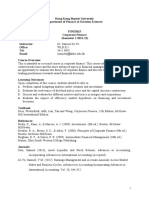

Professional Documents

Culture Documents

Deliver Up To Ten Perfect Rolls at A Time

Uploaded by

YakupovmmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deliver Up To Ten Perfect Rolls at A Time

Uploaded by

YakupovmmCopyright:

Available Formats

TOWER CLAMPS

Deliver up to ten perfect rolls at a time.

Single Tower Clamp

Single Tower Clamps come with equal length arms or

long and short arms. The equal length arm design is used

when the driver is moving rolls in general applications.

The long and short arm configuration is best when tight

stacking is required.

FEATURES

■ All Cascade Tower Clamps include a flow divider for

equal arm movement

■ Open tubular frame structure from high strength steel

■ Thin profile arms and pads

■ High visibility frame

■ Routing of hydraulic tubes and hoses to

maximize visibility

■ Floor stands

■ Pad protectors on lower arms

OPTIONS

■ Hydraulically extendable upper arms

■ Contact pads: Flexipad, Bonded Rubber, Bonded UDP,

Bolt-On Rubber

■ AFC (Adaptive Force Control)

■ Custom roll size ranges handled against the bumper

■ Custom pad size and location modifications

Upper Arm Options ■ Integral sideshifter

■ Integral mounting

Top Arm Shut-Off

The top arms can be shut off to increase the efficiency of

the clamp. For example—when handling just two rolls

instead of four, shutting off the top arms allows the lower

arms to clamp faster without waiting for the top arms to

Extendable Upper Arm (shown above) bottom out.

Allows the upper arms to be positioned to match the

height of the load for optimized stabilization of the load.

Fixed Upper Arm

Ideal when stock sizes do not vary enough to benefit

from an extendable upper arm.

Cascade Tower Clamps are built for

the most demanding applications.

Cascade has worked with the top paper companies and OEMs to develop the

world's best Tower Clamps. Cascade Tower Clamps feature state-of-the-art

hydraulics to control arm sequencing, and are available with the industry's

best selection of contact pads. Driver friendly features are engineered into

every clamp design to promote damage free handling with maximum control

of clamp force and a good range of "against the bumper" handling.

Key Benefits

Fewer Handling Sequences Handling In a More Controlled

When handling 2-10 rolls at one time, Atmosphere

fewer runs in the warehouse are required. The Tower Clamp allows the driver to

move multiple rolls efficiently without the

Fewer Lift Trucks and Drivers hectic pace that would be required of a

One driver and one lift truck accomplish single roll clamp to handle the same

the task of many single roll clamps. number of rolls.

Quicker Loading and Unloading Reduced Handling Costs—

When the supply chain requires rapid Increased Profits

response to moving large volumes of rolls Efficiency = Savings.

in a short time frame the Tower Clamp is

an excellent choice.

Double Tower Clamp

FEATURES

■ All Cascade Tower Clamps include a flow divider for

equal arm movement

■ Open tubular frame structure from high-

strength steel

■ Thin profile arms and pads

■ Solid or Split center arm configurations

■ High visibility frame

■ Pivoting center arm standard

■ Routing of hydraulic tubes and hoses to

maximize visibility

■ Floor stands

■ Pad protectors on lower arms

OPTIONS

■ Hydraulically extendable upper arms

■ Hydraulically positionable center arms

Note the clean lines of the structure and hydraulic components, which ■ Fixed center arm

maximize driver visibility.

■ Contact pads: Flexipad, Bonded Rubber, Bonded

UDP, Bolt-On Rubber

Upper Arm Options ■ AFC (Adaptive Force Control)

■ Custom roll size ranges handled against the bumper

■ Custom pad size and location modifications

■ Integral sideshifter

■ Integral mounting

Top Arm Shut-Off

The top arms can be

shut off to increase

the efficiency of the

Extendable Upper Arm (shown above) clamp. For example—

Allows the upper arms to be positioned to match when handling just

the height of the load for optimized stabilization two rolls instead of

of the load. four, shutting off the

Fixed Upper Arm top arms allows the lower arms to clamp faster with-

Ideal when stock sizes do not vary enough to out waiting for the top arms to bottom out.

benefit from an extendable upper arm.

Arm Sequencing Options for Double Tower Clamps

Double Tower with Fixed or Pivoting Double Tower with Hydraulically Positionable

Center Arms Center Arms

Arms sequence as follows: Arms sequence as follows:

■ Outer long arms move equally when closing and opening. ➀ During closing, outer arms close first to contact roll.

➁ Center arm closes until contacting roll.

➂ Clamp force increases after all roll pads have contacted

the rolls.

The benefits of Hydraulically Positionable Center Arms:

■ Prevents rolls from being pushed across the floor

■ Helps to prevent unwanted roll movement

■ Arm movement is controlled by flow dividers to provide

Fixed Center Arm

equal arm movement during opening and closing.

Pivoting Center Arm Hydraulically Positionable Center Arms

(arm is spring loaded)

Whatever the application, we can handle it.

Damage Reduction Options for Cascade Tower Clamps

• AFC • Four Position Pressure Regulator

AFC (Adaptive Force Control) is a computer- The pressure regulator with three pressure

controlled clamping system that automatically settings plus relief valve permits using the

controls the clamp force in proportion to the minimum hydraulic pressure required to

load weight. satisfactorily clamp a load.

AFC is available for all configurations of

• Light Tower

both the Single and Double Tower Clamp. The

The light tower shows the pressure setting in

system accurately applies the correct amount

use when installed with the Four Position

of clamp force to all arms, even when

Pressure Regulator.

handling partial loads.

• Quick Change Mounting Kit • Single Pressure Setting Relief Valve

Increases versatility by allowing attachments Limits hydraulic pressure in 1 line to

to be easily interchanged. attachment. Two valves required per

auxiliary function.

• Tilt Control • Bi-Directional Pressure Relief Valve

Tilt Control automatically controls the angle of Allows single valve to be used for each

the mast and attachment, which automatically auxiliary function to limit hydraulic pressure

aligns pad to roll, and roll to floor. to attachment.

• Load Cushion™ • Clamp Force Indicator

Hoist system accumulator that absorbs Measuring device that shows the clamp

shocks and reduces the clamp force required force applied to the load. Used for clamp

to handle the load. pressure calibration with systems using

pressure relief valves.

• Pressure Gauge • Portable Clamp Force Tester

To 345 bar. Excessive clamp force is one of the leading

causes of paper roll damage. Use Cascade's

Clamp Force Tester to easily determine how

much force the roll clamp applies to a roll.

• Laser Pointer • Electronic Pressure

Cascade's Laser Pointer Regulator

projects a sharp, red line on Allows operator to select

the paper roll, making it proper clamp force with

easy for the driver to see control switch that can be

where to place the pads on mounted for maximum

the roll. operator convenience.

Cascade Europe • Damsluisweg 56 • PO Box 3009 • 1300 EL, Almere, Netherlands • Tel +31 (0)36 54 92 911 • Fax +31 (0)36 54 92 964

Cascade (UK) Ltd. • Unit 4, 12 O'Clock Court • Attercliffe Road • Sheffield S4 7WW, England • Tel +44 (0) 870 850 8756 • Fax +44 (0) 870 850 8757

Cascade is a registered trademark of Cascade Corporation.

© Cascade Corporation 2005. All rights reserved. www.cascorp.com Form 6057949 GB 5M PP 9/05

You might also like

- Ah Gen v17n1Document50 pagesAh Gen v17n1elcordovez100% (2)

- المرشد-لحل-المعادلات-التفاضلية-العادية ـ موقع الفريد في الفيزياءDocument203 pagesالمرشد-لحل-المعادلات-التفاضلية-العادية ـ موقع الفريد في الفيزياءOmar Reda Abdel Hakim El saaedNo ratings yet

- BSF 42-5 Brochure (Updated)Document6 pagesBSF 42-5 Brochure (Updated)stefansavijaNo ratings yet

- KSC CatalogDocument18 pagesKSC CatalogKSC PARTSNo ratings yet

- Spring and Shock AbsorberDocument16 pagesSpring and Shock AbsorberAzim AzlanNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- 2023 Global Marketing PlaybookDocument64 pages2023 Global Marketing PlaybookmichellebatistaNo ratings yet

- Biotech Companies in IndiaDocument4 pagesBiotech Companies in IndiaBusinessNo ratings yet

- Caterpillar Undercarriage Selection Guide PDFDocument20 pagesCaterpillar Undercarriage Selection Guide PDFmanjunath k sNo ratings yet

- ZX30, ZX35, ZX40, ZX50 EN Product Information ENDocument42 pagesZX30, ZX35, ZX40, ZX50 EN Product Information ENАлексейNo ratings yet

- Winding Class Notes PDFDocument32 pagesWinding Class Notes PDFAkash ThuleNo ratings yet

- Dressta 534e La Ms 4029 Dss11Document8 pagesDressta 534e La Ms 4029 Dss11YakupovmmNo ratings yet

- Man Val Dhv718 enDocument12 pagesMan Val Dhv718 enJorge Gustavo GoyecheaNo ratings yet

- Building Services PDFDocument12 pagesBuilding Services PDFHardik ChoudharyNo ratings yet

- Mooring Design of Floating Platforms - Univ of Western Australia PresentationDocument48 pagesMooring Design of Floating Platforms - Univ of Western Australia Presentationsojanvasudevan100% (2)

- D160SDocument22 pagesD160SYakupovmm100% (1)

- Unimog Brochures Uhn Basic en PDFDocument16 pagesUnimog Brochures Uhn Basic en PDFLuis SousaNo ratings yet

- Manual Grúa N65aDocument8 pagesManual Grúa N65aSaúlBorlandGalindoNo ratings yet

- KL 900 PDFDocument4 pagesKL 900 PDFDamNo ratings yet

- Mitsubishi SBP 10-16NDocument3 pagesMitsubishi SBP 10-16NSzatmáry LászlóNo ratings yet

- New Holland W170 B W190 BDocument24 pagesNew Holland W170 B W190 Bsilvinh0zzzNo ratings yet

- Polipasto YaleDocument8 pagesPolipasto YaleJose Luis Del AngelNo ratings yet

- Outstanding Versatility: Platform Stacker Trucks 24V, 1.2 - 1.6 TonnesDocument8 pagesOutstanding Versatility: Platform Stacker Trucks 24V, 1.2 - 1.6 TonnesMohamed SamiNo ratings yet

- Spacemaster SX: Electric Wire Rope Hoists Electric Wire Rope HoistsDocument6 pagesSpacemaster SX: Electric Wire Rope Hoists Electric Wire Rope Hoistssarexcuca2010No ratings yet

- Hiab ST Cranes: PB-STRG-EN-OS - 12sid - Indd 1 2014-09-09 11.03Document12 pagesHiab ST Cranes: PB-STRG-EN-OS - 12sid - Indd 1 2014-09-09 11.03Hector MoragaNo ratings yet

- Electric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsDocument8 pagesElectric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsThanh Ngoc0% (1)

- Design Control Mehldau PPDocument18 pagesDesign Control Mehldau PPAurelio DutariNo ratings yet

- Fdocuments - in - 239813017 Catalogo Varco BJDocument56 pagesFdocuments - in - 239813017 Catalogo Varco BJAbelardo CortezNo ratings yet

- Telescopic Handler: Lifting Height 12.700 MM Lifting Capacity 3.500 KG Operating Weight 9.800 KGDocument12 pagesTelescopic Handler: Lifting Height 12.700 MM Lifting Capacity 3.500 KG Operating Weight 9.800 KGanzorNo ratings yet

- W170B/ W190B Wheel LoadersDocument22 pagesW170B/ W190B Wheel LoadersPaz RomeroNo ratings yet

- KS Crane Brochure 2007Document16 pagesKS Crane Brochure 2007VO DUC ThaoNo ratings yet

- EN DX17Z Brochure D4600110 07-2019 LowResDocument8 pagesEN DX17Z Brochure D4600110 07-2019 LowResTarandeep KaurNo ratings yet

- Kito Product GuideDocument5 pagesKito Product GuideKito CanadaNo ratings yet

- Bandas Industriales DAYCO PDFDocument70 pagesBandas Industriales DAYCO PDFdidi_carolaNo ratings yet

- FT - Rampa Hidraúlica - Blue GiantDocument4 pagesFT - Rampa Hidraúlica - Blue GiantPATRICIA HERNANDEZNo ratings yet

- Zaxis Series: Hydraulic ExcavatorDocument11 pagesZaxis Series: Hydraulic ExcavatorKakek MerahNo ratings yet

- Next Generation Drilling and Subsea Systems PDFDocument8 pagesNext Generation Drilling and Subsea Systems PDFliu zhao liu zhaoNo ratings yet

- Dump Truck: Nominal Payload With Standard Equipment: Maximum GMW: EngineDocument7 pagesDump Truck: Nominal Payload With Standard Equipment: Maximum GMW: Engineamir sadighiNo ratings yet

- Heavy Duty Class C Double Girder Series 3 Top Running Max-E-Lift Complete Cranes: Top Running Cranes For Ultimate Maximum Lift HeightDocument4 pagesHeavy Duty Class C Double Girder Series 3 Top Running Max-E-Lift Complete Cranes: Top Running Cranes For Ultimate Maximum Lift HeightNgô MạnhNo ratings yet

- Enerpac Support Cylinders PDFDocument4 pagesEnerpac Support Cylinders PDFdarkdarkhbkNo ratings yet

- Eh1100 3Document7 pagesEh1100 3Alfonso BerRamNo ratings yet

- Hanical Transmission: Shaha JalalDocument54 pagesHanical Transmission: Shaha Jalallouiswang1964No ratings yet

- (Eng) Zx17u 5a Ks En282uDocument9 pages(Eng) Zx17u 5a Ks En282uMC TAK LEENo ratings yet

- Not Performance.: Shed PoundsDocument2 pagesNot Performance.: Shed PoundsCapacitaciones RutasNo ratings yet

- Lattice Crawler - PictureDocument6 pagesLattice Crawler - PictureMohamed FathyNo ratings yet

- Captain 57series Cutsheet RequeridDocument4 pagesCaptain 57series Cutsheet RequeridEricNo ratings yet

- AmerLink 9 - 20Document4 pagesAmerLink 9 - 20mkkb mk3No ratings yet

- FL4012Document2 pagesFL4012Leonardo Infante VargasNo ratings yet

- PlateRolls PDFDocument20 pagesPlateRolls PDFgabisaNo ratings yet

- Next Generation Drilling and Subsea Systems BrochureDocument8 pagesNext Generation Drilling and Subsea Systems BrochureralphNo ratings yet

- HYDRO Tow Bar Catalogue - 1701Document6 pagesHYDRO Tow Bar Catalogue - 1701Amiet Chatterpal100% (1)

- FAV Offshore & Sub-Sea Brochure-2016 PDFDocument8 pagesFAV Offshore & Sub-Sea Brochure-2016 PDFDrew B MrtnzNo ratings yet

- Carlisle PowerWedgeCogBelt SellSheet 06071611Document2 pagesCarlisle PowerWedgeCogBelt SellSheet 06071611Fada RayNo ratings yet

- Truck-Mounted Concrete Pump 31-5: Manoeuvrability in Every DimensionDocument9 pagesTruck-Mounted Concrete Pump 31-5: Manoeuvrability in Every DimensionSofNo ratings yet

- Workholding Cylinders EN-USDocument36 pagesWorkholding Cylinders EN-USRoberto RodriguezNo ratings yet

- E24b87 TR 35 45 60 70 100 en (1dd)Document24 pagesE24b87 TR 35 45 60 70 100 en (1dd)JeffreyNo ratings yet

- Bro Flexiguard A-Frame enDocument2 pagesBro Flexiguard A-Frame enBeto AsaberNo ratings yet

- Agi 2019 York - en Masse - Conveyor Brochure Fin WebDocument16 pagesAgi 2019 York - en Masse - Conveyor Brochure Fin WebnareshpaneruNo ratings yet

- Clamping and Lifting Device (CLD) For Single and Multi-Rope Koepe Hoisting InstallationsDocument3 pagesClamping and Lifting Device (CLD) For Single and Multi-Rope Koepe Hoisting InstallationsJose Maria Castro PazosNo ratings yet

- Track-Type Tractor: Engine Weights Rated Net Power at 2,200 RPMDocument16 pagesTrack-Type Tractor: Engine Weights Rated Net Power at 2,200 RPMFathur rohmanNo ratings yet

- Ultimax Rubber SuspensionDocument4 pagesUltimax Rubber SuspensionAnirban GhoshNo ratings yet

- Performance and Durability in One: Kalmar DRT450Document5 pagesPerformance and Durability in One: Kalmar DRT450Info SpeedfixNo ratings yet

- TC250A4 (Manual Controlled)Document9 pagesTC250A4 (Manual Controlled)tursimanm658No ratings yet

- WP contentuploads201401HSL 218 - 110T PDFDocument60 pagesWP contentuploads201401HSL 218 - 110T PDFsundar_kiruthiNo ratings yet

- STS Series Transfer TrailersDocument4 pagesSTS Series Transfer TrailersJose Luis DominguezNo ratings yet

- En AX10u 17uDocument2 pagesEn AX10u 17uYakupovmmNo ratings yet

- EU - AX29u-52u-5 08 03 11 Small LeafletDocument2 pagesEU - AX29u-52u-5 08 03 11 Small LeafletYakupovmmNo ratings yet

- Bobcat - tl360 TL470Document16 pagesBobcat - tl360 TL470YakupovmmNo ratings yet

- En Entl Encl1106 (Подъемники)Document2 pagesEn Entl Encl1106 (Подъемники)YakupovmmNo ratings yet

- Pneumatic Forklift TrucksDocument6 pagesPneumatic Forklift TrucksYakupovmmNo ratings yet

- Pneumatic Diesel/LPG/Gasoline Forklifts: 1500kg To 2000kg RangeDocument6 pagesPneumatic Diesel/LPG/Gasoline Forklifts: 1500kg To 2000kg RangeYakupovmmNo ratings yet

- Pneumatic and Cushion Forklift TrucksDocument6 pagesPneumatic and Cushion Forklift TrucksYakupovmmNo ratings yet

- Self-Propelled Articulating Booms: Z - 30/20N & Z - 30/20N RJDocument2 pagesSelf-Propelled Articulating Booms: Z - 30/20N & Z - 30/20N RJYakupovmmNo ratings yet

- 3 Wheel Electric Forklift Trucks: B13R / 15R / 16R-5 (24V Rear Wheel Drive)Document6 pages3 Wheel Electric Forklift Trucks: B13R / 15R / 16R-5 (24V Rear Wheel Drive)YakupovmmNo ratings yet

- Electric ForkliftDocument46 pagesElectric ForkliftYakupovmmNo ratings yet

- B (BC) 25S-5 Series Brochure - EU - (1106)Document6 pagesB (BC) 25S-5 Series Brochure - EU - (1106)YakupovmmNo ratings yet

- Truckdata 11,0 - 16,0 Tons, Diesel - 1Document4 pagesTruckdata 11,0 - 16,0 Tons, Diesel - 1YakupovmmNo ratings yet

- Pneumatic Forklift Trucks: G20G / G25G / G30G D20G / D25G / D30GDocument6 pagesPneumatic Forklift Trucks: G20G / G25G / G30G D20G / D25G / D30GYakupovmmNo ratings yet

- CSeries 5000-6000L (C2500-C3) USA Technical 2018Document2 pagesCSeries 5000-6000L (C2500-C3) USA Technical 2018YakupovmmNo ratings yet

- DX190W Low0329Document28 pagesDX190W Low0329YakupovmmNo ratings yet

- C4000MK3 Om enDocument81 pagesC4000MK3 Om enYakupovmmNo ratings yet

- Gerbeur Porte Debout WD2330SDocument3 pagesGerbeur Porte Debout WD2330SYakupovmmNo ratings yet

- DG25S-5 погрузчикиDocument6 pagesDG25S-5 погрузчикиYakupovmmNo ratings yet

- Forklift C 5 Pneumatic BrochureDocument11 pagesForklift C 5 Pneumatic BrochureYakupovmmNo ratings yet

- The Versatile Articulated Truck That Does It AllDocument16 pagesThe Versatile Articulated Truck That Does It AllYakupovmm0% (1)

- EN 06SpecSheet C60-80 S0611E.pdf-IVECODocument6 pagesEN 06SpecSheet C60-80 S0611E.pdf-IVECOYakupovmmNo ratings yet

- Pneumatic Forklift Trucks - D20253033S35C-5Document6 pagesPneumatic Forklift Trucks - D20253033S35C-5YakupovmmNo ratings yet

- Ic-Pneumatic Lpg/Diesel Pneumatic or Solid TyresDocument8 pagesIc-Pneumatic Lpg/Diesel Pneumatic or Solid TyresYakupovmmNo ratings yet

- Charlatte T135 Electric TractorDocument2 pagesCharlatte T135 Electric TractorYakupovmmNo ratings yet

- Charlatte Manutention - Fayat Group Charlatte America - Fayat Group Charlatte Manutention UkDocument2 pagesCharlatte Manutention - Fayat Group Charlatte America - Fayat Group Charlatte Manutention UkYakupovmmNo ratings yet

- AC Electric Tow Tractor: Standard FeaturesDocument2 pagesAC Electric Tow Tractor: Standard FeaturesYakupovmmNo ratings yet

- Electric Tow Tractor: Standard FeaturesDocument2 pagesElectric Tow Tractor: Standard FeaturesYakupovmmNo ratings yet

- AC Cargo Tractor: Standard FeaturesDocument2 pagesAC Cargo Tractor: Standard FeaturesYakupovmmNo ratings yet

- Embedded MicrocontrollerDocument30 pagesEmbedded MicrocontrollervinoliabenitaNo ratings yet

- KLV 32v300aDocument129 pagesKLV 32v300aDeddyThungNo ratings yet

- SHELTER FOR COMPOSITE CLIMATES 3rd SEMDocument19 pagesSHELTER FOR COMPOSITE CLIMATES 3rd SEMflower lilyNo ratings yet

- HWDocument6 pagesHWchippNo ratings yet

- Sikadur 31 PlusDocument5 pagesSikadur 31 Plusghazi.tcmarineNo ratings yet

- EXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitDocument9 pagesEXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitCHERUYIOT IANNo ratings yet

- TE.040 System TestScript-Oracle eAM and Primavera Integration v1Document16 pagesTE.040 System TestScript-Oracle eAM and Primavera Integration v1unnikallikattuNo ratings yet

- BIOLOGY Q1 Mod5Document12 pagesBIOLOGY Q1 Mod5Karen Mae CastilloNo ratings yet

- Parametric Modelling of Oldham Coupling: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument6 pagesParametric Modelling of Oldham Coupling: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySri BharathNo ratings yet

- Using Skype To Make Video Calls and Sharing Screen: Intel® Easy StepsDocument4 pagesUsing Skype To Make Video Calls and Sharing Screen: Intel® Easy StepsMercyNo ratings yet

- лексикологія семінар 4Document12 pagesлексикологія семінар 4Yana DemchenkoNo ratings yet

- Seminar ReportDocument6 pagesSeminar ReportgregNo ratings yet

- 980a1003 PDFDocument48 pages980a1003 PDFMichael DavenportNo ratings yet

- JD For Manager - Seo - IquantiDocument4 pagesJD For Manager - Seo - IquantiSaiyed MubassirNo ratings yet

- Faq DhaDocument5 pagesFaq DhaApexal overseas education consultantNo ratings yet

- FINE3015 2122 - CourseOutline Sem1Document2 pagesFINE3015 2122 - CourseOutline Sem1Wang Hon YuenNo ratings yet

- Wild-Food Plants in Southern Ethiopia:: 1. Introduction and BackgroundDocument16 pagesWild-Food Plants in Southern Ethiopia:: 1. Introduction and Backgroundvillamor niezNo ratings yet

- Reading - Types of PrototypesDocument4 pagesReading - Types of Prototypesme.alsiriNo ratings yet

- Research Paper On HerbalifeDocument5 pagesResearch Paper On Herbaliferykkssbnd100% (1)

- IRRI Annual Report 2007Document271 pagesIRRI Annual Report 2007CPS_IRRINo ratings yet

- CHATGPTDocument1 pageCHATGPTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Transformers Project FileDocument14 pagesTransformers Project FiledikshaNo ratings yet

- Unit 4 Lab 1 Moles Molecules and GramsDocument4 pagesUnit 4 Lab 1 Moles Molecules and Gramsapi-239473897No ratings yet

- AA IQBots With Vision Skills - User ManualDocument74 pagesAA IQBots With Vision Skills - User Manualauun rNo ratings yet

- Well Furnished Room For Two Persons Room Charge Extra Person (Above 12 Yrs) Child 4-12 Yrs. AC Charges Per RoomDocument3 pagesWell Furnished Room For Two Persons Room Charge Extra Person (Above 12 Yrs) Child 4-12 Yrs. AC Charges Per RoomPradeep AhireNo ratings yet