Professional Documents

Culture Documents

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

Uploaded by

Moaatazz NouisriCopyright:

Available Formats

You might also like

- Compensation: Offer Letter For David Young-Chan Kay Apple ConfidentialDocument3 pagesCompensation: Offer Letter For David Young-Chan Kay Apple Confidentialrajendra prasad tripathy100% (2)

- JSA FOR ROAD LAYING WORK (Asphalt Paving)Document10 pagesJSA FOR ROAD LAYING WORK (Asphalt Paving)wahyu nugroho88% (8)

- Jsa For Pipe Laying Water and Sewer-1Document8 pagesJsa For Pipe Laying Water and Sewer-1Mikael Naqib83% (6)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- JSA For Vegetation ClearingDocument4 pagesJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Job Hazard Analysis (HDD)Document7 pagesJob Hazard Analysis (HDD)jay RNo ratings yet

- RA 012 Taking Trial PitsDocument2 pagesRA 012 Taking Trial Pitsahmedshah512100% (1)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JOB SAFETY ANALYSIS Grout Placement, Curing and CoatingDocument5 pagesJOB SAFETY ANALYSIS Grout Placement, Curing and Coatingmuhammad zaman67% (3)

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri83% (6)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Safe Work Method Statement: Gypsum Partition/ Column Framing, Cladding& Paneling/Pop PunningDocument6 pagesSafe Work Method Statement: Gypsum Partition/ Column Framing, Cladding& Paneling/Pop PunningSiddharth PNo ratings yet

- 005 HIRARC Hollow Core Slab InstallationDocument5 pages005 HIRARC Hollow Core Slab Installationbdiey100% (5)

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- Job Hazard Analysis of Site SURVEYINGDocument1 pageJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- Safe Work Methode For HDD BoringDocument1 pageSafe Work Methode For HDD Boringiwansalma100% (3)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA For Plaster WorkDocument8 pagesJSA For Plaster WorkZakeer Shaikh100% (1)

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- Health, Safety, & Environment Manual: Piling WorksDocument12 pagesHealth, Safety, & Environment Manual: Piling Worksrizal azizanNo ratings yet

- Coring: Job Safety Analysis (JSA)Document2 pagesCoring: Job Safety Analysis (JSA)Nishad Muhammed100% (1)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- Piling Hazards and RisksDocument4 pagesPiling Hazards and RisksAbhishek Gupta100% (2)

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Risk Assessment - Wall & Floor Tiling: April 2010Document2 pagesRisk Assessment - Wall & Floor Tiling: April 2010wahyu nugroho100% (1)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Land ClearingDocument9 pagesLand ClearingAzmi Fauzi100% (2)

- JSA Road Routine MaintenanceDocument3 pagesJSA Road Routine MaintenanceBen Hammadi Rym100% (2)

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- JSA Topographic SurveyDocument3 pagesJSA Topographic Surveyhermawan tjipto saputroNo ratings yet

- Part VI (E) - Piling Work SafetyDocument26 pagesPart VI (E) - Piling Work SafetyBinz100% (2)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- 007 HIRARC Construction of RC Column (Car Park)Document10 pages007 HIRARC Construction of RC Column (Car Park)bdieyNo ratings yet

- 011.TBSHE JSA 005 Pipelaying WorkDocument8 pages011.TBSHE JSA 005 Pipelaying Worknellaika puspa dewi100% (1)

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Job Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkDocument6 pagesJob Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkAbdul Khairul RiduanNo ratings yet

- Job Hazard Analysis: IP-OPS-066Document9 pagesJob Hazard Analysis: IP-OPS-066ananthu.uNo ratings yet

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- NEW Form JHA-Road Works (27-03-2018) FinalDocument34 pagesNEW Form JHA-Road Works (27-03-2018) FinalKarthik babu100% (3)

- JGS SHES JHRA 002 13 Wire Mesh InstallationDocument2 pagesJGS SHES JHRA 002 13 Wire Mesh Installationarnel sungkip100% (3)

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- Jsa For Sand Filling of SwampDocument5 pagesJsa For Sand Filling of SwampOgunwa Emmanuel50% (2)

- JSA-001 Site Preparation & DevelopmentDocument2 pagesJSA-001 Site Preparation & Developmentba ratnaparkhe50% (2)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule83% (6)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

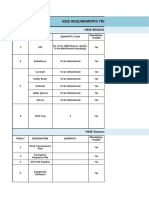

- Hsse Requirements Trakcing RegisterDocument4 pagesHsse Requirements Trakcing RegisterMoaatazz NouisriNo ratings yet

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 pagesDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriNo ratings yet

- Daily HSE Report 22-12-2018Document117 pagesDaily HSE Report 22-12-2018Moaatazz NouisriNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- 120021-Hse-003 - Waste Management PlanDocument21 pages120021-Hse-003 - Waste Management PlanMoaatazz NouisriNo ratings yet

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pages220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriNo ratings yet

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- 120025-Hse-002 Company Hse Project StandardsDocument25 pages120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriNo ratings yet

- Instrument & Control Engineering Head: Curriculum Vitae PirecoDocument2 pagesInstrument & Control Engineering Head: Curriculum Vitae PirecoMoaatazz NouisriNo ratings yet

- CV Civil & Structural Head-O.RAJEHDocument2 pagesCV Civil & Structural Head-O.RAJEHMoaatazz NouisriNo ratings yet

- CV Project Manager-M.Ammar PDFDocument6 pagesCV Project Manager-M.Ammar PDFMoaatazz NouisriNo ratings yet

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 pagesReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriNo ratings yet

- CV Business Adm Mgr-S.DridiDocument2 pagesCV Business Adm Mgr-S.DridiMoaatazz NouisriNo ratings yet

- Attachment 4.1.1Document16 pagesAttachment 4.1.1Moaatazz NouisriNo ratings yet

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- 4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameDocument1 page4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameMoaatazz NouisriNo ratings yet

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- JSA-017 Lifting With Forklift 2Document4 pagesJSA-017 Lifting With Forklift 2Moaatazz NouisriNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- Tool Box Talk - 13 Near Miss ReportingDocument2 pagesTool Box Talk - 13 Near Miss ReportingMoaatazz NouisriNo ratings yet

- Tool Box Talk - 14 Working at HeightsDocument2 pagesTool Box Talk - 14 Working at HeightsMoaatazz NouisriNo ratings yet

- Survey On Pocket MoneyDocument11 pagesSurvey On Pocket MoneyDEVIL GAMER100% (2)

- Morality in AdvertisingDocument40 pagesMorality in AdvertisingPrecely Paul70% (10)

- FIN104 TQ W2-AnswersDocument4 pagesFIN104 TQ W2-AnswersZijingNo ratings yet

- Strama Sample - Coffee IndustryDocument86 pagesStrama Sample - Coffee IndustryChelsea RoqueNo ratings yet

- Perfectly Competitive MarketsDocument36 pagesPerfectly Competitive MarketsSaurabh SharmaNo ratings yet

- Operations and Information ManagementDocument10 pagesOperations and Information ManagementMohamed Fathy Abdelazim SorogyNo ratings yet

- 1771-Article Text-3562-1-10-20210312Document10 pages1771-Article Text-3562-1-10-20210312Ahmad AdityaNo ratings yet

- Total MediaDocument88 pagesTotal Mediabencekatarina4No ratings yet

- Akshay Comp. 21-22Document3 pagesAkshay Comp. 21-22avishkar guptaNo ratings yet

- Catalogue HakanssonDocument26 pagesCatalogue Hakansson1nrestoration1No ratings yet

- MI - 1 (45) So Pyay Aung Win (Life Insurance)Document3 pagesMI - 1 (45) So Pyay Aung Win (Life Insurance)Dr. SNo ratings yet

- A Report On Diageo PLC Financial StatementDocument14 pagesA Report On Diageo PLC Financial Statementjoshua.o.adenijiNo ratings yet

- Bu Mat - MD407 17Document13 pagesBu Mat - MD407 17Larry Wayne Sumpter, JrNo ratings yet

- VQR Question Bank - 1Document2 pagesVQR Question Bank - 1sairam97969No ratings yet

- Request For Proposal: SECTION I - BackgroundDocument5 pagesRequest For Proposal: SECTION I - Backgroundsemhal gebremedhinNo ratings yet

- Chapter 5 - BudgetingDocument16 pagesChapter 5 - BudgetingMary Anne BillonesNo ratings yet

- MKT521, Final, Md. Zayedul Haque, 2020-3-95-027Document5 pagesMKT521, Final, Md. Zayedul Haque, 2020-3-95-027Zayedul Haque ZayedNo ratings yet

- Skoda AutoDocument4 pagesSkoda AutoKhairiah Salleh0% (1)

- Qualitative Process Analysis 1Document42 pagesQualitative Process Analysis 1mtahir777945No ratings yet

- Documentation: Manufacture, Control and DistributionDocument10 pagesDocumentation: Manufacture, Control and DistributionAyalew DesyeNo ratings yet

- R03.1 Standard I ProfessionalismDocument38 pagesR03.1 Standard I Professionalismxczc100% (1)

- DITTO For Gen Z: A Framework For Leveraging The Uniqueness of The New GenerationDocument12 pagesDITTO For Gen Z: A Framework For Leveraging The Uniqueness of The New GenerationNewReader2022No ratings yet

- Contract of AntichresisDocument3 pagesContract of AntichresisPatrice Tan100% (1)

- Iso13485 QOP4201 DocumentControl PDFDocument9 pagesIso13485 QOP4201 DocumentControl PDFQuality and Safety Consultants Co.No ratings yet

- Supply Chain Management - Flow of Materials - Wastes in The Pipeline - Flow of InformationDocument24 pagesSupply Chain Management - Flow of Materials - Wastes in The Pipeline - Flow of InformationkanjanaNo ratings yet

- Supply Chain Resilience Role of Complexities and StrategiesDocument12 pagesSupply Chain Resilience Role of Complexities and StrategiesJoseNo ratings yet

- Influence of Service Excellence On ConsumerDocument11 pagesInfluence of Service Excellence On ConsumerJenishNo ratings yet

- Definition of Executive SummaryDocument4 pagesDefinition of Executive SummaryKen Kou WangNo ratings yet

- Assessments (3,4,5)Document11 pagesAssessments (3,4,5)Rosalie Colarte LangbayNo ratings yet

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

Uploaded by

Moaatazz NouisriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

JOB SAFETY ANALYSIS - Topographic Survey: STEP 1: Likelihood of Occurrence STEP 2: Severity of Result Step 3

Uploaded by

Moaatazz NouisriCopyright:

Available Formats

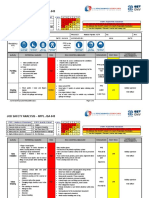

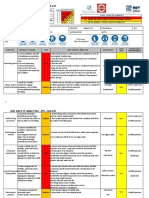

JOB SAFETY ANALYSIS – Topographic Survey

STEP 1: Likelihood of Occurrence STEP 2: Severity of Result STEP 3: A B C D E

1. Expected To Occur (once per week) A. Fatality 1 H H H H M

2. Common (once per month) B. Permanent Disability 2 H H H M M STEP 4: Hazard Risk Assessment

3. Sometimes (once per year) C. Lost Time Injury (LTI) 3 H H M M L H = High Risk (INTOLERABLE, significant and urgent actions required).

4. Rarely (once in < 20 years) D. Medical Treatment / Damage 4 M = Medium Risk (ALARP, reduce to As Low As Reasonably Practicable).

H M M L L

5. Highly Unlikely (once in > 20 years) E. First Aid Injury 5 M M L L L L = Low Risk (Negligible / Tolerable, monitor and manage risk).

PROJECT: PROVISION OF CIVIL WORKS

TITLE: Topographic Survey AT ERAWIN NC-200 FIELD (PIPE No: 001 Rev: 01

STORAGE YARD)

DATE: DATE:

DEVELOPED BY: HSE MANAGER APPROVED BY: SIGN:

29/30/2020 29/30/2020

Mandatory PPE to be

PPE worn as

→ required

→

Activity POTENTIAL HAZARD RISK RISK CONTROL MEASURE RESOURCES POST RISK SUPERVISORY REQUIREMENTS

HSE team to assess continuously the

Work condition not safe conditions of work in the assigned

Procedures and tasks area PTW system Activity supervisor

not clear One person to issue work permits / Foreman

Lack of supervisory Toolbox talks Tool box

Permitting Miscommunication High Competency of personnel and Talk Low

work Not correct PPE worn supervisory for the activity PTW system

Equipment not Define hierarchy and reporting Inspection coordinator

inspected and certified flowcharts certificates

Define proper PPE to be used for the

work

Check inspection certificates of

equipment for the job

C:\Users\asus\Desktop\land yard pipe\Nouveau dossier\JSA-001Topographic Survey.docx Page 1 of 3

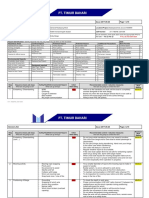

JOB SAFETY ANALYSIS – Topographic Survey

STEP 1: Likelihood of Occurrence STEP 2: Severity of Result STEP 3: A B C D E

1. Expected To Occur (once per week) A. Fatality 1 H H H H M

2. Common (once per month) B. Permanent Disability 2 H H H M M STEP 4: Hazard Risk Assessment

3. Sometimes (once per year) C. Lost Time Injury (LTI) 3 H H M M L H = High Risk (INTOLERABLE, significant and urgent actions required).

4. Rarely (once in < 20 years) D. Medical Treatment / Damage 4 M = Medium Risk (ALARP, reduce to As Low As Reasonably Practicable).

H M M L L

5. Highly Unlikely (once in > 20 years) E. First Aid Injury 5 M M L L L L = Low Risk (Negligible / Tolerable, monitor and manage risk).

Activity POTENTIAL HAZARD RISK RISK CONTROL MEASURE RESOURCES POST RISK SUPERVISORY REQUIREMENTS

Uncontrolled driving due to road Drive carefully, never exceed 30 Km/h

condition Avoid ground workers, allow workers Desert

Collision with other machines High passage defensive Low Activity supervisor

Installation of Pick-up drifts and fall in the Be seen, use lights and horn if needed driving

Post Markers trench Park pick-up far from area

Ground worker hit by pick-up Have a radio in the pick-up Radios

Lost communication networks Have enough extra water prior to every job

Personnel lost in the desert

Personnel exposed to

dehydration / death

Be seen, wear high visibility jackets when

Person hit by machine getting out of the pick-up

movement Watch your steps, do not walk beside the

Pipe rerouting Tripping / falling in the trench trenches Ladder

survey, Slipping falling when pointing Medium Use proper ladder when getting in and out of Low Activity supervisor

Measurement the bar on the top side of the the trench PPE

taking bar Do not walk on the pipe

Person injured by the Dry the pipe from moisture if needed to stand High visibility

measurement bar on a particular position jackets

Person get bite by snakes / Visually check walk ways and trenches for

scorpions presence of venomous animals

Working in dusty environment Wear correct PPE plus dust mask

Persons lost in the desert Buddy system : always monitor in-trench

personnel

C:\Users\asus\Desktop\land yard pipe\Nouveau dossier\JSA-001Topographic Survey.docx Page 2 of 3

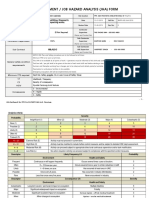

JOB SAFETY ANALYSIS – Topographic Survey

STEP 1: Likelihood of Occurrence STEP 2: Severity of Result STEP 3: A B C D E

1. Expected To Occur (once per week) A. Fatality 1 H H H H M

2. Common (once per month) B. Permanent Disability 2 H H H M M STEP 4: Hazard Risk Assessment

3. Sometimes (once per year) C. Lost Time Injury (LTI) 3 H H M M L H = High Risk (INTOLERABLE, significant and urgent actions required).

4. Rarely (once in < 20 years) D. Medical Treatment / Damage 4 M = Medium Risk (ALARP, reduce to As Low As Reasonably Practicable).

H M M L L

5. Highly Unlikely (once in > 20 years) E. First Aid Injury 5 M M L L L L = Low Risk (Negligible / Tolerable, monitor and manage risk).

Activity POTENTIAL HAZARD RISK RISK CONTROL MEASURE RESOURCES POST RISK SUPERVISORY REQUIREMENTS

Equipment and tools remain on Put back equipment to proper place Plastic bags Activity supervisor

House site Medium Clear all work place from trash Low

keeping Slip trip and fall Segregate trash Trash bins HSE Officer

Trash left in the work place

Participants / Work Crew JSA Reviewed By: Name: Date:

Name (Print Clearly): Signature: Date: Review Comments:

1.

2.

3.

4.

5.

Responsible Supervisors / Foreman

1.

2.

C:\Users\asus\Desktop\land yard pipe\Nouveau dossier\JSA-001Topographic Survey.docx Page 3 of 3

You might also like

- Compensation: Offer Letter For David Young-Chan Kay Apple ConfidentialDocument3 pagesCompensation: Offer Letter For David Young-Chan Kay Apple Confidentialrajendra prasad tripathy100% (2)

- JSA FOR ROAD LAYING WORK (Asphalt Paving)Document10 pagesJSA FOR ROAD LAYING WORK (Asphalt Paving)wahyu nugroho88% (8)

- Jsa For Pipe Laying Water and Sewer-1Document8 pagesJsa For Pipe Laying Water and Sewer-1Mikael Naqib83% (6)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- JSA For Vegetation ClearingDocument4 pagesJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Job Hazard Analysis (HDD)Document7 pagesJob Hazard Analysis (HDD)jay RNo ratings yet

- RA 012 Taking Trial PitsDocument2 pagesRA 012 Taking Trial Pitsahmedshah512100% (1)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JOB SAFETY ANALYSIS Grout Placement, Curing and CoatingDocument5 pagesJOB SAFETY ANALYSIS Grout Placement, Curing and Coatingmuhammad zaman67% (3)

- JSA - Cable Trench ExcavationDocument9 pagesJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri83% (6)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Safe Work Method Statement: Gypsum Partition/ Column Framing, Cladding& Paneling/Pop PunningDocument6 pagesSafe Work Method Statement: Gypsum Partition/ Column Framing, Cladding& Paneling/Pop PunningSiddharth PNo ratings yet

- 005 HIRARC Hollow Core Slab InstallationDocument5 pages005 HIRARC Hollow Core Slab Installationbdiey100% (5)

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- Job Hazard Analysis of Site SURVEYINGDocument1 pageJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- Safe Work Methode For HDD BoringDocument1 pageSafe Work Methode For HDD Boringiwansalma100% (3)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA For Plaster WorkDocument8 pagesJSA For Plaster WorkZakeer Shaikh100% (1)

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- Health, Safety, & Environment Manual: Piling WorksDocument12 pagesHealth, Safety, & Environment Manual: Piling Worksrizal azizanNo ratings yet

- Coring: Job Safety Analysis (JSA)Document2 pagesCoring: Job Safety Analysis (JSA)Nishad Muhammed100% (1)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- Piling Hazards and RisksDocument4 pagesPiling Hazards and RisksAbhishek Gupta100% (2)

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Risk Assessment - Wall & Floor Tiling: April 2010Document2 pagesRisk Assessment - Wall & Floor Tiling: April 2010wahyu nugroho100% (1)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Land ClearingDocument9 pagesLand ClearingAzmi Fauzi100% (2)

- JSA Road Routine MaintenanceDocument3 pagesJSA Road Routine MaintenanceBen Hammadi Rym100% (2)

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- JSA Topographic SurveyDocument3 pagesJSA Topographic Surveyhermawan tjipto saputroNo ratings yet

- Part VI (E) - Piling Work SafetyDocument26 pagesPart VI (E) - Piling Work SafetyBinz100% (2)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- 007 HIRARC Construction of RC Column (Car Park)Document10 pages007 HIRARC Construction of RC Column (Car Park)bdieyNo ratings yet

- 011.TBSHE JSA 005 Pipelaying WorkDocument8 pages011.TBSHE JSA 005 Pipelaying Worknellaika puspa dewi100% (1)

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Job Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkDocument6 pagesJob Hazard Analysis (Jha) Worksheet: Perform Forwork, Rebar and Concrete WorkAbdul Khairul RiduanNo ratings yet

- Job Hazard Analysis: IP-OPS-066Document9 pagesJob Hazard Analysis: IP-OPS-066ananthu.uNo ratings yet

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- NEW Form JHA-Road Works (27-03-2018) FinalDocument34 pagesNEW Form JHA-Road Works (27-03-2018) FinalKarthik babu100% (3)

- JGS SHES JHRA 002 13 Wire Mesh InstallationDocument2 pagesJGS SHES JHRA 002 13 Wire Mesh Installationarnel sungkip100% (3)

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- Jsa For Sand Filling of SwampDocument5 pagesJsa For Sand Filling of SwampOgunwa Emmanuel50% (2)

- JSA-001 Site Preparation & DevelopmentDocument2 pagesJSA-001 Site Preparation & Developmentba ratnaparkhe50% (2)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule83% (6)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- Hsse Requirements Trakcing RegisterDocument4 pagesHsse Requirements Trakcing RegisterMoaatazz NouisriNo ratings yet

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 pagesDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriNo ratings yet

- Daily HSE Report 22-12-2018Document117 pagesDaily HSE Report 22-12-2018Moaatazz NouisriNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- 120021-Hse-003 - Waste Management PlanDocument21 pages120021-Hse-003 - Waste Management PlanMoaatazz NouisriNo ratings yet

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pages220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriNo ratings yet

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- 120025-Hse-002 Company Hse Project StandardsDocument25 pages120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriNo ratings yet

- Instrument & Control Engineering Head: Curriculum Vitae PirecoDocument2 pagesInstrument & Control Engineering Head: Curriculum Vitae PirecoMoaatazz NouisriNo ratings yet

- CV Civil & Structural Head-O.RAJEHDocument2 pagesCV Civil & Structural Head-O.RAJEHMoaatazz NouisriNo ratings yet

- CV Project Manager-M.Ammar PDFDocument6 pagesCV Project Manager-M.Ammar PDFMoaatazz NouisriNo ratings yet

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 pagesReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriNo ratings yet

- CV Business Adm Mgr-S.DridiDocument2 pagesCV Business Adm Mgr-S.DridiMoaatazz NouisriNo ratings yet

- Attachment 4.1.1Document16 pagesAttachment 4.1.1Moaatazz NouisriNo ratings yet

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- 4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameDocument1 page4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameMoaatazz NouisriNo ratings yet

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- JSA-017 Lifting With Forklift 2Document4 pagesJSA-017 Lifting With Forklift 2Moaatazz NouisriNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- Tool Box Talk - 13 Near Miss ReportingDocument2 pagesTool Box Talk - 13 Near Miss ReportingMoaatazz NouisriNo ratings yet

- Tool Box Talk - 14 Working at HeightsDocument2 pagesTool Box Talk - 14 Working at HeightsMoaatazz NouisriNo ratings yet

- Survey On Pocket MoneyDocument11 pagesSurvey On Pocket MoneyDEVIL GAMER100% (2)

- Morality in AdvertisingDocument40 pagesMorality in AdvertisingPrecely Paul70% (10)

- FIN104 TQ W2-AnswersDocument4 pagesFIN104 TQ W2-AnswersZijingNo ratings yet

- Strama Sample - Coffee IndustryDocument86 pagesStrama Sample - Coffee IndustryChelsea RoqueNo ratings yet

- Perfectly Competitive MarketsDocument36 pagesPerfectly Competitive MarketsSaurabh SharmaNo ratings yet

- Operations and Information ManagementDocument10 pagesOperations and Information ManagementMohamed Fathy Abdelazim SorogyNo ratings yet

- 1771-Article Text-3562-1-10-20210312Document10 pages1771-Article Text-3562-1-10-20210312Ahmad AdityaNo ratings yet

- Total MediaDocument88 pagesTotal Mediabencekatarina4No ratings yet

- Akshay Comp. 21-22Document3 pagesAkshay Comp. 21-22avishkar guptaNo ratings yet

- Catalogue HakanssonDocument26 pagesCatalogue Hakansson1nrestoration1No ratings yet

- MI - 1 (45) So Pyay Aung Win (Life Insurance)Document3 pagesMI - 1 (45) So Pyay Aung Win (Life Insurance)Dr. SNo ratings yet

- A Report On Diageo PLC Financial StatementDocument14 pagesA Report On Diageo PLC Financial Statementjoshua.o.adenijiNo ratings yet

- Bu Mat - MD407 17Document13 pagesBu Mat - MD407 17Larry Wayne Sumpter, JrNo ratings yet

- VQR Question Bank - 1Document2 pagesVQR Question Bank - 1sairam97969No ratings yet

- Request For Proposal: SECTION I - BackgroundDocument5 pagesRequest For Proposal: SECTION I - Backgroundsemhal gebremedhinNo ratings yet

- Chapter 5 - BudgetingDocument16 pagesChapter 5 - BudgetingMary Anne BillonesNo ratings yet

- MKT521, Final, Md. Zayedul Haque, 2020-3-95-027Document5 pagesMKT521, Final, Md. Zayedul Haque, 2020-3-95-027Zayedul Haque ZayedNo ratings yet

- Skoda AutoDocument4 pagesSkoda AutoKhairiah Salleh0% (1)

- Qualitative Process Analysis 1Document42 pagesQualitative Process Analysis 1mtahir777945No ratings yet

- Documentation: Manufacture, Control and DistributionDocument10 pagesDocumentation: Manufacture, Control and DistributionAyalew DesyeNo ratings yet

- R03.1 Standard I ProfessionalismDocument38 pagesR03.1 Standard I Professionalismxczc100% (1)

- DITTO For Gen Z: A Framework For Leveraging The Uniqueness of The New GenerationDocument12 pagesDITTO For Gen Z: A Framework For Leveraging The Uniqueness of The New GenerationNewReader2022No ratings yet

- Contract of AntichresisDocument3 pagesContract of AntichresisPatrice Tan100% (1)

- Iso13485 QOP4201 DocumentControl PDFDocument9 pagesIso13485 QOP4201 DocumentControl PDFQuality and Safety Consultants Co.No ratings yet

- Supply Chain Management - Flow of Materials - Wastes in The Pipeline - Flow of InformationDocument24 pagesSupply Chain Management - Flow of Materials - Wastes in The Pipeline - Flow of InformationkanjanaNo ratings yet

- Supply Chain Resilience Role of Complexities and StrategiesDocument12 pagesSupply Chain Resilience Role of Complexities and StrategiesJoseNo ratings yet

- Influence of Service Excellence On ConsumerDocument11 pagesInfluence of Service Excellence On ConsumerJenishNo ratings yet

- Definition of Executive SummaryDocument4 pagesDefinition of Executive SummaryKen Kou WangNo ratings yet

- Assessments (3,4,5)Document11 pagesAssessments (3,4,5)Rosalie Colarte LangbayNo ratings yet