Professional Documents

Culture Documents

Instruction Manual F-14 Tomcat: Disclaimer

Uploaded by

John MondoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual F-14 Tomcat: Disclaimer

Uploaded by

John MondoCopyright:

Available Formats

Instruction Manual

F-14 Tomcat

DISCLAIMER

6mmFlyRC guarantees our kits to be free from defects in both material and workmanship at the date of purchase. This warranty does

not cover any component parts damaged by use or modification. In no case shall 6mmFlyRC's liability exceed the original cost of the

purchased kit. Further, 6mmFlyRC reserves the right to change or modify this warranty without notice.

In that 6mmFlyRC has no control over the final assembly or material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the final user-assembled product. By the act of using the user-

assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this kit

immediately in new and unused condition to 6mmFlyRC for a full refund.

While this kit has been flight tested for normal use, if the plane will be used for extremely high stress flying, such as racing, the

modeler is responsible for taking steps to reinforce the high stress points.

*Special thanks to Steve Shumate, who not only has provided the instructions for the T-38, F-14, F-15, F-18, and Saab Gripen, but has provided

much needed support to 6mmFlyRC. Without Steve, our job would be much harder.

Downloaded from www.Manualslib.com manuals search engine

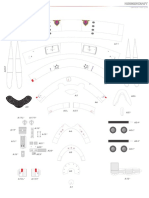

This model was designed to be built from either BlueCore fan-fold foam or

6 mm Depron foam. If using BlueCore, note you’ll need to peel the film

backing off the fuselage exterior parts to allow sanding the fuselage corners

to shape. Leave the film on the wing and empennage parts since it adds

strength, durability, and smoothness.

Note this model is best built using the following types of adhesives:

• Epoxy (both 5 minute and 30 minute)

• Odorless CA (with accelerator)

• Contact glue such as UHU Creativ for Styrofoam

• 3M 77 spray adhesive

ProBond can also be used in place of epoxy. It is lighter than epoxy but

takes much longer to cure (overnight). I have personally found UHU Creativ

for Styrofoam (picture at left) to be the best glue for the majority of assembly,

since it’s easy to use, dries fast (less than 10 minutes), and is quite strong.

Begin by cutting out all of the paper parts templates with scissors, trimming

them to within approximately 1/8” of the lines. Then test fit all of the

templates onto the foam sheet, trying to minimize wasted foam as much as

possible. Once you’re satisfied with the arrangement, remove each template

individually and spray the back of the template LIGHTLY with 3M 77 spray

adhesive. Then replace the template onto the same spot on the foam sheet.

Repeat for every template.

After all the templates are tacked onto the foam, cut out all the pieces by

cutting on the lines with a SHARP hobby knife. When done, peel the paper

templates off of each piece and discard.

Page 2

Downloaded from www.Manualslib.com manuals search engine

1. Begin assembly with the forward fuselage. Lay the two fuselage sides

down flat on the work bench and glue the foam doublers to the locations

shown on the parts templates. Be sure to make two mirror image parts—a

left side and a right side.

Use a heat gun to gently heat the foam and form the curves in these

pieces. Hold each piece up next to the piece it mates to to judge the

curvature.

After the glue has dried, glue the three fuselage bulkheads to one of the

fuselage sides at the locations shown, making sure they are perpendicular.

2. Next glue the two fuselage sides together. Set the fuselage sides upright

and flat on the workbench, apply glue to the edge of the bulkheads, and

push the sides together.

After the glue has dried, glue this assembly to the fuselage bottom piece

as shown.

Glue the two forward fuselage top pieces in (forward of the canopy).

Page 3

Downloaded from www.Manualslib.com manuals search engine

3. Laminate the nose cone pieces together using 3M 77 spray adhesive.

Then glue the assembled nosecone block to the forward fuselage as

shown (5 minute epoxy recommended).

Once the glue has dried, carve the nose cone to shape. Start by tracing

the top view template on the top of the block and cutting the block to that

outline. Begin with coarse sandpaper (60 grit) to rough out the basic

shape, then move to progressively finer sandpaper (first 150, then 220 grit)

to do the final shaping.

Make the canopy using the same procedure. Note the canopy has two

smaller sill pieces that glue on to each side of the canopy to form the lower

sill.

Page 4

Downloaded from www.Manualslib.com manuals search engine

4. Begin assembly of the inlets. Be sure to make two mirror-image inlets!

First glue the small plywood stabilizer support squares to each side in the

locations shown on the plans, and then drill the 3/16” holes for the stab

pivots. Then glue the foam support strips as shown to both the inboard

and outboard inlet sides. Glue the taileron servo doubler to the inboard

inlet side.

Use a heat gun to gently form the required curves in these pieces. Hold

each piece next to the inlet bottom piece to judge the curvature required.

Page 5

Downloaded from www.Manualslib.com manuals search engine

5. Tack glue the three temporary inlet bulkheads to one side (these will be

removed later), and then tack glue the two inlet sides together.

Next glue the inlet bottom piece on. To make sure the inlets are

assembled perfectly square, hook the sides over a bench as shown and

hold the inlets flat against the bench as the glue dries.

After the glue has dried, sand the corners of the inlets to a well-rounded

shape.

Page 6

Downloaded from www.Manualslib.com manuals search engine

6. Glue the inlet diverters to the fuselage sides. Note the bottom of the

diverter butts up against the step in the fuselage bottom piece.

7. Laminate the five motor mount pieces together using 3M 77. Note the

tabbed piece goes in the middle. Then sand the assembly to a tapered

shape as shown.

Glue in the hardwood motor mount using 5 minute epoxy.

Page 7

Downloaded from www.Manualslib.com manuals search engine

8. Sand the forward fuselage to the contours shown. It’s important to do this

now before you glue the inlets to the side of the fuselage, since the inlets

will block access to the aft part of the fuselage. Sand the bottom edges to

a circular shape, and then sand the top edges down to the feathered

shape shown on the diagram at left. Note how the tops of the fuselage

sides blend into the canopy sill.

Page 8

Downloaded from www.Manualslib.com manuals search engine

9. Next glue the inlets to each side of the fuselage. Note that the tabs on the

fuselage bottom piece slide into corresponding slots in the inlet sides,

which automatically ensures proper alignment. But you’ll need to make

sure the inboard forward top edges of the inlets are flush with the top of

the aft fuselage (the area held together with blue tape in the bottom picture

at left). Note that the motor mount also has tabs and slots to ensure

proper alignment as well. 15 minute epoxy is highly recommended for this

step, both for strength and to give you time to get everything aligned

before the glue sets. Set the fuselage upside down on the workbench

(hooked over an edge with the inlet tops sitting flat against the bench) as

the glue cures to ensure this assembly is perfectly flat on top. This is

important because the wing spar box will span across the top and the

wings will fold up on top as well.

After the glue has cured, remove all of the temporary bulkheads inside the

inlets.

Page 9

Downloaded from www.Manualslib.com manuals search engine

10. Now we’ll build the wing sweep mechanism. Begin by cutting out all the

plywood parts using a similar procedure as the foam parts—just tack glue

the paper templates to the wood using 3M 77 spray and then cut the parts

out with a sharp hobby knife (that’s one of the beauties of lite-ply—it can

be cut quickly with a knife!).

When done, you should have all of the parts shown in the bottom picture at

left.

11. Glue the doublers to both ends of the spar box top and bottom pieces.

Laminate the two spacer pieces and glue them in place on top of the

doublers on one side. Then glue the balsa shear webs in place on the

same side. Medium viscosity CA is recommended for all of these joints.

Next laminate the two swing arm pieces together with CA. Be sure to

make two mirror-image parts—the piece with the control arm goes on

bottom for each side.

Page 10

Downloaded from www.Manualslib.com manuals search engine

12. Test fit the top and bottom spar box pieces together. Sand the balsa shear

webs as required until you get a perfect fit. Then glue the top and bottom

pieces together with CA.

Now drill the four ¼” holes for the nylon bolt wing pins—one in each end of

the spar box and one in each swing arm. Use a drill press if at all possible

to ensure the holes are perfectly perpendicular!

Test fit the swing arms and nylon bolts in place, and check to see if they

rotate smoothly. You want them to fit tightly but still rotate smoothly. Sand

the swing arms as required to thin them down until they turn smoothly.

Note that you can also adjust the tension of the swing arms by tightening

the nylon nut and bolt, so it’s OK if the swing arms end up a little loose.

Page 11

Downloaded from www.Manualslib.com manuals search engine

13. Cut the carbon tube wing spars to length and test fit the swing arms and

spars into the wing, trimming as required. Then glue the swing arms and

spars in place using epoxy (note that the side with the control arm goes

down on the swing arms). Place wax paper and heavy books on top of the

wings as the epoxy cures to ensure everything stays perfectly flat. After

the glue cures, put a strip of 3M Satin tape over the top and bottom of the

spar to help hide the joint and provide a smooth wing surface.

Now sand the wing to shape. Sand the leading edge to a well-rounded

shape and sand the trailing edge down to a tapered shape from the top.

This will result in a thin flat-bottom airfoil. Put a strip of Satin tape over the

leading edge to provide durability and smoothness.

14. Glue the 3/8” thick balsa spacer block in the bottom center of the wing

swing box. However, check the fit of your servo first to see if this thickness

puts the servo arm at the same height as the control arms on the wing

swing arms. You may need to use a thicker or thinner spacer depending

on your servo. 3/8” is what worked for the HS-81MG servo used in the

prototype.

Page 12

Downloaded from www.Manualslib.com manuals search engine

15. Make the 1/8” lite-ply servo arm, and then attach a nylon servo arm with

two screws as shown. You may need to experiment to find the exact hole

locations that result in both wings swinging identically forward to back—

and those locations will probably NOT be symmetrical. I found that the left

wing needs a little longer moment arm than the right wing to swing equally.

If one wing swings more than the other, simply increase the moment arm

on that side. The locations shown on the plans are what worked (after

much experimenting) with the HS-81MG servo used in the prototype.

Also note that if this horn seems weak to you (only .25” wide), that’s by

design! This servo arm is intended to be the weak link in the wing swing

mechanism. That way, if you catch a wing on landing, this horn will break

before anything else in the system breaks. This is good because this horn

is easy and quick to replace via the hatch in the top of the fuselage. This

design has already paid off for me—I had a crash landing in one of the

early flights and this arm broke just as intended, preventing any further

damage to the wing or swing mechanism!

16. Glue 1/8” lite-ply strengtheners to the bottom of the servo tray as shown.

Then check the fit of the servo and trim as required. When done, the

assembly should look like the picture on bottom.

I used a Hitec HS-81 MG servo on the prototype, which works OK but is

definitely strains in this application. I think it works well enough that a

larger (and thus heavier) servo isn’t required, but if you choose to do so

there is room for a larger servo. The most important thing is to use a

METAL geared servo (a nylon geared servo is very likely to strip).

Page 13

Downloaded from www.Manualslib.com manuals search engine

17. Glue the servo tray on the bottom of the spacer.

Make the pushrods using 1/16” threaded rods with steel clevises on each

side. I found that the Great Planes small steel clevises happened to work

best, providing a perfect fit with the 1/8” lite-ply control arms. Dubro

clevises didn’t fit nearly as well…

18. Now plug the servo into your receiver and test the wing swing mechanism,

adjusting it as required until it works perfectly. You want both wings to

swing easily and also swing the same amount. If one wing swings more

than the other, adjust the control throws on the servo control arm. If the

wings tend to bind, sand the swing arms down in thickness. Use the

buzzing of the servo to tell you where the problems are—it’ll buzz heavily if

it encounters something it doesn’t like!

For reference, there are mechanical stops on both ends of the wing swing

travel. The step in the wing trailing edges should just touch the back of the

wing swing spar box when the wings are swept fully aft. And the control

arms on the wing swing arms should hit the forward side of the spacer

inside the spar box when the wings are fully forward. Use those extremes

to gauge how much swing is required.

Note that the a key feature of this design is that it is independent from the

rest of the airframe. Thus, everything can be tested and adjusted to work

perfectly BEFORE you install it.

Page 14

Downloaded from www.Manualslib.com manuals search engine

19. Test fit the wing swing box onto the fuselage. The forward side of the spar

box butts up against the step in the inlet tops. Cut clearance holes as

shown for the wing pushrods on the top of each inlet side (4 total). Be

sure to make those holes wide enough to clear the pushrods throughout

the entire swing of the wings.

Next glue in the four segments of ¼” balsa triangle that fit underneath the

spar box. These should be flush with tops of the inlets.

Use this forward wing strake piece as a guide to help you glue the spar

box in with perfect alignment. First test fit the wing strake piece to ensure

it fits well and trim as required. Then draw centerlines on everything

(strake, fuselage, spar box) to help align everything. After you’re confident

everything fits well and is aligned, glue in the spar box and strake together

using epoxy.

Note that the wings are easily removable on this model, even after it’s

finished. To remove the wing, just pull out the nylon bolts at the wing pivot

and unsnap the clevis on the servo arm (using needle-nose pliers through

the access hatch on top). Then slide the wing out, being careful to pull the

pushrods carefully through the clearance holes. Reverse this procedure to

put the wing back on, being careful to guide the wing pushrods back

through the clearance holes. Note there’s no need to ever take the clevis

off the wing control arm—use the clevis at the servo instead.

Page 15

Downloaded from www.Manualslib.com manuals search engine

20. Next install the tailerons. Each taileron has a .157” diameter carbon spar

that pivots inside two small pieces of 3/16” diameter aluminum, which are

supported by two small squares of 1/64” ply glued to the foam inside the

inlets.

Begin by sanding the tailerons to shape. Sand the leading edges to a well-

rounded shape and the trailing edges to a tapered shape. Put a strip of

3M Satin tape on the leading edges to provide durability and smoothness.

Also put a few layers of Satin tape on the forward root of the tailerons to

increase strength.

Cut the carbon spars and aluminum tubes to length. Glue the aluminum

tubes into the plywood squares in the inlets using epoxy. Make sure to put

the carbon rods in the bearings while the epoxy cures to ensure everything

is aligned. Then glue the spars into the tailerons using epoxy.

After the glue is cured, slide the carbon rods through the aluminum

bearings and slide the end stops and control horns onto each rod (but

don’t glue them yet). I used spare servo horns for both the end stops and

taileron control horns (just snip off the arms and drill them out to slide onto

the carbon rod).

Install the servo and make a pushrod using 1/32” music wire (Z-bends are

recommended on each end). Set the length of the pushrod so that the

servo arm and taileron control arm are perfectly vertical. I simply used

tape to hold the servos in place, combined with the friction from a tight-

fitting hole in the foam.

Adjust as required until everything is aligned—the control arms are

vertical, the tailerons are level, and the end stops fit snugly against the

inlet sides. Then put a few drops of CA on the end stops and taileron

control horns to secure them in place.

Page 16

Downloaded from www.Manualslib.com manuals search engine

21. Glue the vertical tail support doublers to the inside of each inlet top piece,

making left and right versions. Then cut the slot for the vertical tails at a

roughly 5 degree cant angle (canted outboard). Use a heat gun to form

the small curve in the aft end for the exhaust nozzle.

Glue the inlet top pieces onto the inlets. Note that the forward edge of

these pieces butts up against the rear edge of the wing spar box.

Page 17

Downloaded from www.Manualslib.com manuals search engine

22. Install the speed control and battery extension wiring. Note that the

battery extension wiring should be twisted and then wrapped with

aluminum foil to reduce RF interference. In the photo here, the speed

control is installed inside the airplane. However, I later learned (the hard

way) that the speed control must be installed OUTSIDE the airplane to

provide cooling and prevent shutdown due to overheating. So cut a hole in

the bottom of the fuselage and route the wiring so that the speed control is

located on the bottom outside of the airplane (see bottom picture).

Laminate the 2 parts for the wing cover center support and glue in place

on the back of the wing spar box (shown in the top picture).

23. Sand the vertical tails to shape, giving the leading edges a round shape

and the trailing edges a tapered shape.

If you’re installing rudders, cut those out and hinge them with Satin tape.

Glue the tails in place using epoxy, canting them outboard at a 5 degree

angle.

Page 18

Downloaded from www.Manualslib.com manuals search engine

24. If you’re installing rudders on this model, install the control runs now. I

used Sullivan light flexible cable pushrods, with 1/32” music wire soldered

on the rudder end and Dubro micro EZ connectors on the servo end. Note

the two small pieces of scrap foam that support the cables near the servo.

Rudders are nice to have and are useful during aerobatics and very low

speed maneuvering. But they are not required for this model to fly well.

25. Install the center aft fuselage top piece using epoxy.

26. Now install all the remaining wing strake pieces, including the aft upper

wing cover (2 pieces) and the forward and aft lower strake pieces.

Note that the forward lower wing strake pieces may need to be notched

inside a little to clear the wing swing pushrods.

Install the turtledeck sides and top. Note that the turtledeck sides are

glued on at a roughly 15 degree angle (canted inboard) to give them that

characteristic F-14 shape.

Page 19

Downloaded from www.Manualslib.com manuals search engine

27. Sand the wing strake and turtledeck to shape as shown.

To reduce the friction of the wing swing mechanism, place a single layer of

packing tape on the insides of the wing slot (top only) and on the top and

bottom of the wing root (but only where it contacts the wing slot). Bare

foam and plywood joints may swing freely on the bench, but once the wing

gets deflected with 1g flight loads these joints need packing tape to keep

the friction down.

Page 20

Downloaded from www.Manualslib.com manuals search engine

28. Cut an access hole for the wing swing servo as shown. Also cut the

access hole for the receiver (not shown here) and install the receiver.

29. The canopy is removable to allow easy access to the battery compartment.

It is held in place with two bamboo skewers forward (toothpicks or carbon

rod could also be used) that slide into matching holes in the forward

bulkhead, and two small strips of Velcro aft that are mounted to short

pieces of ¼” balsa triangle stock.

Cut two 2” lengths of bamboo and sharpen both ends. Stick the bamboo

into the foam at the front of the canopy so that only ½” protrudes and glue

into place.

After the glue dries, push the canopy onto the airplane so that the

protruding ends poke holes into the forward bulkhead. Then glue the

Velcro mounts to the fuselage sides as shown on the plans and attach the

matching Velcro pieces to the mounts and to the canopy.

Page 21

Downloaded from www.Manualslib.com manuals search engine

30. Install the motor and plug it into the speed control leads.

31. CONGRATULATIONS! Your model is now complete.

The model can be painted using standard acrylic craft paint (available at

most craft stores), applied with either a brush or airbrush. Remember to

wipe the foam with rubbing alcohol before painting to remove any grease

or dirt. Rough areas such as the canopy and nosecone can be filled with

standard wall spackling compound thinned with water, which fills the holes

and can be sanded to a very smooth finish (with minimal weight gain).

I hope you enjoy this model as much as I have!

Page 22

Downloaded from www.Manualslib.com manuals search engine

Additional Photos

Here are some additional photos of the prototype F-14 Tomcat Park Jet for reference

Page 23

Downloaded from www.Manualslib.com manuals search engine

Canopy Fwd fuselage doubler

Make 10 and laminate Make 2

with 3M 77 spray Designed by Steve Shumate

Turtledeck sides

Strake middle piece

Make 2 Copyright © 2005 All Rights Reserved

Nose cone top 2 Make 2

- Make All parts are made from 6 mm Depron or

view template Canopy sill Cut top and bottom edges at a roughly 15 degree bevel

(use to aid in BlueCore foam unless otherwise specified

carving to shape)

If you enjoy these plans, please consider sending a small contribution

to the designer to show your appreciation for all the work that went

doubler here

Install fwd fuse into developing them. Suggested contribution is $10 U.S., and can

Turtledeck top

Forward fuselage sides F-3 (trim to fit) be sent via PayPal to jetset44@verizon.net. Thanks for your support!

Nose cone F-2 Make 2 Make 2

Make 12 and laminate

F-1

with 3M 77 spray

strip here

Install 2 layers of 3/8" foam

Fwd fuse top

Fwd fuse top

Make 1

doubler

Make 1

Aft wing cover Cut access hatch for receiver

Make 1

Cut hole to access

and rudder servo

F-3

wing swing servo

F-1 F-2

Make 1 Make 1 4

Make 1

Wing Strake Fences

Strake/inlet top

Make 4 from 3mm Depron

Center support for aft wing cover

Make 1

2 Make 2 and laminate

Fwd Fuselage Gun Pod

(sand to shape)

Make 1

Scale in inches Inlet diverter

Make 2

Rudder servo tray

Upper wing air exhausts

Make 3 and laminate

(decoration)

Make 2

0 2 4 Fwd strake bottom piece

Make 2

Wing panel Taileron servo doubler

Make 2 Make 2

Center aft fuselage

top piece

Make 1

Vertical tail brace - Make 2

Cut slot at 5 deg angle

Cut slot at 5 deg angle

for vertical tails

Aft strake bottom piece

Aft wing cover

center piece

Motor mount Motor mount Make 2

Make 1

Top piece Aft inlet tops

Middle piece Make 2

Make 2 Make 2

Stabilator

Make 2

Drill 1/4" holes both sides

Install 3/8" foam strips here

(after assembled)

Motor mount Inlet inboard sides Cut hole to fit Cut slot to fit

Bottom piece Make 2 servo used .75" x .75" 1/64" ply motor mount

Make 1 Cut slots to accept tabs doublers on inboard side

on center fuselage bottom (drill 3/16" hole for pivot

bearing tubes)

Install 3/8" foam strips here

Install 3/8" foam strips here

Wing sweep servo tray

Make 1 from 1/8" lite-ply

(make 1 from 3/8" balsa)

Vertical tail Inlet outboard sides

Wing sweep servo

(1.0" x 1.87")

Make 2

Lite-ply doubler

Make 2

tray spacer

underneath

Install balsa servo

Cut hole to fit servo

Temporary

tray spacer

Make 2 from 1/4" hard balsa (0.5" height x 8.5" length)

used (HS-81 shown) on top here

Inlet

Wing sweep spar box top and bottom

Bulkhead 3

Wing sweep spar box shear webs

Make 2 from 1/8" lite-ply

Make 1 Install 3/8" foam strips here

Wing sweep servo arm Install root fairings here

Make 1 from 1/8" lite-ply (one on each side)

0.25"

0.78" 0.81"

Temporary Temporary Inlet bottoms

Right wing Left wing Inlet Inlet Make 2

Adjust hole spacing on both sides

as required to get proper amount Bulkhead 1 Bulkhead 2

Vertical tail root fairing - Make 4 Rudder control horns

of swing angle in each wing

(dimensions shown are what worked

(make 2 from 1/32" plywood)

Make 1 Make 1

with the HS-81 servo used on prototype).

Note these holes are not necessarily

symmetrical. Wing swing arm spacer

(make 4 from 1/8" lite-ply,

laminate to make 2 pairs)

(0.5" x 1.0")

Drill 1/16" hole

Drill 1/4" hole thru

(after assembly)

Install spacer

spacer here

Make

Uppe 2 from

Make

Lowe 2 from

Center fuselage bottom

Make 4 from 1/8" lite-ply

r wing 1/8" lite

Wing sweep spar box

Make 1

r wing 1/8" lite

tongue doublers

swing -ply

swing -ply

arm

arm

Downloaded from www.Manualslib.com manuals search engine

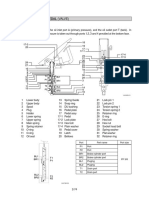

NOTES: Wing Sweep Mechanism Detail

* All parts are made from 6mm Depron or BlueCore foam unless

otherwise indicated Hitec HS-81 MG servo

* If using BlueCore, peel the plastic covering off both sides with 1/8" lite-ply servo arm

of all fuselage parts (leave the skin on all wing and

empennage parts for strength)

* Recommended control deflections (all dimensions

measured at root trailing edge):

Tailerons (pitch): +/- 1.5" (-40% expo)

Tailerons (roll): +/- 1.75" (-40% expo)

Rudder: +/- 7/8" (-30% expo)

* Wing sweep to stabilator mixing is required to keep the

airplane trimmed as the wing sweeps. Set it up so Laminated 1/8" lite-ply tongue

that swinging from full forward to full aft sweep provides 1/8" lite-ply s

Laminated 1/8" lite-ply spacer bottom, and

1/4" trailing edge up stabilator (about 5% mix rate)

* Rudder control is optional and provides better control

for aerobatics and low-speed high alpha flight

* Use a heat gun to gently form the foam in the fuselage 3/8" balsa spacer

to the shapes shown 1/8" lite-ply servo tray

RECOMMENDED POWER SYSTEM:

* For best results choose a power system that provides

20-25 oz static thrust and 45-50 mph pitch speed.

* Prototype used Himax 2015-4100 with 4.4:1 gearing, 9x6 APC

Slowflyer prop, 1320 mAh 11.1V lithium-polymer battery, and

Castle Creations Phoenix 10 speed control

If you enjoy these plans, please consider sending a small contribution

to the designer to show your appreciation for all the work that went

into developing them. Suggested contribution is $10 U.S., and can

be sent via PayPal to jetset44@verizon.net. Thanks for your support!

Vertical tails canted

5 deg outboard

Scale in inches

2

Fuselage Cross Section Detail

0 2 4 6 8

Nosecone and canopy made

from laminated foam sheets

or foam block carved to shape

Span: 40.7"/24.7"

Wing area: 220 sq in

Weight: 20 - 23 oz RTF

Sand forward fuselage/canopy Battery mounted to fuselage

Wing loading: 14 oz/sq ft to contours shown floor with a strip of Velcro

Designed and drawn by Steve Shumate

Copyright © 2005 All Rights Reserved

Downloaded from www.Manualslib.com manuals search engine

Detail

1/16" threaded rod with

steel clevises on each end

Drill 1/4" holes to accept

1/4-20 nylon bolts

0.157" dia. x 5.12" carbon tube

pivoting inside two short pieces

of 3/16" dia. aluminum tubing

Cover wing root and inside

1/8" lite-ply spar box top, of wing slot with packing

bottom, and doublers tape to reduce friction

1/4" balsa shear webs 3/8" balsa triangle

spar box supports

-ply servo tray

(4 places)

3 temporary bulkheads installed

in inlets to aid assembly

Cut hatch for access to

receiver and rudder servo

Wing pin is a 1/4-20 nylon

bolt retained by a nylon nut

.21" dia x 13.0" carbon tube spar

Cover stabilator root on both sides

with 3M Satin tape for strengthening

Sand wing and empennage leading edges round and Sand wing and empennage trailing

apply a piece of 3M Satin tape around the leading edges to a tapered shape

edge to add smoothness and durability

Removable canopy mounted

with two bamboo skewers

forward and two Velcro strips aft

Cut hatch for access

to wing swing servo

CG location

Rudder servo (optional)

4.7"

(or 0.5" forward Receiver

3/8" sq x 4.25"

of wing pivots hardwood motor mount

Downloaded from www.Manualslib.com manuals search engine

You might also like

- T-38 Park Jet Construction GuideDocument16 pagesT-38 Park Jet Construction Guidemam73No ratings yet

- F-14 Park Jet Construction GuideDocument23 pagesF-14 Park Jet Construction Guidemam73100% (1)

- Su-37 Park Jet Plans (Assembly Drawing Tiled)Document2 pagesSu-37 Park Jet Plans (Assembly Drawing Tiled)coloNo ratings yet

- Helicopter Assembly InstructionsDocument8 pagesHelicopter Assembly InstructionsIkhsan AhmadNo ratings yet

- Pipejet: Piper Pa-47 PiperjetDocument7 pagesPipejet: Piper Pa-47 PiperjetFikri NakhlaNo ratings yet

- Snice Mirage 2000 Plan v2 FinalDocument1 pageSnice Mirage 2000 Plan v2 FinalLalith Kumar100% (1)

- Yzf r1 07 Assembly FullDocument20 pagesYzf r1 07 Assembly FullChoky Masih TopiazNo ratings yet

- Flying Paper f22 RaptorDocument4 pagesFlying Paper f22 RaptorJose Anibal Moya DazaNo ratings yet

- AP T45 Goshawk FullDocument8 pagesAP T45 Goshawk FullYusf IbrahemNo ratings yet

- How To Build The Nose SectionDocument2 pagesHow To Build The Nose SectionLorenzo MartinezNo ratings yet

- Total Dash8Document14 pagesTotal Dash8Luiz Fernando MibachNo ratings yet

- Boeing 777-200 Malaysia Airlines Paper Model InstructionsDocument18 pagesBoeing 777-200 Malaysia Airlines Paper Model Instructionsjemadrid100% (3)

- T-38 Park Jet Plans (Parts Templates Tiled) BETA2Document16 pagesT-38 Park Jet Plans (Parts Templates Tiled) BETA2Emerson URNo ratings yet

- Plugin Yz450fm Assembly01Document4 pagesPlugin Yz450fm Assembly01wahidnursalimNo ratings yet

- Bob's Card Models: Douglas DC-6B 1:72Document18 pagesBob's Card Models: Douglas DC-6B 1:72Luiz Fernando MibachNo ratings yet

- Avro Shackleton MR Mk 2 Model KitDocument15 pagesAvro Shackleton MR Mk 2 Model KitSkyrest OrtizNo ratings yet

- Bob's Card Models: Martin Mars Water Bomber (1:72)Document21 pagesBob's Card Models: Martin Mars Water Bomber (1:72)Luiz Fernando MibachNo ratings yet

- Front and side views of an Airbus A320 paper modelDocument20 pagesFront and side views of an Airbus A320 paper modelDaniel433No ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled)Document15 pagesT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewNo ratings yet

- F-107 Instructions FullDocument20 pagesF-107 Instructions Fullmam73No ratings yet

- T-38 Park Jet Plans (Assembly Drawing)Document2 pagesT-38 Park Jet Plans (Assembly Drawing)souheil_souNo ratings yet

- TC Midget: Classic Car Series: 05Document6 pagesTC Midget: Classic Car Series: 05Felixz GiatamaNo ratings yet

- Bonanza JA3907-Flyable EditionDocument1 pageBonanza JA3907-Flyable EditionSilvia Cristina100% (2)

- Sheet 2 of 2: Turn TurnDocument2 pagesSheet 2 of 2: Turn TurnJesùs AlfaroNo ratings yet

- Assembly Instructions For V-2 Rocket: HistoryDocument4 pagesAssembly Instructions For V-2 Rocket: HistoryEmerson URNo ratings yet

- JMSDF AH-64 Apache Longbow by Papermodel - JPDocument2 pagesJMSDF AH-64 Apache Longbow by Papermodel - JPPaperShock100% (1)

- MIG-31 Firefox Construciton ManualDocument9 pagesMIG-31 Firefox Construciton ManualChrisNo ratings yet

- Mig 15 PDFDocument6 pagesMig 15 PDFKhillhing100% (1)

- Blue AngelsDocument11 pagesBlue AngelsJovan Veličković75% (4)

- Card Model a-7E-CorsairDocument4 pagesCard Model a-7E-Corsairhawkeye1175% (4)

- Bob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Document16 pagesBob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Luiz Fernando MibachNo ratings yet

- Dc10 30af Fedex Old N311fe Livery 1 200 Scissors and PlanesDocument3 pagesDc10 30af Fedex Old N311fe Livery 1 200 Scissors and PlanesNguyễn Xuân Tùng THPT Lý Thường KiệtNo ratings yet

- A320 Zones PDFDocument1 pageA320 Zones PDFNasirNo ratings yet

- JAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The CockpitDocument17 pagesJAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The CockpitAndrew AfanasjevNo ratings yet

- Air Asia Puregold A320 Instruction ManualDocument20 pagesAir Asia Puregold A320 Instruction ManualAlbert Liu100% (1)

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoNo ratings yet

- C-17 Globemaster III Scissors and PlanesDocument2 pagesC-17 Globemaster III Scissors and PlanesJuan Pablo Díaz Vanegas100% (1)

- ARES Paper ModelDocument1 pageARES Paper ModelHany ElGezawyNo ratings yet

- BK Papercraft ModelDocument2 pagesBK Papercraft ModelNarciso Rojas50% (2)

- Science of Flight: Introduction To Aerodynamics For The Science Student by Pat MorganDocument30 pagesScience of Flight: Introduction To Aerodynamics For The Science Student by Pat MorganIIEC pulchowkNo ratings yet

- Paper Model - Marek - Aero L-29 ''Delfin'' (Vector 50)Document4 pagesPaper Model - Marek - Aero L-29 ''Delfin'' (Vector 50)Alessandro BaffaNo ratings yet

- Airbus320: Assembly Instructions: Front Over LookDocument20 pagesAirbus320: Assembly Instructions: Front Over LookMaiara TNo ratings yet

- Airbus A350-900 Thai 1 120Document17 pagesAirbus A350-900 Thai 1 120Daniel LambertNo ratings yet

- (Model CardBoard 2003-03) (Airplane) P-51B Mustang (1x50) (4xa4)Document4 pages(Model CardBoard 2003-03) (Airplane) P-51B Mustang (1x50) (4xa4)Mohamed HassanNo ratings yet

- Dsc11 Assembly FullDocument15 pagesDsc11 Assembly FullMichael LesterNo ratings yet

- SU-47 Parts 6mm Depron PDFDocument19 pagesSU-47 Parts 6mm Depron PDFAlejandro LabléeNo ratings yet

- AIRBUS320 PATTERNDocument19 pagesAIRBUS320 PATTERNHuy DoNo ratings yet

- F 35 f35 f16 f22 - CompressDocument32 pagesF 35 f35 f16 f22 - CompressNber2TI service50% (2)

- CRJ 1000Document8 pagesCRJ 1000Eby Doen QeQe100% (1)

- Free Sample PlaneDocument6 pagesFree Sample PlaneArvind N LakshmananNo ratings yet

- Sikorsky CH-34C SpecsDocument23 pagesSikorsky CH-34C Specsandre_tfjr80% (5)

- Paparcraft AC-130H SpookyDocument9 pagesPaparcraft AC-130H SpookyUlises Desentis100% (2)

- Mig 29 Construction Guide v3Document28 pagesMig 29 Construction Guide v3marian32No ratings yet

- JAS 39 Park Jet Construction ManualDocument17 pagesJAS 39 Park Jet Construction Manualmam73No ratings yet

- F-15 Park Jet Construction Guide Rev ADocument21 pagesF-15 Park Jet Construction Guide Rev AAkas AsriNo ratings yet

- F-18 Park Jet Construction Guide Rev ADocument20 pagesF-18 Park Jet Construction Guide Rev ASzymon WójcikNo ratings yet

- Build Jet Wings with Sweep MechanismDocument23 pagesBuild Jet Wings with Sweep MechanismJohn MondoNo ratings yet

- F-22 Construction GuideDocument28 pagesF-22 Construction Guideibmace100% (1)

- F22 FOAM Construction GuideDocument26 pagesF22 FOAM Construction GuideFilip Lisičin100% (1)

- F-22 Construction Guide Scratchbuild Rev ADocument23 pagesF-22 Construction Guide Scratchbuild Rev ARonald Cardenas GNo ratings yet

- Instruction Manual F-14 Tomcat: DisclaimerDocument26 pagesInstruction Manual F-14 Tomcat: DisclaimerJohn MondoNo ratings yet

- Grupos WhatsDocument22 pagesGrupos WhatsJohn MondoNo ratings yet

- Build Jet Wings with Sweep MechanismDocument23 pagesBuild Jet Wings with Sweep MechanismJohn MondoNo ratings yet

- F-14 Park Jet (Parts Templates Tiled)Document25 pagesF-14 Park Jet (Parts Templates Tiled)John MondoNo ratings yet

- F-14 Park Jet Motor Posterior PDFDocument1 pageF-14 Park Jet Motor Posterior PDFAnonymous qX7ZtAFJNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- F-14 Park Jet Motor Posterior PDFDocument1 pageF-14 Park Jet Motor Posterior PDFAnonymous qX7ZtAFJNo ratings yet

- Build Jet Wings with Sweep MechanismDocument23 pagesBuild Jet Wings with Sweep MechanismJohn MondoNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- F-14 Park Jet (Parts Templates Tiled)Document25 pagesF-14 Park Jet (Parts Templates Tiled)John MondoNo ratings yet

- 2008 Open Road RVDocument16 pages2008 Open Road RVJNo ratings yet

- f25570752 - LOAP - 2604 - FRONTPAGE TucanoDocument84 pagesf25570752 - LOAP - 2604 - FRONTPAGE TucanojosueNo ratings yet

- Fendtlotus 1901 enDocument9 pagesFendtlotus 1901 enЄвген ЗаліщукNo ratings yet

- OO7 JET RC Plane PlansDocument15 pagesOO7 JET RC Plane PlansTewelde WorkuNo ratings yet

- Honda CRF 450 R 2007r. Service Manual SerwisówkaDocument169 pagesHonda CRF 450 R 2007r. Service Manual SerwisówkaNight Street WarriorsNo ratings yet

- 2020 - YZF - R1 - Kit Manual - ENDocument82 pages2020 - YZF - R1 - Kit Manual - ENMr. TNo ratings yet

- CVVTDocument50 pagesCVVTMoaed Kanbar94% (18)

- v2.4 MOP2160 - E ZARANDADocument21 pagesv2.4 MOP2160 - E ZARANDAMartín Lescano ParedesNo ratings yet

- Marmon-Herrington CT8 Series Service Manual: Alt-WHEELDocument43 pagesMarmon-Herrington CT8 Series Service Manual: Alt-WHEELPablo PorrasNo ratings yet

- Secondary and Tertiary Cone CrushersDocument4 pagesSecondary and Tertiary Cone CrushersDanielSantosNo ratings yet

- Cesabb 300 B 400Document8 pagesCesabb 300 B 400BeyzaNo ratings yet

- Dealer's Name & Address: Complete Peace of MindDocument10 pagesDealer's Name & Address: Complete Peace of MindcubadesignstudNo ratings yet

- XD - STPIE - 20210909 - 1729 - Vehículo Ligeros906657 - 8AC906657KE150803 - JRCJ14 INDocument3 pagesXD - STPIE - 20210909 - 1729 - Vehículo Ligeros906657 - 8AC906657KE150803 - JRCJ14 INFabian IrarrazabalNo ratings yet

- Diagrams and SchematicsDocument90 pagesDiagrams and SchematicsFELIX AGUILARNo ratings yet

- GM Gas-Powered Airless SprayersDocument16 pagesGM Gas-Powered Airless SprayersDOMINO66No ratings yet

- GARAGETECHNICCATALOGDocument55 pagesGARAGETECHNICCATALOGAbdurahimNo ratings yet

- SP-3700 - Air Dryer Instruction ManualDocument111 pagesSP-3700 - Air Dryer Instruction ManualIsrael PerezNo ratings yet

- Lap. AbuDocument19 pagesLap. Abusyahrul arulNo ratings yet

- 2022 Kia CeratoDocument14 pages2022 Kia CeratoLucas SeñaNo ratings yet

- Group 7 Brake Pedal (Valve)Document2 pagesGroup 7 Brake Pedal (Valve)Quốc Phú ĐinhNo ratings yet

- Robot Drive Systems and End Effectors GuideDocument84 pagesRobot Drive Systems and End Effectors GuideSatheesh KumarNo ratings yet

- 1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulDocument29 pages1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulRubenNo ratings yet

- РеменларDocument3 pagesРеменларAhmadjon AbdujalilovNo ratings yet

- GXR-800 Automatic Coil Winding MachineDocument4 pagesGXR-800 Automatic Coil Winding MachineDavid BernalNo ratings yet

- Genie Boom Lift Parts Manual S-40 and S-45 From S40H-23500 PN 1263382Document264 pagesGenie Boom Lift Parts Manual S-40 and S-45 From S40H-23500 PN 1263382ashraf elsayedNo ratings yet

- ME-SFI Control Unit, ME-SFI Fault Code DescriptionDocument1 pageME-SFI Control Unit, ME-SFI Fault Code DescriptionsooksukonNo ratings yet

- Vespa scooter collectionDocument13 pagesVespa scooter collectionega alvianNo ratings yet

- Preliminary InformationDocument5 pagesPreliminary InformationErik CruzNo ratings yet

- P6820D, P7820D: Abg AbgDocument16 pagesP6820D, P7820D: Abg AbgAashiprashant GautamNo ratings yet

- 3B6 U2MIC Pin Out & Crane ConnectionsDocument1 page3B6 U2MIC Pin Out & Crane ConnectionsBrett MNo ratings yet