Professional Documents

Culture Documents

Casesheet 192 Siwertell Terfron Brazil Grain Unloader

Uploaded by

ers0 ratings0% found this document useful (0 votes)

39 views2 pagesOriginal Title

Casesheet 192 Siwertell Terfron Brazil Grain Unloader (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views2 pagesCasesheet 192 Siwertell Terfron Brazil Grain Unloader

Uploaded by

ersCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

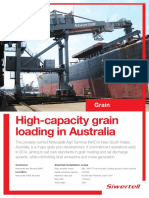

Grain

Ship unloader specified

for new Brazilian port

This ship unloader provides efficient, reliable, clean discharge operations for

barges delivering soya beans and corn to a new agri-bulk export terminal at

the mouth of the Amazon River in Northern Brazil.

Customer Siwertell installation scope

Bunge Brasil Ship unloader model ST-790M

Location Rated unloading capacity 1,500t/h (soya bean), 1,100t/h (soya meal), 1,500t/h (corn)

Barcarena, Pará state, Brazil Maximum barge size 2,500 dwt

Total weight 249t

Challenge Solution Results

When leading agri-business company Siwertell’s ship unloader ST-790M was Siwertell fulfilled its turn-key project

Bunge Brazil planned its new Terfron an ideal solution for this project, meeting obligations to Bunge Brazil’s full

bulk export terminal in Northern Brazil, all Bunge Brazil’s operational needs, as satisfaction, arranging the shipment

it needed a reliable, high capacity ship well as its short lead time requirements. of goods, installation, testing and

unloader to discharge soya beans Bunge Brazil was aware of what it could commissioning in addition to the

arriving by barges of up to 2,500 dwt. expect from Siwertell because it knew equipment supply.

Excellent environmental credentials were about the excellent service that another

essential and there was also a short lead Siwertell unloader is providing in Manaus, The ship unloader handles soya beans

time for realizing the project. Brazil, since 1996 discharging soy beans (1,500t/h), soya meal (1,100t/h) and

and corn for Hermasa Navegacao Da corn (1,500t/h) with no spillage and

The new terminal was constructed Amazonia S/A. minimal dust creation, which leads both

primarily to increase the export capacity to cost savings and an environment-

for soya beans grown in Brazil’s Mato The ship unloader was designed in friendly site.

Grosso State and transported to the Sweden and manufactured in Sweden,

coast by truck and barge. It has relieved Europe and China. It was then shipped Following this order, Siwertell has

the pressure on existing east coast to Brazil in parts (of which some was pre- received additional orders for the same

ports, where frequent long delays have assembled) for further assembly work on type of ship unloaders, e.g. from Cargill

restricted the expansion of Brazil’s soya a local ship yard in Belem before sending in Santarem and ADM in Barcarena.

bean trade. Further northern terminals assembled main parts to the customer’s

are planned, with farmers expecting that site for final assembly, commissioning and

these will eventually handle over half of tests. The agreed delivery time was 14

Brazil’s huge soya bean export trade. months on a turn-key basis.

BT-192-AUG15

Contact

Siwertell works closely together with representatives on all

continents. Please contact our head office below and we

will direct you to your local Siwertell contact.

Siwertell AB

P.O. Box 566 Gunnarstorp, SE-26725 Bjuv, Sweden

+46 42 85800

sales@siwertell.com

siwertell.com

The Siwertell product portfolio includes ship unloaders, mobile ship unloaders,

ship loaders, horizontal and vertical screw conveyors as well as complete dry

bulk terminal solutions. Virtually any dry bulk cargo can be handled and all

Siwertell solutions are designed to ensure sustainable, efficient and safe cargo

operations. Siwertell is part of Cargotec Corporation.

You might also like

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Casesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalDocument2 pagesCasesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalersNo ratings yet

- Floating Ship Unloader Doubles Brazil Terminal CapacityDocument2 pagesFloating Ship Unloader Doubles Brazil Terminal CapacitylrbolNo ratings yet

- ROSA Field TotalDocument18 pagesROSA Field TotalWaldemarNo ratings yet

- Brochure Portaload Portacombi EN 001Document12 pagesBrochure Portaload Portacombi EN 001Fede Del BalzoNo ratings yet

- DampierPORT MAR-APR11 Emea SDocument9 pagesDampierPORT MAR-APR11 Emea SKhải TrươngNo ratings yet

- SBM Currents April 2013 MagazineDocument20 pagesSBM Currents April 2013 MagazinetkkoNo ratings yet

- DRAGADOS Offshore by Oscar Del SantoDocument3 pagesDRAGADOS Offshore by Oscar Del SantoOscar César Del Santo, PhDNo ratings yet

- Casesheet 154 Siwertell MerseyDocks UK Grain UnloaderDocument2 pagesCasesheet 154 Siwertell MerseyDocks UK Grain UnloaderersNo ratings yet

- Darwin LNG: Photo GalleryDocument2 pagesDarwin LNG: Photo GalleryjiokoijikoNo ratings yet

- Dock Facilities at Port Pepard .: 37278-23478 Ayan. 576Document2 pagesDock Facilities at Port Pepard .: 37278-23478 Ayan. 576wwwwNo ratings yet

- Completion of Bankable Feasibility Study For Bel AirDocument4 pagesCompletion of Bankable Feasibility Study For Bel Airdedi_geps100% (1)

- Dock Facilities at Port Pepard .: Report By: AyanDocument2 pagesDock Facilities at Port Pepard .: Report By: AyanwwwwNo ratings yet

- Africa Oil and GasDocument8 pagesAfrica Oil and GasjeedanNo ratings yet

- Siwertell Unloader Meets Subic Grain'S Growing Import Needs: CategoriesDocument2 pagesSiwertell Unloader Meets Subic Grain'S Growing Import Needs: CategoriesersNo ratings yet

- Petromoc, SA Petr Ó Leos de Mo Ç AmbiqueDocument16 pagesPetromoc, SA Petr Ó Leos de Mo Ç AmbiqueFredNo ratings yet

- Ichthys Off Shore Win 01 13Document2 pagesIchthys Off Shore Win 01 13sapreswapnil8388No ratings yet

- Port of Hastings Factsheet DRAFT v15Document2 pagesPort of Hastings Factsheet DRAFT v15Philip AMCNo ratings yet

- Floating Production Storage and Offloading - Wikipedia, The Free EncyclopediaDocument9 pagesFloating Production Storage and Offloading - Wikipedia, The Free Encyclopediamechmonkey007No ratings yet

- Duqm Project 1 Cold Store ProjectDocument15 pagesDuqm Project 1 Cold Store ProjectmohsenmouseliNo ratings yet

- Project: GSEZ Port Project Country: Gabon: Appraisal TeamDocument49 pagesProject: GSEZ Port Project Country: Gabon: Appraisal TeamChristian BarNo ratings yet

- Brella Presentation V2Document27 pagesBrella Presentation V2ramatajamaNo ratings yet

- Project Fact Sheet Karara Wa June 2022Document2 pagesProject Fact Sheet Karara Wa June 2022AliakbarTaghipourNo ratings yet

- FloatingDocument33 pagesFloatingJORDAN FREENo ratings yet

- GULFDocument33 pagesGULFJORDAN FREENo ratings yet

- Fact Sheet Wheatstone Project Overview PDFDocument2 pagesFact Sheet Wheatstone Project Overview PDFsreedar20052185No ratings yet

- Lightweight Ship Unloader Handles Brazilian Coal SupplyDocument2 pagesLightweight Ship Unloader Handles Brazilian Coal SupplyersNo ratings yet

- Parque Das Conchas (Bc-10) : Offshore Oil and Gas ProjectDocument5 pagesParque Das Conchas (Bc-10) : Offshore Oil and Gas Projectegy pureNo ratings yet

- Offshore Production FacilitiesDocument8 pagesOffshore Production FacilitiesPercival Wulfric BrianNo ratings yet

- KBR Ammonia PDFDocument10 pagesKBR Ammonia PDFsadsnd-1100% (1)

- PDF-BulkHandlingNews 2024 01 SmallDocument36 pagesPDF-BulkHandlingNews 2024 01 Smallpios.helectorNo ratings yet

- Fact Sheet Gorgon Project OverviewDocument2 pagesFact Sheet Gorgon Project OverviewsalimNo ratings yet

- Ship LoaderDocument4 pagesShip LoaderRohit RumadeNo ratings yet

- Project Experiences - Gunawan MuktiwibowoDocument29 pagesProject Experiences - Gunawan MuktiwibowoGunawan Raharjo100% (1)

- Factsheet - PortsDocument2 pagesFactsheet - PortsPhilip AMCNo ratings yet

- First Fpso by ShellDocument4 pagesFirst Fpso by ShellsnamprogNo ratings yet

- Sekupang Pulau Buluh, B A T A M, Kepulauan Riau Telp. Kapal TongkangDocument10 pagesSekupang Pulau Buluh, B A T A M, Kepulauan Riau Telp. Kapal TongkangjasmanNo ratings yet

- "Developments at Port Pepard": Report By: and Add Your NameDocument2 pages"Developments at Port Pepard": Report By: and Add Your Nameapi-276074515No ratings yet

- Container Ship Size and Fleet Still GrowingDocument19 pagesContainer Ship Size and Fleet Still GrowingLaura Cristiana IacobNo ratings yet

- PT SANGGAR SARANA BAJA Design, Fabrication, and ServicesDocument36 pagesPT SANGGAR SARANA BAJA Design, Fabrication, and ServicesAdlan Bagus Pradana100% (1)

- Port Pepard: Gateway for car exports from Northwest regionDocument2 pagesPort Pepard: Gateway for car exports from Northwest regionTang Zhong YewNo ratings yet

- Saam Smit Towage Brasil Provides Towage ServicesDocument2 pagesSaam Smit Towage Brasil Provides Towage ServicesgustavoschardongNo ratings yet

- Offshore Pipelines SaipemDocument78 pagesOffshore Pipelines Saipemrylar999100% (5)

- JX1PORT2102Document2 pagesJX1PORT2102Aditya ShindeNo ratings yet

- Asphalt Plant SpecsDocument10 pagesAsphalt Plant SpecsNidDouNo ratings yet

- Drilling Sup. - Ghram Kirk CVDocument4 pagesDrilling Sup. - Ghram Kirk CVhosam aliNo ratings yet

- Marin ReportDocument32 pagesMarin Reportjimmyy90No ratings yet

- Barossa Project Overview - Q3 2018Document4 pagesBarossa Project Overview - Q3 2018kudrat12No ratings yet

- Word BDocument2 pagesWord Bapi-276164301No ratings yet

- Bong ADocument2 pagesBong AchinemeikeNo ratings yet

- Ballast Nedam Offshore-On The-MoveDocument15 pagesBallast Nedam Offshore-On The-MoveHariprasad RajannaNo ratings yet

- Blue MarlinDocument23 pagesBlue MarlinsaulotenorNo ratings yet

- Collection of Maritime Press ClippingsDocument29 pagesCollection of Maritime Press Clippingsluisdavid01No ratings yet

- Tugs & Towing News: "57 Years Tugboatman"Document30 pagesTugs & Towing News: "57 Years Tugboatman"Roy NapitupuluNo ratings yet

- Nigel Gee - Izar Pentamaran ConceptDocument14 pagesNigel Gee - Izar Pentamaran ConceptrmdowlandNo ratings yet

- Dredging and Marine WorksDocument48 pagesDredging and Marine WorksHotnCrispy Crispy100% (1)

- Dredging and Marine Works PDFDocument48 pagesDredging and Marine Works PDFOwais MehboobNo ratings yet

- Raisebore Australia Celebrates 20 Years of InnovationDocument19 pagesRaisebore Australia Celebrates 20 Years of InnovationIng del PeleNo ratings yet

- Training Capabilities Enhanced by New Apprentice School: MARCH 2008Document6 pagesTraining Capabilities Enhanced by New Apprentice School: MARCH 2008ilublessing1No ratings yet

- 4322 11618 1 PB PDFDocument8 pages4322 11618 1 PB PDFFaizSulthanNo ratings yet

- Wheel LoaderDocument28 pagesWheel LoaderersNo ratings yet

- Silo Silo: Grab Ship Unloader Ship LoaderDocument1 pageSilo Silo: Grab Ship Unloader Ship LoaderersNo ratings yet

- Studi Komponen Struktur Pembangunan Jalan Tol Dengan Metode Sewa LahanDocument11 pagesStudi Komponen Struktur Pembangunan Jalan Tol Dengan Metode Sewa LahanersNo ratings yet

- Bollard Catalog - SPDocument28 pagesBollard Catalog - SPrisiana_limuriaNo ratings yet

- Silo Silo: Grab Ship Unloader Ship LoaderDocument1 pageSilo Silo: Grab Ship Unloader Ship LoaderersNo ratings yet

- Pneumatic Grain Conveyors: 1111111) ) LRF J RR I M 1111111Document7 pagesPneumatic Grain Conveyors: 1111111) ) LRF J RR I M 1111111ersNo ratings yet

- Project Sheet - 1304: Port Cranes: Derince Port (Tmo)Document3 pagesProject Sheet - 1304: Port Cranes: Derince Port (Tmo)ersNo ratings yet

- Bulk Vetting Report 2019 190819Document35 pagesBulk Vetting Report 2019 190819ersNo ratings yet

- Aeration System Design For Flat Grain Storages With An Expert SystemDocument7 pagesAeration System Design For Flat Grain Storages With An Expert SystemersNo ratings yet

- 2006 4A OptPort PaperDocument11 pages2006 4A OptPort PaperersNo ratings yet

- RANCANGAN K3 GEDUNG KULIAH BARU IAIN PONTIANAKDocument9 pagesRANCANGAN K3 GEDUNG KULIAH BARU IAIN PONTIANAKHeidy Ayu SumartoNo ratings yet

- Silo Silo: Grab Ship Unloader Ship LoaderDocument1 pageSilo Silo: Grab Ship Unloader Ship LoaderersNo ratings yet

- The Structural Design of Heavy Duty Pavements PDFDocument143 pagesThe Structural Design of Heavy Duty Pavements PDFAljosa Nikolic100% (2)

- Estimating Marine Terminal Dimensions and CostsDocument203 pagesEstimating Marine Terminal Dimensions and CostsDanilo InamineNo ratings yet

- Laporan Final Bandara 3Document1 pageLaporan Final Bandara 3ersNo ratings yet

- 2006 4A OptPort PaperDocument11 pages2006 4A OptPort PaperersNo ratings yet

- SI4243 2021 11 Traffic Forecast NetworkDocument13 pagesSI4243 2021 11 Traffic Forecast NetworkersNo ratings yet

- Estimating Marine Terminal Dimensions and CostsDocument203 pagesEstimating Marine Terminal Dimensions and CostsDanilo InamineNo ratings yet

- Casesheet 191 Siwertell NAT Australia Grain UnloaderDocument2 pagesCasesheet 191 Siwertell NAT Australia Grain UnloaderersNo ratings yet

- Casesheet 192 Siwertell Terfron Brazil Grain UnloaderDocument2 pagesCasesheet 192 Siwertell Terfron Brazil Grain UnloaderersNo ratings yet

- Casesheet 191 Siwertell NAT Australia Grain UnloaderDocument2 pagesCasesheet 191 Siwertell NAT Australia Grain UnloaderersNo ratings yet

- Casesheet 154 Siwertell MerseyDocks UK Grain UnloaderDocument2 pagesCasesheet 154 Siwertell MerseyDocks UK Grain UnloaderersNo ratings yet

- GQ RB Loader Unloader EN 14298 01 WEBDocument13 pagesGQ RB Loader Unloader EN 14298 01 WEBersNo ratings yet

- Casesheet 154 Siwertell MerseyDocks UK Grain UnloaderDocument2 pagesCasesheet 154 Siwertell MerseyDocks UK Grain UnloaderersNo ratings yet

- Mobile Mixing Plants: M1 / M1.25 / M2.25 / M2.5 / M3Document12 pagesMobile Mixing Plants: M1 / M1.25 / M2.25 / M2.5 / M3Omprakash singh100% (1)

- Siwertell Unloader Meets Subic Grain'S Growing Import Needs: CategoriesDocument2 pagesSiwertell Unloader Meets Subic Grain'S Growing Import Needs: CategoriesersNo ratings yet

- Schwinn Exercise Bike IC Pro - IC EliteDocument8 pagesSchwinn Exercise Bike IC Pro - IC EliteLa pandaNo ratings yet

- TSM 26 SdcuDocument3 pagesTSM 26 SdcuWaleed HassanNo ratings yet

- BR High Power Switches and Contactors Solutions Guide ENDocument8 pagesBR High Power Switches and Contactors Solutions Guide ENfassina01No ratings yet

- Rail King Service Rental Equipment PartsDocument6 pagesRail King Service Rental Equipment Partsrogelio palaciosNo ratings yet

- JSW Inquiry - OHE-1Document6 pagesJSW Inquiry - OHE-1Amit AgrawalNo ratings yet

- U760E, U760F (Toyota) : 6 Speed FWD & AWD (Electronic Control)Document5 pagesU760E, U760F (Toyota) : 6 Speed FWD & AWD (Electronic Control)marran almarranyNo ratings yet

- ADOT Specific Requirements For SSL's MSE Plus Concrete Panel Wall SystemDocument24 pagesADOT Specific Requirements For SSL's MSE Plus Concrete Panel Wall SystemDiegoDiazBarrantesNo ratings yet

- Compound Word ListDocument15 pagesCompound Word ListAngela MorilloNo ratings yet

- Imtiyaz Gmail - Booking Confirmation On IRCTC, Train - 12591, 05-Mar-2022, 3A, GD - SCDocument1 pageImtiyaz Gmail - Booking Confirmation On IRCTC, Train - 12591, 05-Mar-2022, 3A, GD - SCwasam anwar AnsariNo ratings yet

- Technical ManualDocument541 pagesTechnical ManualFlorin NiteNo ratings yet

- g94-1524 Diagram - Air Cab TP-5Document1 pageg94-1524 Diagram - Air Cab TP-5Billy JimenezNo ratings yet

- K-Gauge Hla 600: Independent High Level and Overfill Alarm SystemDocument4 pagesK-Gauge Hla 600: Independent High Level and Overfill Alarm SystemPavel ViktorNo ratings yet

- SIRE 2.0 - Instructions For Uploading PhotograDocument32 pagesSIRE 2.0 - Instructions For Uploading PhotograErdem CihanNo ratings yet

- Рессоры - Dosemenler (ALL)Document114 pagesРессоры - Dosemenler (ALL)Сергей МартинюкNo ratings yet

- Intelligent Traffic SystemDocument14 pagesIntelligent Traffic Systemvaishnavi78006No ratings yet

- XSR700-2018 User ManualDocument106 pagesXSR700-2018 User ManualK KNo ratings yet

- Chery-QQ S11 Transmisión Parte 4Document17 pagesChery-QQ S11 Transmisión Parte 4limadacarlos100% (1)

- Functional Safety of Railway SystemsDocument6 pagesFunctional Safety of Railway SystemsDoru ToaderNo ratings yet

- 133 - Battle For The Falklands (1) - Land Forces PDFDocument49 pages133 - Battle For The Falklands (1) - Land Forces PDFCelio Neto100% (6)

- TH 0608Document8 pagesTH 0608sylvaniaheraldNo ratings yet

- Leonardo 125Document88 pagesLeonardo 125Miroslaw Gabalix GabalisNo ratings yet

- Blood On The Tracks, The Turbulent History of Brazil's Central RailwayDocument30 pagesBlood On The Tracks, The Turbulent History of Brazil's Central RailwayChris BurdenNo ratings yet

- SSP-525 The Jetta HybridDocument60 pagesSSP-525 The Jetta HybridashrafzgNo ratings yet

- Automated TransmissionsDocument33 pagesAutomated TransmissionsHERNAN CORTEZ FARFANNo ratings yet

- VAAH to KJFK Flight Plan and Details (Jun 11, 2021Document23 pagesVAAH to KJFK Flight Plan and Details (Jun 11, 2021Nagarjuna Reddy TNo ratings yet

- Cascadia Cafe Parametros 14 LtsDocument3 pagesCascadia Cafe Parametros 14 LtsDuranRod2013No ratings yet

- CS 450 Inspection of Highway Structures: Design Manual For Roads and BridgesDocument139 pagesCS 450 Inspection of Highway Structures: Design Manual For Roads and BridgesgordonNo ratings yet

- TQPFDocument5 pagesTQPFAlexandre AlvesNo ratings yet

- Auto CarDocument100 pagesAuto Carjairojcsf100% (1)