Professional Documents

Culture Documents

Radiator

Uploaded by

rizkyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radiator

Uploaded by

rizkyCopyright:

Available Formats

EG1–216

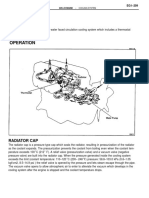

22R–E ENGINE – COOLING SYSTEM

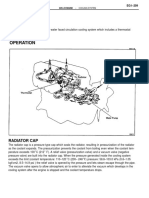

RADIATOR

RADIATOR CLEANING

Using water or a steam cleaner, remove mud and dirt

from the radiator core.

NOTICE: If using a high–pressure type cleaner, be care-

ful not to deform the fins of the radiator core. For exam-

ple, keep a distance of more than 40–50 cm (15.75–

19.69 in.) between the radiator core and cleaner nozzle

when the cleaner nozzle pressure is 2,942–3,432 kPa

(30–35 kgf/cm2, 427–498 psi).

RADIATOR INSPECTION

1. CHECK RADIATOR CAP

Using radiator cap tester, pump the tester until the relief

valve opens. Check that the valve opens between 174 kPa

(0.75 kgf/cm2, 10.7 psi) and 103 kPa

(1.05 kgf/cm2, 14.9 psi).

Check that pressure gauge does not drop rapidly when

pressure on cap is below 59 kPa (0.6 kgf/cm2,

8.5 psi).

If either check is not within limit, replace the radiator cap.

2. CHECK COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant and attach a radiator cap

tester.

(b) Warm up the engine.

(c) Pump it to 118 kPa (1.2 kgf/cm2, 17.1 psi), and check

that the pressure does not drop.

If the pressure drops, check for leaks from the

hoses, radiator or water pump. If no external leaks

are found, check the heater core, block and intake

manifold.

EG1–217

22R–E ENGINE – COOLING SYSTEM

RADIATOR REMOVAL

1. DRAIN COOLANT

2. REMOVE ENGINE UNDER COVER

3. REMOVE AIR INTAKE CONNECTOR

4. REMOVE RADIATOR

(a) Disconnect the reservoir hose.

(b) Remove the radiator hoses.

(c) w/ A/C:

Remove the No. 2 fan shroud.

(d) Remove the No. 1 fan shroud.

(e) A/T:

Disconnect the oil cooler hoses.

HINT:

Be careful as some oil will leak out. Catch it in a

suitable container.

Plug the hose to prevent oil from escaping.

(f) Remove the 4 bolts and radiator.

SERVICE SPECIFICATIONS

SERVICE DATA

Thermostat Valve opening temperature

Valve lift

Radiator Relief valve opening pressure

TORQUE SPECIFICATIONS

Part tightened

Water outlet x Intake manifold

You might also like

- RECAM Catalogue 2012Document83 pagesRECAM Catalogue 2012Maxmore Karumamupiyo100% (1)

- 2AZ FE CoolingDocument35 pages2AZ FE CoolingLuks Fernandez50% (2)

- 2010 Toyota Prius Repair Manual - Exhaust Heat RecirculationDocument10 pages2010 Toyota Prius Repair Manual - Exhaust Heat RecirculationMuhammad Imran Aftab100% (1)

- 1C Engine Fuel System Rz4eDocument119 pages1C Engine Fuel System Rz4eYuber CuevasNo ratings yet

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocument16 pagesStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarNo ratings yet

- Aicool XB - SeriesDocument9 pagesAicool XB - Seriessarjono100% (1)

- AC System PDFDocument81 pagesAC System PDFZeami Abel Pérez CantilloNo ratings yet

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- Generator AuxiliariesDocument39 pagesGenerator Auxiliariesharry2586No ratings yet

- EGR Cooler Removal (4JJ1 Without DPD) : 1. Component ViewsDocument46 pagesEGR Cooler Removal (4JJ1 Without DPD) : 1. Component ViewsPatricio ValenciaNo ratings yet

- Paul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Document817 pagesPaul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Andreea Dobrita67% (3)

- 52 RadiatorDocument2 pages52 RadiatorShaggy UriosteguiNo ratings yet

- 16 - Cooling PDFDocument13 pages16 - Cooling PDFMichael SakellaridisNo ratings yet

- 2AZ-FE Cooling CO 1-35Document36 pages2AZ-FE Cooling CO 1-35AlelukinNo ratings yet

- CO - CoolingDocument43 pagesCO - CoolingOral McnarrinNo ratings yet

- 2AZ-FE CoolingDocument35 pages2AZ-FE CoolingAdedeji OluwatobilobaNo ratings yet

- 1GR-FE CoolingDocument18 pages1GR-FE CoolingJorge Miguel Couto Cabral100% (1)

- On-Vehicle Inspection: - RadiatorDocument2 pagesOn-Vehicle Inspection: - RadiatorsalusfrankNo ratings yet

- Cooling SystemDocument36 pagesCooling SystemCậu TúNo ratings yet

- 51 Ther MostDocument2 pages51 Ther Mostjasmin45No ratings yet

- 1KD Engine Coolan Drain PlugDocument2 pages1KD Engine Coolan Drain Plugkampee100% (1)

- PendinginDocument4 pagesPendinginMhd AdityaNo ratings yet

- ThermostDocument2 pagesThermostrizkyNo ratings yet

- TOYOTA 1CD-FTV D4D Cooling SystemDocument28 pagesTOYOTA 1CD-FTV D4D Cooling SystemLuis Daniel CortesNo ratings yet

- Cooling PDFDocument38 pagesCooling PDFred eagle winsNo ratings yet

- CoolingDocument37 pagesCoolingjasonphxNo ratings yet

- Electric FanDocument1 pageElectric Fanasgharsadeghi68No ratings yet

- Electric Cooling Fan: On Vehicle InspectionDocument1 pageElectric Cooling Fan: On Vehicle InspectionMiguel ruizNo ratings yet

- Ac SystemDocument89 pagesAc SystemMohammed ShareefNo ratings yet

- 2 2az Fe+coolingDocument36 pages2 2az Fe+coolingfredypezNo ratings yet

- Ac System Parts Id SK-KD 19Document89 pagesAc System Parts Id SK-KD 19Louise LucassicNo ratings yet

- Cooling System (2Az-Fe) : On-Vehicle InspectionDocument27 pagesCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Vacuum DehydrationDocument3 pagesVacuum DehydrationMochammad SafiiNo ratings yet

- Ac PDFDocument40 pagesAc PDFAnaníEscarlethLLocllaVásquezNo ratings yet

- Coolant (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : ReplacementDocument3 pagesCoolant (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) ) : Replacementjere aquinoNo ratings yet

- Manual Refrigeracio Toyota2cDocument14 pagesManual Refrigeracio Toyota2cDeivit Utah BastidasNo ratings yet

- Sistema de EnfriamientoDocument7 pagesSistema de EnfriamientoJanetCruzRamirezNo ratings yet

- Bomba HydracellDocument9 pagesBomba HydracellHelison MendesNo ratings yet

- CoolingDocument32 pagesCoolingapi-3833108No ratings yet

- 2010 Toyota Prius Repair Manual - ThermostatDocument4 pages2010 Toyota Prius Repair Manual - ThermostatBilal al zeitawiNo ratings yet

- Sistema de Enfriamiento p5000Document8 pagesSistema de Enfriamiento p5000jorge humberto arellano almaguer100% (1)

- RemoDocument1 pageRemoMansur KhanNo ratings yet

- Sec 1H (4HL1)Document11 pagesSec 1H (4HL1)Susilo purwanggiNo ratings yet

- AjcoolDocument3 pagesAjcoolIonut GrozaNo ratings yet

- On Vehicle Inspection: RadiatorDocument2 pagesOn Vehicle Inspection: RadiatorMiguel ruizNo ratings yet

- Coolant: InspectionDocument32 pagesCoolant: InspectionAiman NasirNo ratings yet

- Electric Cooling Fan: On Vehicle InspectionDocument2 pagesElectric Cooling Fan: On Vehicle InspectionAlfredo jose Medina revattaNo ratings yet

- 6 Machinery House, Cab, Exterior Trim Parts AnywhereDocument57 pages6 Machinery House, Cab, Exterior Trim Parts AnywhereUbeimar RiveraNo ratings yet

- Co K9K 001Document7 pagesCo K9K 001syyNo ratings yet

- Cooling System: Specification Structure Removal and Installation Inspection and AdjustmentDocument8 pagesCooling System: Specification Structure Removal and Installation Inspection and Adjustmentyojar apazaNo ratings yet

- Group62-3 Aire AcondicionadoDocument9 pagesGroup62-3 Aire AcondicionadoKonax Lihysd MandeNo ratings yet

- Cylinder Head: Components For Removal and InstallationDocument40 pagesCylinder Head: Components For Removal and InstallationTeo CovaNo ratings yet

- What To Do WhenDocument5 pagesWhat To Do Whenhwang2No ratings yet

- Evans Install Procedure 2011 Navistar Max Force 13L Ver 05nov2012Document9 pagesEvans Install Procedure 2011 Navistar Max Force 13L Ver 05nov2012Veterano del CaminoNo ratings yet

- Engine Cooling: Coolant Replacement 2 - . - . - . - . - . - . - . - . - . - . .Document9 pagesEngine Cooling: Coolant Replacement 2 - . - . - . - . - . - . - . - . - . - . .danieldario33No ratings yet

- System Flow Pattern: IstatDocument18 pagesSystem Flow Pattern: IstatgenuineswedeNo ratings yet

- AkcoolingDocument3 pagesAkcoolingRicardo VieiraNo ratings yet

- Ac 24Document2 pagesAc 24Tung NguyenNo ratings yet

- Cooling System: To IndexDocument19 pagesCooling System: To Indexsamsul bakhriNo ratings yet

- Gas Burner: Installation, Use and Maintenance InstructionsDocument16 pagesGas Burner: Installation, Use and Maintenance InstructionsJose CANo ratings yet

- Water PumDocument2 pagesWater PumrizkyNo ratings yet

- Cooling System: Radiator CapDocument2 pagesCooling System: Radiator CaprizkyNo ratings yet

- Coolant Check and Replacement: 22R-E EngineDocument1 pageCoolant Check and Replacement: 22R-E EnginerizkyNo ratings yet

- Cooling System: Radiator CapDocument1 pageCooling System: Radiator CaprizkyNo ratings yet

- ThermostDocument2 pagesThermostrizkyNo ratings yet

- Preparation: Recommended ToolsDocument1 pagePreparation: Recommended ToolsrizkyNo ratings yet

- Radiator Removal: Service SpecificationsDocument1 pageRadiator Removal: Service SpecificationsrizkyNo ratings yet

- AbbreviaDocument1 pageAbbreviarizkyNo ratings yet

- Class 1 RelexDocument21 pagesClass 1 RelexrizkyNo ratings yet

- EU Reveals The Future of BITs Between European States and The Rest of The WorldDocument2 pagesEU Reveals The Future of BITs Between European States and The Rest of The WorldrizkyNo ratings yet

- 2023 Reso-01Document3 pages2023 Reso-01John Mark Mercado JubelagNo ratings yet

- DTDC Rate Quotation-4Document3 pagesDTDC Rate Quotation-4Ujjwal Sen100% (1)

- Che 342 Practice Set I IDocument4 pagesChe 342 Practice Set I IDan McNo ratings yet

- Home Work (Satistics AIUB)Document5 pagesHome Work (Satistics AIUB)fukscribdNo ratings yet

- Grade 5 Olympiad: Answer The QuestionsDocument14 pagesGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanNo ratings yet

- MGT 201 Midterm Exam, Version BDocument8 pagesMGT 201 Midterm Exam, Version BCybelle TradNo ratings yet

- A Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingDocument22 pagesA Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingPl TorrNo ratings yet

- Future Generation Computer SystemsDocument18 pagesFuture Generation Computer SystemsEkoNo ratings yet

- DMP 2021 TPJ SRDocument275 pagesDMP 2021 TPJ SRishu sNo ratings yet

- WTO & MFA AnalysisDocument17 pagesWTO & MFA Analysisarun1974No ratings yet

- PT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaDocument16 pagesPT Shri Krishna Sejahtera: Jalan Pintu Air Raya No. 56H, Pasar Baru Jakarta Pusat 10710 Jakarta - IndonesiaihsanlaidiNo ratings yet

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDocument6 pagesEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubNo ratings yet

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDocument2 pagesNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoNo ratings yet

- Enabling Trade Report 2013, World Trade ForumDocument52 pagesEnabling Trade Report 2013, World Trade ForumNancy Islam100% (1)

- 13 - Conclusion and SuggestionsDocument4 pages13 - Conclusion and SuggestionsjothiNo ratings yet

- User Manual OptiPoint 500 For HiPath 1220Document104 pagesUser Manual OptiPoint 500 For HiPath 1220Luis LongoNo ratings yet

- Farmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesDocument13 pagesFarmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesPsychology and Education: A Multidisciplinary JournalNo ratings yet

- 3UF70121AU000 Datasheet enDocument7 pages3UF70121AU000 Datasheet enJuan Perez PerezNo ratings yet

- BSDC CCOE DRAWING FOR 2x6 KL R-1Document1 pageBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosNo ratings yet

- Year Warranty: 1575 - 90 Ave Edmonton, AB Canada T6P 0E2Document2 pagesYear Warranty: 1575 - 90 Ave Edmonton, AB Canada T6P 0E2juanchingarNo ratings yet

- NOS 65-200-90x60-30KWD PDFDocument2 pagesNOS 65-200-90x60-30KWD PDFDao The ThangNo ratings yet

- Keywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeDocument11 pagesKeywords: Communication, Technology, Collaborative, Evaluative Learning, InnovativeNnamani EmmanuelNo ratings yet

- EE FlowchartDocument1 pageEE Flowchartgoogley71No ratings yet

- Section 1: 1. Ofosu, George Nelson 2. OBENG, Kevin Kofi 3.OBENG-OFORI, Afrifa KwameDocument17 pagesSection 1: 1. Ofosu, George Nelson 2. OBENG, Kevin Kofi 3.OBENG-OFORI, Afrifa KwameTony JamesNo ratings yet

- War As I Knew ItDocument2 pagesWar As I Knew ItShreyansNo ratings yet

- Netaji Subhas Open UniversityDocument4 pagesNetaji Subhas Open UniversityraydipanjanNo ratings yet

- Far160 Pyq Feb2023Document8 pagesFar160 Pyq Feb2023nazzyusoffNo ratings yet

- Item No. 6 Diary No 6856 2024 ConsolidatedDocument223 pagesItem No. 6 Diary No 6856 2024 Consolidatedisha NagpalNo ratings yet

- Business English Question PaperDocument4 pagesBusiness English Question PaperKhizra AliNo ratings yet