Professional Documents

Culture Documents

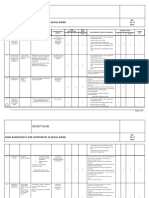

Hazard Task Risk Control Measures

Uploaded by

Ishan DankharaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Task Risk Control Measures

Uploaded by

Ishan DankharaCopyright:

Available Formats

Hazard Task Hazard Risk Control Measures Methods of Risk

No. Identification and Rating Monitoring Rating

Foreseeable Risks (Without Control (with

Controls) Measures Controls)

1. Access Unauthorised entry to site

HIGH Banksman in place for any awkward Checks by Supervisor

LOW

Injury to public reversing

Vehicle collision Mandatory PPE worn

Driving with due care and supervision

Excavation backfilled as soon as

possible.

Open excavation attended.

Sign in sign out to take place.

Never block access and egress routes

with materials and equipment

2. Loading and Falls from Height.

HIGH Safe lift plan in place for lifts by mobile Checks by Supervisor

LOW

Unloading Crushing crane

All guards and covers to be in position

and secured.

Ground workers to wear hi visibility

vests at all times and hard-Hats.

Loads to be tipped only on suitably

level ground to prevent overturning.

All plant and equipment will be

equipped with a Fire extinguisher.

Access roads will be damped down

during fine weather periods to

prevent dust from rising.

Where the operator’s direct field of

vision is obstructed a bank, man

should be available to assist the

operator, this person should be

adequately trained.

3. Excavation of Permit to dig.

Trenches

Underground services

electricity, or water

-gas,

HIGH Ground conditions established by a

survey to identify the type of ground

LOW

Falling materials or plant in which the excavation is to be

Falls of persons. carried out; means of trench support

Ingress of water confirmed upon completion of trial Checks by Supervisor

Collapse of sides holes.

Weakening of adjacent structures Remember that even work in shallow

Noise trenches can be dangerous. You may

need to provide support if the work

involves bending or kneeling in the

trench. No one should be in the

trench unless it is safe to be there.

Where possible ensure that all water

sources are turned off before entering

an excavation

Do not go into unsupported

excavations that have not being

battered to a suitable slope. Never

work ahead of the support.

Do not store spoil or other materials

close to the sides of excavations.

The spoil may fall into the excavation

and the extra loading will make the

sides more prone to collapse.

Contaminants removed following a

suitable risk assessment and method

statement.

Employees and Management must

ensure no-one enters an unsupported

unsafe trench.

Support materials on site before

excavation starts.

Plant and materials kept away from

the side of excavations to prevent

undue pressure or ingress of exhaust

fumes.

if the depth is a particular risk of

anybody falling, suitable guard-rails

placed and suitable access

arrangements, such as ladders or

ramps, provided.

If there is a risk of water ingress,

suitable methods and/or equipment

provided to either prevent the entry

of water or to remove water, e.g.,

water pumps.

4. Laying of Entrapment due to fall/ roll of pipe.

HIGH Operator trained to the Approved Permit to Dig.

LOW

Pipes Operators direct field of vision standard as per the Construction

obscured by load leading to contact Regulations.

with other persons or plant. Vehicles should never be overloaded.

Failure of lifting equipment. Loads should be evenly distributed,

Inadequate supervision. secured and not protruding beyond Checks by Supervisor

Untrained Operatives the sides or back of the vehicle.

Use of mobile phones by operators. Reverse beeper, flashing beacon,

Displacement of load CCTV and or mirrors fitted.

Person being struck by suspended Defective skids removed immediately

pipe causing serious injury of harm. from the line.

Defective and broken skids causing Heavy duty gloves to be worn by

crushing of limbs of entrapment of operatives handling skids.

body parts. All engines’ guards and covers to be in

Manual Handling position and secured.

The cab floor to be kept clean and free

from any obstacles which may affect

the safe operation of the Machine.

Ground workers to wear Hi Visibility

Vests at all times and Hard-Hats.

Warning signs will be erected to alert

pedestrians of Unloading/Loading

Operations.

Traffic management must be in place

where loading/unloading is being

carried out on public roads.

Loads to be tipped only on suitably

level ground to prevent overturning of

skip

Inspection of Work

5. Works

Height

at Fall of a person a distance liable of

causing personal injury.

HIGH Take into accounts the principles of

prevention when working at heights. Equipment for

LOW

Falls of persons off the edge of Work at height must be adequately Working at Height

structures planned and supervised.

Collective fall protection measures Checks by Supervisor

must be given priority.

Trench boxes must have guard and

mid rails.

Inspections on equipment carried out

(i.e., crowd control barriers,

harnesses, fall arrest devices etc)

Safe means of access to the work

location provided using ladders

6. Manual Ligament strains. Muscle strains.

MEDIUM Full training and instruction provided Checks by Supervisor

LOW

Handling Fatigue. in both induction and on-going safety

Abdominal hernias. training.

Prolapsed/herniated discs. Design out the need for manual

Paralysis. handling where possible.

Mechanical aids used wherever

possible.

Workers adhere to guideline weights

& to only lift what they are able to lift.

Assess the load.

Weights marked on all loads.

Lift smaller loads.

Mandatory PPE worn

7 Unauthorised Personal Injury

HIGH Unauthorised entry to the working Checks by Supervisor

LOW

Access area to be reported to site

management.

All barriers to be replaced to secure

access

8. Vehicle

Fuels&

Fire

Explosion

HIGH

Appropriate PPE worn

Ensure employees have a spill kit

Checks by Supervisor

LOW

chemicals & Unintended release / spills available and know how to use it.

Dust Environmental Pollution Fuels stored in safe locations, away

from sunlight and in a secure location.

Water suppression used.

Dust masks worn.

Face fit testing complete

9. Slips, Trips & Cuts and bruises.

HIGH Workplace tidiness maintained by Checks by Supervisor

LOW

Falls Serious bodily injury cleaning up during work, at end of day

to avoid slips and trips –Clean as you

go.

Vigilance from employees as to the

dangers from slips trips and falls

10. Working on General checks by

or near

Collision with plant or traffic.

Traffic Accidents.

HIGH Traffic management plan

accordance with chapter 8 Correct

in

supervisors.

LOW

roads, Inadequate Traffic Management signing/coning/barriers in place for all

Arrangements roadwork’s and path works, including Recorded traffic

Misleading signs site entrance signage Competent management

Close proximity of the public. contractors implementing the TMP. inspections

Collision with plant or traffic Employees operating stop/go batten

or maintaining the system to have

safety at roadwork’s training.

Safe access for vehicles, plant, and

persons

Safe crossing of traffic lanes by site

workers

Employees set out signs before

moving onto work site

You might also like

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoNo ratings yet

- Ra 02 - Anti-Termite TreatmentDocument4 pagesRa 02 - Anti-Termite TreatmentHafiz M WaqasNo ratings yet

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- Risk Assement: Welding & CuttingDocument3 pagesRisk Assement: Welding & CuttingAli Naveed FarookiNo ratings yet

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 pageJob Safety Analysis (JSA) - HVAC Ducting DatenabeelNo ratings yet

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Risk analysis of grouting worksDocument3 pagesRisk analysis of grouting worksRachel Flores100% (2)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerNo ratings yet

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDocument1 pageRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- SWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftDocument7 pagesSWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftBodakunta Ajay VarmaNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Risk Assessment For Installation of Automatic Sliding DoorDocument6 pagesRisk Assessment For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- SWP 03 - Hacking WorksDocument3 pagesSWP 03 - Hacking WorksGerald Wong NttNo ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- 10 - Risk Assessment - PlumpingDocument7 pages10 - Risk Assessment - Plumpingmahmoud nada0% (1)

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Jsa006-Construction of Retaining WallDocument5 pagesJsa006-Construction of Retaining WallWan Muhammad Faiz100% (1)

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENTDocument31 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDocument6 pages03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu NiveriyaNo ratings yet

- Installation of Aluminium Cladding Method StatementDocument4 pagesInstallation of Aluminium Cladding Method StatementAllan Bryan Sario0% (1)

- EPC-3 Gasoline package Assembly & Erection JSADocument3 pagesEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- Risk Assessment For Elevator Shaft Slab Demolition (C01, S10)Document1 pageRisk Assessment For Elevator Shaft Slab Demolition (C01, S10)rayNo ratings yet

- Fencing Installation Risk AssessmentDocument6 pagesFencing Installation Risk AssessmentVictorNo ratings yet

- Concrete Works Method StatementDocument8 pagesConcrete Works Method Statementمحمد فتحىNo ratings yet

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- Temporary Electrical Safety ProcedureDocument9 pagesTemporary Electrical Safety ProcedurejaimonjoyNo ratings yet

- SWP Brick LayingDocument3 pagesSWP Brick LayingHanis MuhamadNo ratings yet

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviNo ratings yet

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- Block Work MSDocument19 pagesBlock Work MSjonesNo ratings yet

- Risk Assessment of Cantilever ScaffoldDocument1 pageRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- Humed Method Statement For Mono-Poles InstallationDocument3 pagesHumed Method Statement For Mono-Poles InstallationUtibe EkongNo ratings yet

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNo ratings yet

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- False CeilingDocument1 pageFalse CeilingGyanendra Narayan Nayak100% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Risk Register DC 52Document3 pagesRisk Register DC 52Pja ShanthaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Demolition of Civil StructureDocument3 pagesDemolition of Civil StructureSikandar MasoodNo ratings yet

- Earthwork Risk AssessmentDocument6 pagesEarthwork Risk AssessmentMuhammad ShafiqNo ratings yet

- Guideline On Laying Unit PaverDocument40 pagesGuideline On Laying Unit PaverDanny LamNo ratings yet

- Garage Locator PDFDocument134 pagesGarage Locator PDFMCS SBINo ratings yet

- Vocabulary Worksheet Public PlacesDocument1 pageVocabulary Worksheet Public PlacesAlexandrina OliveiraNo ratings yet

- Lab No. 1: Which Car Is Faster?Document6 pagesLab No. 1: Which Car Is Faster?Salvacion PrinceNo ratings yet

- Gps Receiver Design TutorialDocument3 pagesGps Receiver Design TutorialPete100% (1)

- Bimota DB5 Motorcycle Owner's Manual PDFDocument95 pagesBimota DB5 Motorcycle Owner's Manual PDFMarisol TorresNo ratings yet

- Turbofan - WikipediaDocument17 pagesTurbofan - WikipediaAnonymous tSYkkHToBPNo ratings yet

- 1.1 Pavement Applications - Highway Classification SystemDocument13 pages1.1 Pavement Applications - Highway Classification SystemRay SilvaNo ratings yet

- Police Verification Form OriginalDocument2 pagesPolice Verification Form OriginalsandeepbodheNo ratings yet

- About KumbakonamDocument5 pagesAbout KumbakonamDeebi ManubaiNo ratings yet

- High Voltage Overhead Power LineDocument2 pagesHigh Voltage Overhead Power Linesunil singhNo ratings yet

- MMJS Article - Export of GoodsDocument2 pagesMMJS Article - Export of GoodsJay DusejaNo ratings yet

- Design of An Aerofoil UpdatedDocument5 pagesDesign of An Aerofoil UpdatedQwer QwerNo ratings yet

- Gas Plano PDFDocument1 pageGas Plano PDFSaul GonzalezNo ratings yet

- Logistic and Supply Chain Managment ANNA UNIVERSITYDocument12 pagesLogistic and Supply Chain Managment ANNA UNIVERSITYKranthy Jc100% (1)

- Flight Ticket - Ranchi To Bangalore: Fare Rules & BaggageDocument2 pagesFlight Ticket - Ranchi To Bangalore: Fare Rules & Baggagesoni100% (2)

- 9@NERACA LB3, 2021-2022vDocument9 pages9@NERACA LB3, 2021-2022vegiNo ratings yet

- Introduction To LRFD For Foundation and Substructure Design - Module 3Document154 pagesIntroduction To LRFD For Foundation and Substructure Design - Module 3MarioNo ratings yet

- Zalamea Vs CADocument6 pagesZalamea Vs CAMichael Parreño VillagraciaNo ratings yet

- GK - Discovery and InventionDocument9 pagesGK - Discovery and InventionBhaskar BodaNo ratings yet

- DC 4.875 50 2.250id xt-38 SpiralDocument1 pageDC 4.875 50 2.250id xt-38 SpiralGarcia MarinNo ratings yet

- Suplayer Metal Working Sipil and Fabrication: Company ProfileDocument10 pagesSuplayer Metal Working Sipil and Fabrication: Company ProfileRuntian TeaNo ratings yet

- Sale of Goods ActDocument33 pagesSale of Goods Actfiza100% (2)

- Water MakerDocument118 pagesWater Makervijuindia1111No ratings yet

- Swedish Road PresentationDocument30 pagesSwedish Road PresentationAsian Development Bank100% (1)

- TCRP RPT 19-Buses PDFDocument37 pagesTCRP RPT 19-Buses PDFPUENTES2407No ratings yet

- Ubbl Pindaan HospitalDocument23 pagesUbbl Pindaan HospitalamirulNo ratings yet

- 1992 Winchester Speedway Nascar Winston Racing Series Race ProgramDocument37 pages1992 Winchester Speedway Nascar Winston Racing Series Race Programisland14No ratings yet

- TrainingDocument165 pagesTrainingmohsolehNo ratings yet

- Boosting Public Transport: ACTION! at 59th UITP World CongressDocument20 pagesBoosting Public Transport: ACTION! at 59th UITP World CongressSTP DesignNo ratings yet