Professional Documents

Culture Documents

Fig909 No Thread Swivel Sway Brace Attachment TOLCO

Uploaded by

Edwin G Garcia ChCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fig909 No Thread Swivel Sway Brace Attachment TOLCO

Uploaded by

Edwin G Garcia ChCopyright:

Available Formats

Seismic Transitional Attachments

Fig. 909 - No-Thread Swivel Sway Brace Attachment

Component of State of

Size Range: 1" (25mm) bracing pipe. For brace pipe sizes larger than California OSHPD Approved

1" (25mm), use Fig. 980. Available with holes for 3⁄8”-16 thru 3⁄4”-10 fastener Seismic Restraints System

attachment.

Material: Steel, hardened cone point set screw

Function: The structural component of a sway and seismic bracing system.

Features: This product’s design incorporates a concentric

attachment opening which is critical to the performance of structural

seismic connections. NFPA 13 (2010) 9.3.5.8.4 indicates clearly that

fastener table load values are based only on concentric loading. No

threading of the bracing pipe is required. Open design allows for easy

inspection of pipe engagement.

D

Application Note: Fig. 909 is used in conjunction with the Fig. 1000,

Fig. 1001, Fig. 4 (A) or Fig. 4L pipe clamp, and joined together with bracing

pipe. Sway brace assemblies are intended to be installed in accordance with

NFPA 13 (or our State of California OSHPD Approved Seismic Restraint Set Screw A

Manual) and the manufacturer’s installation instructions. The required type, Included

B

number and size of fasteners used for the structure attachment fitting shall

be in accordance with NFPA 13 and/or OSHPD.

Mounting Hardware

Approvals: Underwriters Laboratories Listed in the USA (UL) Is Not Included

and Canada (cUL). Included in our Seismic Restraints Catalog

approved by the State of California Office of Statewide Health

Seismic Transitional

Planning and Development (OSHPD). For additional load, spacing

and placement information relating to OSHPD projects, please refer

Attachments

to our Seismic Restraint Systems Guidelines.

Installation Instructions: Fig. 909 is the structural or transitional

attachment component of a longitudinal or lateral sway brace

assembly. It is intended to be combined with the "bracing pipe"

and our "braced pipe" attachment, Fig. 1000, 1001, 4A, 4B or 4L to form a

complete bracing assembly.

NFPA 13 and/or OSHPD guidelines should be followed.

To Install: Place the Fig. 909 onto the bracing pipe. Tighten the set screw

until the head bottoms out on surface. Attachment can pivot for adjustment

to proper brace angle.

Finish: Plain. Contact B-Line for alternative finishes and materials.

Order By: Figure number, fastener attachment size and finish.

Part Hole Size Max. Horizontal Approx.

Number D* A B Design Load (UL) Wt./100

in. (mm) in. (mm) in. (mm) lbs. (kN) lbs. (kg)

909-3/8 13/32” (10.3) 6” (152.4) 15/8” (41.3) 2015 (8.96) 92 (41.7)

909-1/2 17/32” (13.5) 6” (152.4) 15/8” (41.3) 2015 (8.96) 91 (41.3)

909-5/8 11/16” (17.5) 6” (152.4) 15/8” (41.3) 2015 (8.96) 90 (40.8)

909-3/4 13/16” (20.6) 6” (152.4) 15/8” (41.3) 2015 (8.96) 89 (40.4)

Eaton’s B-Line Business seismic bracing components are designed to be compatible only with other B-Line bracing components,

resulting in a listed seismic bracing assembly. B-Line’s warranty for seismic bracing components will be the warranty provided in

B-Line’s standard terms and conditions of sale made available by B-Line, except that, in addition to the other exclusions from

B-Line’s warranty, Eaton’s B-line Business makes no warranty relating to B-Line’s seismic bracing components that are combined

with products not provided by Eaton’s B-Line Business.

All dimensions in charts and on drawings are in inches. Dimensions shown in parentheses are in millimeters unless otherwise specified.

45 Seismic Bracing Products

You might also like

- Kohler Comand PRO CV940 - CV1000 Service ManualDocument72 pagesKohler Comand PRO CV940 - CV1000 Service Manualabduallah muhammadNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Audi A6 C5 FR Wheel Bearing ServicingDocument73 pagesAudi A6 C5 FR Wheel Bearing ServicingtonifausnNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

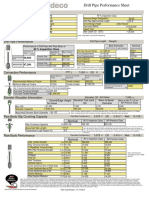

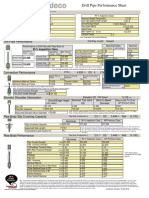

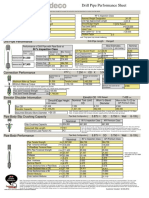

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Kawasaki Versys Service ManualDocument20 pagesKawasaki Versys Service Manualrobyn100% (56)

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Drill Pipe Performance Data SheetDocument3 pagesDrill Pipe Performance Data SheetGarcia C L Alberto100% (1)

- Manual de Mantenimiento de Gruas Jib PDFDocument20 pagesManual de Mantenimiento de Gruas Jib PDFalejandroaleman53No ratings yet

- Brinkman 4435 Owners ManualDocument36 pagesBrinkman 4435 Owners ManualslipsittinNo ratings yet

- RoadStar XV16A Service ManualDocument456 pagesRoadStar XV16A Service Manualsimeonov83100% (2)

- Sae J1102M 2001 (En)Document5 pagesSae J1102M 2001 (En)Oh No PotatoNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Pipe Supports Standards GuideDocument19 pagesPipe Supports Standards GuideoliveiralauroNo ratings yet

- Lokotrack LT1213 component listDocument368 pagesLokotrack LT1213 component listCarlos Israel Gomez67% (6)

- Manual de Partes LDW1003 (6B01E0)Document54 pagesManual de Partes LDW1003 (6B01E0)Enrique AssmannNo ratings yet

- Drill pipe performance and operational limitsDocument3 pagesDrill pipe performance and operational limitsGarcia C L AlbertoNo ratings yet

- 19.ball Valve 9 and 3 PDFDocument4 pages19.ball Valve 9 and 3 PDFShabirNo ratings yet

- Interacting SubframeDocument11 pagesInteracting SubframePatricio G. ArrienNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Drill Pipe Performance and SpecificationsDocument3 pagesDrill Pipe Performance and SpecificationsИнженер Луис А. ГарсиаNo ratings yet

- Asahi Pentax Spotmatic Shutter and Film Mechanism ManualDocument51 pagesAsahi Pentax Spotmatic Shutter and Film Mechanism Manualmamamojo100% (1)

- Clinical and Laboratory Manual of Dental Implant AbutmentsFrom EverandClinical and Laboratory Manual of Dental Implant AbutmentsRating: 3 out of 5 stars3/5 (2)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- SKF Oil PumpDocument48 pagesSKF Oil Pumpjrgonzales24No ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- ISO7005!2!1988Metallicflanges - Part2 CastironflangesDocument39 pagesISO7005!2!1988Metallicflanges - Part2 Castironflangesyonggang duNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Bolting ProcedureDocument3 pagesBolting ProcedureJonathan MartinezNo ratings yet

- Pipe Clamp For Sway Bracing TOLCODocument1 pagePipe Clamp For Sway Bracing TOLCOEdwin G Garcia ChNo ratings yet

- Figura 906 - para AlmacenDocument1 pageFigura 906 - para AlmacenAlejandro Chumpitaz MarchanNo ratings yet

- Fig 980Document2 pagesFig 980FRANCISCO JAVIER JIMENEZ JIMENEZNo ratings yet

- Figura 980Document1 pageFigura 980YoniNo ratings yet

- Soporte Antisísmico Figura 909Document1 pageSoporte Antisísmico Figura 909Carlitos Way Golden BrainNo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Seismic TolcoDocument24 pagesSeismic TolcoJaider CamachoNo ratings yet

- 907 PDFDocument1 page907 PDFAlvaro Quispe MedinaNo ratings yet

- SB Sway Brace AttachmentDocument2 pagesSB Sway Brace Attachmentrvalentino2012No ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Fig. 910 - Swivel Sway Brace FittingDocument1 pageFig. 910 - Swivel Sway Brace FittingANTONIO GUTIERREZ MIRANDANo ratings yet

- Seismic Structural Attachments: Tolco Fig. 69 - Beam Clamp Retaining StrapDocument17 pagesSeismic Structural Attachments: Tolco Fig. 69 - Beam Clamp Retaining StrapUcok DedyNo ratings yet

- Seismic Bracing: Fig. 907 - 4-Way Longitudinal Sway Brace AttachmentDocument1 pageSeismic Bracing: Fig. 907 - 4-Way Longitudinal Sway Brace AttachmentNethajiNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Fig 980Document1 pageFig 980Steve CamposNo ratings yet

- Engineering SWL for falsework rounderDocument3 pagesEngineering SWL for falsework rounderNicholasy FungNo ratings yet

- General Instructions - Rotors Ight ControlsDocument5 pagesGeneral Instructions - Rotors Ight Controlsrama AmeesNo ratings yet

- 825A TolcoDocument1 page825A TolcoANTONIO GUTIERREZ MIRANDANo ratings yet

- Ancon Tapered Thread Couplers International VersionDocument16 pagesAncon Tapered Thread Couplers International VersionRanjan SinghNo ratings yet

- Soporte Antisísmico Fig910Document1 pageSoporte Antisísmico Fig910Michael IturraNo ratings yet

- Catalog - H Hydraulic Setting ToolDocument1 pageCatalog - H Hydraulic Setting ToolCarlos Alberto Aguilera MendezNo ratings yet

- Sanitary Catalog 2012Document36 pagesSanitary Catalog 2012Murugaraj SelvarajNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Memo 097.7 - 103019 - Item 455 Steel RibsDocument5 pagesMemo 097.7 - 103019 - Item 455 Steel RibsBai Alleha MusaNo ratings yet

- Vibration Isolation and Seismic Restraints For Fire ProtectionDocument4 pagesVibration Isolation and Seismic Restraints For Fire Protectionabdullah sahibNo ratings yet

- Fig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCODocument1 pageFig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCOEdwin G Garcia ChNo ratings yet

- Seismic: Contractors & Industrial Supply, IncDocument12 pagesSeismic: Contractors & Industrial Supply, Incjorge1238No ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- Minidropin 1Document4 pagesMinidropin 1Juan Carlos MendezNo ratings yet

- Special Specification 6315 Self Supporting Radio TowerDocument10 pagesSpecial Specification 6315 Self Supporting Radio TowerECiiNo ratings yet

- 03 38 16 - Post-Tensioned ConcreteDocument9 pages03 38 16 - Post-Tensioned ConcreteAnonymous swFolM3gXNo ratings yet

- 2017 Bridge Lee.JDocument11 pages2017 Bridge Lee.JKari ConwayNo ratings yet

- MDCM PDFDocument4 pagesMDCM PDFAhmed Emad AhmedNo ratings yet

- OPSS 903 - Nov09Document28 pagesOPSS 903 - Nov09umerfr2No ratings yet

- OPSS - PROV 903 Apr16Document24 pagesOPSS - PROV 903 Apr16Mark PermaulNo ratings yet

- Seismic Design Guide (2010)Document102 pagesSeismic Design Guide (2010)ingcarlosgonzalezNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- P1042-10L Power Strip LEVITONDocument2 pagesP1042-10L Power Strip LEVITONEdwin G Garcia ChNo ratings yet

- Product Spec or Info Sheet - ODC0S-I1W Pasive SensorDocument2 pagesProduct Spec or Info Sheet - ODC0S-I1W Pasive SensorEdwin G Garcia ChNo ratings yet

- Leviton 41290-HDx MOS HDMI ModuleDocument1 pageLeviton 41290-HDx MOS HDMI ModuleEdwin G Garcia ChNo ratings yet

- Product Spec or Info Sheet - ODC0S-I1WDocument2 pagesProduct Spec or Info Sheet - ODC0S-I1WEdwin G Garcia ChNo ratings yet

- Product Spec or Info Sheet - ODC0S-I1W Pasive SensorDocument2 pagesProduct Spec or Info Sheet - ODC0S-I1W Pasive SensorEdwin G Garcia ChNo ratings yet

- Product Spec or Info Sheet - ODC0S-I1WDocument2 pagesProduct Spec or Info Sheet - ODC0S-I1WEdwin G Garcia ChNo ratings yet

- P1042-10L Power Strip LEVITONDocument2 pagesP1042-10L Power Strip LEVITONEdwin G Garcia ChNo ratings yet

- Leviton 41293-HDx HD15 MOS ModuleDocument2 pagesLeviton 41293-HDx HD15 MOS ModuleEdwin G Garcia ChNo ratings yet

- 5500-192 Power Strip LEVITONDocument3 pages5500-192 Power Strip LEVITONEdwin G Garcia ChNo ratings yet

- Leviton 41290-XMx SS MOS WallplatesDocument2 pagesLeviton 41290-XMx SS MOS WallplatesEdwin G Garcia ChNo ratings yet

- 5500-192 Power Strip LEVITONDocument3 pages5500-192 Power Strip LEVITONEdwin G Garcia ChNo ratings yet

- Data Sheet - GreenMAX Digital SwitchesDocument2 pagesData Sheet - GreenMAX Digital SwitchesSamuel Castro SedanoNo ratings yet

- Leviton 41290-XMx SS MOS WallplatesDocument2 pagesLeviton 41290-XMx SS MOS WallplatesEdwin G Garcia ChNo ratings yet

- Data Sheet - GreenMAX Digital SwitchesDocument2 pagesData Sheet - GreenMAX Digital SwitchesSamuel Castro SedanoNo ratings yet

- Leviton 62460-Xxx EXtreme CAT 6p UTP Patch CordDocument2 pagesLeviton 62460-Xxx EXtreme CAT 6p UTP Patch CordEdwin G Garcia ChNo ratings yet

- Leviton 41293-HDx HD15 MOS ModuleDocument2 pagesLeviton 41293-HDx HD15 MOS ModuleEdwin G Garcia ChNo ratings yet

- Leviton 62460-Xxx EXtreme CAT 6p UTP Patch CordDocument2 pagesLeviton 62460-Xxx EXtreme CAT 6p UTP Patch CordEdwin G Garcia ChNo ratings yet

- Seismic Bracing Products: For Mechanical, Electrical & Plumbing SystemsDocument132 pagesSeismic Bracing Products: For Mechanical, Electrical & Plumbing SystemsEdwin G Garcia ChNo ratings yet

- Seg 12Document386 pagesSeg 12Edwin G Garcia ChNo ratings yet

- Leviton 41290-HDx MOS HDMI ModuleDocument1 pageLeviton 41290-HDx MOS HDMI ModuleEdwin G Garcia ChNo ratings yet

- Seismic Bracing Products: For Mechanical, Electrical & Plumbing SystemsDocument132 pagesSeismic Bracing Products: For Mechanical, Electrical & Plumbing SystemsEdwin G Garcia ChNo ratings yet

- GH Series Nonhazardous Heavyduty Iec309 DevicesDocument10 pagesGH Series Nonhazardous Heavyduty Iec309 DevicesEdwin G Garcia ChNo ratings yet

- Fig909 No Thread Swivel Sway Brace Attachment TOLCODocument1 pageFig909 No Thread Swivel Sway Brace Attachment TOLCOEdwin G Garcia ChNo ratings yet

- Fig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCODocument1 pageFig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCOEdwin G Garcia ChNo ratings yet

- Seg 12Document386 pagesSeg 12Edwin G Garcia ChNo ratings yet

- Fig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCODocument1 pageFig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCOEdwin G Garcia ChNo ratings yet

- GH Series Nonhazardous Heavyduty Iec309 DevicesDocument10 pagesGH Series Nonhazardous Heavyduty Iec309 DevicesEdwin G Garcia ChNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument40 pagesSpare Parts List: Hydraulic BreakersSerkanAlNo ratings yet

- Clinton MODEL AS-870 / 870LCD: Service ManualDocument20 pagesClinton MODEL AS-870 / 870LCD: Service ManualnachcratchNo ratings yet

- Astm F568M 1996Document8 pagesAstm F568M 1996Jesse ChenNo ratings yet

- Stock+list N14C 475 Esn#12049265 CPL#1921Document50 pagesStock+list N14C 475 Esn#12049265 CPL#1921Alexis SanchezNo ratings yet

- T S For Power TransformerDocument11 pagesT S For Power TransformerAbhijeet Kumar SinghNo ratings yet

- Electra Voy 88911 ManualDocument14 pagesElectra Voy 88911 Manualpockyrevolution100% (1)

- Technical Info FlangesDocument12 pagesTechnical Info FlangesPopescu LeonardNo ratings yet

- Sym Euro MX 125 Service ManualDocument193 pagesSym Euro MX 125 Service ManualJavier GallegoNo ratings yet

- WheelHorse Lawn Sweeper Manual 7-2511Document4 pagesWheelHorse Lawn Sweeper Manual 7-2511Kevins Small Engine and Tractor Service100% (1)

- Welded Security Doors & Window ScreensDocument15 pagesWelded Security Doors & Window ScreensARTroom2012No ratings yet

- Install Radio 2219Document39 pagesInstall Radio 2219turand100100% (1)

- WCL8 (Assembly)Document1 pageWCL8 (Assembly)Md.Bellal HossainNo ratings yet

- Basic CylinderDocument24 pagesBasic CylinderSamik MukherjeeNo ratings yet

- United States Patent (10) Patent No.: US 8,356,778 B2Document23 pagesUnited States Patent (10) Patent No.: US 8,356,778 B2Erin GokNo ratings yet

- Astm F 568MDocument9 pagesAstm F 568MZahoor Ahmed MohsanNo ratings yet

- ASPIR Full Size 3D Printed Humanoid RobotDocument45 pagesASPIR Full Size 3D Printed Humanoid RobotCHARLIEBOY77No ratings yet