Professional Documents

Culture Documents

Analysis of contaminants in oils and fats: heavy metals, PAHs, regulations and risks

Uploaded by

ediasianagriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of contaminants in oils and fats: heavy metals, PAHs, regulations and risks

Uploaded by

ediasianagriCopyright:

Available Formats

Contaminants in oils and fats:

analysis

l i andd regulations

l ti

Florence LACOSTE

l COS

ITERG

f lacoste@iterg com

f.lacoste@iterg.com

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013 1

ITERG

A synergy of competences services provided

Quality of Safety of

products

d t

Industrial environment

and Safety

• Analytical Controls

• Production, made‐to‐order refining

• Research and Development

Green chemistryy • Consulting, audit

Consulting audit

And process

• Watch and Information

• Professional Training

French CTI (Technical Industrial Center)

Technology Nutrition, Metabolism

Authorityy : French Ministryy of Industryy

R fi i

Refining and

d Health

H lth

Staff : 80

2012 Budget : 6M€

ISO 9001 V 2008 & ISO 17025

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

2

Contents

Heavy metals

Regulation ?

Polycyclic aromatic hydrocarbons

Polycyclic aromatic hydrocarbons

Recognized analytical methods ?

Mineral oil

Risks ?

Phthalates

Regulation Methods Risks

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

3

Origins of undesirable compounds

Environmental contamination

Environmental contamination Crop protection

i

metals, dioxins & PCBs, PAHs, pesticide residues, mineral oil

mineral oil

Production process

Transport & storage

& storage PAHs, mineral oil, phthalates,

PAHs, mineral oil, phthalates,

phthalates, mineral oil 3‐MCPD esters & glycidol esters

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

4

Heavy metals

Environmental contamination (air, soil)

Regulation & International Food Standard

Codex Standard 193‐1995

(EC) n

(EC) n°1881/2006

1881/2006 – contaminants in foodstuffs

contaminants in foodstuffs

Regulation Methods Risks

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

5

Metals : methods & regulations

graphite furnace Analytical methods

Hollow cathode

ISO 8294 Cu, Fe, Ni

ISO 8294 C F Ni

graphite furnace atomic ISO 15774 Cd

Prism absorption ISO 12193 Pb

inductively coupled plasma ISO/TS 21033 Cd, Pb,

optical emission

optical emission , ,

Cu, Fe, Ni

METALS Cd Pb Ni As Cr

LOQ atomic absorption

(mg/kg) 0,002 0,010 0,015 0,010 0,005

Regulation limit for oils ‐ 0,10

0 10 02

0,2 0,1

0 1 0,05

0 05

(mg/kg) EU&Codex France Codex France

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

6

Metals : occurrence in edible

oils & fats

Lead may be present in some cold‐pressed oils

Lead Cadmium

20 %

ITERG data (1992 ‐1999)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

7

Heavy metals transfer from soil

to rapeseed oil

Metals in the seeds are transferred to meals after seed crushing

Cd-rich urban sludge

Culture

Cu-rich urban sludge

0,09 mg/kg Cadmium

oilseeds

o seeds

3 09 mg/kg

3,09 /k CCopper

Drying , Crushing,

Extraction

ADEME Project – 1999/2001

meall crude

d oil

il

PROLEA

CETIOM

0,17 mg/kg Cadmium < 0,002 mg/kg Cadmium

6,13 mg/kg Copper 0,02 mg/kg Copper

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

8

Polycyclic

y y aromatic

hydrocarbons

Environmental contamination

Production process

Regulation

(EC) n°1881/2006 – contaminants in foodstuffs

Regulation Methods Risks

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

9

PAHs origins in vegetable oils

Oilseeds

Extraction Crude oil

+ * Grapeseed oil

HAP * Coconut oil

v * Pomace olive oil

* Sunflower oil

A ti carbon

Active b

PAHs Deodorisation

Light PAHs

Heavy PAHs

Refined oil

Drying (+ HAP)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

10

Structure of PAHs

naphthalene acenaphthene acenaphthylene fluorene phenanthrene anthracene

GT GT

LIGHT PAHs

fluoranthene pyrene benz(a)anthracene chrysene

GT GT GT GT

benzo(b)fluoranthene benzo(k)fluoranthene benzo(a)pyrene indeno(1 2 3 cd)pyrene

indeno(1,2,3‐cd)pyrene

GT GT

HEAVY PAHs

GT : genotoxic

dibenz(ah)anthracene benzo(ghi)perylene

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

11

PAHs regulation: (EC) n°1881/2006

contaminants in foodstuffs

Maximum Maximum Maximum

PAHs levels oils and levels coconut levels cocoa

fats (µg/kg)

fats (µg/kg) oil (µg/kg)

oil (µg/kg) butter (µg/kg)

butter (µg/kg)

Sum of 4 PAHs: 35,0

‐ benzo[a]pyrene from 1.4.2013

from 1.4.2013

‐ benz[a]anthracene 10,0 20,0 until 31.3.2015

‐ benzo[b]fluoranthene 30,0

‐ chrysene

h from 1.4.2015

5,0

benzo[a]pyrene 2,0 2,0

from 1.4.2013

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

12

PAHs: determination methods

Principle

PAH isolation: liquid chromatography (alumina, silica gel,C18‐silica gel) or

HPLC (donor‐acceptor complex chromatography, size‐exclusion chromatography)

Analysis: HPLC/fluorescence or GC/MS

ISO 15302 : benzo[a]pyrene in oils (LC + HPLC/FLD)

ISO 15753 : 12 PAHs in oils (2 SPE + HPLC/FLD)

ISO 22959 : 17 PAHs in oils (DACC on‐line + HPLC/FLD)

EN xxxx (JRC) : 4 PAHs in foodstuffs (SEC + SPE + GC/MS)

Method ISO 15302 ISO 15753 ISO 22959

BaP LOQ (µg/kg) 0,1 0,2 0,1

Reproducibility (CVR%) 27 % (2,1µg/kg) 41% (3,21µg/kg) 10 % (2,6µg/kg)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

13

PAHs: some difficult matrixes

ISO 15753

ISO 15753 :: sunflower

sunflower oil (1 µg/kg)

oil (1 µg/kg)

: reference solution (5 µg/kg)

(1) NA

(2) AC

11

(3) FL LU

5

200

12

(4) PHE

9

175

8

4

(5) ATR

7

150

14

4

0

10

2

125

(6) FA

13

100

(7) PY 75

15

6

50

(8) BaA

25

(9) CHR 0

0 5 10 15 20 25 30 35 min

(10) BbFA

(11) BkFA LU

: refined pomace olive oil

(12) BaP

: reference solution (5 µg/kg)

1000

(13) DBahA

800

(14) BghiP

600

(15) IP

11

12

400

13

5

3

14

8

10

4

7

6

200

15

1

0

0 5 10 15 20 25 30 35 40 min

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

14

Edible oils: PAH4 Levels

benzo(a)pyèrene

chrysène

Screening 2012 : 21 vegetable oils benz(a)anthracène

( )

benzo(b)fluoranthène

12

EU limit: 10 µg/kg

10

8

PAH4 en µg/kg

6

ITERG data (2012)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

15

Mineral oil

Environmental contamination (air, soil)

contamination (air soil)

Crop protection

Transport & storage

Transport & storage

Production process

Regulation

R l ti

(EC) n°1151/2009 ‐ import of sunflower oil from Ukraine

EFSA Scientific Opinion on Mineral Oil Hydrocarbons in food (2012)

EFSA Scientific Opinion on Mineral Oil Hydrocarbons in food (2012)

Regulation Methods Risks

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

16

Mineral oil composition

EFSA Scientific Opinion, 2012

Mineral oil: complex mixture of hydrocarbons

MOSH:

MOSH straight

i h or branched

b h d alkanes

lk & alkylated

lk l d cycloalkanes

l lk

MOAH: aromatic hydrocarbons including alkyl‐substituted

Hydrocarbon compound number in mineral oil > 100 000 for those

with less than 20 carbon atoms !

Different products & composition: diesel fuel, white oil, lubricant …

Technical grade mineral oil contain 15‐35 % MOAH, which is

minimised in food grade MOSH (white oils)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

17

Mineral oil detected in vegetable oils

2008 contamination of sunflower Natural

hydrocarbons

oil from Ukraine with a mineral oil

oil from Ukraine with a mineral oil

from unknown origin

2009 contamination of walnut oil Mineral oil :

with a food grade lubricant oil during unresolved

complex mixture

refining process

refining process

2010 identification of compounds

eluted as mineral oil in grapeseed oils

eluted as mineral oil in grapeseed oils

2011 contamination of milk fat

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

with a food grade lubricant oil during

ih f d d l bi il d i

Contaminated Sunflower oil (MOSH analysis)

production

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

18

MOSH determination: ISO/ CD 17880

Fractionation of the sample by liquid chromatography on

silica gel or silica gel impregnated with AgNO3

Q

Quantification with an internal standard (C18 or C20)

ifi i ih i l d d (C18 C20)

GC/FID analysis on an short apolar column

Vide

Vid

18,5 g Silicaa gel

1 g oil

On‐column injection (2 µl)

40°C DB5 HT (15 m‐0,25 mm‐0,1 µm)

Elution with hexane Solvent evaporation GC analysis

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

19

MOSH determination: critical points

Cross contamination to be avoided

Quantification of C10 to C50 without loosing the volatile hydrocarbons

Quantification of C10 to C50 without loosing the volatile hydrocarbons

Analysis of all types of samples (crude, refined, vegetable & animal oils & fats)

Limit of quantification as low as possible

Integration of the hump & subtraction of the “natural hydrocarbons”

It is necessary to integrate twice the chromatogram

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

20

Mineral oil determination:

ISO/ CD 17880 pre-collaborative trial

43 participants from 12 countries (2012) dispersed results

50 mg/kg spiked olive oil

50 mg/kg spiked olive oil 450 mg/kg spiked crude soya oil

450 mg/kg spiked crude soya oil

180 600

Lab mean value (mg/kg)

160

n value (mg//kg)

550

140

120 500

100

450

80

Lab mean

60 400

40

350

20

0 300

Laboratories Laboratories

sample olive oil crude soya oil

mean value (mg/kg)

mean value (mg/kg) 62 447

reproducibility (mg/kg) 49 153

Horrat value 3,3 1,9

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

21

Phthalates

T

Transport & storage

t& t

Production process

Regulation

EFSA Scientific Opinion on food additives, flavourings, processing aids and

p g p g

materials in contact with food (2005)

(EC) n°10/2011 ‐ plastic materials and articles intended to come into contact

with food

with food

R l ti

Regulation M th d

Methods Ri k

Risks

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

22

Chemical structures of phthalates

O Di-methyl PHT DMP R1=R2=methyl

C R1 Di th l PHT

Di-ethyl DEP R1 R2 h l

R1=R2=ethyl

O Di-isobutyl PHT DIBP R1=R2=isobutyl

O Di-butyl PHT DBP R1=R2=butyl

C

Di-hexyl PHT DHexP R1=R2=hexyl

O

R2 Benzyl butyl PHT BBP R1=benzyl R1=butyl

Di n heptyl PHT

Di-n-heptyl DHepP R1 R2 heptyl

R1=R2=heptyl

Di-(2-ethyl hexyl) PHT DEHP R1=R2=ethyl‐2 hexyl

DEHP Di-n-octyl PHT DNOP R1=R2=octyl

Oily visquous liquid Di-isononyl PHT DINP R1=R2= isononyl

MW: 390,6 g/mol Di-isodecyl PHT DIDP R1=R2=isodecyl

BP: 385°C

BP: 385 C

Water solubility: 3 µg/l

High affinity for fat (log Kow : 7,5)

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

23

Phthalates are everywhere

Toys Shoes‐Boots‐Gloves

Car undercoating

Car undercoating

Child‐care articles Out‐door & rainwear

Dashboard‐Door

panels‐Safety glass

Cosmetics : Perfume

Flooring‐Roofing‐

Flooring Roofing Wall covering

Wall covering Hairspray‐Deodorant Pharmaceuticals

Ph ti l

Adhesives‐Sealant‐Rubber Skin emollient‐nail polish Medical devices :

Paints‐Shower curtains fingernail elongators Catheters‐Blood bag

Wires & cables‐Fresheners

Wires & cables Fresheners

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

24

(EC) n°10/2011 - Plastic materials &

articles into contact with food

Specific migration

Specific migration

T b

To be used as

d

limit in food

BBP 30 mg/kg

Plasticizer

Pl ti i in single‐use material containing non‐fatty

i i l t i l t i i f tt

DINP

∑ = 9 mg/kg foods except infant formulae

DIDP

DEHP 1,5 mg/kg Plasticizer in repeated use materials containing non‐

DBP 0,3 mg/kg fatty foods

Material containing these phthalates cannot

be used for oils & fats

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

25

DEHP migration in rapeseed oil

Chromatogram Plots t bi )

(PVC tubing)

MCounts 10-03-2009-05-37-56-CO raff.SMS TIC Filtered

50:249

ITERG data, 2008 Rapeseed oil before migration

75

7.5

SPME/GC/MS

SPME/GC/MS

5.0

2.5

DEHP (DIOP)

+ 23.939 min

26.078 min

21.028 min

17.176 min

16.239 min

11.608 min

13.274 min

DNOP

DHexP

DIBP

DBP

DMP

DEP

0.0

MCounts 10 03 2009 08 10 47 CO raff

10-03-2009-08-10-47-CO ff + ttuyau.SMS

SMS TIC Filt

Filtered

d

50:249

Rapeseed oil after immersion of PVC tubing

23.942 min

DNHepP

7.5

DEHP

5.0

2.5

26.002 min

+ 17.173 min

26.099 min

21.115 min

21.320 min

15.074 min

11.582 min

13.272 min

DNOP

DHexP

DIDP

BBP

DBP

DMP

DBA

DEP

0.0

10 15 20 25 30

minutes

Oil sample kept in a bottling machine tub

p p g 3 825 mg/kg of DEHP !

g/ g

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

26

Phthalates: ITERG’s procedure

m/z 111 (adipates)

GC/MS m/z 149 (phthalates)

5 50:500

DNPP

PDMS

DBP

4 DEHP

DHexP

DMP

3

1 g oil DEP

DNOP

DB5ms 2

(30 m; 0,25 mm; 0,25 µm) 1

HS SPME

HS SPME A l i

Analysis 0

7.5 10.0 12.5 15.0 17.5 20.0 22.5 25.0

minutes

kCounts

200

Advantages of the method : 150

100 DINP

No contamination, no solvent

50 DIDP

Rapid analysis (45 min) 0

25 26 27 28 29 minute

30

Sensitive LOQ < 0,1 mg/kg (excepted DINP & DIDP) s

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

27

DEHP in oils & fats

43

5

mg/kg

4

ITERG data, 2009

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

28

Conclusions

• Research of contaminants is part of multiple controls conducted by

fat and oil industry to fulfill the EC regulation n°1881/2006.

• In the absence of regulation, the detection of contaminants must

be addressed in partnership with authorities according to the

toxicity of molecules.

• Risks are rather limited due to the efficient elimination during oil‐

refining steps

• H

However some contaminants

i can be

b formed

f d during

d i theh production

d i

process of vegetable oils such as esters of 3‐MCPD & esters of

g y

glicydol.

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

29

A special

p thanks to….

ITERG Analysis Department team

COMPOSITIONAL ANALYSIS OF LIPIDS – Ghent – 20‐21 June 2013

30

You might also like

- CHM23 03 LSDocument4 pagesCHM23 03 LSDaniel ChooNo ratings yet

- Cassava Starch SpecificationDocument5 pagesCassava Starch SpecificationTarekegn GaromsaNo ratings yet

- Win PPB 10-000 (RoHS 4 สาร WIN PPB INK)Document3 pagesWin PPB 10-000 (RoHS 4 สาร WIN PPB INK)fazlul hoqueNo ratings yet

- SM00000026400 SIMPERM GREEN G (PG7) SIPL 26400 TDS Rev 5Document3 pagesSM00000026400 SIMPERM GREEN G (PG7) SIPL 26400 TDS Rev 5pqmnvnbsynfoushaetNo ratings yet

- Substances - Limits - Testing MethodsDocument18 pagesSubstances - Limits - Testing MethodsKurt ChenNo ratings yet

- AG2 Index of Preferred Methods May2021 v4Document75 pagesAG2 Index of Preferred Methods May2021 v4nureNo ratings yet

- MR Zafer Sarsar - President & Ceo Allied Resourcing Company (Offshore) S.A.LDocument3 pagesMR Zafer Sarsar - President & Ceo Allied Resourcing Company (Offshore) S.A.LFantania BerryNo ratings yet

- ID-411 OKI and Similar Standards enDocument2 pagesID-411 OKI and Similar Standards enSiddharthBhasneyNo ratings yet

- Product Environmental Profile: XS8C40PC440 Inductive Proximity SwitchDocument4 pagesProduct Environmental Profile: XS8C40PC440 Inductive Proximity SwitchhafinNo ratings yet

- Product Environmental Profile: XS8C40PC440 Inductive Proximity SwitchDocument4 pagesProduct Environmental Profile: XS8C40PC440 Inductive Proximity SwitchSamuelNo ratings yet

- Spectra Solutions SDN, BHD (Malaysia)Document3 pagesSpectra Solutions SDN, BHD (Malaysia)Fantania BerryNo ratings yet

- 100% Irrevocable Transferable Letter of Credit / SBLC at Sight (Non PB Is Released)Document3 pages100% Irrevocable Transferable Letter of Credit / SBLC at Sight (Non PB Is Released)Fantania BerryNo ratings yet

- Acc Scope NAL 056 - 2022Document9 pagesAcc Scope NAL 056 - 2022mezghichebiovitalNo ratings yet

- FCO For China & Middle EastDocument3 pagesFCO For China & Middle EastFantania BerryNo ratings yet

- 2020-Majestic Primer-TEST REPORT FOR GREEN LABELDocument4 pages2020-Majestic Primer-TEST REPORT FOR GREEN LABELphan tuan datNo ratings yet

- Iso 3188 1978Document8 pagesIso 3188 1978pratita ameliaNo ratings yet

- 023101.101 Hardness CorrectionDocument5 pages023101.101 Hardness CorrectionGiorgi GhambashidzeNo ratings yet

- TDS V-Pigment Yellow 83Document3 pagesTDS V-Pigment Yellow 83Arifin HNNo ratings yet

- 16-SOUTH AFRICA 2014-09 Monitoring of Facility-Level GHG EmissionsDocument28 pages16-SOUTH AFRICA 2014-09 Monitoring of Facility-Level GHG EmissionsKhoa Nguyen DangNo ratings yet

- nose bar certificateDocument5 pagesnose bar certificateMamdouhNo ratings yet

- LORODAC 6-24: Product DescriptionDocument3 pagesLORODAC 6-24: Product Descriptions0n1907No ratings yet

- RPT 12 07Document118 pagesRPT 12 07CHRISTOS KALOUDISNo ratings yet

- DIN ISO EEC EC Normen Blatt Fur Kjeldahl Solutions LOW 0Document2 pagesDIN ISO EEC EC Normen Blatt Fur Kjeldahl Solutions LOW 0Giang Lê HươngNo ratings yet

- Hpi Brochure Ssi November2018 PDFDocument8 pagesHpi Brochure Ssi November2018 PDFSami AhmadNo ratings yet

- Việt Nguyễn Company Profile Ver2 - CompressedDocument65 pagesViệt Nguyễn Company Profile Ver2 - Compressedtu.vietnguyencoNo ratings yet

- Attachment 0Document10 pagesAttachment 0Buyung MaulanaNo ratings yet

- ISO Standards in ProcessDocument20 pagesISO Standards in ProcessYeni OktaviaNo ratings yet

- 9 PIS Asam BateraiDocument2 pages9 PIS Asam BateraiRidwan Dzi Angel PieceNo ratings yet

- Biodiesel, Analytical Aspects: Florence LACOSTE, Lionel LAGARDERE Institut Des Corps Gras, Rue Monge, Pessac (France)Document9 pagesBiodiesel, Analytical Aspects: Florence LACOSTE, Lionel LAGARDERE Institut Des Corps Gras, Rue Monge, Pessac (France)BijayNo ratings yet

- Advance in The Determination of Chemical Oxygen DemandDocument32 pagesAdvance in The Determination of Chemical Oxygen DemandDawit FiremichaelNo ratings yet

- Specification and Trading of EthanolDocument22 pagesSpecification and Trading of EthanolusergarciaNo ratings yet

- BAT WTbref PDFDocument851 pagesBAT WTbref PDFJoter007No ratings yet

- Jotaplast Test ReportDocument4 pagesJotaplast Test ReporttatanuzullaNo ratings yet

- Catalytic Oxidation Techology - Sud Chemie (Very Good)Document25 pagesCatalytic Oxidation Techology - Sud Chemie (Very Good)daraj darajNo ratings yet

- Johnson Matthey - Mercury Removal in Oil & GasDocument33 pagesJohnson Matthey - Mercury Removal in Oil & GasSo NicNo ratings yet

- Johnson Matthey - Mercury Removal in Oil & Gas PDFDocument33 pagesJohnson Matthey - Mercury Removal in Oil & Gas PDFSo NicNo ratings yet

- IGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1Document12 pagesIGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1KHALED KHALEDNo ratings yet

- Moving Towards International Standards in The Oil and Gas IndustryDocument17 pagesMoving Towards International Standards in The Oil and Gas IndustrySayed Saad ShehataNo ratings yet

- 20312e00 Guidelines For Chemical Treatments of PipelinesDocument68 pages20312e00 Guidelines For Chemical Treatments of Pipelinesamra_41100% (4)

- Ministry of Health of Malaysia Guidelines On The Safe Used of Processing AidsDocument21 pagesMinistry of Health of Malaysia Guidelines On The Safe Used of Processing AidsklkeoNo ratings yet

- CE Test ReportDocument14 pagesCE Test ReportCamilo WispNo ratings yet

- Innovative Refining Technology - Crude Oil Quality Improvement (Coqi®)Document6 pagesInnovative Refining Technology - Crude Oil Quality Improvement (Coqi®)scribd_thakurNo ratings yet

- Product Specifications: Cagliata Cheese 45% Fat inDocument2 pagesProduct Specifications: Cagliata Cheese 45% Fat inJason ThorntonNo ratings yet

- Propylene Oxide Handling and Storage Considerations: Technical BulletinDocument4 pagesPropylene Oxide Handling and Storage Considerations: Technical BulletinHari SimhaNo ratings yet

- BAR Reference For Waste IncinerationDocument764 pagesBAR Reference For Waste IncinerationmayangNo ratings yet

- Corrosion CertificateDocument2 pagesCorrosion CertificateCruseenvirotechNo ratings yet

- 2 Presentation Dr. Pankaj DesaiDocument37 pages2 Presentation Dr. Pankaj DesaiMitesh ShahNo ratings yet

- ERM-CC144 Report PDFDocument79 pagesERM-CC144 Report PDFAndres Julian Montoya EstradaNo ratings yet

- Model FXDocument2 pagesModel FXManuel100% (1)

- Determination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsDocument19 pagesDetermination of Volatile and Semi-Volatile Organic Compounds From Vehicle Interior MaterialsJefferson CruzNo ratings yet

- Webinar MaduDocument27 pagesWebinar MadudandydarmawanNo ratings yet

- Basic Gas Processing & Conditioning - 1. General Introduction of NGDocument31 pagesBasic Gas Processing & Conditioning - 1. General Introduction of NGirawan ardiansyahNo ratings yet

- 692489003 电镀RoHS报告 20220818Document4 pages692489003 电镀RoHS报告 20220818Toan Cao0% (1)

- Safety Hiblack 30LDocument3 pagesSafety Hiblack 30Lalfa twoNo ratings yet

- BIOFIT - Ukraine 10 Nov 2021 - 3 - GBA - Biomethane Market in GermanyDocument28 pagesBIOFIT - Ukraine 10 Nov 2021 - 3 - GBA - Biomethane Market in GermanyAnna YaroshenkoNo ratings yet

- Hindustan Chemicals Co Srt40 Exe Summ EngDocument16 pagesHindustan Chemicals Co Srt40 Exe Summ EngHarshNo ratings yet

- Product Specifications: Skim Milk PowderDocument2 pagesProduct Specifications: Skim Milk PowderJason ThorntonNo ratings yet

- Specification Sheet: Luong Quoi Coconut Co., LtoDocument2 pagesSpecification Sheet: Luong Quoi Coconut Co., LtoNguyễn Tiến DũngNo ratings yet

- CA-BA-Chemistry Basic KnowledgeDocument42 pagesCA-BA-Chemistry Basic Knowledgevikasverma90No ratings yet

- Kema B.V. Metering, Protection & Substation Automation LaboratoryDocument9 pagesKema B.V. Metering, Protection & Substation Automation LaboratoryediasianagriNo ratings yet

- Head Office: In-House MethodDocument8 pagesHead Office: In-House MethodediasianagriNo ratings yet

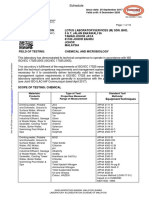

- Accredited lab testing scopeDocument4 pagesAccredited lab testing scopeediasianagriNo ratings yet

- Concrefy B.V. LaboratoryDocument7 pagesConcrefy B.V. LaboratoryediasianagriNo ratings yet

- L210 SceDocument1 pageL210 SceediasianagriNo ratings yet

- L220 SceDocument6 pagesL220 SceediasianagriNo ratings yet

- Vitamin D 1.0 Mio IU/G: Chemical Name of Active IngredientDocument2 pagesVitamin D 1.0 Mio IU/G: Chemical Name of Active IngredientediasianagriNo ratings yet

- Common or Usual Name Scienti C NameDocument3 pagesCommon or Usual Name Scienti C NameediasianagriNo ratings yet

- Eurofins Lab Zeeuws Vlaanderen (LZV) B.VDocument4 pagesEurofins Lab Zeeuws Vlaanderen (LZV) B.VediasianagriNo ratings yet

- Iso TS 23647 2010Document11 pagesIso TS 23647 2010ediasianagriNo ratings yet

- Shellife PredictionDocument16 pagesShellife PredictionediasianagriNo ratings yet

- Shelf Life Prediction of Edible Cotton Peanut and Soybean Seed Oils Using An Empirical Model Based On Standard Quality TestsDocument19 pagesShelf Life Prediction of Edible Cotton Peanut and Soybean Seed Oils Using An Empirical Model Based On Standard Quality TestsediasianagriNo ratings yet

- SAMM 384 ScheduleDocument25 pagesSAMM 384 ScheduleediasianagriNo ratings yet

- Physikalische EigenschaftenDocument29 pagesPhysikalische EigenschaftenZen AlkaffNo ratings yet

- LP 1272 IdnDocument1 pageLP 1272 IdnediasianagriNo ratings yet

- SDS Food Grade Refined Vegetable OilsDocument4 pagesSDS Food Grade Refined Vegetable OilsYahya Ardian100% (1)

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriNo ratings yet

- NO: SAMM 188: Issue Date: 7 March 2018 Valid Until: 18 April 2021Document38 pagesNO: SAMM 188: Issue Date: 7 March 2018 Valid Until: 18 April 2021ediasianagriNo ratings yet

- Trans Fat Substitutes Reviewed for Food ApplicationsDocument15 pagesTrans Fat Substitutes Reviewed for Food ApplicationsediasianagriNo ratings yet

- ISO Certified Chemical Testing Lab ScheduleDocument6 pagesISO Certified Chemical Testing Lab ScheduleediasianagriNo ratings yet

- Palm Oil SDS Safety SummaryDocument7 pagesPalm Oil SDS Safety SummaryediasianagriNo ratings yet

- Reg PreserveDocument18 pagesReg PreserveediasianagriNo ratings yet

- A Blood Analysis Lab ProtocolDocument51 pagesA Blood Analysis Lab ProtocolediasianagriNo ratings yet

- Palm Oil SDS Safety SummaryDocument7 pagesPalm Oil SDS Safety SummaryediasianagriNo ratings yet

- FELDA Analytical Lab, FELDA Agricultural Services SBDocument14 pagesFELDA Analytical Lab, FELDA Agricultural Services SBediasianagriNo ratings yet

- ISO/IEC 17025 Accredited Chemical and Microbiology Testing ScheduleDocument16 pagesISO/IEC 17025 Accredited Chemical and Microbiology Testing ScheduleediasianagriNo ratings yet

- Laboratory Accreditation ScheduleDocument35 pagesLaboratory Accreditation ScheduleediasianagriNo ratings yet

- IUPAC Standard Method-OilDocument151 pagesIUPAC Standard Method-OilAbu Kansha33% (3)

- Sorbitol PDFDocument11 pagesSorbitol PDFdaniNo ratings yet

- 3204-9-Resource Use and SustainabilityDocument25 pages3204-9-Resource Use and SustainabilityKezia NatashaNo ratings yet

- VW Golf 7 2015 Suspension Steering EngDocument375 pagesVW Golf 7 2015 Suspension Steering Engcloantaf100% (1)

- Bitumen Water ProofingDocument23 pagesBitumen Water ProofingAkshthagowda848_1952No ratings yet

- Book Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayDocument2 pagesBook Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayPDNo ratings yet

- E32-433T30D User Manual: Sx1278 433Mhz 1W Dip Wireless ModuleDocument22 pagesE32-433T30D User Manual: Sx1278 433Mhz 1W Dip Wireless ModuleSergey SevruginNo ratings yet

- Integral CalculusDocument48 pagesIntegral CalculusVincent CortezNo ratings yet

- Wall Mountable Switches - Wall Mounting GuideDocument3 pagesWall Mountable Switches - Wall Mounting GuideMarcos FilipeNo ratings yet

- Grundfos CR 5 4 A A A e HqqeDocument10 pagesGrundfos CR 5 4 A A A e HqqePrejit RadhakrishnaNo ratings yet

- Attachment No 2 PDFDocument10 pagesAttachment No 2 PDFTusharRoyNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Premal PatelNo ratings yet

- 52 Blower StoryDocument7 pages52 Blower StoryBentley SpottingNo ratings yet

- Model146C DynamicGasCal 156file - 18125Document150 pagesModel146C DynamicGasCal 156file - 18125api-26966403100% (1)

- Man and Mystery Vol 13 - Monsters and Cryptids (Rev06)Document139 pagesMan and Mystery Vol 13 - Monsters and Cryptids (Rev06)Pablo Jr AgsaludNo ratings yet

- MiG 21Document29 pagesMiG 21Zoran Vulovic100% (2)

- Effect of Blast Induced Vibrations On GroutDocument55 pagesEffect of Blast Induced Vibrations On GroutDavid marpaungNo ratings yet

- SignaLink USB Product Guide - 02.2018Document22 pagesSignaLink USB Product Guide - 02.2018Rafael D. B. AnellaNo ratings yet

- The Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsDocument4 pagesThe Mini Percutaneous Nephrolithotomy (Mini-PCNL) and Percutaneous Nephrolithotomy (PCNL) in Pediatric PatientsMarius DanilaNo ratings yet

- The Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierDocument1 pageThe Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierAzrinshah Abu BakarNo ratings yet

- Computer Education ModuleDocument22 pagesComputer Education ModuleJulia Melissa CzapNo ratings yet

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (1)

- NIA045462022 KL 13 AR 1130 Royal Enfield Motors LTD Classic X 350 ESDocument10 pagesNIA045462022 KL 13 AR 1130 Royal Enfield Motors LTD Classic X 350 ESAkhil DasNo ratings yet

- Power Grid Corporation of India Limited Construction ManagementDocument8 pagesPower Grid Corporation of India Limited Construction ManagementRahul RanjanNo ratings yet

- SP 5300DN SP 5310DN SÑljguideDocument32 pagesSP 5300DN SP 5310DN SÑljguidepaypkerry_179706015No ratings yet

- Ship Construction IonsDocument25 pagesShip Construction Ionsanon-49038083% (6)

- Chip Mong Noro Mall: Property OverviewDocument4 pagesChip Mong Noro Mall: Property OverviewHe VansakNo ratings yet

- Des 415 Research 01Document29 pagesDes 415 Research 01Just scribble me For funNo ratings yet

- PHYS205 Matlab Lab TasksDocument4 pagesPHYS205 Matlab Lab TasksjacobNo ratings yet

- Acute Pain - Mastectomy - Breast CADocument2 pagesAcute Pain - Mastectomy - Breast CAAngie MandeoyaNo ratings yet

- 5 Commandments of DatingDocument8 pages5 Commandments of DatingBariki MwasagaNo ratings yet