Professional Documents

Culture Documents

Non-shrinking eco-friendly grout

Uploaded by

penghzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Non-shrinking eco-friendly grout

Uploaded by

penghzCopyright:

Available Formats

GROUT 280 ECO

NON SHRINKING REPAIR MORTAR

- GENERAL PATCHING GROUT

TECHNICAL DATA

Appearance : Grey powder

Setting Time : Initial Set ≥ 1 hr

BS EN 196 - 3:2005 + A1:2008 Final Set ≤ 10 hrs

ECO FRIENDLY HIGH STRENGTH NON SHRINK

Volume Change - : 0 to 3%

ASTM C827:2001 a (2005)

Compressive Strength : ≥ 40 N/mm2

DESCRIPTION ASTM C109 / 109M:2008

Lanko Grout 280 ECO is a cementitious non-shrink

grout with low embodied carbon footprint and is Bond Strength @ 28 days : ≥1.5 N/mm2

approved by the Eco-labelling authority in Singapore BS EN 12615:1999

as a sustainable building material. It requires only on Flow Consistency : 30 - 45% Flow

site addition of water to produce a high strength, ASTM C1437:2007

non-shrink grout that is non-corrosive, non-oxidising

and free of chlorides and nitrates. Yield per bag : Around 0.014m3

Wet Density : Approx. 2100 kg/m3

USES

Lanko Grout 280 ECO is primarily used for: Filler : Graded Sand

• Floor patching.

Specifications are subject to change without notification. Results shown are

• Bonding new concrete to old. typical but reflect test procedures used. Actual field performance will depend

• Vertical repair. on installation methods and site conditions.

ADVANTAGES

• Environmentally friendly.

• Non-shrinking, free of bleeding and settlement.

• High early compressive and flexural strength.

• Achieve strong non-corrosive bonding to steel and

concrete.

• Chlorides and iron free.

• Pre-mixed to eliminate site variations and errors.

SGBP 2016 - 549

GROUT 280 ECO

SURFACE PREPARATION APPLICATION (CON’T)

Substrate should be cleaned and roughened. All

loose materials and free water must be Bedding Mortars:

removed. Damp the substrate with water before For floor topping / levelling mixes, Lanko Grout 280

application. ECO could be used with Lanko 751 to improve

adhesion:

MIXING

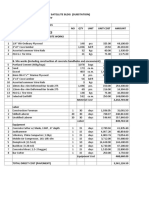

For optimum result, mechanical mixer should Lanko Grout 280 ECO 25 kg

be used. The recommended amount of water Sand (2.4 - 5mm) 5 - 10 kg

(3.6 litres to 4.5 litres) should be measured and Lanko 751 3 litres

poured into the mixer. Slowly add Lanko Grout Water 3 - 4 litres

280 ECO and mix continuously for 4 to 5 minutes. *Amount of sand added depend on site application

APPLICATION Curing:

Lanko Grout 280 ECO is ready to use with the Immediately after finishing, exposed area should be

addition of water. thoroughly cured with wet hessian or curing

compound.

Floor And Vertical Patching / Repairs:

Compact Lanko Grout 280 ECO into the repair PACKAGING

area and finish with a steel trowel. Addition of Lanko Grout 280 ECO is available in 25 kg bag.

bonding agent improves abrasion resistance:

SHELF LIFE

Lanko Grout 280 ECO 25 kg Shelf life of up to 12 months from the date of

Lanko 751 2 litres manufacture when stored in a dry place free from

Water 1 - 2 litres moisture contact.

Maximum 25 kg of 3mm gravel / granite chips HEALTH & SAFETY

can be added to this mix without reducing Lanko Grout 280 ECO is non-hazardous. In case of

mechanical properties. eye contact, wash with plenty of water. If irritation

persists, seek immediate medical attention. Refer

to safety data sheet.

Disclaimer

The use of this product is beyond the manufacturer's control and

liability is restricted to the replacement of material proven faulty.

The manufacturer is not responsible for any loss or damage arising

from incorrect usage. Specifications are subjected to changes

without prior notice. Before application, customers and users are

requested to check that they have the latest version of this

document from our website www.parexgroup.com.sg

PAREXGROUP PTE LTD

28 TUAS SOUTH AVENUE 8, SINGAPORE 637648

TEL: (65) 6861 0632 FAX: (65) 6862 3915

EMAIL: SALES@ PAREXGROUP.COM.SG

WEBSITE: WWW.PAREXGROUP.COM.SG

ParexGroup, a French multi-national company with

headquarters in Paris, is a leading manufacturer of

speciality products for the construction industry with

operations in more than 20 countries, and our 2700 people

around the world are the cornerstone of our growing

Updated TM39 Aug 2017

organization.

You might also like

- Davco Grout 280 ECO - BROCHURE - 2 PDFDocument2 pagesDavco Grout 280 ECO - BROCHURE - 2 PDFbenjaminNo ratings yet

- 2918 Mapeproof 1k Turbo UkDocument4 pages2918 Mapeproof 1k Turbo UkFloorkitNo ratings yet

- Setseal B - TDSDocument4 pagesSetseal B - TDShussam jumah100% (1)

- Fosroc Auramix 300 AdmixtureDocument2 pagesFosroc Auramix 300 Admixture892513822950% (2)

- Concure WBDocument2 pagesConcure WBR.ThangarajNo ratings yet

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadNo ratings yet

- TDS - Bronco Cemgrout SP75Document4 pagesTDS - Bronco Cemgrout SP75Jignessh JoshiNo ratings yet

- Flexible cement waterproof coatingDocument2 pagesFlexible cement waterproof coatingGobinda Nayek100% (1)

- 187 NanoGrout EGDocument2 pages187 NanoGrout EGTristan Irvin Asi100% (3)

- Softscaping Methodology - PHILAM PolygonDocument7 pagesSoftscaping Methodology - PHILAM PolygonLiselle CustodioNo ratings yet

- Nitomortar GP, BC & UADocument3 pagesNitomortar GP, BC & UAsiranepNo ratings yet

- Cempol SBR: Bonding AdmixtureDocument2 pagesCempol SBR: Bonding AdmixtureJagdishNo ratings yet

- Construction Chemical Floor HardenerDocument2 pagesConstruction Chemical Floor HardenerAndy100% (1)

- GeoGreen Blanket Provides Environmentally-Friendly Slope StabilizationDocument13 pagesGeoGreen Blanket Provides Environmentally-Friendly Slope Stabilizationshravan38100% (2)

- Sun PU GardDocument2 pagesSun PU GardUmeshchandra PatilNo ratings yet

- Solcourse - Polythene DPM DatasheetDocument2 pagesSolcourse - Polythene DPM DatasheetkibzeamNo ratings yet

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocument4 pagesNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorNo ratings yet

- Nitoflor BrochureDocument13 pagesNitoflor BrochureMaha MuflehNo ratings yet

- Masterkure 181 - KsaDocument2 pagesMasterkure 181 - KsaSHAIK ASIMUDDINNo ratings yet

- Pumpable cementitious grout for filling voidsDocument4 pagesPumpable cementitious grout for filling voidsIqbal Muhammad100% (1)

- Masterkure 343 - 270810Document2 pagesMasterkure 343 - 270810Muhammad Nurfadhli100% (1)

- Prodorlac SPLDocument2 pagesProdorlac SPLkhrisna.dipa.utama50% (2)

- CICO Thermoseal XLDocument2 pagesCICO Thermoseal XLsanjayNo ratings yet

- Waterproofing Membranes Under 40 CharactersDocument4 pagesWaterproofing Membranes Under 40 CharactersshashiNo ratings yet

- Hycrete Data Sheet - Hycrete W1000Document2 pagesHycrete Data Sheet - Hycrete W1000Anthony AjuloNo ratings yet

- Fosroc Nitoflor TF120 UB: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF120 UB: Constructive SolutionstalatzahoorNo ratings yet

- Construction Waterstop Splicing and Field Fabrication ToolsDocument34 pagesConstruction Waterstop Splicing and Field Fabrication ToolshahaerNo ratings yet

- High Performance Microsilica Concrete AdmixtureDocument2 pagesHigh Performance Microsilica Concrete AdmixtureTori Small100% (1)

- Multifix All Mechanical Anchor - Design GuideDocument28 pagesMultifix All Mechanical Anchor - Design GuideConstantino Ramirez (Cons)No ratings yet

- MasterSeal 380 TDSDocument2 pagesMasterSeal 380 TDSEngTamerNo ratings yet

- Road ConstructionDocument5 pagesRoad ConstructionmetincetinNo ratings yet

- MasterPel 707 v1Document3 pagesMasterPel 707 v1Jaga NathNo ratings yet

- Nitoproof 600PFDocument3 pagesNitoproof 600PFshyamsundar_ceNo ratings yet

- BITUMEN SEAL DESIGN CALCULATIONDocument5 pagesBITUMEN SEAL DESIGN CALCULATIONSekson Lapcharoensin100% (1)

- Sikadur 732Document2 pagesSikadur 732Hafidh Roiy100% (1)

- Cyclone-Brochure PubDocument2 pagesCyclone-Brochure Pubsk lukoNo ratings yet

- Solvent Primer Data SheetDocument2 pagesSolvent Primer Data SheetDipin Nediya Parambath100% (1)

- Master Emaco S5400Document2 pagesMaster Emaco S5400WahyudiBlueghostNo ratings yet

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kNo ratings yet

- Adobe Vermeer Block Press Bp714 ShettDocument5 pagesAdobe Vermeer Block Press Bp714 ShettambrosiofdmNo ratings yet

- PWD Pithoragarh Item Rate BoQ for Protection/Treatment work of Chronic land slide ZoneDocument6 pagesPWD Pithoragarh Item Rate BoQ for Protection/Treatment work of Chronic land slide ZoneSOMNATH JANANo ratings yet

- Al Jazeera Rawa15Document1 pageAl Jazeera Rawa15hemajsuryaNo ratings yet

- Conplast WP 421 PDFDocument2 pagesConplast WP 421 PDFharsoNo ratings yet

- Msds Chryso Plast SL 210 - 7327 - 4196Document5 pagesMsds Chryso Plast SL 210 - 7327 - 4196Thilan SenarathneNo ratings yet

- Cementitious tile adhesive for wet areasDocument3 pagesCementitious tile adhesive for wet areasAnamika KadamNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- Sikament 163 PDFDocument3 pagesSikament 163 PDFMetaniaSuwarning100% (1)

- Fosroc Chemical Breaker PDFDocument2 pagesFosroc Chemical Breaker PDFtalatzahoorNo ratings yet

- Tudalen 65 - Expires 01-06-2025Document13 pagesTudalen 65 - Expires 01-06-2025Muhammad YusufNo ratings yet

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- ESTOP TDS - Estogard CS Lining R002.i.21Document2 pagesESTOP TDS - Estogard CS Lining R002.i.21Dewi OktoraNo ratings yet

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 pagesSikatherm® Foam 45 IN: Product Data SheetTarun KumarNo ratings yet

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocument4 pagesStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127No ratings yet

- Nitoflor SL2050: Constructive SolutionsDocument4 pagesNitoflor SL2050: Constructive SolutionsNishant VasuNo ratings yet

- Lanko Grout 280 Eco BrochureDocument2 pagesLanko Grout 280 Eco BrochureMrgsrzNo ratings yet

- TM Grout 180Document2 pagesTM Grout 180williamNo ratings yet

- Tec 305 HF: Highly Fluid Non-Shrink Cementitious GroutDocument2 pagesTec 305 HF: Highly Fluid Non-Shrink Cementitious Groutmanikandan4strlNo ratings yet

- Sikagrout®-214 Ae: Product Data SheetDocument3 pagesSikagrout®-214 Ae: Product Data Sheetmohammed rinshinNo ratings yet

- Weberep 331 TXDocument2 pagesWeberep 331 TXmoizm53No ratings yet

- 3 SlimDek Structural 48240Document26 pages3 SlimDek Structural 48240Konstantinos KalemisNo ratings yet

- DIN EN 1504-BasfDocument48 pagesDIN EN 1504-Basfcostinl100% (4)

- Streamlined Processing by Public Agencies For New Erection of Warehouses Not Exceeding 2 StoreysDocument6 pagesStreamlined Processing by Public Agencies For New Erection of Warehouses Not Exceeding 2 StoreyspenghzNo ratings yet

- Everything you need to know about railway protection plansDocument4 pagesEverything you need to know about railway protection plansShumei ZhouNo ratings yet

- Aluminium Alloy en Aw 6060 Material Data Sheet AlumincoDocument1 pageAluminium Alloy en Aw 6060 Material Data Sheet AlumincoGilbertoNo ratings yet

- Efficient ALC Panel Construction MaterialDocument10 pagesEfficient ALC Panel Construction MaterialpenghzNo ratings yet

- AWA AS1288 Glass GuideDocument96 pagesAWA AS1288 Glass GuideChristian Bar100% (2)

- Aluminium Alloy SGDocument54 pagesAluminium Alloy SGpenghzNo ratings yet

- LCP Purlins GirtsDocument16 pagesLCP Purlins GirtsGarfieldNo ratings yet

- Aluminium Louvre Window SystemsDocument18 pagesAluminium Louvre Window SystemspenghzNo ratings yet

- Floor Vibrations - SteelConstruction - InfoDocument24 pagesFloor Vibrations - SteelConstruction - InfopenghzNo ratings yet

- 6060-T6 Aluminum: Mechanical PropertiesDocument9 pages6060-T6 Aluminum: Mechanical PropertiespenghzNo ratings yet

- ECO Panel, ALC, AAC Panel Archi RFA 045r - CompiledDocument22 pagesECO Panel, ALC, AAC Panel Archi RFA 045r - CompiledpenghzNo ratings yet

- Gypsum Board Self WeightDocument4 pagesGypsum Board Self WeightpenghzNo ratings yet

- ECO Panel, ALC, AAC Panel Archi RFA 045r - CompiledDocument22 pagesECO Panel, ALC, AAC Panel Archi RFA 045r - CompiledpenghzNo ratings yet

- Plastic Neutral Axis Calculation ExampleDocument2 pagesPlastic Neutral Axis Calculation Examplepenghz100% (1)

- Masonry Brick Normalised Strength PDFDocument2 pagesMasonry Brick Normalised Strength PDFpenghzNo ratings yet

- Effect of Chloride Attack On Durability of Concrete - Concrete TechnologyDocument1 pageEffect of Chloride Attack On Durability of Concrete - Concrete TechnologypenghzNo ratings yet

- Imperfections PDFDocument57 pagesImperfections PDFcipribratuNo ratings yet

- Roof Tile Catalog - Cobert - Sellection of Good Material For Roofing SystemDocument6 pagesRoof Tile Catalog - Cobert - Sellection of Good Material For Roofing SystempenghzNo ratings yet

- Welded ConnectionsDocument9 pagesWelded ConnectionsAnonymous 1sJXK1DKZNo ratings yet

- Chapter 3 - Review On Properties of Natural Singapore Marine ClayDocument6 pagesChapter 3 - Review On Properties of Natural Singapore Marine ClaypenghzNo ratings yet

- Aluminium Louvre Window Systems PDFDocument18 pagesAluminium Louvre Window Systems PDFpenghzNo ratings yet

- Design Methods of Pile PDFDocument30 pagesDesign Methods of Pile PDFfazle rabbiNo ratings yet

- Lecturer Notes of Design of Drainage Notes PDFDocument340 pagesLecturer Notes of Design of Drainage Notes PDFpenghzNo ratings yet

- Chapter 4 Foundation in Singapore PDFDocument85 pagesChapter 4 Foundation in Singapore PDFpenghzNo ratings yet

- Modulus ElasticityDocument8 pagesModulus ElasticityLhizaNo ratings yet

- Marine Clay DataDocument30 pagesMarine Clay DataYam BalaoingNo ratings yet

- Woodhandbook Extracts PDFDocument30 pagesWoodhandbook Extracts PDFhuamin2008No ratings yet

- Synopsis On Training & DevelopmentDocument6 pagesSynopsis On Training & DevelopmentArchi gupta86% (14)

- Lesson Plan Nº1Document7 pagesLesson Plan Nº1Veronica OrpiNo ratings yet

- Social Studies Bece Mock 2024Document6 pagesSocial Studies Bece Mock 2024awurikisimonNo ratings yet

- Sample Interview Questions – Promoting Diversity and InclusionDocument3 pagesSample Interview Questions – Promoting Diversity and InclusionLiah Piano-Beast UchihaNo ratings yet

- Math Lesson on Completing PatternsDocument7 pagesMath Lesson on Completing PatternsJazmyne Obra100% (1)

- Work Systems The Methods Measurement and Management of Work 1St Edition Groover Solutions Manual Full Chapter PDFDocument51 pagesWork Systems The Methods Measurement and Management of Work 1St Edition Groover Solutions Manual Full Chapter PDFdieulienheipgo100% (8)

- Nature and Scope of History as a Social ScienceDocument14 pagesNature and Scope of History as a Social SciencejustadorkyyyNo ratings yet

- Pump Card Analysis Simplified and ImprovedDocument14 pagesPump Card Analysis Simplified and ImprovedOsmund MwangupiliNo ratings yet

- KireraDocument3 pagesKireramurithiian6588No ratings yet

- PROPOSED ARFF BUILDINGDocument27 pagesPROPOSED ARFF BUILDINGDale Bryan S DalmacioNo ratings yet

- Limit of Outside Usage Outside Egypt ENDocument1 pageLimit of Outside Usage Outside Egypt ENIbrahem EmamNo ratings yet

- Activity No.1 in GED 103Document2 pagesActivity No.1 in GED 103Kenneth HerreraNo ratings yet

- Ch15 Differential Momentum BalanceDocument20 pagesCh15 Differential Momentum Balance89kkNo ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Our Products: Powercore Grain Oriented Electrical SteelDocument20 pagesOur Products: Powercore Grain Oriented Electrical SteelkoalaboiNo ratings yet

- Galvanic CorrosionDocument5 pagesGalvanic Corrosionsatheez3251No ratings yet

- The Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsDocument16 pagesThe Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsAndres ZuñigaNo ratings yet

- Mil PRF 23699FDocument20 pagesMil PRF 23699FalejandroNo ratings yet

- Cegep Linear Algebra ProblemsDocument92 pagesCegep Linear Algebra Problemsham.karimNo ratings yet

- Trends and Fads in Business SVDocument2 pagesTrends and Fads in Business SVMarie-Anne DentzerNo ratings yet

- Nasya - Paralellism - New Dengan Tambahan Dari LongmanDocument28 pagesNasya - Paralellism - New Dengan Tambahan Dari LongmannasyaayuNo ratings yet

- Benevolent Assimilation Proclamation AnalysisDocument4 pagesBenevolent Assimilation Proclamation AnalysishgjfjeuyhdhNo ratings yet

- Radproduction Chapter 2-9Document276 pagesRadproduction Chapter 2-9Christian DioNo ratings yet

- Costallocationvideolectureslides 000XADocument12 pagesCostallocationvideolectureslides 000XAWOw Wong100% (1)

- Socrates 8dDocument8 pagesSocrates 8dcarolinaNo ratings yet

- .Design and Development of Motorized Multipurpose MachineDocument3 pages.Design and Development of Motorized Multipurpose MachineANKITA MORENo ratings yet

- Eugene A. Nida - Theories of TranslationDocument15 pagesEugene A. Nida - Theories of TranslationYohanes Eko Portable100% (2)

- Fif-12 Om Eng Eaj23x102Document13 pagesFif-12 Om Eng Eaj23x102Schefer FabianNo ratings yet

- ZFDC 20 1HDocument1 pageZFDC 20 1Hkentier21No ratings yet

- Sistem Informasi Geografis Pemetaan Lahan PertaniaDocument12 pagesSistem Informasi Geografis Pemetaan Lahan PertaniaRizal Nurrahman HabibNo ratings yet