Professional Documents

Culture Documents

Scope - : Methods of Test For Cables

Uploaded by

Anwarul AfrojOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope - : Methods of Test For Cables

Uploaded by

Anwarul AfrojCopyright:

Available Formats

UDC 621.315’21 : 620.

174 IS : 10810( Part 50 ) - 1984

( Reaffirmed 1996 )

Indian Standard

METHODS OF TEST FOR CABLES

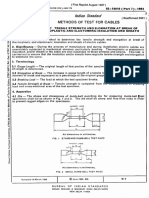

PART 50 BENDING TEST

. scope- Prescribes the method for carrying out bending test oncsbles.

Note - Normally bending test, by itself, is not a complete test and to assess the effect of bending, apart from

visual examination, this test is followed by other test(s) as prescribed in relevant specification.

!. SignifKance - All electric cables are subjected to bending operations during handling and

nstallation. The minimum radii are specified in the relevant specifications. In order to ensure

hat the cables withstand, without damage or showing any cracking of the sheaths, the recommend-

!d bending radii during installation and handling, it is necessary to conduct a bending test which

s more rigorous than what the cable is likely to be subjected to in actual practice.

1. Terminology

I.1 Bending - Operation of winding, unwinding, winding in reverse and unwinding of the cable on

:est cylinder having predetermined diameter depending on type and diameter of the cable.

1. Apparatus

I.1 Test Cylinder - Having diameter as specified in relevant specification.

1.2 Vernier Calliper - Least count 0.01 mm.

5. Material - No material other than the specimen is required for performing this test.

6. Test Specimen - A sufficient length of cable with open ends to give at least one complete turn

round the test cylinder.

6.2 Number of Specimens - One.

7. Conditioning - No pre-conditioning of specimen is required.

6. Test Procedure

8.1 The cable sample shall undergo, at ambient temperature, 3 bending cycles, each cycle shall

consist of winding the cable sample on the test cylinder, unwinding, winding on again in the

reverse direction and unwinding. The bending shall be carried out at a reasonably uniform speed

between 15 and 30 seconds per half cycle.

8.2 After the above operation the specimen shall be subjected to visual examination and other

test(s) as specifed in individual specification.

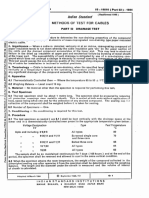

9. Tabulation of Observations

Sample Description Over all Test Cylinder Visual -Results of Subsequent

No. of Sample DiaFa?t;; of Diameter Observations Tests ~( in Accordance

with Relevant Speci-

mm mm ikation )

Adopted 14 March 1984 @ Soptembei 3985, ISI Gr 9

I I I

INDIAN STANDARDS INSTITUTION

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

IS:1D810(mPart 50)-1984

10. Cahilation - No calculation is involved.

11. Report

11.l Reference Specification

Sample Description Results of Test

No. of Sample Subsequent to Bending

11.2 Conclusion- Specimen meets/does not meet the requirement of the specification.

Printed at New India Printing Press, Khurja. India

You might also like

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardAnwarul AfrojNo ratings yet

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesBilal AhmadNo ratings yet

- Hdian Standard I I: Methods of Test For CablesDocument2 pagesHdian Standard I I: Methods of Test For CablesAnwarul AfrojNo ratings yet

- Indian Standard 9 Vir : Cables "Re - KfianDocument1 pageIndian Standard 9 Vir : Cables "Re - KfianVatsalNo ratings yet

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesARUN BNo ratings yet

- Disclosure To Promote The Right To InformationDocument5 pagesDisclosure To Promote The Right To InformationVinay ShrivastavNo ratings yet

- Instructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureDocument2 pagesInstructions No. TK-7: Backflow Preventer Test Kit Field Testing ProcedureAli mohammadNo ratings yet

- SCL-QF-042 - IS 616 Observation SheetDocument54 pagesSCL-QF-042 - IS 616 Observation SheetRAVIRAJ DATTATRAYA PADOLNo ratings yet

- 1828 1 PDFDocument16 pages1828 1 PDFsunitkghosh1No ratings yet

- Astm E426Document4 pagesAstm E426Rafi YusohNo ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardARUN BNo ratings yet

- Methods of Test For Cables: Indian Standard Y& "M-,4 R-F/RDocument3 pagesMethods of Test For Cables: Indian Standard Y& "M-,4 R-F/RVatsalNo ratings yet

- V7?a?cllclu,: Proforma For Analysis of Unit Rate of DewateringDocument4 pagesV7?a?cllclu,: Proforma For Analysis of Unit Rate of Dewateringashish ku bhatiaNo ratings yet

- Transformer Oil Testing Lab - NABL Accredited (HTTP://WWW - Powerelectronical.com)Document3 pagesTransformer Oil Testing Lab - NABL Accredited (HTTP://WWW - Powerelectronical.com)mustafa1805100% (2)

- Changes/Amendments in Astm E309-95 and E309-11 Along With Relevant Bpi In-Practice/Corrective ActionsDocument2 pagesChanges/Amendments in Astm E309-95 and E309-11 Along With Relevant Bpi In-Practice/Corrective ActionsMahmood KhanNo ratings yet

- Eddy Current Testing Procedure IUDocument10 pagesEddy Current Testing Procedure IUDanielNo ratings yet

- Is 4985 StiDocument9 pagesIs 4985 StiraviNo ratings yet

- 1 - Annealing Test For Wires Used in ConductorsDocument2 pages1 - Annealing Test For Wires Used in ConductorsPuspendra ShuklaNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationabcNo ratings yet

- 7 - Tensile Strength and Elongation at Break of Thermoplastic and Elastomeric Insulation and SheathDocument4 pages7 - Tensile Strength and Elongation at Break of Thermoplastic and Elastomeric Insulation and SheathPuspendra ShuklaNo ratings yet

- LED Driver Test Report IEC 61347 2 13 36CDocument11 pagesLED Driver Test Report IEC 61347 2 13 36CLingaraj Suresh LingaianNo ratings yet

- Prosedur T, K, YDocument28 pagesProsedur T, K, YMuhammad AsrilNo ratings yet

- 3.7 Appendix D - Minimum RequirementsDocument14 pages3.7 Appendix D - Minimum RequirementsendyNo ratings yet

- Disclosure To Promote The Right To InformationDocument6 pagesDisclosure To Promote The Right To Informationkajale.shrikantNo ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardAnwarul AfrojNo ratings yet

- 1 Annaling TestDocument2 pages1 Annaling TestProduction TortekNo ratings yet

- Eddy Current SpecificationsDocument7 pagesEddy Current SpecificationsBhavani PrasadNo ratings yet

- Test Charts Machines For Surface Grinding With Two Columns For Grinding SlidewaysDocument16 pagesTest Charts Machines For Surface Grinding With Two Columns For Grinding SlidewaysBVS NAGABABUNo ratings yet

- User Handbook-Test Panel - 1234Document36 pagesUser Handbook-Test Panel - 1234Savinda JanszNo ratings yet

- JKTH23002048Document17 pagesJKTH23002048faid cvmaNo ratings yet

- ASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFDocument7 pagesASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFMarcosNo ratings yet

- IEC 60793-1-52 (2001) Change of TemperatureDocument10 pagesIEC 60793-1-52 (2001) Change of TemperaturejudyyangchNo ratings yet

- 7155 - 8 Scraper ConveyorDocument4 pages7155 - 8 Scraper ConveyorMann GurpreetNo ratings yet

- Methods of Test For Cables: Indian StandardDocument3 pagesMethods of Test For Cables: Indian StandardVatsalNo ratings yet

- Is 10810 45 1984 PDFDocument7 pagesIs 10810 45 1984 PDFTapas HiraNo ratings yet

- Ultrasonic Testing ProcedureDocument12 pagesUltrasonic Testing ProcedureRohit Kumar Mishra100% (1)

- Field Quality Plan of EHV Power CablesDocument10 pagesField Quality Plan of EHV Power CablesMohammed TauseefNo ratings yet

- Is - 14222 - 1995Document8 pagesIs - 14222 - 1995sangitaghaisasNo ratings yet

- Blood Sedimentation Tube, Wintrobe, Glass, Reusable: Standard Specification ForDocument2 pagesBlood Sedimentation Tube, Wintrobe, Glass, Reusable: Standard Specification ForAhmed AlzubaidiNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationSCRIBDNo ratings yet

- FM 2151Document82 pagesFM 2151Nafeesa SalehNo ratings yet

- Testing IsDocument37 pagesTesting Iskrishkar2010No ratings yet

- Standard Practice For Ultrasonic Examination of Austenitic Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Austenitic Steel ForgingssyyouNo ratings yet

- Hkwol KKFN LVSFVD Iapj Ijh (K.K (Lh-Ch-Vkj-Ijh (K.K) : HKKJRH EkudDocument10 pagesHkwol KKFN LVSFVD Iapj Ijh (K.K (Lh-Ch-Vkj-Ijh (K.K) : HKKJRH EkudBinayak KumarNo ratings yet

- Article 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesDocument7 pagesArticle 26 Eddy Current Standards Standard Practice For Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy TubesAnonymous 4IpmN7OnNo ratings yet

- IEC 60793-1-53 (2001) Water ImmersionDocument9 pagesIEC 60793-1-53 (2001) Water ImmersionjudyyangchNo ratings yet

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Document20 pagesNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNo ratings yet

- Eddy Current Testing ProcedureDocument10 pagesEddy Current Testing ProcedureLalit MohanNo ratings yet

- Is Iec 61701 1995Document8 pagesIs Iec 61701 1995vijay_rainaNo ratings yet

- Ieee Test Motors: Standard Procedure For Single-Phase InductionDocument21 pagesIeee Test Motors: Standard Procedure For Single-Phase InductionHAMNo ratings yet

- Is 9000 7 6 1988Document9 pagesIs 9000 7 6 1988seshu.oblum.1998No ratings yet

- Random Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeDocument9 pagesRandom Mtrasonic Examination of Butt Welds: Prepared Pipe Fabrication Institute Engineering CommitteeДенис ПекшуевNo ratings yet

- Para Consulta: Glass Capillary Kinematic ViscometersDocument25 pagesPara Consulta: Glass Capillary Kinematic ViscometersJUAN CARLOSNo ratings yet

- Astm G155Document12 pagesAstm G155calidadlaboratorio20No ratings yet

- Ndi06 51 00 02 001Document8 pagesNdi06 51 00 02 001Jorge FernandezNo ratings yet

- Elmm@Ir 3T?'Mw&Pjrw@Rii: Ww%7Mlz'5Document7 pagesElmm@Ir 3T?'Mw&Pjrw@Rii: Ww%7Mlz'5parameswarroutNo ratings yet

- 1Document6 pages1colinyNo ratings yet

- Motor CommissioningDocument9 pagesMotor CommissioningVigneshNo ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationKittuNo ratings yet

- D 4839 - 03 - RDQ4MZKDocument6 pagesD 4839 - 03 - RDQ4MZKAnwarul AfrojNo ratings yet

- ASTM Molybdenum in Water PDFDocument4 pagesASTM Molybdenum in Water PDFAna MiraNo ratings yet

- Astm B-499-02Document4 pagesAstm B-499-02Anwarul AfrojNo ratings yet

- Sampling Particulate Ion-Exchange Materials: Standard Practices ForDocument7 pagesSampling Particulate Ion-Exchange Materials: Standard Practices ForAnwarul AfrojNo ratings yet

- Astm A500 Pipe Tolerances (Round Tubing)Document1 pageAstm A500 Pipe Tolerances (Round Tubing)Anwarul AfrojNo ratings yet

- Recovery of Enteroviruses From Waters: Standard Practice ForDocument3 pagesRecovery of Enteroviruses From Waters: Standard Practice ForAnwarul AfrojNo ratings yet

- ASTM B504-Coulometric Method For Coating ThicknessDocument4 pagesASTM B504-Coulometric Method For Coating ThicknessReshan VidurangaNo ratings yet

- Astm A101 PDFDocument8 pagesAstm A101 PDFtrjithinrajNo ratings yet

- BS en 50200-2006Document32 pagesBS en 50200-2006Anwarul AfrojNo ratings yet

- Methods of Test For Cables: Indian StandardDocument2 pagesMethods of Test For Cables: Indian StandardAnwarul AfrojNo ratings yet

- BS 6485-1999 PVC Covered Overhead ConductorDocument12 pagesBS 6485-1999 PVC Covered Overhead ConductorAnwarul AfrojNo ratings yet

- BS en 60332-3-22-2009Document18 pagesBS en 60332-3-22-2009Anwarul AfrojNo ratings yet

- Is 3711-2012 Steel and Steel Products-Location and Preparation of Samples and Test Pieces For Mechanical TestingDocument25 pagesIs 3711-2012 Steel and Steel Products-Location and Preparation of Samples and Test Pieces For Mechanical TestingAnwarul AfrojNo ratings yet

- Product Manual PM-1239-pt1-cmd2 PDFDocument12 pagesProduct Manual PM-1239-pt1-cmd2 PDFMohd Masoom AliNo ratings yet

- Is 4711 2008Document9 pagesIs 4711 2008Rishab TanejaNo ratings yet

- IS 3803-2-1989 Steel Conversion of Elongation Values - Part-2 Austenitic SteelsDocument35 pagesIS 3803-2-1989 Steel Conversion of Elongation Values - Part-2 Austenitic SteelsAnwarul AfrojNo ratings yet

- Is 2329 2005Document9 pagesIs 2329 2005madhunikhilNo ratings yet

- IS 3803-1 1989 Conversion of Elongation ValuesDocument35 pagesIS 3803-1 1989 Conversion of Elongation ValuesSoumen MidyaNo ratings yet

- Plant ModuleDocument26 pagesPlant ModuleHitesh JainNo ratings yet

- THINK - l2 Final Extension TestDocument3 pagesTHINK - l2 Final Extension TestAngelinaKNo ratings yet

- Border-Study/: "Borderless" and Cross-Border EducationDocument10 pagesBorder-Study/: "Borderless" and Cross-Border EducationSan TyNo ratings yet

- Lesson Plan in Science 3 Ranking 2020Document4 pagesLesson Plan in Science 3 Ranking 2020Karrylle Casin-Seguera Absalon100% (1)

- Che 402: Analytical ChemistryDocument12 pagesChe 402: Analytical ChemistryKrizzete HernandezNo ratings yet

- Fem BitsDocument9 pagesFem BitsSrinivasaReddyM64% (22)

- F3 Math Ch1A Linear Inequalities in One UnknownDocument8 pagesF3 Math Ch1A Linear Inequalities in One Unknown何俊昇No ratings yet

- Fret Position Calculator - Stewmac CavaquinhoDocument1 pageFret Position Calculator - Stewmac CavaquinhoJosé Luiz Magalhães de CarvalhoNo ratings yet

- Sheet Metal Cutting111111Document60 pagesSheet Metal Cutting111111Mintesnot AdeNo ratings yet

- Lec# 16 Breakdown in LiquidsDocument12 pagesLec# 16 Breakdown in LiquidsVishal MeghwarNo ratings yet

- Grammar - Subject Verb AgreementDocument10 pagesGrammar - Subject Verb AgreementArpitha100% (1)

- Types of Academic Text: 1. Understanding The Importance of GenreDocument9 pagesTypes of Academic Text: 1. Understanding The Importance of GenreThelma LanadoNo ratings yet

- Standard Specification: Tecnicas Reunidas, S.ADocument9 pagesStandard Specification: Tecnicas Reunidas, S.AaquilesanchezNo ratings yet

- Mobile Phones and RadiationDocument6 pagesMobile Phones and RadiationGehanShabanNo ratings yet

- Simon E3 CatalogueDocument16 pagesSimon E3 CataloguemarketingsneNo ratings yet

- Mock Exam - MathDocument4 pagesMock Exam - MathFati FleurNo ratings yet

- Markov Clustering AlgorithmDocument53 pagesMarkov Clustering AlgorithmAaryan GuptaNo ratings yet

- Faculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreDocument21 pagesFaculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreNatasha YusofNo ratings yet

- IS-13875-Part 1-1993 (Reaff 2020) (Digital Measuring Instruments For Measuring & Control)Document14 pagesIS-13875-Part 1-1993 (Reaff 2020) (Digital Measuring Instruments For Measuring & Control)Samiran SenNo ratings yet

- 7728 ID Optimasi Dosis Pupuk Nitrogen Dan Fosfor Pada Tanaman Kelapa Sawit Elaeis GuineeDocument7 pages7728 ID Optimasi Dosis Pupuk Nitrogen Dan Fosfor Pada Tanaman Kelapa Sawit Elaeis GuineeHdyt FFNo ratings yet

- Department of Transport Merchant Shipping Notice No. M.1214Document5 pagesDepartment of Transport Merchant Shipping Notice No. M.1214Игорь БакановNo ratings yet

- Essentialism vs. Social Constructionism in The Study of Human Sexuality (1998) - DeLamater & Hyde PDFDocument10 pagesEssentialism vs. Social Constructionism in The Study of Human Sexuality (1998) - DeLamater & Hyde PDFKhoa LeNo ratings yet

- Scientific Notation Unit TestDocument3 pagesScientific Notation Unit TestMohamed AbdisamedNo ratings yet

- Quarter 3 - Module 1 Writing and Composition: Department of Education Republic of The PhilippinesDocument28 pagesQuarter 3 - Module 1 Writing and Composition: Department of Education Republic of The PhilippinesEditha FernandezNo ratings yet

- Chapter 1 - Part 4 PDFDocument27 pagesChapter 1 - Part 4 PDFأحمد الرقبNo ratings yet

- Book - 1914 - Mathematical Recreations and EssaysDocument505 pagesBook - 1914 - Mathematical Recreations and Essaysankit madanNo ratings yet

- CAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanDocument7 pagesCAPILLAN, SHAIRA - Semi-Detailed-Lesson-PlanShai Ra CapillanNo ratings yet

- Introduction To Java Programming Comprehensive Version 10th Edition Liang Solutions ManualDocument26 pagesIntroduction To Java Programming Comprehensive Version 10th Edition Liang Solutions ManualStacyGonzalezyoar100% (52)

- Macroeconomics 6th Edition Williamson Solutions ManualDocument36 pagesMacroeconomics 6th Edition Williamson Solutions Manualfagotbouge3q7x96% (26)

- The National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Document93 pagesThe National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Cable KurwitzNo ratings yet