Professional Documents

Culture Documents

Sox Compliance: Fabian Kock

Uploaded by

Shamit BugaliaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sox Compliance: Fabian Kock

Uploaded by

Shamit BugaliaCopyright:

Available Formats

MARITIME

SOx Compliance

Operational Experience 2020

Fabian Kock

1 DNV GL © 21 August 2020 SAFER, SMARTER, GREENER

Agenda

Bunker price development

Scrubber retrofits: Current situation

Remote survey options for Scrubbers

Challenges with HSFO stored on board

Challenges with Scrubbers in operation

Options in case of sensor failures

Fuels update

DNV GL © 21 August 2020

Bunker price development

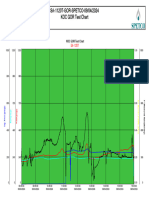

Bunker prices VLSFO vs. HSFO

800.00 400.00

700.00 350.00

VLSFO Bunker Prices (0.5% Sulphur), Singapore

HSFO 380cst Bunker Prices (3.5% Sulphur), Singapore

600.00 300.00

Price Difference

Price difference USD/tonne

350 USD/t

Bunker price USD/tonne

500.00 250.00

200 USD/t difference -> reasonable payback

400.00 200

200.00

The future?

300.00

60 USD/t 150.00

200.00 100.00

100.00 50.00

0.00 0.00

03-Jan-2020 02-Feb-2020 03-Mar-2020 02-Apr-2020 02-May-2020 01-Jun-2020 01-Jul-2020 31-Jul-2020

3 DNV GL © 21 August 2020

Scrubber retrofits: Current situation

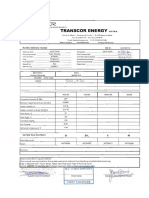

World Fleet Under SOx Scrubber Retrofit

World Fleet, Total SOx Scrubber Fitted

3500 World Fleet Under SOx Scrubber Retrofit 350

3000 300

2500 250

2459

Total number installed

Registered in GISIS (2020-08-12)

in repair yard

2000 200

1500 150

1000 100

69

500 50

0 0

Source: Clarksons

4 DNV GL © 21 August 2020

Remote survey options for Scrubbers

Commissioning at quay side and/ or sea trial

Is remote verification/ Survey of commissioning scope

possible?

Some default pre-conditions:

Only applicable for “Scheme B” certification according to

MEPC.259(68) (continuous emission monitoring with

parameter checks)

Only for sister vessel with same scrubber maker

Sea trial attendance by class for the commissioning test on the first vessel of a series of an alteration project with satisfactory

result. Sea trial attendance for same serial in different yards will be evaluated on case by case base.

The commission test items at quay side is preferably carried out in the same retrofit yard and by the same surveyor in charge of

retrofit

Due to validity of calibration of essential sensors (PAH, turbidity or SO2/CO2) the commissioning at sea should be performed

shortly after the successfully completed quay test (validity of calibration is normally 90 days)

Quay test completion in yard may be a trigger for a remote survey.

Kick off meeting will be arranged before quay test start or even earlier for each serial in different yards.

5 DNV GL © 21 August 2020

Remote survey options for Scrubbers

MARPOL related: Which items have to be finalised in the yard?

Following items have to be witnessed by surveyor:

Verification of EGC Installation:

– The physical installation of the EGCS to be inspected

Continuous exhaust gas monitoring system (CEMS) – Emissions to Air:

– Verifications of system layout

Analyser Verification Test (SO2 and CO2):

– Verification of gas analyser calibration (calibration gases to be provided by

the applicant!)

Continuous washwater monitoring system:

– calibration (calibration kids to be provided by applicant!)

Data recording and compliance report:

– Verification of recorded Emission Data and Compliance Report

6 DNV GL © 21 August 2020

Challenges with HSFO stored on board

HSFO on board after March 1st 2020?

Did you get stuck in yard with HSFO in your fuel tanks before March 1st

2020?

IMO does not consider COVID-19 to fall under force majeure (the fact that DNV GL might

consider Covid-19 as force majeure is irrelevant in this context).

In Circular letter No.4204/Add.1 IMO is asking “close cooperation among all Member States to overcome

challenges related to the implementation and enforcement of the relevant IMO instruments.”

There is no general procedure in place how to deal with ships, which are currently ion dry dock for

installation of EGCS, having non-compliant fuel oil on board.

(As a side note: The “unforeseen delay” clause in MARPOL only applies to new buildings and not

alterations/conversions).

This being said, DNV GL acting as recognised organisations on behalf of Administrations is not in the

position to make decision, which deviate from an Annex of MARPOL and it is up to the flag state to

define actions.

A ship in dry dock and not provided with Flag authorization MEPC.1/Circ.881 will apply, implying that the

PSC, flag and ship needs to agree on contingency measures, possibly resulting in debunkering.

7 DNV GL © 21 August 2020

Challenges with HSFO stored on board

Proposed actions to be agreed with flag state

Did you get stuck in yard with HSFO in your fuel tanks before

March 1st 2020?

The following proposal is feasible option, which can be proposed to the flag state, and already

has been approved by some flag states:

1. Bunker survey carried out by DNV GL surveyor reporting remaining Volume of non-compliant

fuel, involved tanks, valves and seals.

2. Photographs of sealing arrangement to be provided including copy of tank arrangement

drawing.

3. Extract of ORB stating tanks involved, sealing arrangement and remaining ROB of HSFO by

CE.

4. Item 1 could be exchanged with a bunker survey report carried out by an independent

recognized bunker survey organization.

5. Issuance of Survey statement or Statement of fact covering items 1. to 4.

6. DNV GL or owner approaching flag state asking for “close cooperation among all Member

States to overcome challenges related to the implementation and enforcement of the

relevant IMO instruments.”

8 DNV GL © 21 August 2020

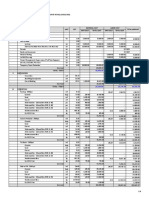

Operational experience

Operational experience: DNV GL Scrubber experience questionnaire

Questions were send out to 61 owners/operators, having in total

802 “Scrubber years” of experience

Response rate was 26%

Questionnaire consisted of 23 questions

Planning

Installation

Operation

General comments

All answers here:

https://forms.office.com/Pages/AnalysisPage.aspx?id=Kw7

xrem21kG-L8ErtWYBnDHg2OjRl51NvnmLU-

FvM95UNFU1NEhHVEpQNDk3S0RRSUFDMEVHOEE0TS4u&

AnalyzerToken=pUy8jUfkJzzhwgMRHLVfympdNf53KMZM

9 DNV GL © 21 August 2020

Operational experience – frequent failures

Operational challenges – what fails most often?

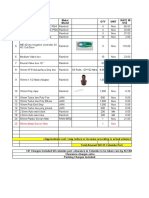

Overboard discharge pipe after 3 month of operation

10 DNV GL © 21 August 2020

Operational experience – frequent failures

Components most prone to failure – corrosion

Overboard discharge pipe after 3 Leakage

Damaged epoxy coating and subsequent hole

month of operation (pipe design:

carbon steel pipe + special coating)

Based on experiences, DNV GL updated in 2017 its rule requirements for SOx scrubber overboard

piping, requiring annual thickness measurements of the scrubber overboard valve distance piece.

For more info see DNV GL class rules, Part 7, Chapter 1, Section 2 3.1.9

11 DNV GL © 21 August 2020

Operational experience – frequent failures

Components most prone to failure - sensors

Having reliable monitoring equipment is of utmost

importance since they are the basis to show compliance of

the system

Sensor failure due to e.g. fouling

– Understanding why the sensors fail

– Calibration of sensors and missing calibration certificate

– “Faulty alarms”

– Sensor maintenance is important, variations form ship to

ship should be observed

MEPC.1/Circ.883 “GUIDANCE ON INDICATION OF

ONGOING COMPLIANCE IN THE CASE OF THE FAILURE OF

A SINGLE MONITORING INSTRUMENT”

12 DNV GL © 21 August 2020

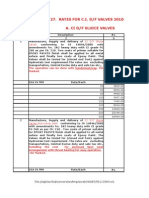

Sensor failures

Actions in case of MARPOL related failure: MECP.1/circ883

ALARM – EMISSION

EXCEEDANCE

SHORT-TERM TEMPORARY SENSOR FAILURE

MALFUNCTION

EMMISSION EXCEEDANCE

Depending on flag

requirement

INTERIM INDICATION

RECTIFIED WITHIN

yes CONTINUED EGCS OPERATION CA yes OF ONGOING

ONE HOUR

COMPLIANCE

NOTIFICATION TO

no yes CA

AUTHORITIES

NOTIFCATION TO

SUFFICIENT AUTHORITIES

ACCIDENTAL

COMPLIANT FUEL ON no CA

BREAKDOWN PROPOSED COURSE

BOARD no

OF ACTION

13 DNV GL © 21 August 2020

Sensor failures

Models used in other sectors: Torque display in cars

• Torque measurement shafts

installed in cars?

• No! Torque is only measured on

the test bed during design and a

model is generated based on the

input of other sensors

BMW: Sport display

DNV GL © 21 August 2020

Sensor failures

1. Generate “Certified” Model (neural network) of EGCS parameters (offline)

Get (offline) data “Certified” Neural network

of EGCS under Neural network coefficients stored on board

“normal”

operation:

• Engine load(s)

• Flow rates

• Temperatures

• SO2

• CO2

e.g. rbfcreate()

• pH

• …

15 DNV GL © 21 August 2020

Sensor failures

2. Actions in case of sensor failure (onboard): “Virtual sensor”

“Certified” Neural network

coefficients stored on board:

“Virtual sensor”

Onboard data of

EGCS in case of

sensor failure

• Engine load(s)

• Flow rates SO2

• Temperatures

• SO2

• CO2 CO2

• pH

Input n-2

• …

e.g. rbfinterp()

excel sheet with NN coeffs.

….

16 DNV GL © 21 August 2020

Update on fuels

ISO PAS 23263

Fuels should still be purchased according to ISO 8217:2017

Kinematic viscosity is expected to range widely. Particular

attention should be given to the correct temperature and viscosity

settings in the fuel system.

Temperature control will be important for maintaining cold flow

properties and avoid wax formation.

Fuel blend formulations are expected to vary widely, and suppliers

cannot guarantee the compatibility between different fuels of

which one or both contain a residual component. Managing such fuels

on board relies on the competence of the fuel purchaser and the

ship’s crew. Ship operators should aim to minimize commingling

of fuel to prevent incompatibility issues.

17 DNV GL © 21 August 2020

Fuels update

DNV GL Rules: “ER” notation and qualifier “Enhanced”

DNV GL class notation ER with additional voluntary qualifier “Enhanced”

for installations with enhanced availability additionally requires:

Approval of failure mode report for the EGCS control and safety system

Manufacturer and Product Certificate (MC and PC) for EGC Unit

Redundant pumps

Sea-water supply system shall be connected to at least two sea-water

inlets, preferably on opposite sides of the ship

Sea-water supply suction lines for systems with EGCS pen, EGCS hybrid

and EGCS closed qualifiers shall be provided with strainers which can be

cleaned without interrupting the water supply

EGCS units (any type) shall be provided with works (W) certificate for the

scrubber unit material and the welding of joints shall be carried out by

qualified welders using approved welding procedure specifications and type

approved welding consumables

18 DNV GL © 21 August 2020

You need more information?

DNV GL Global Sulphur Cap 2020 webpage and DATE

https://www.dnvgl.com/gsc

19 DNV GL © 21 August 2020

Thank you

Dr. Fabian Kock

Head of Environmental Certification

www.dnvgl.com

Fabian.kock@dnvgl.com

+49 172 4044 585

The trademarks DNV GL®, DNV®, the Horizon Graphic and Det Norske Veritas®

SAFER, SMARTER, GREENER are the properties of companies in the Det Norske Veritas group. All rights reserved.

20 DNV GL © 21 August 2020

You might also like

- 8.50 Lacks Pipeline CorrectedDocument68 pages8.50 Lacks Pipeline CorrectedChimakurthy NagarapanchayatNo ratings yet

- CRS-ITP2 Plumbing BOM Rev. by AEC 04122017 - FB CommDocument11 pagesCRS-ITP2 Plumbing BOM Rev. by AEC 04122017 - FB CommRhowelle TibayNo ratings yet

- Mil e 7016FDocument48 pagesMil e 7016Fgustavojorge12No ratings yet

- BOQ Site Devpt.Document15 pagesBOQ Site Devpt.Angelica PonceNo ratings yet

- IUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryDocument6 pagesIUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryTinh T. LeNo ratings yet

- Siemens Basics of AC DrivesDocument116 pagesSiemens Basics of AC DrivesSleman ShackoorNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Reconcilation of Materials at RMC PlantDocument8 pagesReconcilation of Materials at RMC PlantakshatNo ratings yet

- Electrical and Mechanical PlanDocument14 pagesElectrical and Mechanical PlanMarielle Bias MercadoNo ratings yet

- Wallenius Wilhelmsen HistoryDocument28 pagesWallenius Wilhelmsen Historymanayani52100% (1)

- AFE - Drilling & Completion: Well ProgramDocument2 pagesAFE - Drilling & Completion: Well Programemilia597No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Bill of Quantities: Structural WorksDocument5 pagesBill of Quantities: Structural WorksBernard MacahigNo ratings yet

- NS0 157Document42 pagesNS0 157Muthu LNo ratings yet

- Covered Basketball Court Monte Royal Angle BarDocument8 pagesCovered Basketball Court Monte Royal Angle BarRon Gerald RicaNo ratings yet

- Photography Is The: PictureDocument3 pagesPhotography Is The: PictureJrom EcleoNo ratings yet

- Cash-Flow Relocare2Document4 pagesCash-Flow Relocare2Adrian AdiNo ratings yet

- F109 Final Drawing LE 65 1 Boat Davit and D48sz Boat Winch - Tif PDFDocument46 pagesF109 Final Drawing LE 65 1 Boat Davit and D48sz Boat Winch - Tif PDFShamit Bugalia100% (1)

- Aircraft Wires and CablesDocument226 pagesAircraft Wires and Cablesjohn Bronson100% (1)

- Production Plan: Barging Equipment No Min Charge Unit (Hours)Document14 pagesProduction Plan: Barging Equipment No Min Charge Unit (Hours)Achmad DjunaidiNo ratings yet

- Equipments CostDocument1 pageEquipments Costdarkkaizer23No ratings yet

- Granite DadoDocument3 pagesGranite DadomanishNo ratings yet

- 04 August Crop ProjectionsDocument6 pages04 August Crop ProjectionsKyle MushongaNo ratings yet

- Item No. Work Description Unit Qty Material Cost Unit Cost: A. Concrete Encasement L.MDocument4 pagesItem No. Work Description Unit Qty Material Cost Unit Cost: A. Concrete Encasement L.Mkristinegrace27No ratings yet

- 05-02-20 Plant CalibrationDocument4 pages05-02-20 Plant CalibrationMangeysh S. ChauhanNo ratings yet

- Road BSR 2018-1Document93 pagesRoad BSR 2018-1Rajat JangidNo ratings yet

- Stratigraphic 16 LithDocument1 pageStratigraphic 16 LithHeiman Alfredo Paz OrtegaNo ratings yet

- General Antioxidant AnalysisDocument2 pagesGeneral Antioxidant AnalysisHaileslassieNo ratings yet

- Weight Curves For ShipsDocument11 pagesWeight Curves For ShipsJuan Silva100% (1)

- Valve RatesDocument34 pagesValve RatesDeepthy VasavanNo ratings yet

- Mix DesignsDocument1 pageMix DesignssohanpmeharwadeNo ratings yet

- Permian Region: Drilling Productivity ReportDocument1 pagePermian Region: Drilling Productivity ReportdNo ratings yet

- Office Pricelist Year 2011 Intrs 4.0-4.25%Document12 pagesOffice Pricelist Year 2011 Intrs 4.0-4.25%Enrie LorayNo ratings yet

- Flag Pole GardenDocument1 pageFlag Pole GardenAlejandro AbellaNo ratings yet

- Bill of Materials: Project: Location: OwnerDocument2 pagesBill of Materials: Project: Location: OwnerMark Anthony PanahonNo ratings yet

- FalconDocument15 pagesFalconJoseph EffiongNo ratings yet

- Carbolite PDFDocument2 pagesCarbolite PDFJeffrey JohnsonNo ratings yet

- Soil Tes TakabonerateDocument8 pagesSoil Tes Takaboneratediraf disoraNo ratings yet

- Proposed Commercial Building With Gas StationDocument5 pagesProposed Commercial Building With Gas StationCarla Jane Claro DonaNo ratings yet

- TRABAJO PRP-Joaquin LopezDocument8 pagesTRABAJO PRP-Joaquin Lopezmatina14No ratings yet

- Cross Section: Patok 1 Bacaan Rambu Benang Atas Benang BawahDocument10 pagesCross Section: Patok 1 Bacaan Rambu Benang Atas Benang BawahTogiNo ratings yet

- 2023-0005-02 Bill of MaterialsDocument3 pages2023-0005-02 Bill of MaterialsLhyenmar HipolNo ratings yet

- Tugas Pert 9 AKL LANJT 1 (P6-1) - Siti Rahmah - 2019210010Document2 pagesTugas Pert 9 AKL LANJT 1 (P6-1) - Siti Rahmah - 2019210010Siti RahmahNo ratings yet

- Supply of Power CableDocument7 pagesSupply of Power CableArshad Ali AnjumNo ratings yet

- RMD For EmaarDocument61 pagesRMD For Emaaraliengineer953No ratings yet

- Item Ledger EntriesDocument4 pagesItem Ledger EntriespamungkasNo ratings yet

- Transportation MethodDocument9 pagesTransportation MethodTia OktarinaNo ratings yet

- Cost Index City 3 VDocument2 pagesCost Index City 3 VSHAILENDRANo ratings yet

- 25 90mm Metal Screen Filter 1 NosDocument2 pages25 90mm Metal Screen Filter 1 NosMilinda DiasNo ratings yet

- JMC Projects (I) LTD: Calibration Report For Batching PlantDocument7 pagesJMC Projects (I) LTD: Calibration Report For Batching PlantGautam VenkatNo ratings yet

- Sa 1120 Spetco 090424Document4 pagesSa 1120 Spetco 090424hp9mzbjzsfNo ratings yet

- Cost of Production of Wheat Crop 2018-19 Under Average Conditions and Sources in The PunjabDocument1 pageCost of Production of Wheat Crop 2018-19 Under Average Conditions and Sources in The PunjabAmeet KumarNo ratings yet

- Takeoff and Landing Performance AnalysisDocument1 pageTakeoff and Landing Performance Analysisritikachoudhari68No ratings yet

- TR at 10,000 FT: TR at Standard Sea Level Conditi On (SSLC)Document4 pagesTR at 10,000 FT: TR at Standard Sea Level Conditi On (SSLC)Queen Anne Mhajheelah MagcuroNo ratings yet

- PricesDocument2 pagesPricesInk Bright TradingNo ratings yet

- Cocorna-1 LithDocument1 pageCocorna-1 LithHeiman Alfredo Paz OrtegaNo ratings yet

- Tariff Booklet - Contr - Nov 2015 (Updated 28.06.2017)Document10 pagesTariff Booklet - Contr - Nov 2015 (Updated 28.06.2017)NorZafirahMisemanNo ratings yet

- Axia 2023Document1 pageAxia 2023suhayl azlanNo ratings yet

- Accomplisment Report 7.27.2022Document1 pageAccomplisment Report 7.27.2022AdonisNo ratings yet

- 1414-Electric Room 1 Calculation Report Rev.02Document28 pages1414-Electric Room 1 Calculation Report Rev.02zakariaelrayesusaNo ratings yet

- WP5: City Scenario of Gulshan-e-Iqbal Town: Prof. Sarosh H Lodi Department of Civil Engineering, NED University, KarachiDocument44 pagesWP5: City Scenario of Gulshan-e-Iqbal Town: Prof. Sarosh H Lodi Department of Civil Engineering, NED University, KarachiMukesh KumarNo ratings yet

- Eforturi Sectiunea 2Document5 pagesEforturi Sectiunea 2nanesculNo ratings yet

- ExcelDocument2 pagesExcelAjy SetiawanNo ratings yet

- Comparison Prot Charge 2017-22Document5 pagesComparison Prot Charge 2017-22talha ikhNo ratings yet

- CPFDocument14 pagesCPFAfif FauziNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Cylinder 1Document1 pageCylinder 1Shamit BugaliaNo ratings yet

- Orissa 150328033131 Conversion Gate01Document33 pagesOrissa 150328033131 Conversion Gate01Shamit BugaliaNo ratings yet

- Cylinder 5Document1 pageCylinder 5Shamit BugaliaNo ratings yet

- WS CB III Eng SomeoneDocument2 pagesWS CB III Eng SomeoneShamit BugaliaNo ratings yet

- Orissa 150328033131 Conversion Gate01Document33 pagesOrissa 150328033131 Conversion Gate01Shamit BugaliaNo ratings yet

- Materials and Qualification Procedures For Ships: Book NDocument14 pagesMaterials and Qualification Procedures For Ships: Book NJosue Rios NavaNo ratings yet

- Stern Tube Bearing PB PDFDocument1 pageStern Tube Bearing PB PDFShamit BugaliaNo ratings yet

- Art - Integrated Project Work - HindiDocument1 pageArt - Integrated Project Work - HindiShamit Bugalia100% (1)

- LR Class Direct User GuideDocument36 pagesLR Class Direct User GuideShamit BugaliaNo ratings yet

- LR Class Direct User GuideDocument36 pagesLR Class Direct User GuideShamit BugaliaNo ratings yet

- Colour Card HempelDocument2 pagesColour Card HempelShamit BugaliaNo ratings yet

- sr-32 VSDocument176 pagessr-32 VSShamit BugaliaNo ratings yet

- Lsmgo BDN PDFDocument1 pageLsmgo BDN PDFShamit BugaliaNo ratings yet

- Letter of Offer For Buyback of L T Infra Long Term Infrastructure BondsDocument4 pagesLetter of Offer For Buyback of L T Infra Long Term Infrastructure BondsShamit Bugalia100% (1)

- Hfo Bunker ReportDocument1 pageHfo Bunker ReportShamit Bugalia100% (1)

- Hydraulic Course ManualDocument190 pagesHydraulic Course ManualMadan YadavNo ratings yet

- EU Low Sulphur DirectiveDocument6 pagesEU Low Sulphur DirectiverpNo ratings yet

- Hfo BDNDocument1 pageHfo BDNShamit BugaliaNo ratings yet

- Interview Guide: Emily Roy: Director of MarketingDocument2 pagesInterview Guide: Emily Roy: Director of MarketingShamit BugaliaNo ratings yet

- Daniel Edwards: Survey Date Report DateDocument4 pagesDaniel Edwards: Survey Date Report DateShamit BugaliaNo ratings yet

- Income Tax Issue Taken Up by MUIDocument3 pagesIncome Tax Issue Taken Up by MUIShamit BugaliaNo ratings yet

- IMO Conventions MatrixDocument18 pagesIMO Conventions MatrixMSD65352300No ratings yet

- IMO Conventions MatrixDocument18 pagesIMO Conventions MatrixMSD65352300No ratings yet

- IMO Conventions MatrixDocument18 pagesIMO Conventions MatrixMSD65352300No ratings yet

- GoalDocument11 pagesGoalcaptainnkumar1043No ratings yet

- Requirements For Transferees FinalDocument29 pagesRequirements For Transferees FinalKaren GedalangaNo ratings yet

- DjikstraDocument5 pagesDjikstramanoj1390No ratings yet

- Resume - Abishek AntonyDocument4 pagesResume - Abishek AntonyabishekantonyNo ratings yet

- UntitledDocument50 pagesUntitledapi-118172932No ratings yet

- HabaCHIAN Slat Conveyor ChainsDocument128 pagesHabaCHIAN Slat Conveyor Chainsjunico76No ratings yet

- Dodge Ram Truck 2015 Hitch Plate Prep Parts DiagramDocument4 pagesDodge Ram Truck 2015 Hitch Plate Prep Parts DiagramStephen RivettNo ratings yet

- ME (PE) II Sem SyllabusDocument71 pagesME (PE) II Sem Syllabusm elangoNo ratings yet

- ("Love",:Ruby) .Each ( - I - P I)Document32 pages("Love",:Ruby) .Each ( - I - P I)hervalNo ratings yet

- CV FaisalDocument3 pagesCV FaisalAnonymous UNekZM6No ratings yet

- Human Resource Management 7 Steps in Developing HRM StrategyDocument11 pagesHuman Resource Management 7 Steps in Developing HRM StrategyjaysoreNo ratings yet

- Practice - Creating A Discount Modifier Using QualifiersDocument37 pagesPractice - Creating A Discount Modifier Using Qualifiersmadhu12343No ratings yet

- A Guide To Flame Photometer AnalysisDocument17 pagesA Guide To Flame Photometer Analysisarun231187100% (1)

- GarciaDocument10 pagesGarciaMarco Toledo BastosNo ratings yet

- FFSA BriefDocument4 pagesFFSA Briefcontactnandu7415No ratings yet

- Os Se VB Mis SadDocument336 pagesOs Se VB Mis SadMuhammad Sikandar DarNo ratings yet

- Evaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanDocument33 pagesEvaluating Chiller & Chiller Plant Efficiency: Jonathan SpreemanhoangpalestineNo ratings yet

- Thesis Process MiningDocument98 pagesThesis Process MiningRamyapremnathNo ratings yet

- MemoDocument12 pagesMemoGaurav GoelNo ratings yet

- Color CCD Imaging With Luminance Layering: by Robert GendlerDocument4 pagesColor CCD Imaging With Luminance Layering: by Robert GendlerbirbiburbiNo ratings yet

- The Effectiveness of Acceptance and Commitment-BasDocument18 pagesThe Effectiveness of Acceptance and Commitment-BasRaphaele ColferaiNo ratings yet

- RFQ - Printer Cartridge HP - A0066Document1 pageRFQ - Printer Cartridge HP - A0066منتظر عليNo ratings yet

- An Overview of Transceiver SystemsDocument11 pagesAn Overview of Transceiver SystemssurvivalofthepolyNo ratings yet

- The Basics of Business Management Vol I PDFDocument284 pagesThe Basics of Business Management Vol I PDFKnjaz Milos100% (1)

- Pet CRD CRPDN Adc MBBL MDocument125 pagesPet CRD CRPDN Adc MBBL MpmellaNo ratings yet