0% found this document useful (0 votes)

827 views8 pagesDistillation Column Basics and Piping

Distillation columns separate liquid mixtures using trays or plates to bring the vapor and liquid phases into contact. Feed is introduced along the column shell and cascades down the stacked trays while vapor rises up, contacting the liquid. Absorption and stripping operations use this process to absorb or strip components between a gas and liquid. Fractionation columns separate crude oil and other feeds into distillate products of varying boiling points through heating, vaporization, condensation, and refluxing within the column and with a reboiler providing heat at the bottom.

Uploaded by

Rahul ChandrawarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

827 views8 pagesDistillation Column Basics and Piping

Distillation columns separate liquid mixtures using trays or plates to bring the vapor and liquid phases into contact. Feed is introduced along the column shell and cascades down the stacked trays while vapor rises up, contacting the liquid. Absorption and stripping operations use this process to absorb or strip components between a gas and liquid. Fractionation columns separate crude oil and other feeds into distillate products of varying boiling points through heating, vaporization, condensation, and refluxing within the column and with a reboiler providing heat at the bottom.

Uploaded by

Rahul ChandrawarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Basics of Distillation Column Piping: Introduces the fundamental concept of distillation column piping, explaining the separation of liquid mixtures and associated equipment.

- Absorption & Stripping: Describes the absorption and stripping processes used in petrochemical plants, highlighting operations and key components.

- Fractionation: Covers the concept of fractionation in distillation columns, discussing its types and operational principles.

- Distillation Column Internals: Describes the internal structure of distillation columns, focusing on packed and trayed towers with illustrative diagrams.

- Reboiler: Details the function and importance of the reboiler in distillation columns, including heat exchange processes.

- Reboiler Connections: Explains how the reboiler is integrated with the distillation column, focusing on connections and operational details.

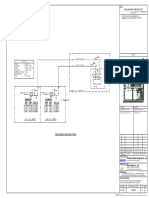

- Process Flow Diagram: Presents a schematic diagram illustrating the process flow within a distillation column system, detailing component interactions.