Professional Documents

Culture Documents

TF100-20C Rynglok Poster

TF100-20C Rynglok Poster

Uploaded by

LorenzoTanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TF100-20C Rynglok Poster

TF100-20C Rynglok Poster

Uploaded by

LorenzoTanCopyright:

Available Formats

Aeroquip Rynglok Tube

® ® Repair System

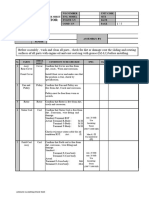

Rynglok Basic Part Number Designation How To Order Rynglok Fitting System

R8 X X XX T R8XXXXT ( ) ( ) ( ) Installation Sequence

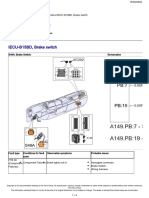

T = Titanium fitting material (6Al-4V) Port No. 3 (side port)1,2

Configuration number (see chart below) 1,2 1. Mark the Tube 4. Swaging the Fitting

1 = Standard production fitting Port No. 2 (right port)

1

4 = Extra-fine thread for High Pressure Flareless Port No. 1 (left port) , largest Rynglok fitting end on the run,

Connection Type: if all ends are Rynglok or any separable end

0 = Permanent, all Rynglok fitting ends Basic part number

1 = ArcSeal™ (separable) male or female

1 Tube size is specified in 1/16” increments, (i.e., 08 = 8/16ths or 1/2”)

2 = Flareless (separable) male or female 2 Port 2 and 3 only required for reducer fittings

3 = Flared (separable) male or female To swage the fitting, apply pressure. Upon completion

Position the Rynglok Marking Gage (P/N: RTSG0-01-XX)

R8 = Rynglok titanium high pressure repair fitting on the end of the cut tube. Use a suitable marking pen of swaging, release the pressure, the moveable jaw will

to make the position and inspection marks. return to the original position.

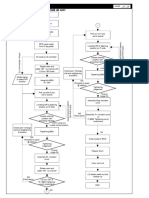

2. Position the Fitting 5. Inspect the Installation

EXTRA FINE THREAD,

PERMANENT TO PERMANENT TO PERMANENT TO

Fitting Groove

HIGH PRESSURE FLARELESS Inspection

Mark

ARCSEAL™

Inspection

“MS” FLARELESS **Fittings for use on the Airbus A380 5080-psi “AN” FLARED Mark

High-pressure fluid delivery systems

FEMALE MALE

PERMANENT MALE MALE MALE FEMALE MALE MALE MALE

MATES WITH MALE FEMALE BULKHEAD FEMALE Position Position

Mark

TO AS85421/1 OR BULKHEAD BULKHEAD NAS 1760 EN6123 & BULKHEAD AS4395

Mark

AS85421 & MS33514 AS4396 AS1708 Place the fitting on the tube within the limits of Visually inspect that the ring is fully advanced onto the

PERMANENT AS85720/1 AS85421/2 MS33515 MODIFIED AS5827 AS5828 (MS33656) the positioning mark. fitting using the Rynglok Inspection Gauge

AS85720 (MS33657) (P/N: RTSG0-51-XX). Be sure to verify that the edge of

the fitting is within the limits of the inspection mark.

3. Position the Tool

UNION Moveable Jaw

The above steps are repeated for each leg of

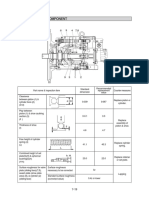

Non-Reducer R80101T( ) R81121T( ) R81141T( ) R81101T( ) R82121T( ) R82141T( ) R82101T( ) R82421T( ) R82441T( ) R82401T( ) R83121T( ) R83141T( ) R83101T( ) the Rynglok fitting.

Reducer R80151T( )( ) R81171T( )( ) R81191T( )( ) R81151T( )( ) R82171T( )( ) R82191T( )( ) R82151T( )( ) R82471T( )( ) R82491T( )( ) R82451T( )( ) R83171T( )( ) R83191T( )( ) R83151T( )( )

When using the tool in the forward mode as For a more detailed outline of the Rynglok installation

shown, position the tool onto the fitting with the sequence see our installation bulletin.

45° ELBOW tube side of the ring nested into the moveable

jaw. If positioned properly, the front end of the

tool will be in the fitting groove. Make sure that

the fitting is bottomed into the tool.

Non-Reducer R80102T( ) R81122T( ) R81142T( ) R81102T( ) R82122T( ) R82142T( ) R82102T( ) R82422T( ) R82442T( ) R82402T( ) R83122T( ) R83142T( ) R83102T( ) The fitting can also be positioned with the center

of fitting nested on the moveable jaw (operation

in Reverse mode).

Reducer R80152T( )( ) R81172T( )( ) R81192T( )( ) R81152T( )( ) R82172T( )( ) R82192T( )( ) R82152T( )( ) R82472T( )( ) R82492T( )( ) R82452T( )( ) R83172T( )( ) R83192T( )( ) R83152T( )( )

90° ELBOW Other Helpful Rynglok Products

Non-Reducer R80103T( ) R81123T( ) R81143T( ) R81103T( ) R82123T( ) R82143T( ) R82103T( ) R82423T( ) R82443T( ) R82403T( ) R83123T( ) R83143T( ) R83103T( )

Reducer R80153T( )( ) R81173T( )( ) R81193T( )( ) R81153T( )( ) R82173T( )( ) R82193T( )( ) R82153T( )( ) R82473T( )( ) R82493T( )( ) R82453T( )( ) R83173T( )( ) R83193T( )( ) R83153T( )( )

TEE

(Separable on Run)

Rynglok Hose Fittings (AE30705X) available for Optional Multi-Axis Swivel can be added to tool

joining Aeroquip brand 246 hose to tubing for for easier connection to hose.

3000-psi applications.

Non-Reducer R80104T( ) R81124T( ) R81144T( ) R81104T( ) R82124T( ) R82144T( ) R82104T( ) R82424T( ) R82444T( ) R82404T( ) R83124T( ) R83144T( ) R83104T( )

Reducer R80154T( )( )( ) R81174T( )( )( ) R81194T( )( )( ) R81154T( )( )( ) R82174T( )( )( ) R82194T( )( )( ) R82154T( )( )( ) R82474T( )( )( ) R82494T( )( )( ) R82454T( )( )( ) R83174T( )( )( ) R83194T( )( )( ) R83154T( )( )( )

TEE

(Separable on Side)

Non-Reducer R81126T( ) R81146T( ) R81106T( ) R82126T( ) R82146T( ) R82106T( ) R82426T( ) R82446T( ) R82406T( ) R83126T( ) R83146T( ) R83106T( )

Rynglok Extended Length Unions (R80501TXX) are

capable of joining two tube sections when a longer

Reducer R81176T( )( )( ) R81196T( )( )( ) R81156T( )( )( ) R82176T( )( )( ) R82196T( )( )( ) R82156T( )( )( ) R82476T( )( )( ) R82496T( )( )( ) R82456T( )( )( ) R83176T( )( )( ) R83196T( )( )( ) R83156T( )( )( ) span is required.

Copyright © 2013 Eaton

All Rights Reserved

Copying or Editing is

Forbidden

Form No. TF100-20C

June 2013

You might also like

- Transmission, IdentificationDocument2 pagesTransmission, IdentificationHumberto LojanNo ratings yet

- 10 ElectricityDocument42 pages10 ElectricityVikash SharmaNo ratings yet

- Enerpac L2596 GDocument108 pagesEnerpac L2596 GGabriel OniszczukNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumDocument6 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Chromium-MolybdenumAnilNo ratings yet

- Effect of R Ratio On Performance of Injection-Pressure-Operated Gas Lift ValvesDocument11 pagesEffect of R Ratio On Performance of Injection-Pressure-Operated Gas Lift ValvesrkNo ratings yet

- Hitachi Special Tools PDFDocument27 pagesHitachi Special Tools PDFPrudz0% (4)

- Ilford Delta 400 Film GuideDocument7 pagesIlford Delta 400 Film GuideKiel BryantNo ratings yet

- Model 1700 Training Activity TwoDocument12 pagesModel 1700 Training Activity Twoyao nestorNo ratings yet

- PM Check List - CB & BusbarDocument7 pagesPM Check List - CB & BusbarRizky VidiyanaNo ratings yet

- FHWA-TS-78-209 - Guideline For Cone Penetration TestDocument158 pagesFHWA-TS-78-209 - Guideline For Cone Penetration TestmlakkissNo ratings yet

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (4)

- Installation & Maintenance Instructions Regulator R07Document1 pageInstallation & Maintenance Instructions Regulator R07miguel angel ramirez lazoNo ratings yet

- Air Pressure Regulator - R4041IMDocument1 pageAir Pressure Regulator - R4041IMECR EnergyNo ratings yet

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

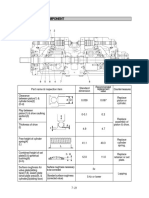

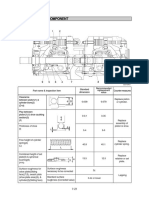

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Maintenance Schedule of Electrically Operated Points (Inclusive of Clamp Type Point)Document3 pagesMaintenance Schedule of Electrically Operated Points (Inclusive of Clamp Type Point)Saurabh MoharirNo ratings yet

- Structure Identifier Overview: Labeling Full Designation Structure DescriptionDocument4 pagesStructure Identifier Overview: Labeling Full Designation Structure DescriptionPablo Ignacio Jaque MuñozNo ratings yet

- Point Maintenance Schedule News em ChangesDocument3 pagesPoint Maintenance Schedule News em ChangesSaurabh MoharirNo ratings yet

- Specification For Transformer: ANSI C57.12-01Document1 pageSpecification For Transformer: ANSI C57.12-01Charlie MendozaNo ratings yet

- Alternator Assembling Check Sheet3Document5 pagesAlternator Assembling Check Sheet3Erik dwi KurniawanNo ratings yet

- FlowDocument1 pageFlowbambangNo ratings yet

- Group 2 Major ComponentDocument8 pagesGroup 2 Major ComponentDavidNo ratings yet

- 34a. TS 047 (Micom P941, P942 & P943) Rev 1Document6 pages34a. TS 047 (Micom P941, P942 & P943) Rev 1Atiqun NabiNo ratings yet

- Pipe Rupture ValvesDocument5 pagesPipe Rupture ValvesMS Mechanic HSM 2No ratings yet

- 3-13. Slim Low Static Ducted Type (Type M1) 8. Slim Low Static Ducted Type (M1 Type)Document1 page3-13. Slim Low Static Ducted Type (Type M1) 8. Slim Low Static Ducted Type (M1 Type)Loc DoNo ratings yet

- ImpactDocument4 pagesImpactbenito vegaNo ratings yet

- Char-Lynn: Steering Control UnitsDocument7 pagesChar-Lynn: Steering Control UnitsIslam ShoukryNo ratings yet

- Char-Lynn: Steering Control UnitsDocument6 pagesChar-Lynn: Steering Control UnitsIslam ShoukryNo ratings yet

- RJ 6Document4 pagesRJ 6Zarko DramicaninNo ratings yet

- Group 2 Major ComponentDocument9 pagesGroup 2 Major ComponentTaha RdmanNo ratings yet

- 270305-ESQUEMA ELECT Y CARACT SERIE TitaniumDocument20 pages270305-ESQUEMA ELECT Y CARACT SERIE TitaniumOlger Quintero Tapia100% (1)

- Ffu 0000234 01Document21 pagesFfu 0000234 01Karunia LestariNo ratings yet

- HL, 2otf.: (Alternative Single Completely Shop or As Provisions Boiler and Section DivisionDocument3 pagesHL, 2otf.: (Alternative Single Completely Shop or As Provisions Boiler and Section DivisionAmrut ChalkeNo ratings yet

- SPEC 2500 KVA Dry CW Fans & HousingDocument1 pageSPEC 2500 KVA Dry CW Fans & Housingarfan akbarNo ratings yet

- HMTS PM Check SheetDocument1 pageHMTS PM Check SheetFernando LourençoNo ratings yet

- Valvula DBDS 4Document8 pagesValvula DBDS 4electricidad.acasiNo ratings yet

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- Ampis 75122Document10 pagesAmpis 75122JacqsynnNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument7 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet

- R210LC-7 7-2Document10 pagesR210LC-7 7-2Krystian PalaciosNo ratings yet

- Mano StarDocument3 pagesMano StarImam Syafi'iNo ratings yet

- ROUP 2 MAJOR COMPONENT HyundaiDocument9 pagesROUP 2 MAJOR COMPONENT Hyundaiعمروصالح كليسNo ratings yet

- Aop 555Document24 pagesAop 555guiguiXXXNo ratings yet

- RSP PPs Presentation For CMODocument82 pagesRSP PPs Presentation For CMOVenkatesh NaiduNo ratings yet

- 7 - 420kV RP Spares CatalogueDocument3 pages7 - 420kV RP Spares CatalogueNisarg ShahNo ratings yet

- Ahw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Document6 pagesAhw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Parag Lalit SoniNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDocument1 pageChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiNo ratings yet

- Valtek Flow Boosters: General InformationDocument8 pagesValtek Flow Boosters: General Informationberry MikeNo ratings yet

- TS78L00 Series: Taiwan SemiconductorDocument11 pagesTS78L00 Series: Taiwan SemiconductorEM JANo ratings yet

- EAO PB E-Stop and Stop Switches ENDocument16 pagesEAO PB E-Stop and Stop Switches ENCosmyn IpsilatNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpMustofa TofaNo ratings yet

- Group 2 Major ComponentDocument8 pagesGroup 2 Major Componentdeniden2013No ratings yet

- Digital Wiper Control For Intermittent and Wipe/ Wash Mode: DescriptionDocument13 pagesDigital Wiper Control For Intermittent and Wipe/ Wash Mode: DescriptionAndika PrasetyaNo ratings yet

- DatasheetDocument2 pagesDatasheetRobertoNo ratings yet

- Megger (6172 901) Service Manual LT RCDT300 SeriesDocument48 pagesMegger (6172 901) Service Manual LT RCDT300 SeriesAntonioNo ratings yet

- Nissan Re4Fo4A, Ford 4F20E: Accumulator Valve KitDocument2 pagesNissan Re4Fo4A, Ford 4F20E: Accumulator Valve Kitflash_24014910No ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpSergey MovchanNo ratings yet

- Oversized Volumetric Flow Rate Kit: Audi 01J, 01TDocument1 pageOversized Volumetric Flow Rate Kit: Audi 01J, 01TАндрей ЛозовойNo ratings yet

- 1972 A Strain-Gauge Brushless TorqueDocument5 pages1972 A Strain-Gauge Brushless TorqueLuana FortesNo ratings yet

- 1N4933, 1N4934, 1N4935, 1N4936, 1N4937 Axial-Lead Glass Passivated Fast Recovery RectifiersDocument5 pages1N4933, 1N4934, 1N4935, 1N4936, 1N4937 Axial-Lead Glass Passivated Fast Recovery Rectifierssadegh karamyNo ratings yet

- 1N4935GDocument5 pages1N4935GAKMNo ratings yet

- PC817XJ0000F Series: DIP 4pin General Purpose PhotocouplerDocument15 pagesPC817XJ0000F Series: DIP 4pin General Purpose PhotocouplerbjrjNo ratings yet

- Protector Station Monitor: FeaturesDocument1 pageProtector Station Monitor: FeatureszoupezeenNo ratings yet

- Oversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPODocument2 pagesOversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPOEko hari PrasetyoNo ratings yet

- Mark Scheme (Results) Summer 2015: Pearson Edexcel GCE in Core Mathematics 4 (6666/01)Document32 pagesMark Scheme (Results) Summer 2015: Pearson Edexcel GCE in Core Mathematics 4 (6666/01)Inas AbdelsabourNo ratings yet

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdDocument7 pagesPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdSun lrNo ratings yet

- Klawiatura Dell KB216Document1 pageKlawiatura Dell KB216Diogo Borges OliveiraNo ratings yet

- Unit Iv Adc & Dac 2 MarksDocument5 pagesUnit Iv Adc & Dac 2 MarkssasirekhaNo ratings yet

- Classification of Client Server SystemDocument3 pagesClassification of Client Server SystemKavisha PatelNo ratings yet

- MCQs Bank S (1) AnswerDocument7 pagesMCQs Bank S (1) AnswerHabiba SamehNo ratings yet

- 6-FMX Series: 6-FMX-150B Front Terminal BatteryDocument2 pages6-FMX Series: 6-FMX-150B Front Terminal BatteryPMV DeptNo ratings yet

- BSCMathematical Science - 2022-II-IV-VI Sem (CBCS) 2019-2020-07-04-2022Document2 pagesBSCMathematical Science - 2022-II-IV-VI Sem (CBCS) 2019-2020-07-04-2022Ruchi AgarwalNo ratings yet

- Capacitance and DielectricsDocument47 pagesCapacitance and DielectricsWael DoubalNo ratings yet

- IJOPCM (Vol 5 4 3 D 12)Document9 pagesIJOPCM (Vol 5 4 3 D 12)Fustei BogdanNo ratings yet

- Soil Mechanics-IDocument8 pagesSoil Mechanics-IMilan GhoshNo ratings yet

- ME 2201-Lecture 4 (Mechanical Properties of Material)Document29 pagesME 2201-Lecture 4 (Mechanical Properties of Material)fontawesome111No ratings yet

- Acute Hemodialysis PrescriptionDocument15 pagesAcute Hemodialysis PrescriptionsstdocNo ratings yet

- Weapon Delivery Analysis and Ballistic Flight Testing: Agard 10Document176 pagesWeapon Delivery Analysis and Ballistic Flight Testing: Agard 10BarisNo ratings yet

- Design of Seismic ArresterDocument3 pagesDesign of Seismic ArresterChandan vatsNo ratings yet

- Buchholz Relay Series - EMB (Updated - 9-April-07)Document20 pagesBuchholz Relay Series - EMB (Updated - 9-April-07)dobathinhNo ratings yet

- Design Fabrication and Performance Test of Melon Shelling MachinesDocument19 pagesDesign Fabrication and Performance Test of Melon Shelling MachinesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CPVC Injection Molding, PVC.Document2 pagesCPVC Injection Molding, PVC.Werner SchrammelNo ratings yet

- Assignment 4 15Document2 pagesAssignment 4 15Senthil RokeshNo ratings yet

- A Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Document13 pagesA Generalization of Wilson's Theorem: R. Andrew Ohana June 3, 2009Ramón Darío CarrasqueroNo ratings yet

- 2016 CompDocument5 pages2016 CompLong NguyễnNo ratings yet

- Unacademy JeeDocument27 pagesUnacademy JeePriyanuj Bora50% (2)

- Group Members: Assignment 2 - Report Writing LGB 10503 Engineering ScienceDocument11 pagesGroup Members: Assignment 2 - Report Writing LGB 10503 Engineering ScienceAfiq AbidinNo ratings yet

- Starch GelatinizationDocument1 pageStarch GelatinizationFaleh Setia BudiNo ratings yet