Professional Documents

Culture Documents

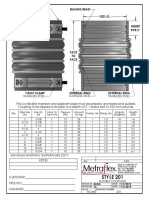

Fig. 910 - Swivel Sway Brace Fitting

Uploaded by

ANTONIO GUTIERREZ MIRANDAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fig. 910 - Swivel Sway Brace Fitting

Uploaded by

ANTONIO GUTIERREZ MIRANDACopyright:

Available Formats

Component of State of

Fig. 910 - Swivel Sway Brace Fitting California OSHPD Approved

Seismic Restraints System

Size Range — 1” and 11⁄4” bracing pipe. For brace pipe sizes larger than

11/4”, use

TOLCO Fig. 980.

Material — Carbon Steel

Function — For bracing pipe against sway and seismic disturbances. The

building attachment component of a sway brace system; the

Fig. 910 is used in conjunction with the Fig. 1001, Fig. 1000 or with a Fig.

4A Pipe Clamp and joined together with a brace pipe per NFPA 13.

Features — This product’s design incorporates a concentric attachment

opening which is critical to the performance of structural seismic connec-

tions. NFPA 13 (2010) 9.3.5.8.4 indicates that fastener table load values are

based only on concentric loading. Universal swivel design allows Fig. 910

to be attached at any surface angle.

Approvals — Underwriter’s Laboratories Listed in the USA (UL) and

Canada (cUL). Included in our Seismic Restraints Catalog approved by

the State of California Office of Statewide Health Planning and Development

(OSHPD). For additional load, spacing and placement

information relating to OSHPD projects, please refer to the TOLCO Seismic

Restraint Systems Guidelines.

Installation Instructions — The Fig. 910 is a structural or transitional

attachment component of a longitudinal or lateral sway brace assembly. It

is intended to be combined with the “bracing pipe”, and TOLCO “braced

pipe” attachment, Fig. 1000, 1001, 4A, 4B or 4L to form a complete bracing

assembly. Follow NFPA 13 and/or OSHPD guidelines.

To Install — Thread the pipe into the Fig. 910 until pipe threads are visible

through inspection site hole. Attachment can pivot for adjustment to proper

brace angle.

Note — The Fig. 910 Swivel Attachment and the Fig. 1001, Fig. 1000, Lateral Brace

or Fig. 4A Pipe Clamp make up a sway brace system of (UL) Listed

attachments and bracing materials which satisfies the requirements of

Underwriters’ Laboratories and the National Fire Protection Association

(NFPA).

Finish — Pre-Galvanized

Order By — Figure number, pipe size and finish.

Dimensions • Weights

Max. Design Load

Pipe Size A B C D E F Approx. Wt./100

Lbs.

1 2 1 1/2 3 9/16 2 5/16 2 1600 88

1 1/4 1 3/16 1 5/16 3 9/16 2 5/16 2 5/16 1600 99

NOTE - Available with hole sizes to accommodate up to 3/4” fastener. Consult factory.

Cooper B-Line, Inc.’s (“Cooper B-Line”) seismic bracing components are designed to be compatible only with other Cooper B-Line bracing components,

resulting in a listed seismic bracing assembly. Cooper B-Line’s warranty for seismic bracing components will be the warranty provided in Cooper B-Line’s

standard terms and conditions of sale made available by Cooper B-Line, except that, in addition to the other exclusions from Cooper B-Line’s warranty, Cooper

B-Line makes no warranty relating to Cooper B-Line’s seismic bracing components that are combined with products not provided by Cooper B-Line.

COOPER B-LINE 1375 Sampson Ave • Corona, CA 92879 • 800.786.5266 • FAX: 951.737.0330

www.tolco.com

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Shell & Tube Installation, Operation & Maintenance ManualDocument14 pagesShell & Tube Installation, Operation & Maintenance Manualnidhul07No ratings yet

- BILL OF QUANTITIES FOR PROPOSED CONSTRUCTION OF TWO-STOREY MULTI-PURPOSE HALLDocument8 pagesBILL OF QUANTITIES FOR PROPOSED CONSTRUCTION OF TWO-STOREY MULTI-PURPOSE HALL槐序初夏No ratings yet

- Requirements for Branch Connections to Flare HeadersDocument3 pagesRequirements for Branch Connections to Flare Headersgpskumar22No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Ductile Iron Pipe Installation Guide 05 2015Document134 pagesDuctile Iron Pipe Installation Guide 05 2015Anonymous R7EKGEDNo ratings yet

- Inspection and Test Plan For Line PipeDocument4 pagesInspection and Test Plan For Line PipeMohamed BencharifNo ratings yet

- Mercer 9100Document16 pagesMercer 9100dtmgoNo ratings yet

- Quincy CompressorDocument112 pagesQuincy CompressorRichard EV100% (2)

- PE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFDocument53 pagesPE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFmarin cristian100% (1)

- ASTM.F994 Penetration ConnectionsDocument6 pagesASTM.F994 Penetration Connectionsnkpong849005No ratings yet

- Propulsion Brochure PDFDocument28 pagesPropulsion Brochure PDFnaufragatoNo ratings yet

- Saes A 134Document13 pagesSaes A 134Mohamed Soliman100% (1)

- Pipe Hangers Supports Seismic BracingDocument5 pagesPipe Hangers Supports Seismic BracingBryan S. AlejandroNo ratings yet

- CPM1500 CP of Onshore Well CasingsDocument22 pagesCPM1500 CP of Onshore Well Casingskirubha_karan2000No ratings yet

- VS-HS Storage Systems Product Manual Ws PDFDocument38 pagesVS-HS Storage Systems Product Manual Ws PDFmehmacarNo ratings yet

- Soporte Antisísmico Fig910Document1 pageSoporte Antisísmico Fig910Michael IturraNo ratings yet

- TOLCO Fig. 907 - Multi-Angle AttachmentDocument1 pageTOLCO Fig. 907 - Multi-Angle AttachmentAndrés HLNo ratings yet

- Figura 980Document1 pageFigura 980YoniNo ratings yet

- Soporte Antisísmico Figura 909Document1 pageSoporte Antisísmico Figura 909Carlitos Way Golden BrainNo ratings yet

- OSHPD Approved Sway Brace AttachmentDocument1 pageOSHPD Approved Sway Brace Attachmentmakmak9No ratings yet

- Fig 980Document1 pageFig 980Steve CamposNo ratings yet

- Fig. 1000 - "Fast Clamp" Sway Brace Attachment: Maximum Design Load 1" Thru 4" Pipe Size - 2015 Lbs. 6" Size - 1265 LbsDocument2 pagesFig. 1000 - "Fast Clamp" Sway Brace Attachment: Maximum Design Load 1" Thru 4" Pipe Size - 2015 Lbs. 6" Size - 1265 LbsrutyNo ratings yet

- Fig909 No Thread Swivel Sway Brace Attachment TOLCODocument1 pageFig909 No Thread Swivel Sway Brace Attachment TOLCOEdwin G Garcia ChNo ratings yet

- Soporte Antisísmico Fig1001Document1 pageSoporte Antisísmico Fig1001Michael IturraNo ratings yet

- Soporte Antisísmico Fig980Document1 pageSoporte Antisísmico Fig980Michael IturraNo ratings yet

- 825A TolcoDocument1 page825A TolcoANTONIO GUTIERREZ MIRANDANo ratings yet

- Fig. 4A - Pipe Clamp For Sway BracingDocument1 pageFig. 4A - Pipe Clamp For Sway BracingZaira LorenaNo ratings yet

- 907 PDFDocument1 page907 PDFAlvaro Quispe MedinaNo ratings yet

- Fig. 906 - Sway Brace Multi-Fastener Adapter: Dimensions - WeightsDocument1 pageFig. 906 - Sway Brace Multi-Fastener Adapter: Dimensions - WeightsMichael IturraNo ratings yet

- Fig. 909 - No-Thread Swivel Sway Brace Attachment: A Brand ofDocument1 pageFig. 909 - No-Thread Swivel Sway Brace Attachment: A Brand ofZaira LorenaNo ratings yet

- Clevis HangerDocument60 pagesClevis HangerFernando RuizNo ratings yet

- Seismic Bracing: Fig. 907 - 4-Way Longitudinal Sway Brace AttachmentDocument1 pageSeismic Bracing: Fig. 907 - 4-Way Longitudinal Sway Brace AttachmentNethajiNo ratings yet

- Figura 906 - para AlmacenDocument1 pageFigura 906 - para AlmacenAlejandro Chumpitaz MarchanNo ratings yet

- Soporte Antisísmico Fig800Document1 pageSoporte Antisísmico Fig800Michael IturraNo ratings yet

- Reversible Beam Clamps for RodsDocument1 pageReversible Beam Clamps for RodsmikesazNo ratings yet

- Soporte Antisísmico Fig825Document1 pageSoporte Antisísmico Fig825Michael IturraNo ratings yet

- Data Sheet: Available Mounting ConfigurationsDocument2 pagesData Sheet: Available Mounting Configurationsgil1187No ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Significant Changes in AWWA D100-11Document6 pagesSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- Alpine Standard Sheets NBCC2005Document3 pagesAlpine Standard Sheets NBCC2005Rick HenbidNo ratings yet

- RandD ShaftDocument4 pagesRandD ShaftloloNo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Seismic TolcoDocument24 pagesSeismic TolcoJaider CamachoNo ratings yet

- Anatomy of A Grooved JointDocument6 pagesAnatomy of A Grooved JointHowardNo ratings yet

- Pipe Clamp For Sway Bracing TOLCODocument1 pagePipe Clamp For Sway Bracing TOLCOEdwin G Garcia ChNo ratings yet

- 393 Part CSR-BT e 20180305Document72 pages393 Part CSR-BT e 20180305Atsil DzakwanNo ratings yet

- CO2 cylinder assembly data sheetDocument1 pageCO2 cylinder assembly data sheetAlejandroNo ratings yet

- Fig. 4L Longitudinal "In-Line" Sway Brace AttachmentDocument1 pageFig. 4L Longitudinal "In-Line" Sway Brace AttachmentFausto CalderonNo ratings yet

- Saej 499 Av 001Document5 pagesSaej 499 Av 001willianNo ratings yet

- Process Piping Systems: Scrubber Design and Installation RequirementsDocument6 pagesProcess Piping Systems: Scrubber Design and Installation RequirementsCamilo Andres Cardozo FajardoNo ratings yet

- Special Specification 6315 Self Supporting Radio TowerDocument10 pagesSpecial Specification 6315 Self Supporting Radio TowerECiiNo ratings yet

- 5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Document6 pages5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Maximiliano StaitiNo ratings yet

- Descarga 1er Paso Mercer 91-52j11t84u1Document16 pagesDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNo ratings yet

- AF Catalog PDFDocument34 pagesAF Catalog PDFCarlos MNo ratings yet

- Grapa Tipo CDocument1 pageGrapa Tipo CZaira LorenaNo ratings yet

- Globe Valve: GL-1601C (EN)Document20 pagesGlobe Valve: GL-1601C (EN)amandaNo ratings yet

- Ref For Deflection Criteria StructureDocument5 pagesRef For Deflection Criteria StructurePutu RustikaNo ratings yet

- Casing Design and Connection TypesDocument21 pagesCasing Design and Connection TypesNadji MohamedasaadNo ratings yet

- C 506 Â " 00 QZUWNI1SRUQDocument8 pagesC 506 Â " 00 QZUWNI1SRUQjorge napa magallanesNo ratings yet

- Section 15060 - Hangers and SupportsDocument9 pagesSection 15060 - Hangers and SupportsLuciano SalituriNo ratings yet

- SB Sway Brace AttachmentDocument2 pagesSB Sway Brace Attachmentrvalentino2012No ratings yet

- CPVC BrochureDocument8 pagesCPVC BrochureMina MagdyNo ratings yet

- WHA-1260XL Water Hammer ZurnDocument2 pagesWHA-1260XL Water Hammer ZurnJeffry GabilanNo ratings yet

- ASTM F1387 Approval Letter PDFDocument4 pagesASTM F1387 Approval Letter PDFRafael AndradeNo ratings yet

- Understanding Overhead Crane Deflection and CriteriaDocument3 pagesUnderstanding Overhead Crane Deflection and Criteriaram_babu_59No ratings yet

- Discontinuous HD BULLDOG ACP Annulus Casing PackerDocument3 pagesDiscontinuous HD BULLDOG ACP Annulus Casing PackerColinNo ratings yet

- Model 1260XL: Water Hammer ArresterDocument2 pagesModel 1260XL: Water Hammer ArresterAbou Backar Sittique JNo ratings yet

- Mercer Valve 9100 Relief Valve Flanged AEDocument16 pagesMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNo ratings yet

- 1065 Forged Brass Full Bore Gate ValveDocument7 pages1065 Forged Brass Full Bore Gate ValveKishan ChandrasekaraNo ratings yet

- Catálogo Tolco PDFDocument80 pagesCatálogo Tolco PDFAgustin RosasNo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoANTONIO GUTIERREZ MIRANDANo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Fig. 910 - Swivel Sway Brace FittingDocument1 pageFig. 910 - Swivel Sway Brace FittingANTONIO GUTIERREZ MIRANDANo ratings yet

- 980 SB Universal Swivel Sway Brace Attachment UlDocument1 page980 SB Universal Swivel Sway Brace Attachment UlANTONIO GUTIERREZ MIRANDANo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Light Welded Bracket Spec SheetDocument2 pagesLight Welded Bracket Spec SheetANTONIO GUTIERREZ MIRANDANo ratings yet

- Light Welded Bracket Spec SheetDocument2 pagesLight Welded Bracket Spec SheetANTONIO GUTIERREZ MIRANDANo ratings yet

- 825A TolcoDocument1 page825A TolcoANTONIO GUTIERREZ MIRANDANo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- 825A TolcoDocument1 page825A TolcoANTONIO GUTIERREZ MIRANDANo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document1 pageMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)CESAR VELEZNo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)CESAR VELEZNo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Amerex Corporation: Rugged Model 240Document1 pageAmerex Corporation: Rugged Model 240john castilloNo ratings yet

- 980 SB Universal Swivel Sway Brace Attachment UlDocument1 page980 SB Universal Swivel Sway Brace Attachment UlANTONIO GUTIERREZ MIRANDANo ratings yet

- Nitrogen Cylinder Operated - Wheeled UnitsDocument1 pageNitrogen Cylinder Operated - Wheeled UnitsANTONIO GUTIERREZ MIRANDANo ratings yet

- Metraloop: Down Have The 180 Return Supported. (See Installation Instructions.)Document1 pageMetraloop: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- STYLE 201: Flexible Coupling Size I.D. Insert Pipe 2" Sealing BeadDocument1 pageSTYLE 201: Flexible Coupling Size I.D. Insert Pipe 2" Sealing BeadANTONIO GUTIERREZ MIRANDANo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)ANTONIO GUTIERREZ MIRANDANo ratings yet

- KP Parts Overview Jan 2020Document94 pagesKP Parts Overview Jan 2020ANTONIO GUTIERREZ MIRANDANo ratings yet

- Wheeled Catalog 2Document12 pagesWheeled Catalog 2CESAR VELEZNo ratings yet

- Negotiated BQ-Falmouth Market - PAYMENT MedleyDocument185 pagesNegotiated BQ-Falmouth Market - PAYMENT MedleyDaniel EvansNo ratings yet

- Catalog Vane AVK PDFDocument52 pagesCatalog Vane AVK PDFdutucojNo ratings yet

- Abreviaturas ValvulasDocument3 pagesAbreviaturas ValvulasROBINSONNo ratings yet

- Chiller Water Pressure DropDocument4 pagesChiller Water Pressure DropCử NguyễnNo ratings yet

- Section 23 81 26Document16 pagesSection 23 81 26Ismail MohammadNo ratings yet

- Manual Supra 644Document47 pagesManual Supra 644hosmangramajoNo ratings yet

- HOUSING COMPLEX CONSTRUCTION PROJECT COST ESTIMATEDocument32 pagesHOUSING COMPLEX CONSTRUCTION PROJECT COST ESTIMATEAV ChavdaNo ratings yet

- SKL Digest: Base Brand Series Type Form Dosage Function Type of Scale Not Suitable Check Suitable RecommendedDocument2 pagesSKL Digest: Base Brand Series Type Form Dosage Function Type of Scale Not Suitable Check Suitable RecommendedChoice OrganoNo ratings yet

- BOQ Sipil GI 150 KV TarjunDocument5 pagesBOQ Sipil GI 150 KV TarjunMarketing MptNo ratings yet

- 2008 Pigging PowerPointDocument59 pages2008 Pigging PowerPointLEO_GONZALEZ100% (1)

- Rock Bolting Techniques for Roof and Wall StabilizationDocument9 pagesRock Bolting Techniques for Roof and Wall StabilizationsamratNo ratings yet

- Spe 128337 PDFDocument8 pagesSpe 128337 PDFDaniel DamboNo ratings yet

- Draft Plant Design PaperDocument65 pagesDraft Plant Design Paper202040336No ratings yet

- A358 PDFDocument6 pagesA358 PDFwiNo ratings yet

- Epw Standards Specification ManualDocument339 pagesEpw Standards Specification Manuallinux905No ratings yet

- DZL 4-1.25-AiiDocument10 pagesDZL 4-1.25-AiiSamulaNo ratings yet

- General welding requirements for technical standardDocument11 pagesGeneral welding requirements for technical standardKunal SrivastavaNo ratings yet

- JIS G 4805 Seamless Pipe Steel StandardsDocument12 pagesJIS G 4805 Seamless Pipe Steel StandardsGerardo Emmanuel Romana BrianoNo ratings yet

- Installation and Operating Manual: Engine Air StartersDocument17 pagesInstallation and Operating Manual: Engine Air StartersMauricio Ariel H. OrellanaNo ratings yet

- Manual Daikin VRVDocument20 pagesManual Daikin VRVErnesto BonillaNo ratings yet

- Ej 01 ProsperDocument47 pagesEj 01 ProsperMarcelo Ayllón RiberaNo ratings yet