Professional Documents

Culture Documents

Thin Layer Drying of Grains and Crops

Uploaded by

AD DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thin Layer Drying of Grains and Crops

Uploaded by

AD DCopyright:

Available Formats

ASAE S448 DEC98

Thin-Layer Drying of Grains and Crops

Developed by the ASAE Grain and Feed Processing and Storage preferred. A dried sample should be reconstituted only once. Frozen

Committee; approved by the Food and Process Engineering Institute samples should be thawed and used only once.

Standards Committee; adopted by ASAE December 1993; reaffirmed for 4.3 Drying. Particles in the thin layer should be exposed fully to the

one year December 1998. airstream. The airstream approaching the sample should be as uniform

as possible in temperature and humidity at a given cross section parallel

1 Purpose and scope to the thin layer so that the air contacts sample particles uniformly. Care

should be exercised to prevent displacement of particles in the thin-layer

1.1 The purpose of this Standard is to provide a unified procedure for holder during a test. This situation may arise in a vertical thin-layer in

determining and presenting the drying characteristics of grains and which airstream flows horizontally through the product, or in a horizontal

crops. thin-layer in which airstream flows upward through the product. The air

1.2 The drying data determined and presented according to this velocity approaching the product should be at least 0.3 m/s.

Standard can be used in characterizing the drying rate of product, 4.4 Measurements. Nearly continuous recording of the sample mass

product drying computer simulation, performance testing of drying loss during drying is required. The corresponding records of particle

equipment, and product quality evaluations. temperature (surface or internal) are optional but preferred. The time

1.3 This Standard applies specifically to grains and crops that are dried interval between recordings depends on the mean dry bulb air

by forced air convection. temperature. Higher temperatures require shorter time intervals between

readings. A typical time interval for drying with 60 °C dry-bulb air

temperature is as follows: every 5 s during the first 5 min, every 1 min

2 Normative references during the next hour, and every 15 min thereafter. It is recommended to

The following standard contains provisions which, through reference in divert the airflow away from the sample occasionally to record the sample

this text, constitutes provisions of this Standard. At the time of mass with no airflow. This ‘‘no airflow’’ mass should be determined 3 to

publication, the editions indicated were valid. All standards are subject to 4 times during a drying test. Other parameters such as mean dry bulb air

revision, and parties to agreements based on this Standard are temperature, relative humidity, and air velocity should be measured

encouraged to investigate the possibility of applying the most recent occasionally to assure consistent operation of the dryer.

edition of the standard indicated below. Standards organizations maintain

registers of currently valid standards. 4.5 Accuracy of measurements. Temperature sensors shall be

accurate to 6 1 °C. Mass shall be measured with an accuracy of 0.2%

ASAE D245.4 DEC93, Moisture Relationships of Grains of sample mass so that the calculated moisture content is within 0.002

(decimal dry basis) of the product’s actual moisture content. Relative

humidity may be measured directly or computed from measurements of

3 Definitions dry bulb temperature and wet bulb (or dew point) temperature; it shall be

3.1 thin-layer: A layer of material exposed fully to an airstream during accurate to within 6 3 percentage points. The air velocity measurement

drying. The depth (thickness) of the layer should be uniform and should shall be accurate within 6 5%.

not exceed three layers of particles.

4.6 Duration of experiment. In most cases the experiment should

3.2 initial moisture content, Mi : Moisture content of a product prior to continue until the moisture ratio, MR, defined in clause 6 equals 0.05. Me

the start of drying, expressed as a decimal on a dry basis. should be determined experimentally or numerically from equation in 3.4.

3.3 final moisture content, Mf : Moisture content of a product at the

completion of drying, expressed as a decimal or a dry basis.

3.4 equilibrium moisture content, Me : Moisture content of a product in 5 Reporting

equilibrium with mean dry bulb temperature and relative humidity of the

5.1 Sample identification shall consist of

drying air, expressed as a decimal on a dry basis. Equations given in

ASAE D245 should be used whenever possible. — type (preferably botanical name) and variety;

— year;

4 General requirements — location of harvest;

4.1 Start-up. Tests should be conducted after drying equipment has — harvest moisture content;

reached steady-state conditions. Steady state is achieved when the — storage conditions and history;

approaching airstream temperature variation about the set-point is less — sample purity;

than or equal to 1 °C and approaching airstream relative humidity

variation about the set point is less than or equal to 3 percentage points. — sample preparation (see 4.2).

4.2 Sample. The sample shall be clean and representative in particle 5.2 Drying conditions used shall be specified. These conditions include:

size. It shall be free from broken, cracked, weathered, and immature — initial and final moisture contents (decimal, dry basis);

particles and other materials that are not inherently part of the product. — drying time (h, min or s);

The sample should preferably have its natural moisture content. In the

absence of a fresh sample, the moisture content of the sample may be — approaching air velocity (m/s);

reconstituted either by wetting with water spray or by conditioning in a — mean dry bulb temperature (°C);

humid environment. Reconstituted samples shall be conditioned at room — relative humidity (%).

temperature in a sealed container for at least 24 h. Water should not be

All air-condition data shall include mean and standard deviations

added directly to the sample if this causes physical or chemical changes

computed for the duration of the drying test.

that significantly affect drying rate of the product. In such cases,

reconstituting the sample by placing it in a humid environment is 5.3 Drying rate data reported shall consist of either of the following two

ASAE STANDARDS 1999 581

forms: appears to be an inadequate representation of the drying behavior of

— the numerical values of moisture content versus time; most crops especially in high temperature drying applications (dry bulb

air temperature higher than 40 °C for grains).

— the estimated values of k and n including standard errors of

estimates in Page’s equation 5.5 Previously determined values of k and n are reported in table 1 for

grain products. The range of test conditions is also shown. For those

products for which equation 2 was found in the literature, it is assumed

M2Me

MR 5 5exp~ 2 kt n ! (1) n equals 1.

M i2 M e

The units for parameters k and n shall be consistent with the unit of t (h, 6 Notation

min, or s) and shall include the standard deviation of each. The range of 6.1 The following notation is used in this Standard:

equation 1 (ranges of temperature, relative humidity, and moisture — A constant;

content) shall be clearly stated. See 3.6 for the duration of experiment.

If drying is terminated prior to MR equals 0.05, the ending moisture — B constant;

content on which the model is based should be specified. — d . b . dry basis;

5.4 Reporting additional forms of drying equations such as those — k constant;

involving diffusion theories is optional. The simple first order equation

— M instantaneous moisture content, decimal dry basis;

M2Me — Mi initial moisture content, decimal dry basis;

MR 5 5exp~ 2 kt ! (2)

M i2 M e — M e equilibrium moisture content, decimal dry basis;

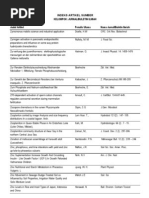

Table 1 – Constants k and n in the thin-layer drying equations 1 and 2. Equations and constants are given for other drying models (see notation in clause

6).

t

Product Constants unit Range Source

Barley k 50.0462 exp(0.0154T ) min 50< T <150 Bruce (1985)

n 50.49213.8431025 ( T 2123) 2 0.215< M i <0.41

Corn k 5exp(27.173511.2793 ln T10.1378v ) h 2.2<T<71.1 Misra and Brooker (1980)

n 50.0811 ln(rh)10.78 M i 3< rh <83

0.18< M i <0.60

Grass (fresh ryegrass) k 50.3431023 exp(0.02028T ) s T <200 O’Callaghan et al. (1971)

n 51

Lentils k 50.18262610.0043T h 23< T <80 Tang et al. (1989)

n 5 20.527 5< rh <70

Peanut pods (Virginia type) k 5exp(20.78052320.144026T 10.35831022 T 2 1 h 27< T <35 Kulasiri et al. (1989)

2.13941rh 10.71599M i 20.137131T rh ) 26< rh <47

n 50.9886720.019836T 20.60831023 T 2 21.033613 0.59< M i 0.77

rh20.6382401M i 10.0499769T rh

Canola k 51.355220.00301M i 20.00751T 20.5112v h 30< T <60 Patil and Ward (1989)

n 50.506820.0015M i 10.0103T 20.2440v 0.21<v<0.53

13.7< M i <0.25

Rice, rough k 50.0295820.4456rh 10.01215T h 32< T <51 Agrawal and Singh (1977)

n 50.1336511.93653rh 21.77431rh 2 10.009468T 19< rh <85

Rice, parboiled MR 50.134 exp(253105 kt )10.586 exp(253104 t ) h 17.3< T <40.2 Byler and Brook (1984)

1 0.28 exp(283103 kt ), k 5 exp(23590/[ T 1 273]) 25< rh <51

Sorghum t 5 A ln MR1B(ln MR)2 h 26.5< T <71 Paulsen and Thompson (1973)

A 5225.8710.335420.001075T 2 71< T <115.5

A 50.05420.0017T 26.5< T <115.5

B 530.5 exp(20.018T )

Soybeans k 50.03310.0003T min 32< T <49 Hutchinson and Otten (1982)

n 50.374410.00916T rh 34< rh <65

Sunflower (oilseed) k 55.6631024 T 1.271 min 27< T <93 Li et al. (1987)

n 50.828120.004T 10.000091T M i 0.26< M i <0.33

Walnuts k 5exp(20.68110.011M i 10.952 ln(Mi )1 h 27< T <43.2 Anigbankpu et al. (1980)

0.000152(1.8T 132) 2 25< rh <76

n 51

Wheat k 5139.3 exp(24426/[ T 1273]) s T <100 O’Callaghan et al. (1971)

n 51

White beans k 50.046620.0104rh min 32< T <49 Hutchinson and Otten (1982)

n 50.400210.00728rh T 34< rh <65

582 ASAE STANDARDS 1999

— MR moistureratio5 M 2 M e / M i 2 M ; — T temperature, °C;

— n constant; — t time, s, min, h;

— rh relative humidity, %; — v air velocity, m/s.

Annex A Kulasiri, D. G., D. H. Vaughan, J. S. Cundiff and W. F. Wilcke. 1989. Thin

(informative) layer drying rates of Virginia type peanuts. ASAE Paper No. 89-6600.

Bibliography Li, Y., V. Morey and M. Afinrud. 1987. Thin layer drying rates of oilseed

sunflower. Transactions of the ASAE 30(4):1171–1175, 1180.

Misra, M. K. and D. B. Brooker. 1980. Thin layer drying and rewetting

The following documents are cited as reference sources used in

equations for shelled yellow corn. Transactions of the ASAE 23(5):1254–

development of this Standard:

1260.

Anigbankpu, C. S., T. R. Rumsey, and J. F. Thompson. 1980. Thin layer

O’Callaghan, J. R., D. J. Menzies and P. H. Bailey. 1971. Digital

drying and equilibrium moisture content equations for Ashley walnuts.

simulation of agricultural drier performance. J. Agric. Engng. Res.

ASAE Paper No. 80-6507.

16:223–244.

Agrawal, Y. C. and R. D. Singh. 1977. Thin layer drying studies for short

Paulsen, M. R. and T. L. Thompson. 1973. Drying analysis of grain

grain rice. ASAE Paper No. 77-3531.

sorghum. Transactions of the ASAE 16(3):537–540.

Bruce, D. M. 1985. Exposed layer barley drying: three models fitted to

Patil, B. G. and G. T. Ward. 1989. Heated air drying of rapeseed.

new data up to 150 °C. J. Agric. Engng. Res. 32:337–347.

Agricultural Mechanization in Asia, Africa, and Latin America. 20(4):52–

Byler, R. K. and R. C. Brook. 1984. Thin layer model, temperature and 58.

relative humidity variable. ASAE Paper No. 84-2535.

Tang, J., S. Sokhansanj and F. W. Sosulski. 1989. Thin-layer drying of

Hutchinson, D. and L. Otten. 1982. Thin layer drying of soybeans and lentil. ASAE Paper No. 89-6540.

white beans. ASAE/CSAE Paper No. 82-104.

ASAE STANDARDS 1999 583

You might also like

- D1412 PDFDocument5 pagesD1412 PDFDIAZCORDOBANo ratings yet

- (Food Preservation Technology Series) Jorge Welti-Chanes, Jose Miguel Aguilera - Engineering and Food For The 21st century-CRC Press (2002) PDFDocument1,036 pages(Food Preservation Technology Series) Jorge Welti-Chanes, Jose Miguel Aguilera - Engineering and Food For The 21st century-CRC Press (2002) PDFAlexander FierroNo ratings yet

- Sopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilDocument6 pagesSopha-2021-Investigation To The Optimum Amount of CA, MG and S For The Cultivation of Shallot in Alluvial SoilGinaAliyaSophaNo ratings yet

- Kombucha Cascara PDFDocument4 pagesKombucha Cascara PDFSacha INchi CentreNo ratings yet

- Food Chemistry: Andrea Heeger, Agnieszka Kosin Ska-Cagnazzo, Ennio Cantergiani, Wilfried AndlauerDocument7 pagesFood Chemistry: Andrea Heeger, Agnieszka Kosin Ska-Cagnazzo, Ennio Cantergiani, Wilfried Andlauercentro surcolombiano de investigación en café uscoNo ratings yet

- Bab I Pendahuluan 1.1. Latar BelakangDocument9 pagesBab I Pendahuluan 1.1. Latar Belakangetto bnetNo ratings yet

- Uji Organoleptik Pada SorgumDocument10 pagesUji Organoleptik Pada SorgumMayaLestariBanjarnahorNo ratings yet

- Borang Permohonan Skim HACCPDocument3 pagesBorang Permohonan Skim HACCPChan Chee LeongNo ratings yet

- Pengolahan Pascapanen PadiDocument9 pagesPengolahan Pascapanen Padimickey4477No ratings yet

- DAFTAR PUSTAKA PengeringanDocument1 pageDAFTAR PUSTAKA Pengeringannur irfana mardiyahNo ratings yet

- Fahroji, 2016 PDFDocument9 pagesFahroji, 2016 PDFrosyidaNo ratings yet

- ID Biologi Dan Perilaku Kawin Sycanus AnnulDocument6 pagesID Biologi Dan Perilaku Kawin Sycanus AnnulPramedicaPerdanaPutraNo ratings yet

- ANOVA For Quadratic ModelDocument23 pagesANOVA For Quadratic ModelyesiNo ratings yet

- Single-Use Polystyrene Food Containers and Plastic Bag StudyDocument68 pagesSingle-Use Polystyrene Food Containers and Plastic Bag StudyHNNNo ratings yet

- 2 File Struktur OrganisasiPOKPHANDDocument2 pages2 File Struktur OrganisasiPOKPHANDWahyuNurSalimNo ratings yet

- Karakteristik Papan Partikel Dari Bambu Dengan Perekat Getah DamarDocument11 pagesKarakteristik Papan Partikel Dari Bambu Dengan Perekat Getah DamarGhina Fatikah SalimNo ratings yet

- Laporan Praktikum Pertanian Berlanjut (Aspek Budidaya Pertanian) .Document27 pagesLaporan Praktikum Pertanian Berlanjut (Aspek Budidaya Pertanian) .mardianiNo ratings yet

- Pengaruh Lama Perendaman Dalam Larutan Nacl Dan Lama Pengeringan Terhadap Mutu Tepung Talas Belitung (Xanthosoma Sagittifolium)Document12 pagesPengaruh Lama Perendaman Dalam Larutan Nacl Dan Lama Pengeringan Terhadap Mutu Tepung Talas Belitung (Xanthosoma Sagittifolium)Mutia RahmaNo ratings yet

- Pengaruh Variasi Konsentrasi Nacl Pada T 47b3998e PDFDocument8 pagesPengaruh Variasi Konsentrasi Nacl Pada T 47b3998e PDFMayraniNo ratings yet

- Refrigerant R22 - PropertiesDocument6 pagesRefrigerant R22 - PropertiesIndra Pradana0% (1)

- Grain Optical SortingDocument2 pagesGrain Optical SortingSharifah NuruljannahNo ratings yet

- Pengaruh Formula Coating Terhadap Viabilitas Dan Vigor Serta Daya Simpan Benih Padi (Oryza Sativa L.) PDFDocument8 pagesPengaruh Formula Coating Terhadap Viabilitas Dan Vigor Serta Daya Simpan Benih Padi (Oryza Sativa L.) PDFFaza Fauzan SyarifNo ratings yet

- Pematangan Buah PisangDocument25 pagesPematangan Buah PisangAlDO19O166-Ghena Sekar KinantiNo ratings yet

- Bambang Sigit Amanto, Siswanti, Angga AtmajaDocument8 pagesBambang Sigit Amanto, Siswanti, Angga AtmajaIrji Rizqi SabilaNo ratings yet

- Mesin Pengolah Susu Kedelai Kapasitas 30 Kilogram PerjamDocument6 pagesMesin Pengolah Susu Kedelai Kapasitas 30 Kilogram PerjamruslysmgNo ratings yet

- Composition and Antioxidant Activity of Kale (Brassica Oleracea L. Var. Acephala) Raw and CookedDocument10 pagesComposition and Antioxidant Activity of Kale (Brassica Oleracea L. Var. Acephala) Raw and CookedJonathanNo ratings yet

- Annisa Indah Kirana - Tugas Evaporasi PDFDocument5 pagesAnnisa Indah Kirana - Tugas Evaporasi PDFANNISA KIRANANo ratings yet

- Kabupaten BlitarDocument83 pagesKabupaten BlitarSepto AjiNo ratings yet

- Ejercicios TermodinamicaDocument3 pagesEjercicios TermodinamicaJavier Lopez VegaNo ratings yet

- Ratnasari & Cintamulya, 2021Document10 pagesRatnasari & Cintamulya, 2021A R CANDY POTOTNo ratings yet

- F12ikp PDFDocument128 pagesF12ikp PDFAnank SetiyawanNo ratings yet

- TorefaksiDocument4 pagesTorefaksirifkasyaputriNo ratings yet

- Dodol CoklatDocument42 pagesDodol CoklataghniaNo ratings yet

- Fmipa Unimus 2020: ISBN:978-602-5614-35-4Document7 pagesFmipa Unimus 2020: ISBN:978-602-5614-35-4Nella sriNo ratings yet

- International Rules For Seed Testing 2022: Introduction To The ISTA RulesDocument14 pagesInternational Rules For Seed Testing 2022: Introduction To The ISTA RulesLolpo KolpoNo ratings yet

- Jurnal Internasional Tomat PDFDocument8 pagesJurnal Internasional Tomat PDFPrimaldo marmoraNo ratings yet

- DadihDocument12 pagesDadihTaqiyyah RahmawatiNo ratings yet

- Jurnal Uji Kadar AirDocument11 pagesJurnal Uji Kadar AirEndang IstiqomahNo ratings yet

- AOAC. (1995) - Method of Analysis. Association of Official Analytical Chemistry, Washington, DC.Document5 pagesAOAC. (1995) - Method of Analysis. Association of Official Analytical Chemistry, Washington, DC.Leny Widyawati RahayuNo ratings yet

- MSDS For AgricultureDocument2 pagesMSDS For AgricultureWahyu Sylvitria BNo ratings yet

- 164368Document87 pages164368HJ Hwang100% (1)

- Proposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewDocument8 pagesProposed Hazard Analysis and Critical Control Point (HACCP) Plan For Production of Ready-to-Drink Fura-Da-Nono - A ReviewUMYU Journal of Microbiology Research (UJMR)No ratings yet

- Probit Analysis MiniTab - Waktu (LT50)Document3 pagesProbit Analysis MiniTab - Waktu (LT50)Hendra A. Herlambang100% (1)

- Characterization of Edamame Ice Cream Produced Under Different Type and Amount of StabilizerDocument9 pagesCharacterization of Edamame Ice Cream Produced Under Different Type and Amount of StabilizerBimantara PurnamaNo ratings yet

- Principle of BE PDFDocument210 pagesPrinciple of BE PDFRofi AnwarNo ratings yet

- PriDocument8 pagesPritubNo ratings yet

- ViskositasDocument7 pagesViskositasFitrotul KamilaNo ratings yet

- Jurnal KAKAODocument14 pagesJurnal KAKAOstarlessskyNo ratings yet

- GamalDocument11 pagesGamalAnonymous DxKiceCnuw100% (1)

- Laporan Manajemen Perkebunan Kelapa SawitDocument39 pagesLaporan Manajemen Perkebunan Kelapa SawitAdani dholifunNo ratings yet

- Analisis Alasan Penolakan Produk Pangan Ekspor Indonesia Oleh Amerika Serikat Dan Eropa Selama Tahun Skripsi M. Angga Saputra FDocument92 pagesAnalisis Alasan Penolakan Produk Pangan Ekspor Indonesia Oleh Amerika Serikat Dan Eropa Selama Tahun Skripsi M. Angga Saputra FIrfan SolehNo ratings yet

- Astm D 2014 - 97 (2010)Document5 pagesAstm D 2014 - 97 (2010)alexander guerraNo ratings yet

- Sumber (Jurnal)Document931 pagesSumber (Jurnal)Bebek Jantan TangguhNo ratings yet

- Tensiómetros Jet Fill Soilmoisture® 2011Document7 pagesTensiómetros Jet Fill Soilmoisture® 2011linaNo ratings yet

- CV Kerja Praktek NadiraDocument3 pagesCV Kerja Praktek NadiranadiradwpNo ratings yet

- Guide 35: Reference Materials - General and Statistical Principles For CertificationDocument8 pagesGuide 35: Reference Materials - General and Statistical Principles For CertificationfaridsidikNo ratings yet

- 127 329 2 PBDocument14 pages127 329 2 PBSenki Desta G, ST, MT, IPMNo ratings yet

- Skripsi. Kemasan AktifDocument52 pagesSkripsi. Kemasan AktifGalni karangoraNo ratings yet

- Ansi Asabe S436.1 Jun1996 (R2012)Document4 pagesAnsi Asabe S436.1 Jun1996 (R2012)StephanNo ratings yet

- Thin-Layer Drying of Grains and CropsDocument3 pagesThin-Layer Drying of Grains and CropsgarcogiazNo ratings yet

- Ultra-Small Fluorescent Inorganic Nanoparticles For BioimagingDocument24 pagesUltra-Small Fluorescent Inorganic Nanoparticles For BioimagingAD DNo ratings yet

- The Inorganic Dust Pneumoconioses: Richard P. Stankus and John E. SalvaggioDocument13 pagesThe Inorganic Dust Pneumoconioses: Richard P. Stankus and John E. SalvaggioAD DNo ratings yet

- Fluorescent Reconstitution On Deposition of PM2.5 inDocument6 pagesFluorescent Reconstitution On Deposition of PM2.5 inAD DNo ratings yet

- Advanced Materials - 2007 - Kim - Aggregation Enhanced Fluorescence in Organically Modified Silica Nanoparticles ADocument5 pagesAdvanced Materials - 2007 - Kim - Aggregation Enhanced Fluorescence in Organically Modified Silica Nanoparticles AAD DNo ratings yet

- Author Final VersionDocument35 pagesAuthor Final VersionAD DNo ratings yet

- Luminescent Nanomaterials For Biological LabelingDocument14 pagesLuminescent Nanomaterials For Biological LabelingAD DNo ratings yet

- Fabrication of Silica Nanoparticles With Both Efficient Fluorescence and StrongDocument8 pagesFabrication of Silica Nanoparticles With Both Efficient Fluorescence and StrongAD DNo ratings yet

- Direct Fluorescent Labeling For Efficient Biological Assessment of Inhalable ParticlesDocument12 pagesDirect Fluorescent Labeling For Efficient Biological Assessment of Inhalable ParticlesAD DNo ratings yet

- A Poly Vinyl Alcohol Nanoparticle Platform For Kinetic Studies of Inhaled ParticlesDocument11 pagesA Poly Vinyl Alcohol Nanoparticle Platform For Kinetic Studies of Inhaled ParticlesAD DNo ratings yet

- Unit 2-2 - Managing Individuals For Higher PerformanceDocument28 pagesUnit 2-2 - Managing Individuals For Higher PerformanceAD DNo ratings yet

- Particle Size Influences The Immune Response Produced by Hepatitis B Vaccine Formulated in Inhalable ParticlesDocument15 pagesParticle Size Influences The Immune Response Produced by Hepatitis B Vaccine Formulated in Inhalable ParticlesAD DNo ratings yet

- Bunkers and SilosDocument28 pagesBunkers and Siloskalpanaadhi100% (1)

- Unit 2-1 - Organizational BehaviourDocument57 pagesUnit 2-1 - Organizational BehaviourAD DNo ratings yet

- Unit 3 - 1 - Strategic IntentDocument37 pagesUnit 3 - 1 - Strategic IntentAD DNo ratings yet

- Unit 1-2 Development of Mannagement TheoriesDocument43 pagesUnit 1-2 Development of Mannagement TheoriesAD DNo ratings yet

- Unit 1-1 - IntroductionDocument36 pagesUnit 1-1 - IntroductionAD DNo ratings yet

- Grain Dryer DesignDocument41 pagesGrain Dryer DesignAshish Sharma70% (10)

- Question 16 - Carbocations Can Be Stabilized (Lowe... - CheggDocument3 pagesQuestion 16 - Carbocations Can Be Stabilized (Lowe... - CheggAD DNo ratings yet

- Liu 2008Document4 pagesLiu 2008AD DNo ratings yet

- Thin-Layer Drying Model For SoybeansDocument4 pagesThin-Layer Drying Model For SoybeansAD DNo ratings yet

- Investigation of Carbon Monoxide in Heavy Traffic Intersections ofDocument6 pagesInvestigation of Carbon Monoxide in Heavy Traffic Intersections ofAD DNo ratings yet

- 388 OCTIBER 2019 V Sem Agricultural Technology Post Harvest TechnologyDocument13 pages388 OCTIBER 2019 V Sem Agricultural Technology Post Harvest TechnologyAD DNo ratings yet

- QUESTION 1 Which of The Following Are Ways That We...Document4 pagesQUESTION 1 Which of The Following Are Ways That We...AD DNo ratings yet

- Phase Change Substance Property Tables: in SI Units For ME 201 Section 001 Spring 2012Document26 pagesPhase Change Substance Property Tables: in SI Units For ME 201 Section 001 Spring 2012Dugao Aya-osNo ratings yet

- Sustainability 12 07880 v2Document31 pagesSustainability 12 07880 v2AD DNo ratings yet

- University of Moratuwa: Faculty of Engineering Department of Civil EngineeringDocument5 pagesUniversity of Moratuwa: Faculty of Engineering Department of Civil EngineeringAD DNo ratings yet

- Organic Reactions and Organic Reactions and Their Mechanisms Their MechanismsDocument23 pagesOrganic Reactions and Organic Reactions and Their Mechanisms Their MechanismsElena TrofinNo ratings yet

- A Pair of Electron(s) in The O Bond Spreads Ou...Document1 pageA Pair of Electron(s) in The O Bond Spreads Ou...AD DNo ratings yet

- .Dñks ChiqkaorDocument9 pages.Dñks ChiqkaorAD DNo ratings yet

- Er9000en 21204 1.00Document106 pagesEr9000en 21204 1.00Alexandru AnghelNo ratings yet

- Joshi - Quant Job InterviewDocument329 pagesJoshi - Quant Job InterviewPiciBivNo ratings yet

- 5 6316334533637570613Document5 pages5 6316334533637570613Nishant PathakNo ratings yet

- A330 RR Trent 700 Technical Training Manual General Familiarization Course - T4 General Level 1Document68 pagesA330 RR Trent 700 Technical Training Manual General Familiarization Course - T4 General Level 1Owen100% (2)

- 4401 SyllabusDocument1 page4401 SyllabusTony LeungNo ratings yet

- MSA WorksheetDocument33 pagesMSA WorksheetSandrawarman BalasundramNo ratings yet

- Crafting The Service Environment: Text Book Chapter 10Document25 pagesCrafting The Service Environment: Text Book Chapter 10Sneha DussaramNo ratings yet

- BrusselsDocument1 pageBrusselskmiqdNo ratings yet

- GBP Statement: Beatriz Manchado FloresDocument2 pagesGBP Statement: Beatriz Manchado Floresmr.laravelNo ratings yet

- Egcuwa - Butterworth Profile PDFDocument84 pagesEgcuwa - Butterworth Profile PDFsbuja7No ratings yet

- Apex CheatsheetDocument4 pagesApex CheatsheetAmit GangwarNo ratings yet

- Fire Warden Training: Richard Hagger - ConsultantDocument61 pagesFire Warden Training: Richard Hagger - ConsultantRichard Hagger100% (2)

- Qualities of A Good PresenterDocument2 pagesQualities of A Good PresenterMuhammad Umair KhanNo ratings yet

- Reptilian Astral WarsDocument4 pagesReptilian Astral WarsAlienraces1No ratings yet

- Lesson - TrendsDocument26 pagesLesson - TrendsLloydNo ratings yet

- Guide Identifying Handling Low Density Asbestos Fibre BoardDocument6 pagesGuide Identifying Handling Low Density Asbestos Fibre Boardhitman1363No ratings yet

- Quarter 3-LP-Eng10-Lesson3Document4 pagesQuarter 3-LP-Eng10-Lesson3Cynthia LuayNo ratings yet

- Contrastive Morphology The Morpheme Is The Smallest Unit of A Language That Has A Binary Nature (That CanDocument6 pagesContrastive Morphology The Morpheme Is The Smallest Unit of A Language That Has A Binary Nature (That CanIrynaNo ratings yet

- Online Medical Delivery ServiceDocument10 pagesOnline Medical Delivery ServiceYESHUDAS JIVTODENo ratings yet

- GAP Guidelines: Management Programs (Overview)Document27 pagesGAP Guidelines: Management Programs (Overview)LleiLlei100% (1)

- SB-165 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-165 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Micro SplatDocument17 pagesMicro SplatCarlosAndresGarnicaSalazarNo ratings yet

- BLUE COLLAR JOBS Vs WHITE COLLAR JOBS.Document2 pagesBLUE COLLAR JOBS Vs WHITE COLLAR JOBS.Nelson VersozaNo ratings yet

- 04-68350A Manual CCN DM01-DI01 PDFDocument47 pages04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Brand Identity WalmartDocument101 pagesBrand Identity WalmartGuilherme Welter50% (2)

- Chap1 Organizational Behavior 2020Document52 pagesChap1 Organizational Behavior 2020DarshanNo ratings yet

- Sitronix ST7565RDocument72 pagesSitronix ST7565RStuart CouttsNo ratings yet

- Excel Charts and Graph TipsDocument6 pagesExcel Charts and Graph TipsKrystalNo ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- Glenbard East Lesson PlanDocument8 pagesGlenbard East Lesson Planapi-608726850No ratings yet