekriNo ratings yet

- Power System ModelingDocument27 pagesPower System ModelingFrancisco AndradeNo ratings yet

- Guardian VFD PC Pump Controller WEBDocument2 pagesGuardian VFD PC Pump Controller WEBRoger GracieNo ratings yet

- Service Bulletin Trucks: Instrumentation TroubleshootingDocument4 pagesService Bulletin Trucks: Instrumentation Troubleshootingsetiup holjiNo ratings yet

- PowerWorld - Contingency AnalysisDocument222 pagesPowerWorld - Contingency AnalysisFikret VelagicNo ratings yet

- Distribution System Reliability AnalysisDocument22 pagesDistribution System Reliability AnalysisAndres VergaraNo ratings yet

- ReadmeDocument49 pagesReadmeSudah Sirnakah SemuaNo ratings yet

- Generator Diesel Chicago Pneumatic CPSG 14Document2 pagesGenerator Diesel Chicago Pneumatic CPSG 14diconNo ratings yet

- PTM WhatsNew V4 - 10 ENUDocument30 pagesPTM WhatsNew V4 - 10 ENUYusuf BhikhapurwalaNo ratings yet

- Torque Follower Setup Rev 1Document7 pagesTorque Follower Setup Rev 1NelsonNo ratings yet

- RatronBrochure7 08Document2 pagesRatronBrochure7 08synchrogridNo ratings yet

- Adjustment of Servo System : (Trial Run of Unit / Trial Run Combined With Mechanism)Document7 pagesAdjustment of Servo System : (Trial Run of Unit / Trial Run Combined With Mechanism)Chandru ChristurajNo ratings yet

- Tettex TTR 2796Document6 pagesTettex TTR 2796Ilic NebojsaNo ratings yet

- f0332002 Tapmotion TD Ism enDocument12 pagesf0332002 Tapmotion TD Ism enknsbNo ratings yet

- Example Ramping Overcurrent ENU PDFDocument21 pagesExample Ramping Overcurrent ENU PDFOscar Ordoñez VelasquezNo ratings yet

- Fundamental, Technology and Manufacturing in Indonesia: HV Power TransformerDocument82 pagesFundamental, Technology and Manufacturing in Indonesia: HV Power TransformerAriNo ratings yet

- AC Inverter Drive: A1000 SeriesDocument8 pagesAC Inverter Drive: A1000 Seriesabhi_0302No ratings yet

- Short-Circuit Analysis IEC StandardDocument46 pagesShort-Circuit Analysis IEC Standarddiogoufrn-1No ratings yet

- SC Exercise IEC PDFDocument10 pagesSC Exercise IEC PDFRikarjo SilitongaNo ratings yet

- Ion 75007600Document8 pagesIon 75007600Juan Pablo GaeteNo ratings yet

- ArcFlash Example13-Solution PDFDocument6 pagesArcFlash Example13-Solution PDFgilbertomjcNo ratings yet

- Chapter 08 - AC ElementsDocument349 pagesChapter 08 - AC Elementsyanuartw7No ratings yet

- Gensys Compact Prime Sales Documentations en g2022Document4 pagesGensys Compact Prime Sales Documentations en g2022Hdjdhdbrb3odfbNo ratings yet

- A1000Document8 pagesA1000monikaNo ratings yet

- Facts About FACTSDocument31 pagesFacts About FACTSHarsimran KaurNo ratings yet

- Resume ZahidDocument7 pagesResume ZahidEngr Irfan AkhtarNo ratings yet

- IEC: Short-Circuit Example 1: ObjectivesDocument10 pagesIEC: Short-Circuit Example 1: ObjectivesEma Robertho NaniNo ratings yet

- EEMDocument17 pagesEEMSandaruwan සුජීවNo ratings yet

- Using the 7720-1-EVM: PFC Design TipsDocument6 pagesUsing the 7720-1-EVM: PFC Design TipsPriyam ChakrabortyNo ratings yet

- D1 5 VSD TransformersDocument51 pagesD1 5 VSD TransformersalgotrNo ratings yet

- © 1996-2009 Operation Technology, Inc. - Workshop Notes: DC Load Flow/DC Short-CircuitDocument24 pages© 1996-2009 Operation Technology, Inc. - Workshop Notes: DC Load Flow/DC Short-CircuitSAEL SOLARNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignFrom EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo ratings yet

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- IEC - Short-Circuit Example 1 (Solution) : DescriptionDocument3 pagesIEC - Short-Circuit Example 1 (Solution) : DescriptionFrancisco AndradeNo ratings yet

- Shortcircuit ANSIDocument50 pagesShortcircuit ANSIMarioEnriqueAlcocerÁvilaNo ratings yet

- Short-Circuit Analysis IEC StandardDocument46 pagesShort-Circuit Analysis IEC Standarddiogoufrn-1No ratings yet

- IEC - Short-Circuit Example 2: DescriptionDocument9 pagesIEC - Short-Circuit Example 2: DescriptionFrancisco AndradeNo ratings yet

- SC Exercise ANSIDocument5 pagesSC Exercise ANSIdiogoufrn-1No ratings yet

- SC Exercise IEC 1Document3 pagesSC Exercise IEC 1Mahmoud AlhashemNo ratings yet

- Transformer MVA SizingDocument19 pagesTransformer MVA SizingFrancisco AndradeNo ratings yet

- Generator Circuit Breaker Example: DescriptionDocument7 pagesGenerator Circuit Breaker Example: DescriptionFrancisco AndradeNo ratings yet

- Generator Circuit Breaker Example: DescriptionDocument6 pagesGenerator Circuit Breaker Example: DescriptionFrancisco AndradeNo ratings yet

- Load Flow Example B2 (IEC)Document2 pagesLoad Flow Example B2 (IEC)Francisco AndradeNo ratings yet

- Load Flow Example B1 (IEC) : Purpose & DescriptionDocument3 pagesLoad Flow Example B1 (IEC) : Purpose & DescriptionFrancisco AndradeNo ratings yet

- Creating A One-Line Diagram (IEC) : Purpose & DescriptionDocument5 pagesCreating A One-Line Diagram (IEC) : Purpose & DescriptionFrancisco AndradeNo ratings yet

- Load Flow Example B3: ETAP Workshop Notes ©1996-2011, ETAP/Operation Technology, Inc. Page 1 of 1Document1 pageLoad Flow Example B3: ETAP Workshop Notes ©1996-2011, ETAP/Operation Technology, Inc. Page 1 of 1Francisco AndradeNo ratings yet

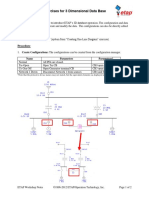

- IEC 3D DB Exercise WorkshopDocument2 pagesIEC 3D DB Exercise Workshopsilentidea8317No ratings yet

- AC Network: © 1996-2010 ETAP/Operation Technology, Inc. - Workshop Notes: AC NetworkDocument63 pagesAC Network: © 1996-2010 ETAP/Operation Technology, Inc. - Workshop Notes: AC NetworkSAEL SOLARNo ratings yet

- Ejem 1 - Creating An OLDDocument5 pagesEjem 1 - Creating An OLDHibelertCordóvaEspinosaNo ratings yet

- Exercises For 3 Dimensional Data Base: Purpose & DescriptionDocument2 pagesExercises For 3 Dimensional Data Base: Purpose & DescriptionSAEL SOLARNo ratings yet

- RELAY PROTECTION OF TRANSMISSION LINESDocument80 pagesRELAY PROTECTION OF TRANSMISSION LINESMurugan100% (2)

- Current Steering CircuitsDocument35 pagesCurrent Steering CircuitsBenazir Begam100% (1)

- CMOS V.S TTLDocument5 pagesCMOS V.S TTLexe.dave.qNo ratings yet

- Barco 55" Nearseamless LCD Video WallDocument3 pagesBarco 55" Nearseamless LCD Video WallAli GhafouriNo ratings yet

- TC 917 SystemDocument4 pagesTC 917 SystemcafeeesmoNo ratings yet

- High Current Glass Passivated Single-Phase Bridge Rectifiers up to 1000V 25ADocument3 pagesHigh Current Glass Passivated Single-Phase Bridge Rectifiers up to 1000V 25ASero StivNo ratings yet

- Per Unit System 2022Document42 pagesPer Unit System 2022Muhammad HaikalNo ratings yet

- Soundcraft GB8Document2 pagesSoundcraft GB8scoginjmNo ratings yet

- 820-1540, 051-6482, MLB (GILA EVT1) Rev 13, 11.21.2003Document70 pages820-1540, 051-6482, MLB (GILA EVT1) Rev 13, 11.21.2003aplus guideNo ratings yet

- Display Device: Types of Electronic DisplaysDocument4 pagesDisplay Device: Types of Electronic DisplaysBattuguldur BatuNo ratings yet

- KBPC25005/W - KBPC2510/W: 25A Bridge RectifierDocument2 pagesKBPC25005/W - KBPC2510/W: 25A Bridge RectifierEnzo CeballosNo ratings yet

- 74LCX125 Low Voltage Quad Buffer With 5V Tolerant Inputs and OutputsDocument13 pages74LCX125 Low Voltage Quad Buffer With 5V Tolerant Inputs and Outputsfenixtec1No ratings yet

- Wej Electronic Co.,Ltd: BC846AW, BW BC847AW, BW, CW BC848AW, BW, CWDocument4 pagesWej Electronic Co.,Ltd: BC846AW, BW BC847AW, BW, CW BC848AW, BW, CWserver hostNo ratings yet

- Project Report On Automatic Night Lamp With Morning Alarm 3Document3 pagesProject Report On Automatic Night Lamp With Morning Alarm 3Amal KrishnanNo ratings yet

- Seven Band Graphic Equalizer Data Sheet: Description FeaturesDocument4 pagesSeven Band Graphic Equalizer Data Sheet: Description FeaturesAlexander MontellanoNo ratings yet

- Seminar Presentation Electrical Power Theft Detection: Akhlesh Kumar Jindal 13085008 B.Tech. (Part-4)Document16 pagesSeminar Presentation Electrical Power Theft Detection: Akhlesh Kumar Jindal 13085008 B.Tech. (Part-4)Akhilesh JindalNo ratings yet

- PLC Siemens25Document20 pagesPLC Siemens25chokamNo ratings yet

- Parallel Operation of Synchronous GeneratorDocument7 pagesParallel Operation of Synchronous Generatorfahrid mudoriNo ratings yet

- 467 Experiment3Document10 pages467 Experiment3mid_cyclone100% (1)

- VLSI Lab Assignment Final AjithDocument44 pagesVLSI Lab Assignment Final Ajithsndpkv4999No ratings yet

- Amiga Floppy Drive Compatibility List: 3.5 DrivesDocument8 pagesAmiga Floppy Drive Compatibility List: 3.5 DrivesautreraNo ratings yet

- Nuts & Volts 25-10 - Oct 2004Document108 pagesNuts & Volts 25-10 - Oct 2004blahblahname100% (2)

- Introduction To ComputerDocument25 pagesIntroduction To ComputerChandini LANo ratings yet

- Memories I: Dr. T.Y. Chang Nthu Ee 2007.11.20 - 22 - 27Document38 pagesMemories I: Dr. T.Y. Chang Nthu Ee 2007.11.20 - 22 - 27api-19668941No ratings yet

- Raymarine t150 t400Document40 pagesRaymarine t150 t400LittleGaryNo ratings yet

- Chapter 2 Basic Physics of SemiconductorsDocument42 pagesChapter 2 Basic Physics of SemiconductorsKyusang ParkNo ratings yet

- MCP1825/MCP1825S: 500 Ma, Low Voltage, Low Quiescent Current LDO RegulatorDocument39 pagesMCP1825/MCP1825S: 500 Ma, Low Voltage, Low Quiescent Current LDO RegulatorZireael EDNo ratings yet

- Timing Closure Using LatchesDocument3 pagesTiming Closure Using Latchesasic_masterNo ratings yet

- WWW - AD-POWER - CN: Class-D Amplifier ModuleDocument6 pagesWWW - AD-POWER - CN: Class-D Amplifier ModulehydropowNo ratings yet

- Chameleon Chips PresentationDocument24 pagesChameleon Chips Presentationmanojreads100% (1)