Professional Documents

Culture Documents

Battery Recharge Testing

Battery Recharge Testing

Uploaded by

AMAR1980Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Battery Recharge Testing

Battery Recharge Testing

Uploaded by

AMAR1980Copyright:

Available Formats

Battery Recharge

EQUI-ZZ_UUID_NUMBER -> Manufacturer’s date (MFRD)

EQUI-ZZ_MAC_ADDRESS -> Latest Re-charging date (LRCD)

Logging table for the MFRD/LRCD updates: table > ZMS_LRCD_HIST

1. Inbound ASN (SAP IT)

LOAD ID Vendor Info Vendor Code

305420104 JDM1 Suzhou CN CM 2266985

304609594 Chicony Dongguan CN CM 656118114

304716165 FOXLINK Dongguan CN CM 2115939

304491484 Foxlink Xuzhou CN CM 3021636

305183330 Liteon Dongguan CN CM 656035938

305068070 Chicony Wujiang CN CM

656118114

306668174 Quanta Shanghai CN CM 2203295

306441593 Liteon 656035938

306070987 IQOR - CANADA

306603732 IQOR - MEXICO

+ EMEA & HK -> ASN files too (local SAP IT)

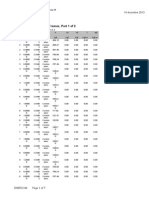

2. Updating the current database Report: ZMS_EQUI_BATTERY_LIFE ( SAP IT & local SAP IT)

3. Batter Aging Report : ZMS_AGING_BATTERY_LIFE ( Testing team)

Playbook for the recharging rules based on the Material/Material group: ZMS_SHELF_LIFE

4. Transaction: ZINBOUND_PACK (Testing team)

5. ROC Booking transaction: (Testing team)

6. Utility program to check the MFRD/LRCD for a given serial no:

ZMSFT_DISPOSITION_API_TOOL (Testing team)

7. Transformation & Bundling: (Ryan)

Scenario -1:

Get all the serial numbers that need to be recharged from Aging report.

Upload the serials into the table: (ZPP_GY). Follow the GREEN-YELLOW process (Tcodes:

ZURS; ZPGY).

Create an internal production order REPID type (Order type: ZP05) from SKU A -> SKU A

In ZSTEP1, a popup will appear for the recharged devices -> We should capture

RECHARGING DATE & STATUS (S – success or F - failure) of the recharge.

Output message (ZRCH) only should be triggered for the recharged HU’s.

Scenario -2: SKU A -> SKU B

Updating the EQUI (MFRD/LRCD) dates into the new Material?

Scenario -3: Bundling

Scenario -4: DeBundling

You might also like

- Acd2-Mrl Sur en PDFDocument100 pagesAcd2-Mrl Sur en PDFGutmonarch88% (16)

- ACD2 Elevador XIzi ACD2-MRL - SUR - EN PDFDocument93 pagesACD2 Elevador XIzi ACD2-MRL - SUR - EN PDFIván Sulbaran100% (2)

- ENOTE0094 Recovering - QuickServer - FS QS 1010 - FS QS 1210 - FS QS 1510 PDFDocument5 pagesENOTE0094 Recovering - QuickServer - FS QS 1010 - FS QS 1210 - FS QS 1510 PDFElvis Paiva ViteNo ratings yet

- Dipal - Trade Compliance - 2019Document2 pagesDipal - Trade Compliance - 2019AMAR1980No ratings yet

- t000004112 Filename2 Barauni TechDocument251 pagest000004112 Filename2 Barauni TechNikhil KarkeraNo ratings yet

- TATA BSC Up Gradation Plan: 1. IntroductionDocument13 pagesTATA BSC Up Gradation Plan: 1. IntroductionmaxiszteNo ratings yet

- Sfu Mxu DebuggingDocument17 pagesSfu Mxu DebuggingRinkoo RazdanNo ratings yet

- PARAmetter Setting 7500 For ALL 20-10 ISS01Document16 pagesPARAmetter Setting 7500 For ALL 20-10 ISS01ăn uốngNo ratings yet

- SCL Logic Synthesis ReportDocument10 pagesSCL Logic Synthesis ReportAishwarya a nairNo ratings yet

- BMS Report - FinalDocument13 pagesBMS Report - FinalLogeeswaran MurugappanNo ratings yet

- Functionality and Item Need To TestDocument3 pagesFunctionality and Item Need To TestKuda BetinaNo ratings yet

- FDS6Document82 pagesFDS6simran_99No ratings yet

- CA7FIN2Document49 pagesCA7FIN2Suthandira Devi E0% (1)

- Documentation of CDR Collection From Ewsd SwitchDocument11 pagesDocumentation of CDR Collection From Ewsd Switch830139No ratings yet

- 7.1.4 Load BalancingDocument17 pages7.1.4 Load BalancingmhmdmhmdNo ratings yet

- High Speed Micromouse Servo Controller Based On DSP and FpgaDocument8 pagesHigh Speed Micromouse Servo Controller Based On DSP and FpgaNilotpal SinhaNo ratings yet

- Audit Points Detail - XLSX - PendenciesDocument15 pagesAudit Points Detail - XLSX - PendenciesCA Harsimran KaurNo ratings yet

- 5060 MGC10 Replacing A Rouzic Card - Ed05Document19 pages5060 MGC10 Replacing A Rouzic Card - Ed05Iptech solutionsNo ratings yet

- BW - MM - IC - Inventory Controlling Extraction Steps - SCNDocument7 pagesBW - MM - IC - Inventory Controlling Extraction Steps - SCNAlejandro LevitNo ratings yet

- Nota SAP EWMDocument7 pagesNota SAP EWMAriel QuidelNo ratings yet

- Canopen: ⌕㸠⌆Ⱘ Can-Bus 催ሖण䆂Document21 pagesCanopen: ⌕㸠⌆Ⱘ Can-Bus 催ሖण䆂Allen YaoNo ratings yet

- DescriptionsDocument7 pagesDescriptionsRiyas MohamedNo ratings yet

- Tampa 2500 TA52XC056 1389129 Tampa 2500 TA52XC056 1389129 Tampa 2500 TA52XC056 1389129Document27 pagesTampa 2500 TA52XC056 1389129 Tampa 2500 TA52XC056 1389129 Tampa 2500 TA52XC056 1389129Ankur SharmaNo ratings yet

- MID 039 - CID 1847 - FMI 02: Pantalla AnteriorDocument4 pagesMID 039 - CID 1847 - FMI 02: Pantalla AnteriorWalterNo ratings yet

- ML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)Document18 pagesML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)EnformableNo ratings yet

- Datos EsfuerzosDocument7 pagesDatos EsfuerzosChiclla Quispe PercyNo ratings yet

- DFU ExplainDocument18 pagesDFU Explainjoshua camachoNo ratings yet

- Ericsson RNC Iu PS Link Creation ProceduDocument9 pagesEricsson RNC Iu PS Link Creation ProceduhamidboulahiaNo ratings yet

- O&MactivityDocument34 pagesO&MactivityMangata AcaronarNo ratings yet

- Comandos 4GDocument39 pagesComandos 4GcarlosrelvasNo ratings yet

- UFN714Document9 pagesUFN714Perla EspinosaNo ratings yet

- Tracking Abnormal Ecsa Growth: February 2002 WWW - Rizzuto.itDocument4 pagesTracking Abnormal Ecsa Growth: February 2002 WWW - Rizzuto.itÖzgür HepsağNo ratings yet

- SSV Report KpakmDocument38 pagesSSV Report KpakmAshit SinghNo ratings yet

- Trouble mds9148 00Document21 pagesTrouble mds9148 00Pavan NavNo ratings yet

- 3g2ip Sumadi CbnongDocument11 pages3g2ip Sumadi CbnongAddi CumsNo ratings yet

- Sap PC NTSDocument2 pagesSap PC NTSBiswajit GhoshNo ratings yet

- Action Items For IT ProjectDocument2 pagesAction Items For IT ProjectVIJAY BANSALNo ratings yet

- Modelo BMDocument5 pagesModelo BMRafael CombitaNo ratings yet

- Cópia de FCOM - ATR72 - Rev32.0Document3,176 pagesCópia de FCOM - ATR72 - Rev32.0EMANUEL MARCELO CABRERA FERRUFINONo ratings yet

- 1413439986 - BẢNG GIÁ THIẾT BỊ SIEMENS - CTY AN PHƯƠNG - NĂM 2014-2015 PDFDocument38 pages1413439986 - BẢNG GIÁ THIẾT BỊ SIEMENS - CTY AN PHƯƠNG - NĂM 2014-2015 PDFKHOATIENNo ratings yet

- 1996 OKI LCD Driver Controller DatabookDocument232 pages1996 OKI LCD Driver Controller Databookpiptendo100% (1)

- Ireland EUWest Windows SGroupsDocument148 pagesIreland EUWest Windows SGroupsaksNo ratings yet

- Firmware Up Gradation Procedure in Sun 3510 StoredgesDocument6 pagesFirmware Up Gradation Procedure in Sun 3510 Storedgesakuma27No ratings yet

- LogDocument9 pagesLogLeovi Lovienchia arbeliandha putriNo ratings yet

- Creating LPARs Using NPIV - SAN Boot LUN Instead of Local Boot LUNDocument22 pagesCreating LPARs Using NPIV - SAN Boot LUN Instead of Local Boot LUNHazman HussainNo ratings yet

- BLK-1 LV MSDDocument326 pagesBLK-1 LV MSDanbesivam87_49857255No ratings yet

- Commands Are Given With Description & Configuration Example All Configurations Are Extracted From Real World NetworkDocument12 pagesCommands Are Given With Description & Configuration Example All Configurations Are Extracted From Real World NetworkSivaraman AlagappanNo ratings yet

- Fmult/Accum: Low Resource Design ProposalDocument9 pagesFmult/Accum: Low Resource Design Proposalabhishek9126No ratings yet

- Cxc-2000pvr Service ManualDocument63 pagesCxc-2000pvr Service ManualGoran StojkovicNo ratings yet

- Edc SopDocument19 pagesEdc SopjamshedpurskechersNo ratings yet

- Technical - Bulletin - AWHP SW PRG Change Notification (CH29) - Rev.1.1 - 220117Document9 pagesTechnical - Bulletin - AWHP SW PRG Change Notification (CH29) - Rev.1.1 - 220117Fabian ArayaNo ratings yet

- Ups SystemDocument59 pagesUps Systemsuman_94103No ratings yet

- FOC2029N3V1Document2 pagesFOC2029N3V1RyanNo ratings yet

- NotesDocument3 pagesNotesmarvsvillanNo ratings yet

- PRD SonyInv 2000148693 20100220 LOCALDELIVERY SINDocument11 pagesPRD SonyInv 2000148693 20100220 LOCALDELIVERY SINAsdfg hjklNo ratings yet

- Manual Config OLT C320Document12 pagesManual Config OLT C320Achmad SholehanNo ratings yet

- LA693Document6 pagesLA693Juan Angel TESNo ratings yet

- Cooling Systems, Radiators & Associated Parts (C.V. OE & Aftermarket) World Summary: Market Values & Financials by CountryFrom EverandCooling Systems, Radiators & Associated Parts (C.V. OE & Aftermarket) World Summary: Market Values & Financials by CountryNo ratings yet

- Transportation Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryFrom EverandTransportation Equipment Wholesale Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- GIS RFP 12-05-2023-FinalDocument33 pagesGIS RFP 12-05-2023-FinalAMAR1980No ratings yet

- Master Pack SlipDocument2 pagesMaster Pack SlipAMAR1980No ratings yet

- Resume TejesvaniMVDocument1 pageResume TejesvaniMVAMAR1980No ratings yet

- RFB-IS-24200469 PH Centrify SWDocument21 pagesRFB-IS-24200469 PH Centrify SWAMAR1980No ratings yet

- View Bill 02282024Document10 pagesView Bill 02282024AMAR1980No ratings yet

- MUlti - Serial - Test DataDocument15 pagesMUlti - Serial - Test DataAMAR1980No ratings yet

- Request For Bid: Solicitation RFB-IS-24200422-1 Bid Due: 12/19/23 12:00:00 PMDocument24 pagesRequest For Bid: Solicitation RFB-IS-24200422-1 Bid Due: 12/19/23 12:00:00 PMAMAR1980No ratings yet

- Serial Numbers Detailed DataDocument307 pagesSerial Numbers Detailed DataAMAR1980No ratings yet

- Cart ManifestDocument1 pageCart ManifestAMAR1980No ratings yet

- Bol GT7Document1 pageBol GT7AMAR1980No ratings yet

- Vol 3 (Disbursing Fiscal) 20230419Document177 pagesVol 3 (Disbursing Fiscal) 20230419AMAR1980No ratings yet

- Transformation & Bundling Juniper Phase 2 (Order Creation 850 Split Logic For De-Bundling)Document3 pagesTransformation & Bundling Juniper Phase 2 (Order Creation 850 Split Logic For De-Bundling)AMAR1980No ratings yet

- Battery Recharge Rollout AOCDocument11 pagesBattery Recharge Rollout AOCAMAR1980No ratings yet

- Load Id Vendor Info Vendor Code 2266985 656118114 856 2115939 3021636 656035938 856 656118114Document2 pagesLoad Id Vendor Info Vendor Code 2266985 656118114 856 2115939 3021636 656035938 856 656118114AMAR1980No ratings yet

- SD Manual Bundling ProcessDocument6 pagesSD Manual Bundling ProcessAMAR1980No ratings yet

- Test Scenario ID DescDocument9 pagesTest Scenario ID DescAMAR1980No ratings yet

- Education, Honors, and Certifications: Dipal Medavarapu 14134 Mountain Ave.,Chino, CA 91710 PH: (201) 673-1437Document3 pagesEducation, Honors, and Certifications: Dipal Medavarapu 14134 Mountain Ave.,Chino, CA 91710 PH: (201) 673-1437AMAR1980No ratings yet

- Megan Wu: Work ExperienceDocument5 pagesMegan Wu: Work ExperienceAMAR1980No ratings yet

- (Priority - 11) (Priority - 1) : TablesDocument1 page(Priority - 11) (Priority - 1) : TablesAMAR1980No ratings yet

- ASUG Panel Deck - SAP AribaDocument24 pagesASUG Panel Deck - SAP AribaAMAR1980No ratings yet

- Arlington Heights, IL 60004 (847) 770-0984: Essential Duties/ResponsibilitiesDocument6 pagesArlington Heights, IL 60004 (847) 770-0984: Essential Duties/ResponsibilitiesAMAR1980No ratings yet

- Chesterfield Municipal LandfillDocument3 pagesChesterfield Municipal LandfillAMAR1980No ratings yet

- SCH Spring WeekendDocument6 pagesSCH Spring WeekendAMAR1980No ratings yet

- Asug U 2h2018 KeynoteDocument11 pagesAsug U 2h2018 KeynoteAMAR1980No ratings yet