Professional Documents

Culture Documents

Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressor

Uploaded by

احمد تاشهاويOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressor

Uploaded by

احمد تاشهاويCopyright:

Available Formats

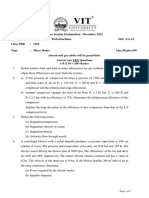

Mechanical Power Department

4th year

Turbo-machinery II

Centrifugal Compressor

1- Determine the adiabatic efficiency, temperature of the air at the exit, and the power input of a

centrifugal compressor from the following given data:

Impeller tip diameter = 1m Speed = 5945 rpm

Mass flow rate of air = 28 kg/s Static pressure ratio P3/P1=2.2

Atmospheric pressure = 1 bar Atmospheric temperature = 25OC

Slip factor = 0.90 Neglect the power input factor

2- A centrifugal compressor has an impeller with 21 vanes, which are radial at exit, a vaneless diffuser

and no inlet guide vanes. The compressor has the following data:

Inlet stagnation temperature = 300 K inlet e stagnation pressure = 100 kPa

Air mass flow rate, = 2.3 kg/s the impeller tip speed = 500 m/s

the mechanical efficiency = 96% diffuser exit velocity = 100 m/s

Total to total efficiency . = 82 % The diffuser efficiency = 84%

Degree of reaction = 50 % The air inlet velocity= = 150 m/s

The blade exit width = 6mm

(i) Determine the driving power on the shaft.

(ii) Determine the total and static pressures at diffuser exit

(iii) Determine the exit total and static pressures, absolute Mach number and radial velocity.

(iv) Determine the total-to-total efficiency for the impeller.

(v) Estimate the inlet/outlet radius ratio for the diffuser (conservation of angular momentum)

(vi) Find a suitable rotational speed for the impeller

3- A centrifugal compressor has inlet guide vanes fitted at the eye such that free vortex flow is archived at

entry to the blades. At the tip radius of the eye the inlet relative Mach number is not to exceed 0.75 and

an impeller total-to-total efficiency of 0.9 is required. The air leaves the tip of the inlet guide vanes

with a velocity of 90 m/s, the impeller tip diameter is 0.45 m and the outlet diameter is 0.76 m. The

radial component of velocity at exit from the impeller is 50m/s and the impeller rotates at 12,000 rpm.

If a slip factor of 0.9 is assumed, find the guide-vane inlet angle at the tip and the static pressure at

impeller outlet. Assume T01 = 288 K and p01 = 101.3 kPa.

1 Mohamed Hassan Gobran

Mechanical Power Department

4th year

Turbo-machinery II

Centrifugal Compressor

4- . A centrifugal compressor has the following design data:

Inlet stagnation temperature = 288 K inlet stagnation pressure = 101 kPa

Air mass flow rate, = 15 kg/s The speed = 16000 rpm

the impeller isentropic efficiency = 90% Width of vaneless space = 42 mm

Axial depth of vaneless space = 37 mm Slip factor = 0.9

Power coefficient = 1.04 Impeller outlet diameter = 0.55 m

a) Assuming no pre-whirl at the inlet, what are the stagnation conditions at the impeller outlet?

b) Show that the radial velocity is approximately 100m/s at the impeller outlet and calculate the Mach

number and air angle at the impeller outlet.

c) Calculate the angle of the diffuser vane leading edges and the Mach number at this radius if the

diffusion in the vaneless space is isentropic.

5- The stagnation pressure and temperature at the inlet of a centrifugal compressor are 101 kPa and 290 K

respectively. The impeller has 19 radial vanes and no inlet guide vanes. The following data apply.

Air mass flow rate, = 2 kg/s the impeller tip speed = 525 m/s

the mechanical efficiency = 96% diffuser exit velocity = 95 m/s

Total to total efficiency . = 81 % The diffuser efficiency = 83%

Power factor = 1.04 The air inlet velocity= = 160 m/s

The blade exit width = 6mm Degree of reaction =50%

(a) Determine the shaft power

(b) Calculate the total and static pressures at diffuser outlet

(c) Find the radial velocity, absolute Mach number and total and static pressures at the impeller exit.

(d) Determine the impeller total-to-total efficiency

(e) If a vaneless diffuser is fitted, what is the ratio of inlet to outlet radius of the diffuser?

(f) Determine the impeller speed. (Diffuser efficiency = (h3s - h2 )/(h3-h2))

6- The following data apply to a double-sided centrifugal compressor

Inlet stagnation temperature =290 K Inlet stagnation pressure =1 bar

Air mass flow rate, = 10 kg/s Rotational speed = 15000 rpm

Eye tip diameter = 0.28m Eye hub diameter = 0.14 m

2 Mohamed Hassan Gobran

Mechanical Power Department

4th year

Turbo-machinery II

Centrifugal Compressor

Impeller outer diameter . = 0.48 m Slip factor =0.89

Power factor = 1.03 The air inlet velocity= = 145 m/s

Calculate:

(1) the impeller vane angles at the eye tip and eye root,

(2) power input, and

(3) the maximum Mach number at the eye.

(4) Recalculate the maximum Mach number at the impeller eye for the same data as in the

previous question, assuming pre-whirl angle of 20O.

7- Consider a centrifugal compressor impeller with the following inlet and design parameters:

Known/design inlet conditions

Inlet absolute stagnation temperature and pressure are 288 K and 1.01 × 105 Pa, respectively, i.e.,

our design point operation is at the standard sea level static condition

C1 = Cz1 = 150 m/s, this gives an axial inlet Mach number of ∼0.5, no preswirl, which is our

design choice

Hub-to-tip radius ratio is rh1∕r1 = 0.5, this too is a design choice

Limit the relative Mach number at the eye radius to 1.0, to avoid shock losses in the inducer

Compressor adiabatic efficiency c = 0.72 estimated based on similar machines

Compressor mass flow rate is = 5 kg/s

Known/design exit conditions

Cr2 = Cz1 = 150 m/s, this could be our design choice,which sizes the impeller exit area

_ Impeller rim speed is U2 = 520 m/s, we chose the maximum rim speed in this example

Impeller exit vane angle ′2 = 20O, i.e., we chose a backsweep design to reduce M2

Allow for a 10O slip angle, which makes the exit relative flow angle 2 = 30O.

Assume equal total pressure loss parameter in the impeller and the radial diffuser

Calculate

(a) the absolute Mach number entering the radial diffuser, M2, and its components, i.e., radial and

tangential Mr2 and M 2

(b) the relative Mach number at the impeller exit, M2r

(c) the compressor pressure ratio c and its polytropic efficiency ec

3 Mohamed Hassan Gobran

Mechanical Power Department

4th year

Turbo-machinery II

Centrifugal Compressor

(d) the inlet flow area and the “eye” radius r1

(e) the shaft angular speed

(f) the impeller exit radius r2

(g) the impeller exit width b

(h) the shaft power

8- A centrifugal compressor rotor is operated at 10,000 rpm on a test stand where the atmospheric

conditions are those of a standard sea level day. The compressor has an axial inlet with a hub diameter

of 13.35 cm and an eye diameter of 25.40 cm. The compressor has a radial exhaust, and the rotor tip

diameter is 50.80 cm. If the average inlet Mach number is 0.7, determine the

(a) mass flow through the compressor,

(b) power required to drive the compressor,

(c) total temperature at the compressor exit,

(d) portion of the required power due to the centrifugal effect, and

(e) overall pressure ratio of the `machine, if the adiabatic efficiency of compression ηc = 85%.

9- A radial bladed centrifugal compressor designed with zero prewhirl (axial entry) for a turbojet engine

is shown in Figure and has the following data:

slip angle = 14O impeller tip radius = 26.3 cm

impeller eye radius =15 cm impeller hub radius = 7 cm

impeller tip width = 4.4 cm number of vanes =29

diffuser inner radius = 30.5 cm diffuser outer radius = 40.6 cm

N = 16,750 rpm

The compressor operates with an axial inlet Mach number of 0.8 at maximum rpm at the impeller inlet as

the aircraft moves through the atmosphere at standard sea level conditions.

a) Determine the linear speed of rotation at the impeller tip, eye, and hub.

(b) Determine the inlet flow area allowing for 5% blockage by vane thickness.

(c) Sketch the inlet blade design showing proper diameters and blade angles at the hub, eye, and at

the station midway between the two.

(d) Calculate the airflow rate.

(e) If σ =0.94, draw the exit velocity diagram to scale and indicate all magnitudes.

4 Mohamed Hassan Gobran

Mechanical Power Department

4th year

Turbo-machinery II

Centrifugal Compressor

(f) If ηc = 80%, determine P3, Pt3, T3, and Tt3.

(g) What is the entrance angle for the fixed diffuser vanes? (Note that angular momentum of the fluid

is conserved in the annulus between the impeller tip and the diffuser entrance.)

(h) What is the diffuser entrance Mach number?

(i) What is the pressure ratio of the compressor Pt3/Pt2?

(j) What is the torque and power required to drive the impeller?

10-A centrifugal compressor which is fitted to an aircraft has the following data:

Air mass flow rate, = 6 kg/s the impeller rotational speed = 15000 rpm

Isentropic efficiency . = 82 % Total pressure ratio = 4

Eye inner radius . = 8 cm Eye outer radius = 16 cm

Ambient pressure = 0.365 bar Ambient temperature = 236 K

A/C forward speed = 240 m/s Inlet Pre-whirl angle =30O

i. Find the maximum Mach number at the impeller inlet

ii. Find the maximum Mach number at the impeller inlet when there is no pre-whirl

iii. Find the impeller diameter

iv. Find the impeller exit blade width (Ca1=Cr2)

v. If the diffuser inlet r3=1.2 r2 and the width of the vaneless space at the diffuser inlet = 2mm in

excess of the impeller exit width, find the diffuser inlet Mach number

5 Mohamed Hassan Gobran

You might also like

- Centrifugal CompressorDocument2 pagesCentrifugal CompressorAyman EsaNo ratings yet

- PSet03 TurboB2020Document2 pagesPSet03 TurboB2020Kyillos SaaidNo ratings yet

- 7ADC8292A41A4EB196A3FFDEE99589FDDocument4 pages7ADC8292A41A4EB196A3FFDEE99589FDyashvantNo ratings yet

- Centrifugal CompresserDocument13 pagesCentrifugal CompresserSaurabhMehraNo ratings yet

- Page 1 of 3Document3 pagesPage 1 of 3yashvantNo ratings yet

- Centrifugal CompressorDocument2 pagesCentrifugal CompressorHassan KamilNo ratings yet

- AE321-Tutorial 7Document3 pagesAE321-Tutorial 7Hritik singh parmarNo ratings yet

- Assignment I 3rd RegularDocument2 pagesAssignment I 3rd RegularRoha EngineeringNo ratings yet

- Propulsion 1 Unit-V Question Bank (Compressors)Document4 pagesPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- Assignment FD Compressors and BlowersDocument2 pagesAssignment FD Compressors and BlowersXheikhKaleemNo ratings yet

- Class: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2Document2 pagesClass: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2santhosh bandariNo ratings yet

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33No ratings yet

- ME401 - Assignment 4: October 21, 2014Document3 pagesME401 - Assignment 4: October 21, 2014Prakhar GuptaNo ratings yet

- TurbomachinesDocument2 pagesTurbomachinesThesinghNo ratings yet

- Assignment 6Document3 pagesAssignment 6Muhammad Jawad IsmaeelNo ratings yet

- Turbo MachinesDocument2 pagesTurbo MachinesDarani PriyaNo ratings yet

- 210479820563440B840B297C6C79B23CDocument3 pages210479820563440B840B297C6C79B23CyashvantNo ratings yet

- Sheet 2Document2 pagesSheet 2Medo NassarNo ratings yet

- TM 7me4a Question Bank Mid Term IDocument1 pageTM 7me4a Question Bank Mid Term IVijay SharmaNo ratings yet

- AE-422 Flight Propulsion I Dr. Abdullah M. Al-GarniDocument0 pagesAE-422 Flight Propulsion I Dr. Abdullah M. Al-GarniNiraj BhaktwartiNo ratings yet

- 4Document6 pages4robinston jeyasinghNo ratings yet

- Assignment Centrifugal ComprsssorDocument2 pagesAssignment Centrifugal ComprsssorSubrat Kumarr Panda100% (1)

- Model Question Paper 13.406 TURBO MACHINERY (S) : Part A Answer All QuestionsDocument3 pagesModel Question Paper 13.406 TURBO MACHINERY (S) : Part A Answer All Questionssk sanketNo ratings yet

- Design and Analysis of Impeller For Centrifugal Blower Using Solid WorksDocument5 pagesDesign and Analysis of Impeller For Centrifugal Blower Using Solid WorksMuhammadTayyabNo ratings yet

- Assignment and WorksheetDocument2 pagesAssignment and WorksheetAbebe AyingdaNo ratings yet

- GDJP QBDocument40 pagesGDJP QBguna sekaranNo ratings yet

- Me0302 Assn Tutorial QDocument4 pagesMe0302 Assn Tutorial QVijay Pal Singh0% (1)

- 3-QUESTION PAPER TEE 2020 Model PaperDocument2 pages3-QUESTION PAPER TEE 2020 Model PapermvzhvschdbsKNo ratings yet

- 14 - Final Exam (Only Questions)Document3 pages14 - Final Exam (Only Questions)حسن محمود حسن محمد 3760No ratings yet

- Question Bank: AE1254 - PROPULSION IDocument8 pagesQuestion Bank: AE1254 - PROPULSION ISêlvâkûmâr JayabalaNo ratings yet

- AOT303 - Ktu Qbank PDFDocument8 pagesAOT303 - Ktu Qbank PDFUmarul MushtaqNo ratings yet

- r05312105 Aerospace Propulsion IDocument8 pagesr05312105 Aerospace Propulsion ISrinivasa Rao GNo ratings yet

- Assignment 04Document16 pagesAssignment 04Pritam SahNo ratings yet

- 08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Document3 pages08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Senthil AnnaunivNo ratings yet

- GDJP Model 14Document2 pagesGDJP Model 14Sundar MahalingamNo ratings yet

- Paper 4A3 2015Document5 pagesPaper 4A3 2015feutseuNo ratings yet

- Me 2351 Gas Dynamics and Jet PropulsionDocument2 pagesMe 2351 Gas Dynamics and Jet PropulsionMohanraj SubramaniNo ratings yet

- Me 2351 Gas Dynamics and Jet PropulsionDocument2 pagesMe 2351 Gas Dynamics and Jet PropulsionMohanraj SubramaniNo ratings yet

- Numericals On Centrifugal and Axial CompressorsDocument2 pagesNumericals On Centrifugal and Axial CompressorsMoiz Tinwala33% (3)

- Axial Flow Compressors and Fans - DixDocument4 pagesAxial Flow Compressors and Fans - DixYanganani SindeloNo ratings yet

- 4.internal Exam - II (Unit III & IV) P-2Document1 page4.internal Exam - II (Unit III & IV) P-2gowrisankar32No ratings yet

- Me-402 Fluid Machinery Experiment-1: 1. Objective and Test StandardDocument8 pagesMe-402 Fluid Machinery Experiment-1: 1. Objective and Test StandardSurjit DuttaNo ratings yet

- Applied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetDocument4 pagesApplied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetShashi Kant KhalkhoNo ratings yet

- BE 2019 TurbomachinaryDocument5 pagesBE 2019 TurbomachinarySuyash Shinde.No ratings yet

- Turbomachines Jan 2014Document2 pagesTurbomachines Jan 2014Prasad C M100% (1)

- Air Comperssor Test Rig ReciprocatingDocument4 pagesAir Comperssor Test Rig ReciprocatingShashank pNo ratings yet

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDocument6 pagesγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzNo ratings yet

- Ae2255 QB 2014Document8 pagesAe2255 QB 2014vicky CJNo ratings yet

- Turbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineDocument4 pagesTurbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineEchebiri Collins100% (1)

- COMPSDocument2 pagesCOMPSHarsh NklkNo ratings yet

- Pressure Ake Int Absolute Stage Last of Pressure e Arg Disch AbsoluteDocument8 pagesPressure Ake Int Absolute Stage Last of Pressure e Arg Disch Absolutemasih tadayonNo ratings yet

- Propulsion Homework Exercises A 12-08Document11 pagesPropulsion Homework Exercises A 12-08jgolloberNo ratings yet

- Propulsion Ii Question BankDocument13 pagesPropulsion Ii Question BankSathya NarayananNo ratings yet

- 6 Centrifugal BlowerDocument7 pages6 Centrifugal BlowerdhundterahoNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationFrom EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNo ratings yet

- 4 رضاDocument9 pages4 رضااحمد تاشهاويNo ratings yet

- Assignment # 2: Course NameDocument2 pagesAssignment # 2: Course Nameاحمد تاشهاويNo ratings yet

- Air Plane Types and It's Generation: DR / Mefreh MeladDocument6 pagesAir Plane Types and It's Generation: DR / Mefreh Meladاحمد تاشهاويNo ratings yet

- Hvac ModelDocument1 pageHvac Modelاحمد تاشهاويNo ratings yet

- Titanium Alloys and Its PropertiesDocument26 pagesTitanium Alloys and Its PropertiesAnand Prabhu100% (1)

- Section5 1Document22 pagesSection5 1sonti11No ratings yet

- Dissertation Topics Airline IndustryDocument6 pagesDissertation Topics Airline IndustryWhoCanWriteMyPaperSingapore100% (1)

- Evaluation of Fuel Consumption of B747-400 in Short-Range Flight With Catapult AssistDocument7 pagesEvaluation of Fuel Consumption of B747-400 in Short-Range Flight With Catapult AssistEzra GeteNo ratings yet

- Easa TCDS A.026 - L 410 14 01032011Document49 pagesEasa TCDS A.026 - L 410 14 01032011Jozef CernanNo ratings yet

- Alitalia 404Document154 pagesAlitalia 404Adrian OcampoNo ratings yet

- PPTDocument14 pagesPPTSanthosh Kumar VempatiNo ratings yet

- Air France A319 CRMDocument7 pagesAir France A319 CRMChazCounterNo ratings yet

- Aic-A 05 20170330 PDFDocument2 pagesAic-A 05 20170330 PDFmarceloptpNo ratings yet

- Seagull CatalogueDocument39 pagesSeagull CatalogueandresNo ratings yet

- The Helicopter Museum: Newsletter Vol. 8Document8 pagesThe Helicopter Museum: Newsletter Vol. 8John ClewsNo ratings yet

- 3M - Industrial Abrasives CatalogueDocument76 pages3M - Industrial Abrasives CataloguevishwanathanskNo ratings yet

- CombatFlight Simulator 3 ReviewDocument14 pagesCombatFlight Simulator 3 ReviewtumbNo ratings yet

- Asme B1.21M-1997 (2018)Document68 pagesAsme B1.21M-1997 (2018)Md. Firozur RahmanNo ratings yet

- Beechcraft King Air C90, C90a, C90GT & E90Document226 pagesBeechcraft King Air C90, C90a, C90GT & E90aero estoqueNo ratings yet

- Evaluation of Store Separation Characteristics From Aircraft Using Aerodynamic TechnologyDocument6 pagesEvaluation of Store Separation Characteristics From Aircraft Using Aerodynamic Technologyflateric74@yandex.ruNo ratings yet

- Do228 Systems Reference GuideDocument7 pagesDo228 Systems Reference GuideJose Otero De SantiagoNo ratings yet

- HovedkatalogccDocument352 pagesHovedkatalogccibraheemNo ratings yet

- A320 - Instructor Training (Sim - Line) FormsDocument6 pagesA320 - Instructor Training (Sim - Line) FormsDevdatt SondeNo ratings yet

- 090 Communications (ATPL Ground Training Series) - 2014Document178 pages090 Communications (ATPL Ground Training Series) - 2014BoukhariNo ratings yet

- Plano Del Aeromodelo KK ComancheDocument13 pagesPlano Del Aeromodelo KK ComancheWalter GutierrezNo ratings yet

- Coca ColaPaperF 15Document32 pagesCoca ColaPaperF 15tononoink86% (7)

- Heathrow Airline Stand Allocation Guide 1 1Document2 pagesHeathrow Airline Stand Allocation Guide 1 1Jeremy PetersonNo ratings yet

- QB A320 FA NEO DifferencesDocument10 pagesQB A320 FA NEO DifferencesPhạm Hà Tiến0% (2)

- CH20Document14 pagesCH20Juan pablo Valencia jaramilloNo ratings yet

- Aircraft Ground Handling ChecklistDocument2 pagesAircraft Ground Handling ChecklistFarell Ardyan100% (1)

- Utilization Category 1Document2 pagesUtilization Category 1alageshvijayNo ratings yet

- DBMS Lab ManualDocument16 pagesDBMS Lab ManualVibhu DadhichiNo ratings yet

- Books For CPLDocument3 pagesBooks For CPLSabari Sasichandran71% (7)

- EGSSLKMT PDF 13mar22Document59 pagesEGSSLKMT PDF 13mar22Matthew StratfordNo ratings yet