Professional Documents

Culture Documents

(F-L3-MR-188) Workplace Inspection Sheet

Uploaded by

Abdul MueedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(F-L3-MR-188) Workplace Inspection Sheet

Uploaded by

Abdul MueedCopyright:

Available Formats

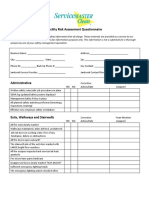

Doc# F-L3-MR-188

WEEKLY WORKPLACE INSPECTION SHEET Issue# 03

Issue Date: 22-02-2020

Quality Department

Name Of Inspector:______________________________

Date: ____________________

Performance

Domain Activities / Work Place Conditions Yes No Observation Counter Action Target Date

Marks

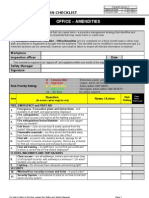

Floor: Clean and Signs are posted when floors are

wet (e.g. when floor are washed, spills)

Aisles are marked clear and unobstructed

Stairs kept clear and unobstructed

Safety instructions signs are in good condition

Furniture / office equipment's secure from tipping;

appropriate for work being done / Chairs conditions.

Emergency lighting: In good condition & Charging

light on

Fire extinguishers: appropriate type, on its place and

pressurized.

Fire

Fire exit doors: in good condition, unlocked & free

Protection

from obstruction (Both Sides)

& Warning

Check Nozzle with Hose pipes, Hydrant points, &

System

call points.

Check fire panel for (abnormal indication, lose wiring

etc.)

Workers Know the Evacuation Plan (ask worker)

Washrooms are clean

Electronic tap, Dryer, hand wash in working

condition

First aid Box at its place with required items.

Hygiene & List of first aiders are posted.

First Aid Closure operators are using Sanitizer, Hair net,

Shoe net

Emergency Eyewash (or shower) available & in

working order

Employees know to get First aid when needed (ask

from worker)

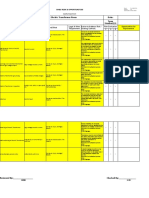

Materials are shelved/Staked properly as per limit.

Material Work done Above 2m follows "Work At Height"

Handling & Procedure.

Storage

Fork lifter operators are trained (Ask Worker)

During manual loading / unloading follows WI.

Hazardous substance are properly labeled, stored

and disposed off (observe)

MSDS is pasted / available in areas where

Hazardous chemicals are stored & worker are well aware &

Substance trained on safety and remedial actions.

Hazardous material are kept at designated place.

Flammable product stored properly

PPE's is available & worn

Personal

PPE's is maintained (Ask Worker)

Protective

Equipment PPEs requirement MMC available in depts.

Workers train in Use Of PPE's (Ask Worker)

No multi plugging.

Avoid Extension boards, if required use only PASS

made Extension board

Electrical Electrical cords are properly insulated

Safety Machines properly grounded

Clear access to electrical panels and no

combustible material stored / posted within 24

inches around.

Guarding , Fencing & Safety devices in place on

machines

Tools & Portable equipment has safety guarding

Machinery Emergency switches clearly marked and easy to

reach

Lockout / Tag out available.

Emergency numbers for internal & external contacts

Security are easily available.

Visitor / Contractor rules are in place.

Total Marks

Total ____ marks obtain out of 40 marks.

Total Compliance Percentage: ______%

Note: Every "Yes" is considered as "1" mark & "No" is considered as "0" mark.

Prepared By:____________________ Checked By:____________________

You might also like

- Please Note That This Spreadsheet Contains Inspection Forms For Many LocationsDocument11 pagesPlease Note That This Spreadsheet Contains Inspection Forms For Many LocationseliiiiiiNo ratings yet

- Internal Safety ChecklistDocument1 pageInternal Safety ChecklistAnkit SharmaNo ratings yet

- Inspection ChecklistDocument4 pagesInspection ChecklistAli haiderNo ratings yet

- # Monthly Inspection Check List-PDDocument7 pages# Monthly Inspection Check List-PDArjun KoiralaNo ratings yet

- C822444-COR-HS-FRM-0004 Office HSE Inspection FormDocument9 pagesC822444-COR-HS-FRM-0004 Office HSE Inspection FormAndrianto BakriNo ratings yet

- VG OE RF 046 - Warehouse Shutdown ChecklistDocument1 pageVG OE RF 046 - Warehouse Shutdown ChecklistEchague GjNo ratings yet

- Monthly Housekeeping Evaluation Checklist: 1. OfficesDocument7 pagesMonthly Housekeeping Evaluation Checklist: 1. Officesjohn haider gamolNo ratings yet

- 6s Audit Workshop FormDocument22 pages6s Audit Workshop FormGman0% (1)

- Check List: Managing Industrial Technology & Design WorkspacesDocument5 pagesCheck List: Managing Industrial Technology & Design Workspacesmohammed sameeullahNo ratings yet

- Barge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckDocument4 pagesBarge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckHermawan Alief100% (1)

- What Is An Example of An Inspection Checklist For A Manufacturing FacilityDocument7 pagesWhat Is An Example of An Inspection Checklist For A Manufacturing FacilityaKureishi100% (1)

- Inspection ChecklistsDocument6 pagesInspection Checklistsmegaspice0% (1)

- Kopya 5S Audits Check Sheet and Comments Sheet - Issue2Document2 pagesKopya 5S Audits Check Sheet and Comments Sheet - Issue2Nihat ÖzdemirNo ratings yet

- Facility Safety Checklist: Personal Protective Equipment Emergency/Osha Related ItemsDocument2 pagesFacility Safety Checklist: Personal Protective Equipment Emergency/Osha Related Itemscahenke100% (2)

- Safety Industrial Safety Inspection ChecklistDocument2 pagesSafety Industrial Safety Inspection ChecklistAhmadi HasanNo ratings yet

- Manufacturing Plant Audit ChecklistDocument6 pagesManufacturing Plant Audit ChecklistAnurag SrivastavaNo ratings yet

- Pinch Points V1110.1Document1 pagePinch Points V1110.1bob geldofNo ratings yet

- Workplace inspection checklistDocument5 pagesWorkplace inspection checklistmyo lwinNo ratings yet

- Safety Audit ChecklistDocument5 pagesSafety Audit ChecklistAbhishekNo ratings yet

- FINAL 2005 Standard IC Construction ChecklistDocument4 pagesFINAL 2005 Standard IC Construction Checklistnurul kartikasariNo ratings yet

- MHI - Safety Audit Inspection ChecklistDocument4 pagesMHI - Safety Audit Inspection ChecklistDominic John Armada0% (1)

- 22 Safety ChecklistsDocument30 pages22 Safety ChecklistsIrvys G. Juarez Dordi100% (2)

- Office Safety ChecklistDocument3 pagesOffice Safety ChecklistGagan VashishthaNo ratings yet

- Facility Safety ChecklistDocument2 pagesFacility Safety ChecklisteastNo ratings yet

- WP-HSE-010 (Bored Pile)Document1 pageWP-HSE-010 (Bored Pile)Armando AballeNo ratings yet

- EPACK HSE MANAGEMENT SYSTEM AUDITDocument3 pagesEPACK HSE MANAGEMENT SYSTEM AUDITJyotiranjan RoutNo ratings yet

- Workshop Inspection Checklist: Safe@WorkDocument4 pagesWorkshop Inspection Checklist: Safe@WorkChickenChick07No ratings yet

- Workplace Hazard Inspection ChecklistDocument3 pagesWorkplace Hazard Inspection ChecklistWisnu KertaningnagoroNo ratings yet

- Intro Summary Main Findings and ConclusionDocument4 pagesIntro Summary Main Findings and Conclusionjimento0% (1)

- Facility Entrance and Safety First Impression: Y / N 0,1,2,3 or 4Document2 pagesFacility Entrance and Safety First Impression: Y / N 0,1,2,3 or 4krissregionNo ratings yet

- 22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentDocument30 pages22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentMohammed Hasnain Saleem/KSA/EMD100% (1)

- Planned Inspection - FIRE SAFETY ChecklistDocument5 pagesPlanned Inspection - FIRE SAFETY ChecklistJose Aguilos BotanaNo ratings yet

- Facility Risk Assessment QuestionnaireDocument5 pagesFacility Risk Assessment QuestionnaireGrayNo ratings yet

- LOCATION SAFETY CHECKDocument14 pagesLOCATION SAFETY CHECKMorena AbellarNo ratings yet

- Inspectors: DateDocument7 pagesInspectors: DateMuruganNo ratings yet

- Audit Checklist FormDocument2 pagesAudit Checklist Formmendel lopezNo ratings yet

- Workshop ChecklistDocument4 pagesWorkshop Checklisttalabira100% (1)

- HSE Inspection - ChecklistDocument30 pagesHSE Inspection - ChecklistMutaman EldirdiriNo ratings yet

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- Inspeksi SMK3Document30 pagesInspeksi SMK3Ulva YuliantiNo ratings yet

- Workplace - Inspection Checklist UpdatedDocument8 pagesWorkplace - Inspection Checklist UpdatedNate JamesNo ratings yet

- Halliburton Energy Services Hot Work PermitDocument48 pagesHalliburton Energy Services Hot Work PermitMed Hillel Elarouci67% (3)

- Typical JHA FormDocument5 pagesTypical JHA FormNasrullah Jan100% (4)

- Job Safety Awareness TrainingDocument32 pagesJob Safety Awareness TrainingHCKoh100% (1)

- Conserve O Gram: Fire Safety 101: A Fire Safety Self-Inspection ChecklistDocument6 pagesConserve O Gram: Fire Safety 101: A Fire Safety Self-Inspection ChecklistKavita ChrantimathNo ratings yet

- Quick Reference For SupervisionDocument7 pagesQuick Reference For SupervisiongrantNo ratings yet

- JSP Cast House Crane MaintenanceDocument5 pagesJSP Cast House Crane MaintenanceasyyasNo ratings yet

- Laboratory Inspection Checklist: Safe@WorkDocument5 pagesLaboratory Inspection Checklist: Safe@WorkAlpha Excellence consultingNo ratings yet

- Safety Inspection Checklist With OSHA References 2011 UpdatedDocument167 pagesSafety Inspection Checklist With OSHA References 2011 UpdatedphuyangNo ratings yet

- Labour Camp InspectionDocument4 pagesLabour Camp InspectionChandirprakash KrishnamoorthyNo ratings yet

- Workplace Inspection Checklist BlankDocument7 pagesWorkplace Inspection Checklist BlanksifuclenNo ratings yet

- Workplace Inspection ChecklistDocument3 pagesWorkplace Inspection ChecklistMick Rustichelli100% (2)

- Checklist For 5-Star Safety Documentation-SOADocument15 pagesChecklist For 5-Star Safety Documentation-SOAYASIRNo ratings yet

- IGC2 Element 4 Work EquipmentDocument48 pagesIGC2 Element 4 Work EquipmentAlaa100% (3)

- Work PermitDocument2 pagesWork PermitDoita Dutta ChoudhuryNo ratings yet

- 5 SDocument9 pages5 Sarai29733No ratings yet

- Accommodation Inspection Checklist: Safe@WorkDocument4 pagesAccommodation Inspection Checklist: Safe@WorkAccrescenet hseNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- SOC Management System: Strive For Continual ImprovementDocument4 pagesSOC Management System: Strive For Continual ImprovementAbdul MueedNo ratings yet

- Cantten Risk Assessment OH&SDocument1 pageCantten Risk Assessment OH&SAbdul MueedNo ratings yet

- Smarter Supply Chain Can Help and SupportDocument3 pagesSmarter Supply Chain Can Help and SupportAbdul MueedNo ratings yet

- How Smarter Supply Chain Management Can Help Your BusinessDocument10 pagesHow Smarter Supply Chain Management Can Help Your BusinessAbdul MueedNo ratings yet

- Approved Suppliers List: SCM DepartmentDocument2 pagesApproved Suppliers List: SCM DepartmentAbdul MueedNo ratings yet

- Risk assessment for airbag handlingDocument3 pagesRisk assessment for airbag handlingAbdul MueedNo ratings yet

- Halaal & Food Safety System AwarenessDocument14 pagesHalaal & Food Safety System AwarenessAbdul MueedNo ratings yet

- Inspeksi SMK3Document30 pagesInspeksi SMK3Ulva YuliantiNo ratings yet

- Electric Transformer Room Risk Assissment.Document3 pagesElectric Transformer Room Risk Assissment.Abdul MueedNo ratings yet

- HACCP4PackagingV3 WithslidefooterDocument27 pagesHACCP4PackagingV3 Withslidefootertalha amjadNo ratings yet

- Head Protection & Safety HelmetDocument1 pageHead Protection & Safety HelmetAbdul MueedNo ratings yet

- General SafetyDocument21 pagesGeneral SafetyAbdul MueedNo ratings yet

- Safety Commitee MeetingDocument9 pagesSafety Commitee MeetingAbdul MueedNo ratings yet

- Risk Assessment of Plastic Packaging Materials for Food SafetyDocument39 pagesRisk Assessment of Plastic Packaging Materials for Food SafetyHon Le VanNo ratings yet

- Hazard Analysis and Risk - Based Preventive Controls For Human Food Draft Guidance For IndustryDocument21 pagesHazard Analysis and Risk - Based Preventive Controls For Human Food Draft Guidance For IndustryAnonymous cePb20No ratings yet

- Final - Rigid Plastic - May 6 2010Document30 pagesFinal - Rigid Plastic - May 6 2010Abdul Mueed100% (1)

- OHSMS AwarenessDocument12 pagesOHSMS AwarenessAbdul MueedNo ratings yet

- Tools - Applications Risk ManagementDocument45 pagesTools - Applications Risk Managementrachmad pgNo ratings yet

- Safety Talk TopicsDocument44 pagesSafety Talk TopicsAbdul Mueed100% (5)

- Checksheet For Daily Power-Off.: Date: - Inspected ByDocument1 pageChecksheet For Daily Power-Off.: Date: - Inspected ByAbdul MueedNo ratings yet

- Hazard Analysis Critical Control Point Plan: What Is A Food Safety Management System? What Is A HACCP Plan?Document1 pageHazard Analysis Critical Control Point Plan: What Is A Food Safety Management System? What Is A HACCP Plan?Abdul MueedNo ratings yet

- Employee Safety Performance SheetDocument40 pagesEmployee Safety Performance SheetAbdul MueedNo ratings yet

- ICH Q9 - Guideline PDFDocument23 pagesICH Q9 - Guideline PDFLuis CárdenasNo ratings yet

- Halaal & Food Safety System AwarenessDocument14 pagesHalaal & Food Safety System AwarenessAbdul MueedNo ratings yet

- Halaal & Food Safety System AwarenessDocument14 pagesHalaal & Food Safety System AwarenessAbdul MueedNo ratings yet

- Worklife Balance and Stress ManagementDocument28 pagesWorklife Balance and Stress ManagementShobit ChakrabortyNo ratings yet

- Midterm LaborDocument8 pagesMidterm LaborMark Gerard NebriaNo ratings yet

- Lean Manufacturing Case Study - Buck KnifesDocument11 pagesLean Manufacturing Case Study - Buck KnifesHarsh Modi100% (2)

- HR Drives Strategy at XYZ IncDocument2 pagesHR Drives Strategy at XYZ IncAnkur JainNo ratings yet

- Business CycleDocument9 pagesBusiness CycleiamshijasNo ratings yet

- The Labor Code of The Philippines: By: Lysander R. Bague R.NDocument15 pagesThe Labor Code of The Philippines: By: Lysander R. Bague R.NlkristinNo ratings yet

- Review Questions For PROFESSIONAL PRACTICE (ALE)Document3 pagesReview Questions For PROFESSIONAL PRACTICE (ALE)Janelle Joy AgustinNo ratings yet

- Safety Quiz TitleDocument2 pagesSafety Quiz TitleTalibandz404No ratings yet

- Defiance in Phlan ALDocument32 pagesDefiance in Phlan ALAlfredo Jauregui FarfanNo ratings yet

- TEST BANK CHAPTER 14 KEY CONCEPTSDocument7 pagesTEST BANK CHAPTER 14 KEY CONCEPTSNada KhaledNo ratings yet

- The importance of human behavior in our daily lives/TITLEDocument36 pagesThe importance of human behavior in our daily lives/TITLEprince husainNo ratings yet

- Building Human ResourcesDocument27 pagesBuilding Human ResourceskingshukbNo ratings yet

- Knitting Machine MechanicDocument75 pagesKnitting Machine MechanicSakibMDShafiuddinNo ratings yet

- Child Labor in Pakistan Causes Consequences and PreventionDocument12 pagesChild Labor in Pakistan Causes Consequences and PreventionAxis Mahni SialNo ratings yet

- Q) "OB Is A Multi-Disciplinary Field of Study" JustifyDocument29 pagesQ) "OB Is A Multi-Disciplinary Field of Study" JustifyNandha KumarNo ratings yet

- Causes of GrievanceDocument7 pagesCauses of GrievanceECAS BBANo ratings yet

- GJ Human Resource PlanningDocument29 pagesGJ Human Resource PlanningRavi SistaNo ratings yet

- TUPAD ProgramDocument3 pagesTUPAD ProgramLeizly GutierrezNo ratings yet

- Book Summary - Assignment - Wycliffe - Okelo (200447259)Document33 pagesBook Summary - Assignment - Wycliffe - Okelo (200447259)Wycliffe OkeloNo ratings yet

- Tata Motors Recruitment, Selection Process & Employee PoliciesDocument5 pagesTata Motors Recruitment, Selection Process & Employee PoliciesCraft DealNo ratings yet

- Eric Hopkins - Working Hours and Conditions During The Industrial Revolution - A Re-Appraisal - TEXT PDFDocument16 pagesEric Hopkins - Working Hours and Conditions During The Industrial Revolution - A Re-Appraisal - TEXT PDFBojanNo ratings yet

- 2H Delta All ModulesDocument22 pages2H Delta All ModulesSuccessfactors SupportNo ratings yet

- Assessment Brief BU7039 2022-23 For Module Starting in November 2022 (May 22 Cohort - BU7039 NOV MCA)Document10 pagesAssessment Brief BU7039 2022-23 For Module Starting in November 2022 (May 22 Cohort - BU7039 NOV MCA)Nabeel RehmanNo ratings yet

- A Quantitative Correlational Study Between Transformational LeadeDocument177 pagesA Quantitative Correlational Study Between Transformational LeadePrincess Camille RamosNo ratings yet

- Layoff & Voluntary Retirement SchemeDocument11 pagesLayoff & Voluntary Retirement SchemeAbhijeet SinghNo ratings yet

- BPO DONE Group 1 Written ReportDocument7 pagesBPO DONE Group 1 Written ReportClaire OperañaNo ratings yet

- Ghana Revenue Authority PAYE scheduleDocument1 pageGhana Revenue Authority PAYE schedulejoseph borketeyNo ratings yet

- Oman Labor Law: Social Security SchemesDocument12 pagesOman Labor Law: Social Security SchemesTaimoor HassanNo ratings yet

- Sachar Committee Report On MinoritiesDocument22 pagesSachar Committee Report On MinoritiesRitika Raj SrivastavaNo ratings yet

- SHE 5.0.60 Section 17 (1) Health 0 Safety RepresentativeDocument1 pageSHE 5.0.60 Section 17 (1) Health 0 Safety RepresentativeVicky LandmanNo ratings yet