Professional Documents

Culture Documents

Hfx135D Water Recycling: HFX Ion Exchange Systems

Uploaded by

nermeen ahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hfx135D Water Recycling: HFX Ion Exchange Systems

Uploaded by

nermeen ahmedCopyright:

Available Formats

World-ClassEquipment&ProcessExpertise

HFX Ion Exchange Systems

HFX135D WATER RECYCLING

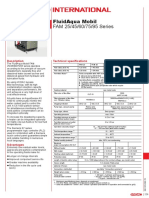

TANKS OPERATING SPECIFICATIONS

System Feed Feed Water Quality

Volume 6,500 gallons Temperature 55°F-105oF

DI Water pH 3-10 SU

Volume 8,000 gallons TSS <5 mg/L

SKID MOUNTED COMPONENTS TDS <600 mg/L

Feed Pumps Chlorine <2 mg/L

Number Two (2) Product Water Quality

Horsepower 20 HP TDS <2 mg/L

Motor Control (Optional) Variable H2 Drive Conductivity <5 μg/L

Standard Pre-Treatment** Silica <20 μg/L

System Hydrus HF336cbOD System Flow 135 gpm

Vessel Construction PE Lined Fiberglass REGENERATION SPECIFICATIONS

Media Granular Activated Carbon Flow Configuration Alternating Duplex

3

Volume per Vessel 14 ft Regeneration Countercurrent

Bag Filters Waste Flow 30 gpm

Number Four (4) Cycle Time 75 minutes

Filter Rating 5-micron Cation Exchangers

Cation & Anion Exchangers* HCI per Cycle 77 gallons

Number Two (2) of each Waste per cycle 2,200 gallons

Vessel Size 48” x 72" Grains Capacity 1,100,000

Construction PE Lined Fiberglass Anion Exchangers

Cation Resin Strong Acid NaOH per cycle 41 gallons

Anion Resin Strong Base Waste per Cycle 2,400 gallons

Volume per Vessel 55 ft3 Grains Capacity 990,000

Controls UTILITIES

Inlet Conductivity Signet 2850 Electrical Voltage 208-230/460

Outlet Conductivity Signet 2850 Full Load Amps 210/105

Outlet Flow Signet 2537 Compressed Air 5 scfm @80-psi

Outlet pH Signet 2750 Make-up Water 35 gpm

Controller CompactLogix PHYSICAL DATA

Touchscreen 10.4” PanelView 6+ Shipping/Operating Wgt 7,000/15,000 lbs

Drum Low level Sensors One (1) of Each Frame/Coating 304SS/Polyurethane

DI Supply Pumps Piping Schedule 80 PVC

Number Two (2) Available Options

Horsepower 20 HP *HP - High Purity Duplex Cation for 3-5 MegOhm

Motor control (optional) Variable H2 Drive **EP - Enhanced Pretreatment for TSS Fitration

UV Sterilization Tank-size dependent

For more information visit www.waterinnovations.net

Contact at 760.294.1888 sales@waterinnovations.net

©2016 Water Innovations HFX 135D July 2016 1|Page

World-ClassEquipment&ProcessExpertise

HFX Ion Exchange Systems

HFX135D WATER RECYCLING

Operating Profile - Removes d i s s o l v e d solids from c om p a t i b l e feed water wit h T DS < 6 00- m g/ l u s i n g p r e -

t r e a t m e n t b y back-washable carbon & replaceable bag filtration followed by two-stage, separate-bed cation & anion

exchange. Produces a near-continuous supply of deionized water with duplex components with 50% of the resin in

reserve or in regeneration. Water quality of less than 5 µS is produced when operated within design parameters.

System Feed Tank - Constructed of HDLPE and sized based on system operating capacity. Analog level control provides

for automatic water make-up supply, system operation, high level alarm, and to prevent the feed pump from running dry.

PVC tank fittings for inlets & outlets pipes including tank isolation valve are included. As applicable, includes required

seismic anchoring with PE certification.

System Feed Pumps - Skid-mounted in duplex configuration with automatic alternating to share service load to extend

operating life. Sized to provide full rated-service flow even during periodic media backwashing. Constructed of 316 SS,

Viton® & ceramic wetted-parts. Centrifugal-drive 230/460VAC TEFC motor with optional variable Hz drives for soft-start to

optimize operating efficiency. Includes common skid inlet & outlet with pumps isolation & check valves for service.

Carbon Filters - Sized for minimum service flow of 8-gpm per ftt2 of bed surface area. Utilizes Hydrus control valves for

automatic up-flow backwash to remove accumulated particles. Minimum duplex vessels enabling backwash during service

cycle without need to take system off-line. Utilizes filtered water from the vessel(s) remaining on-line. Vessels inlet outlet &

drains piped in parallel with isolation valves for service. Backwash is automatically triggered based upon the totalized flow

since the previous backwash based on an operator-adjustable set point manually through the HMI.

Bag Filters - There are minimum two (2) bag filter housings piped in parallel

collectively rated for nominal system flow while allowing one filter to be taken off-

line for change-out. The housings are constructed of reinforced polypropylene

and are individually valve so one housing can be serviced while the other(s)

remains in operation. Filter bags are made of polypropylene and have a nominal

rating of 5 microns.

Cation & Anion Exchanger – Both are two-vessel units alternating between

service & regeneration controlled by air-actuated valves. Service flow as

pressurized by the feed pump is down-flow with internal distribution utilizing an

upper slotted diffuser and a bottom hub-&-lateral assembly.

Regenerations –Initiated in Feed-forward mode based on resin loading as

calculated separately for the Cation and Anion in-service vessel by measuring

the feed water quality and flow. Feed-back regenerations are triggered based

on the outlet water quality and with cation or alternatively anion regeneration

triggered based on outlet water pH as an indicator of relative exhaustion.

Deionization Media - Each cation vessel shall utilize high-capacity, strong acid,

macroporous cation resin, with an exchange capacity of >20,000 grains per cubic

foot when regenerated with 4 pounds of hydrochloric acid per cubic foot of resin. The cation resin will have a minimum of

10% cross-linking. Each Anion vessel shall include high-capacity, weak and strong base anion resins, with an exchange

capacity of >18,000 grains per cubic foot when regenerated with 6 pounds of sodium hydroxide per cubic foot of resin. The

weak and strong base resin bead sizes are designed to keep the two layers separate. Inert plastic beads shall be used to

pack both the Cation and Anion resin vessels while still allowing the resin minimum space for expansion and contraction.

For more information visit www.waterinnovations.net

Contact at 760.294.1888 sales@waterinnovations.net

©2016 Water Innovations HFX 135D July 2016 2|Page

World-ClassEquipment&ProcessExpertise

HFX Ion Exchange Systems

HFX135D WATER RECYCLING

Chemical Draw - The regenerating vessel will draw regeneration chemicals from a customer provided 55-gallon drum or

bulk tank. The feed is educted by a pressurized DI water feed with chemical concentration verified with a hydrometer and

adjusted with proportional valving to control the flow of chemical regulated from 0-10 lbs/ft3.

DI Water Storage Tank - Constructed of HDLPE and sized based on a combination of system operating capacity and

requirement for regeneration water. Analog level control provides for automatic system operation, high level alarm, and to

prevent the feed pump from running dry. PVC tank fittings for inlets & outlets pipes including tank isolation valve are included.

As applicable, includes required seismic anchoring with PE certification. DI water is continuously recirculated through an

UV Sterilizer at 3-4 tank turn-overs per hour to retard biological growth.

DI Water Supply Pump - Skid-mounted in duplex configuration with automatic alternating to share service load to extend

operating life. Sized to provide full rated-service flow even during resin regeneration which utilizes accumulated DI water.

Constructed of 316 SS, Viton® & ceramic wetted-parts. Centrifugal-drive 230/460VAC TEFC motor with optional variable

Hz drives for soft-start to optimize operating efficiency. Skid outlets to service with a diaphragm valve for flow control and

for regeneration with a pressure-regulating valve for consistent supply pressure. The DI water supply loop recirculates to

the tank with a pressure-retaining valve to ensure adequate supply pressure.

System Skids - Components other than tanks are skid-mounted, pre-piped, & pre-wired limiting installation to interconnect

piping & electrical connections. Construction is of 304- SS with sandblasting prior to a polyurethane coating. Skids include

feet for securing skids to the floor and lugs for electrical grounding of electrical components.

Piping - Piping is Schedule 80 PVC with both solvent welded and threaded connections.

System Controls – Operation, monitoring, and control of the integrated system utilizes an Allen-Bradley CompactLogix

programmable automation controller (PAC) with Human-machine interface (HMI) through a Panelview Plus color touch

screen. System operation while highly automated also employs manual control with an intuitive operator-friendly interface.

Product water to process is assured with recirculation of “off-spec” water to the feed tank if above an operator-adjustable

set point. System operating set points and alarms are set at the touch screen which is password protected to limit access

to the operator, supervisor, maintenance, or engineer based on necessity and relative expertise.

Additional Options

** HP – High Purity Duplex Polishing Cation Exchanger – With added duplex polishing-cation skid to produce higher

quality DI water in the range of 3-5 MegOhm.

** EP – Enhanced Pre-treatment –With added Hydrus Macrolite® multi-media backwashable filters for removal of up to

50 mg/l suspended solids larger in size than 5-microns.

For more information visit www.waterinnovations.net

Contact at 760.294.1888 sales@waterinnovations.net

©2016 Water Innovations HFX 135D July 2016 3|Page

World-ClassEquipment&ProcessExpertise

HFX Ion Exchange Systems

HFX135D WATER RECYCLING

For more information visit www.waterinnovations.net

Contact at 760.294.1888 sales@waterinnovations.net

©2016 Water Innovations HFX 135D July 2016 4|Page

You might also like

- Design of Water Treatment PlantDocument77 pagesDesign of Water Treatment PlantNikhil89% (175)

- 2022 Grade 9 Term 3 Geography WorksheetsDocument28 pages2022 Grade 9 Term 3 Geography WorksheetsHell Naw100% (1)

- Rapid Sand Filter Design Example PDFDocument2 pagesRapid Sand Filter Design Example PDFWONG TS95% (21)

- Enviro Caretech: Tel No.:-9610238442Document9 pagesEnviro Caretech: Tel No.:-9610238442Pawan KhandelwalNo ratings yet

- Table of Rating FactorDocument4 pagesTable of Rating FactorNin BANo ratings yet

- Ecosoft Мо-9 Industrial Reverse Osmosis System: ApplicationsDocument2 pagesEcosoft Мо-9 Industrial Reverse Osmosis System: ApplicationsMehdi AcilNo ratings yet

- Invoice-Mr Mubarak-IkateDocument2 pagesInvoice-Mr Mubarak-IkateGeorges Abi JaoudeNo ratings yet

- 700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/minDocument2 pages700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/mineduardoNo ratings yet

- Ufbw-2202063 TD & CD Shamara 1Document21 pagesUfbw-2202063 TD & CD Shamara 1ali mohammedNo ratings yet

- HPK03Document4 pagesHPK03Tan CkNo ratings yet

- Plug LX-15T and LX-30T Liquefaction PproductsDocument2 pagesPlug LX-15T and LX-30T Liquefaction PproductsLiu YangtzeNo ratings yet

- Specification Water Treatment PlantDocument19 pagesSpecification Water Treatment PlantZachi UkiNo ratings yet

- Bwt Мо-9 Industrial Reverse Osmosis System: ApplicationsDocument2 pagesBwt Мо-9 Industrial Reverse Osmosis System: ApplicationsMehdi AcilNo ratings yet

- Specification RO Water Treatment PlantDocument16 pagesSpecification RO Water Treatment PlantZachi UkiNo ratings yet

- FuelGen 65 Spec Sheet 04-10Document2 pagesFuelGen 65 Spec Sheet 04-10dragosghetu36No ratings yet

- Isi SwroDocument2 pagesIsi SwroachmadinNo ratings yet

- Isi Swro PDFDocument2 pagesIsi Swro PDFachmadinNo ratings yet

- Water Treatment System - Thermogenics Mexico OTSG PDFDocument15 pagesWater Treatment System - Thermogenics Mexico OTSG PDFAnonymous 6meMTlNo ratings yet

- EN7654 3 06 18 - FAM Economy PDFDocument8 pagesEN7654 3 06 18 - FAM Economy PDFPritesh KoratNo ratings yet

- MP-Filtri Catalogue ProtectedDocument48 pagesMP-Filtri Catalogue Protectedvut73 aNo ratings yet

- New Filter Cart 2022 - REV1Document5 pagesNew Filter Cart 2022 - REV1Divya AgarwalNo ratings yet

- Ficha Tecnica Filtro - FX15 - Completo PDFDocument11 pagesFicha Tecnica Filtro - FX15 - Completo PDFLourdes JaveNo ratings yet

- DCI-2 Brief Spec-Rev01Document1 pageDCI-2 Brief Spec-Rev01jack allenNo ratings yet

- Hematology Eco Reagent GLB Brochure PDFDocument2 pagesHematology Eco Reagent GLB Brochure PDFYasushi KoezukaNo ratings yet

- Midiro ™: Reverse Osmosis SystemsDocument2 pagesMidiro ™: Reverse Osmosis SystemsEta TrutaNo ratings yet

- NEW - IONPRO - VWS BRASIL (Modo de Compatibilidade)Document19 pagesNEW - IONPRO - VWS BRASIL (Modo de Compatibilidade)Alon CarlosNo ratings yet

- EDI SystemsDocument3 pagesEDI SystemsKesharkala PckgingNo ratings yet

- Plant ReportDocument5 pagesPlant ReportAli Hassan RazaNo ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- High-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigDocument4 pagesHigh-Pressure Oil-Injected Rotary Screw Compressors: GR 110-200 (FF) Up To 20 Bar (E) / 290 PsigMateusDinizNo ratings yet

- Give Your Family 100% Safe & Tasty WaterDocument2 pagesGive Your Family 100% Safe & Tasty WaterAnupam JadhavNo ratings yet

- Water-Cooled Series R (TM) RTHD Product Report PDFDocument2 pagesWater-Cooled Series R (TM) RTHD Product Report PDFMajho CanilangNo ratings yet

- HF 760 - HF 761 Series: in Line High Pressure FiltersDocument28 pagesHF 760 - HF 761 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- Commercial RO Systems: M ERO SeriesDocument7 pagesCommercial RO Systems: M ERO SeriesAna María BravoNo ratings yet

- AdVantEdge Full Line BrochureDocument16 pagesAdVantEdge Full Line BrochureErich Thomas TulusNo ratings yet

- A. Power Plant Overview (By Mr. Tomy Suryatama)Document34 pagesA. Power Plant Overview (By Mr. Tomy Suryatama)Dimas Febrian SaputraNo ratings yet

- Hydraulic HRK10 PDFDocument4 pagesHydraulic HRK10 PDFRamiro Rojas MachucaNo ratings yet

- HF 745 / HF 748 Series: in Line High Pressure FiltersDocument24 pagesHF 745 / HF 748 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- HPK02Document4 pagesHPK02Tan CkNo ratings yet

- BrineGo Spec SheetDocument2 pagesBrineGo Spec SheetBubbles :DNo ratings yet

- 1st Appraisal Presentation 2Document17 pages1st Appraisal Presentation 2Talha Jamil MalikNo ratings yet

- 1000 Liter Ion Exchange GalleriaDocument5 pages1000 Liter Ion Exchange GalleriaBiswajit SahooNo ratings yet

- HF 735 Series: in Line High Pressure FiltersDocument20 pagesHF 735 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- Air-Cooled Series R (TM) Product ReportDocument2 pagesAir-Cooled Series R (TM) Product ReportBernard Bonnin CervantesNo ratings yet

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNo ratings yet

- Specification Water Treatment Plant R1Document18 pagesSpecification Water Treatment Plant R1Zachi Uki100% (1)

- Utimec LF 700 Agitator: Technical Data SheetDocument7 pagesUtimec LF 700 Agitator: Technical Data SheetBBBBBBNo ratings yet

- Fuel Conditioning System Web Email SMDocument4 pagesFuel Conditioning System Web Email SMammakhomsamNo ratings yet

- Brief Spesification Passengers 42MDocument5 pagesBrief Spesification Passengers 42MBambang Irawan GintingNo ratings yet

- Bluebasic Adblue Production machine-EBR1500B 20ft Container Type 219030 CHINADocument7 pagesBluebasic Adblue Production machine-EBR1500B 20ft Container Type 219030 CHINAAram AseerNo ratings yet

- Rapid StrataDocument2 pagesRapid StrataHansonNo ratings yet

- Oil Rig SpecDocument1 pageOil Rig SpecJoao CarlosNo ratings yet

- 100 SWRO MF DatasheetDocument4 pages100 SWRO MF Datasheetwael72No ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- 3000 LTR RO PLANT ISI PLANT R KDocument17 pages3000 LTR RO PLANT ISI PLANT R KVidya SinghNo ratings yet

- MAPX204 Skid PDFDocument1 pageMAPX204 Skid PDFEurasia Maritime & Industrial EquipmentsNo ratings yet

- Barnstead EASYpure IIDocument2 pagesBarnstead EASYpure IITako JankhoteliNo ratings yet

- LTE PresentationDocument28 pagesLTE PresentationKapa Kamalakar100% (1)

- Instruction ManualDocument585 pagesInstruction Manualthiagoluz2015No ratings yet

- Skid Steer Loader: Engine Gross Power Net Power Breakout Force Rated Load Bucket Capacity Operating WeightDocument2 pagesSkid Steer Loader: Engine Gross Power Net Power Breakout Force Rated Load Bucket Capacity Operating WeightLucy MorenoNo ratings yet

- Hydraulic Proppant Fracturing PDFDocument41 pagesHydraulic Proppant Fracturing PDFJLLMexNo ratings yet

- Self Loading Concrete Mixer: Product Performance PrideDocument4 pagesSelf Loading Concrete Mixer: Product Performance PridePrasunNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- BC Towbrosec BR Au 0915 LRDocument8 pagesBC Towbrosec BR Au 0915 LRnermeen ahmedNo ratings yet

- Domestic Wastewater Treatment Chap7Document6 pagesDomestic Wastewater Treatment Chap7nermeen ahmedNo ratings yet

- Volatile Organic Compound Removal Study GuideDocument13 pagesVolatile Organic Compound Removal Study Guidenermeen ahmedNo ratings yet

- Domestic Wastewater Treatment Chap8Document6 pagesDomestic Wastewater Treatment Chap8nermeen ahmedNo ratings yet

- Drinking Water Safety PlanDocument2 pagesDrinking Water Safety Plannermeen ahmedNo ratings yet

- Water Sanitation and TreatmentDocument12 pagesWater Sanitation and Treatmentnermeen ahmedNo ratings yet

- BC Towbrosec BR Au 0915 LRDocument8 pagesBC Towbrosec BR Au 0915 LRnermeen ahmedNo ratings yet

- Guidance On The Authorisation of Discharges To Groundwater Version 1 Part1 of 2Document84 pagesGuidance On The Authorisation of Discharges To Groundwater Version 1 Part1 of 2nermeen ahmedNo ratings yet

- Sanitary Inspection (Practical Exercise) : Participant NotesDocument3 pagesSanitary Inspection (Practical Exercise) : Participant Notesnermeen ahmedNo ratings yet

- Clari-Daf Systems For Portable Water ClarificationDocument9 pagesClari-Daf Systems For Portable Water ClarificationEric RodriguezNo ratings yet

- MENA-Reference PW GambellaDocument1 pageMENA-Reference PW Gambellanermeen ahmedNo ratings yet

- Drinking Water SamplingDocument176 pagesDrinking Water Samplingnermeen ahmedNo ratings yet

- Biological Treatment For Drinking WaterDocument5 pagesBiological Treatment For Drinking Waternermeen ahmedNo ratings yet

- Monitoring The Quality of Drinking Water During Storage and DistributionDocument26 pagesMonitoring The Quality of Drinking Water During Storage and Distributionnermeen ahmedNo ratings yet

- Water PollutionDocument52 pagesWater Pollutionnermeen ahmedNo ratings yet

- TP40 1 IntroductionDocument10 pagesTP40 1 Introductionnermeen ahmedNo ratings yet

- Drinking Water Treatment Sludge Production and DewaterabilityDocument1,036 pagesDrinking Water Treatment Sludge Production and DewaterabilityDIVerrelliNo ratings yet

- DEGREMONT GUIDE2012 EN REV02 BDDocument30 pagesDEGREMONT GUIDE2012 EN REV02 BDnermeen ahmedNo ratings yet

- Surface Water QualityDocument272 pagesSurface Water Qualitynermeen ahmedNo ratings yet

- Water Treatment Technologies For Chemical ContaminantsDocument67 pagesWater Treatment Technologies For Chemical Contaminantsnermeen ahmedNo ratings yet

- Report Wash UNICEFDocument64 pagesReport Wash UNICEFJuan ChongNo ratings yet

- Bellevillewatert 00 HarguoftDocument254 pagesBellevillewatert 00 Harguoftnermeen ahmedNo ratings yet

- Review of Biologically Active Filters in Drinking Water ApplicationsDocument11 pagesReview of Biologically Active Filters in Drinking Water Applicationsnermeen ahmedNo ratings yet

- Nature Based Solutions For WaterDocument154 pagesNature Based Solutions For Waterandik_yNo ratings yet

- Physical Unit Operations: Grit ChamberDocument36 pagesPhysical Unit Operations: Grit Chambernermeen ahmedNo ratings yet

- SPDManualForPrinting v95b3Document516 pagesSPDManualForPrinting v95b3bima0407No ratings yet

- Guidance Manual For Compliance With The Filtration and Disinfection Requirements PDFDocument580 pagesGuidance Manual For Compliance With The Filtration and Disinfection Requirements PDFเดือนห้า หน้าแล้งNo ratings yet

- Confined Spaces: Nicole A. Clarke Manager, Eastern Region Tank Industry ConsultantsDocument72 pagesConfined Spaces: Nicole A. Clarke Manager, Eastern Region Tank Industry Consultantsnermeen ahmedNo ratings yet

- Appendices: Appendix ADocument120 pagesAppendices: Appendix Anermeen ahmedNo ratings yet

- Assessement Task 1 Orifice Weirs TubesDocument3 pagesAssessement Task 1 Orifice Weirs TubesDiana CapistranoNo ratings yet

- Anup KashyapDocument10 pagesAnup KashyapAnup KashyapNo ratings yet

- Zly 418 (Fishes) - University of IlorinDocument20 pagesZly 418 (Fishes) - University of IlorinGaniu MustaphaNo ratings yet

- 2023 07 30-Natural-BeautiesDocument3 pages2023 07 30-Natural-BeautiesGwendolyn GoldNo ratings yet

- SPAR PLUMBING EQUIPMENTS AND PIPES - enDocument32 pagesSPAR PLUMBING EQUIPMENTS AND PIPES - enEmilienne Laure NgahaneNo ratings yet

- The Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Document6 pagesThe Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Kasim ButkovicNo ratings yet

- The Effectiveness of Pistia Stratiotes L. (Water Lettuce) in Treating of Greywater SystemDocument35 pagesThe Effectiveness of Pistia Stratiotes L. (Water Lettuce) in Treating of Greywater SystemAira Joy AnyayahanNo ratings yet

- LN-8 Weather and ClimateDocument4 pagesLN-8 Weather and Climateswetha swithinNo ratings yet

- Environmental Studies - Unit 1 Entire UnitDocument53 pagesEnvironmental Studies - Unit 1 Entire UnitRudyNo ratings yet

- SDS-C10 HCA179 Chartek 1709 Grey Part A - Kor - EngDocument10 pagesSDS-C10 HCA179 Chartek 1709 Grey Part A - Kor - EngMinha Mubarok Ibn MasduqiNo ratings yet

- Aaditri EmpireDocument10 pagesAaditri EmpireAbhishek SinghNo ratings yet

- BiodiversityDocument73 pagesBiodiversityNila FirmaliaNo ratings yet

- PSC20EDocument62 pagesPSC20EYu SimonNo ratings yet

- Rhizofiltration AgreentechnologyforDocument7 pagesRhizofiltration AgreentechnologyforLate EntryNo ratings yet

- SRP Assessment Task - FinalDocument12 pagesSRP Assessment Task - Finalapi-507574580No ratings yet

- Lawn and Landscape Watering Schedule - 201905201618099144Document2 pagesLawn and Landscape Watering Schedule - 201905201618099144dragos.gaitanaruNo ratings yet

- Bataan Eswm0909Document2 pagesBataan Eswm0909sorbisorbiNo ratings yet

- The History of Civil Engineering WrittenDocument17 pagesThe History of Civil Engineering WrittenDiana Wagner WinterNo ratings yet

- 20W40 MSDSDocument2 pages20W40 MSDSAbhinav SrivastavaNo ratings yet

- Framework For Local Government To Implement Integrated Water Resource Management Linked To Water Service DeliveryDocument12 pagesFramework For Local Government To Implement Integrated Water Resource Management Linked To Water Service DeliveryChanel el hifnawyNo ratings yet

- Project ReportDocument66 pagesProject ReportAisarya DasNo ratings yet

- Hydraulic Analysis Report - C-302 - INT-1Document28 pagesHydraulic Analysis Report - C-302 - INT-1pasantedemicrobiologNo ratings yet

- Rip CurrentDocument2 pagesRip CurrentMystique GarciaNo ratings yet

- Lithospheric MantleDocument16 pagesLithospheric MantleFarahhhNo ratings yet

- Gravel Pit Staff ReportDocument20 pagesGravel Pit Staff ReportinforumdocsNo ratings yet

- The Renewable Energy Is The Future of High-Rise Buildings.: January 2010Document29 pagesThe Renewable Energy Is The Future of High-Rise Buildings.: January 2010EyraJane Santos Dela CruzNo ratings yet

- Land Behind BaghdadDocument245 pagesLand Behind BaghdadBahuvirupakshaNo ratings yet